(

DS 648

To be handed to the workshop

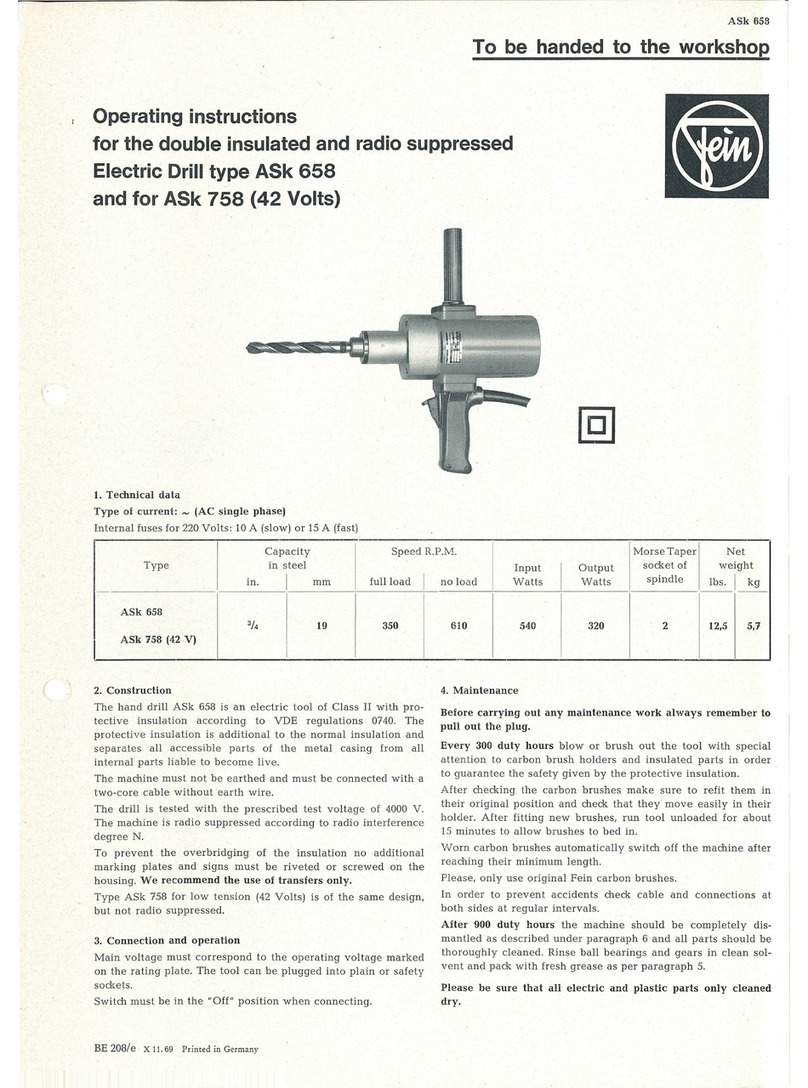

Operating instructions

for the Two Speed Electric Drill type DS

648

and for DS 7

48

(42

Volts}

1.

Technical

Data

Type

of

current

:

~

(AC

single

phase)

Double

insulation

without

earth

wire

according

to

VDE 0740

Radio

suppressed

according

to

VDE

0875

Capacity

in

Type

R.P.M.

in.

steel

I

I

mm

light

metal

in

. I

mm

full

load

I

1st

speed

DS 648 } Sfs 16 3

/4

20 370

DS 748

2nd

speed

(42V)

3f· 10

19h2

15 900

2.

Operation

Remove

all

signs

of

grease

from

chuck.

Main

voltage

must

correspond

to

the

operation

voltage

marked

on

the

rating

plate.

Switch

must

be

in

"Off"

position

when

connecting.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed.

We

recommend

the

use

of

transfers.

Changing

of

the

speed.

Push

slide

valve

(55)

into

the

position

I

or

II.

Change

speed

only

at

stand-still

of

the

machine.

Tapered

Net

weight

Input

I

Output

Spindle

no

load

Watts Watts

lbs. 1

kg

600 500 300 B 16 7.3 3.3

1400

gear

grease.

Loosen

screws

(70,

71)

and

take

off

gear

head.

Only

use

the

Fein

special

grease

Sst

1.

Quantity

of

grease:

90 g

(3

'h

oz.).

Order

Reference

for

the

tube

of

apptox

. 180 g:

MZ

60-4/Sst 1.

After

900

working

hours

clean

machine

thoroughly.

Rinse

gears

and

ball

bearings

in

clean

solvent

and

pack

with

fresh

grease

Sst

1.

The

space

between

inner

and

outer

ring

is

to

be

one

third

filled

with

grease

in

order

to

prevent

to

prevent

overheating

of

the

bearings.

Dismantling

see

paragraph

4.

3.

Maintenance

and

lubrication

Clean

electric

parts

only

dry.

Pull

out

plug

before

carrying

out

any

maintenance

work.

Replace

carbon

brushes

when

they

have

worn

down

to

7

mm

After

300

working

hours

clean

air

openings

of

the

motor

(0.28 in).

To

replace

brushes

see

paragraph

4,

sections

1

and

3.

housing.

Blow

out

motor

with

dry

pneumatic

air.

Renew

the

Only

use

Fein

carbon

brushes.

After

fitting

new

brushes

check

BE

235/e X 2. 73

Printed

in

German

y