12

11

10

3

4

13

SawStop®Contractor Mobile Base6

Installing Your Mobile Base

Fig. 8

Fig. 9

Fig. 10

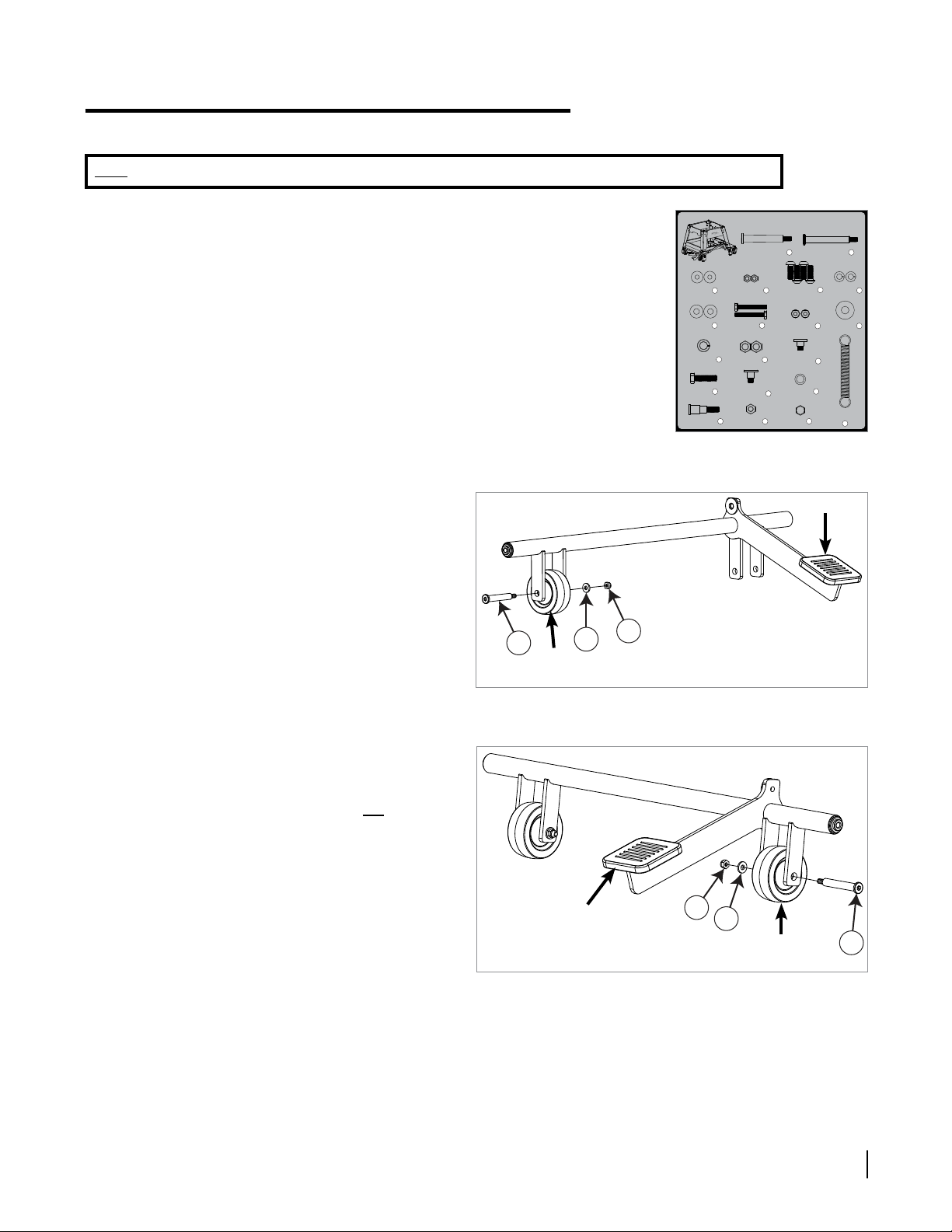

8. Mount the two casters to the outer corners of the

caster support by inserting the threaded shaft on

the casters through the corresponding holes in the

support and holding the casters in place with two

M10.5 x 25 washers, two M10.5 x 17 lock washers

and two caster nuts, as shown in Fig. 8. Fully

tighten the caster nuts with a 14 mm wrench.

9. Next, install the linkage bar between the wheel

support and the caster support. To do this, remove

the M6 nylon hex nut and the M6 washer from the

axle for the wheel closest to the foot pad (this is

the nut that was not tightened in step 3), but do

not remove the axle or wheel. Locate the linkage

bar and note that it has a non-threaded hole at one

end and a plastic washer glued near the middle of

the linkage bar. Position the linkage bar so that the

plastic washer faces toward the inside of the stand,

and slide the non-threaded hole at the end of the

linkage bar over the exposed shoulder on the axle,

as shown in Fig. 9. Reinstall the M6 washer and

the M6 nylon hex nut on the axle and fully tighten

the nut with a 10 mm wrench and a 5 mm hex key.

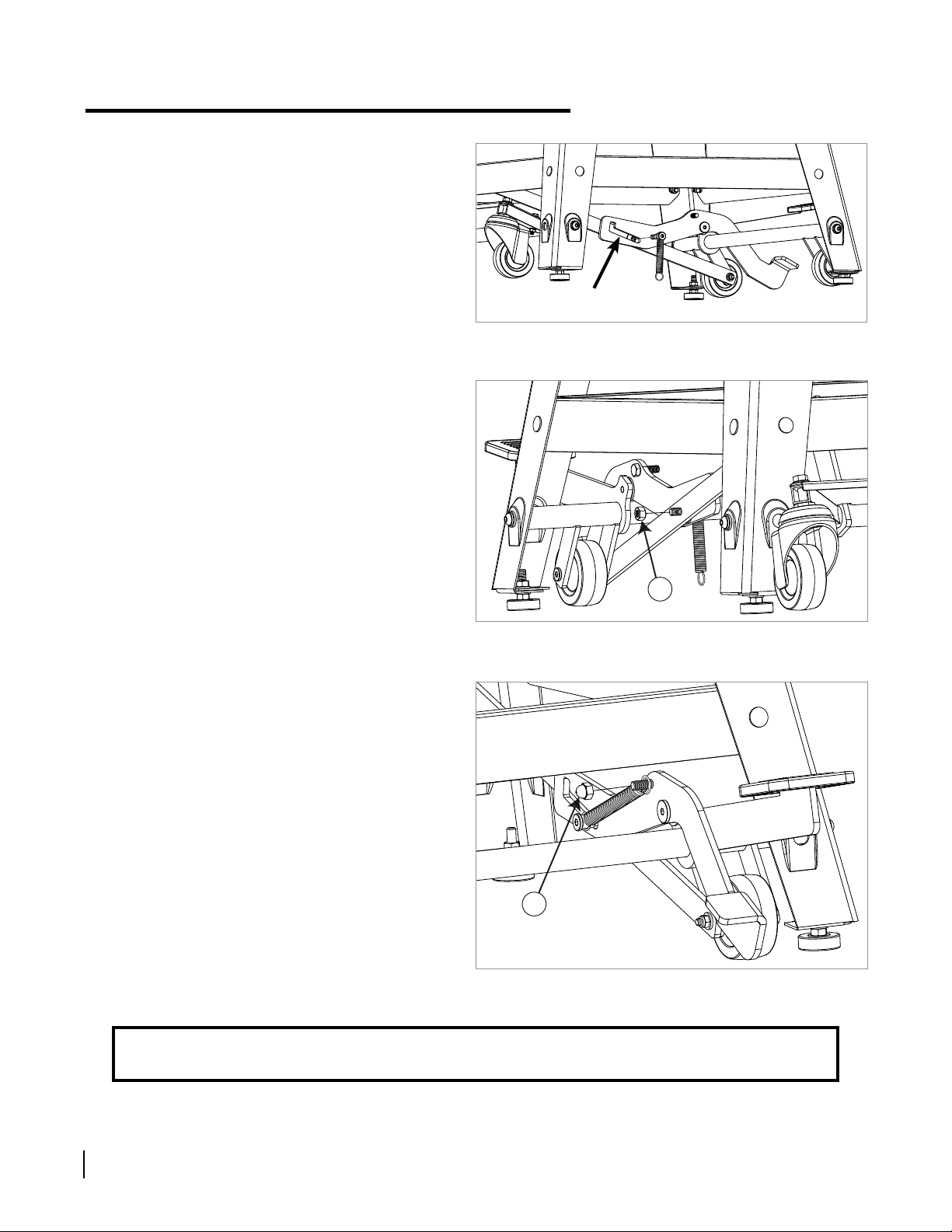

10. Connect the other end of the linkage bar to the

connecting lever on the caster support by inserting

the M8 x 15.7 shoulder socket screw through the

hole in the connecting lever so that the hole ts

over the shoulder on the screw, and then threading

the screw into the threaded hole in the linkage bar,

as shown in Fig. 10. Fully tighten the shoulder

socket screw with a 5 mm hex key.

linkage

bar

linkage bar

connecting

lever

plastic washer

axle

non-threaded

hole

3 inch

caster