Component

Parts

0

z

Order

>-

...

&

Description

....

Reference

o!

~

0

z

Order

>-

Description

...

&

....

Reference

o!

~

I

1-21

MK

2-22-2 1

motor

housing,

assembled

only

for

ASz

648 a

1-12

MK

2-22-1 1

motor

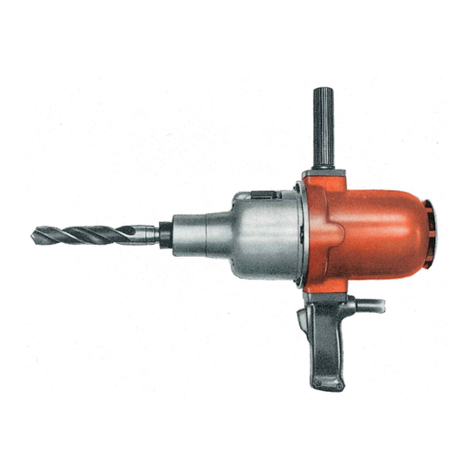

housing, assembled

15-21 without cable 36-48 LA 8-121-2a 1

drill

head,

assembled

1

MK

2-22 1

motor

housing 37-48 LA 8-121-1a 1 outer bearing, assembled

2,

3

EZ

12-52-1 2

carbon

holder, assembled 44

ZR

15-30x1 1 gear wheel,

43

teeth

2 EZ 12-52 2 carbon holder

46

ZR

16-12x1 1 countershaft pinion, 9

teeth

3

FD

7-32 2 spring 47

ZR

15-28x1 1 countershaft gear wheel, 29 teeth

4

SR

41-MJ,SxiO 4 fillister

head

screw

53

RJ

12-58 1 sealing ring

5

EZ

11-67 2 carbon b!-ush

6

SR

3-M4x6 2 fillister head screw

[ 7

state

type

1 pole housing

with

winding, assembled

and

voltage

only

for

ASz

648 b

36-48 LA 8-121-2b 1

drill

head,

assembled

8

PT

37-13 2 securing

plate

37-48 LA

8-121-lb

1 outer bearing, assembled

9

SR

1-M4x60 2 hexagon screw

10

]S

28-10 1

air

conducting ring

12 · EZ 1-73 1 switch, 2 poles

13

JS

13-90 1 cable protecting sleeve

44

ZR

15-29x1 1 gear wheel,

38

teeth

46

ZR

16-11x1 1 countershaft pinion, 13

teeth

47

ZR

15-28x1 1 countershaft gear wheel, 29 teeth

53

R]

12-58 1 sealing ring

14

EZ

7-133 1 ·cable

15

PT

31-21 1 cable clamping bridge

16

SR

3-M3,5x10 2 fillister

head

screw

only

for

ASz

648 d

17

EZ

22-57 1 capacitor

18

SR

3-M3,5x5 1 fillister

head

screw

19

PT

28-50 1 cover

36-48 LA 8-121-2 d 1

drill

head,

assembled

37-48 LA 8-121-1 d 1 outer bearing, assembled

20 SR 6-M3,5x12 1 -countersunk screw

21

SR

3-M4x18 3 fillister

head

screw

44

ZR

15-34x1 1 gear wheel, 35

teeth

46

ZR

16-17x1 1 countershaft pinion, 18

teeth

25

-

29

state

type 1

armature

with

winding, commutator

a

nd

voltage

and

fan, balanced

47 ZR15-33x0,75 1 countershaft gear wheel, 38 teeth

53

RJ

12-65 1 sealing ring

29 FL 4-10 1 fan

36 LA 6-178 1 intermediate

be~ring

37 LA 8-121 1

outer

bearing

42

Volts

39

WB

1-64 1 drill

shaft

1-21 MK 2-22-6 1

motor

housing, assembled

40

LK

16-3 1 groove ball bearing

41

BU

1-223 1 bushing

42

RJ

27a-35 x19,5 1 Nilos ring

1-12

MK

2-22-5 1 motor housing, assembled

15-

21

without cable

2, 3

EZ

12-53-1 2 carbon holder, assembled

2 EZ 12-53 2 carbon holder

43

LK

1-8 1 groove ball bearing 5

EZ

11-72 2 carbon brush

45

RJ

18-32 1

threaded

ring

48

LK

1-2 2 groove

ball

bearing 14

EZ

6-110

--

1--

' cable

50

SR

33-M5x55 2 socket he

ad

cap screw

51

SR

33-M5x65 2 socket

head

cap screw

Accessories

52

PT

5d-M5 4 securing

plate

EZ 11-67 2 carbon brush only for 220 V

54

LK

16-46 1 groove ball bearing EZ

11

-72 2 carbon brush only for 42 V

55

LK

16-10 1 groove ball bearing z10-10 1 he

xa

gon socket wrench