Fenner QD:HVAC User manual

Installation and

Operating

Instructions

AC Variable Speed Drive

0.75kW - 160kW

200 - 480 Volt 1 & 3 Phase

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 2

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

Page 2 www.fptgroup.com

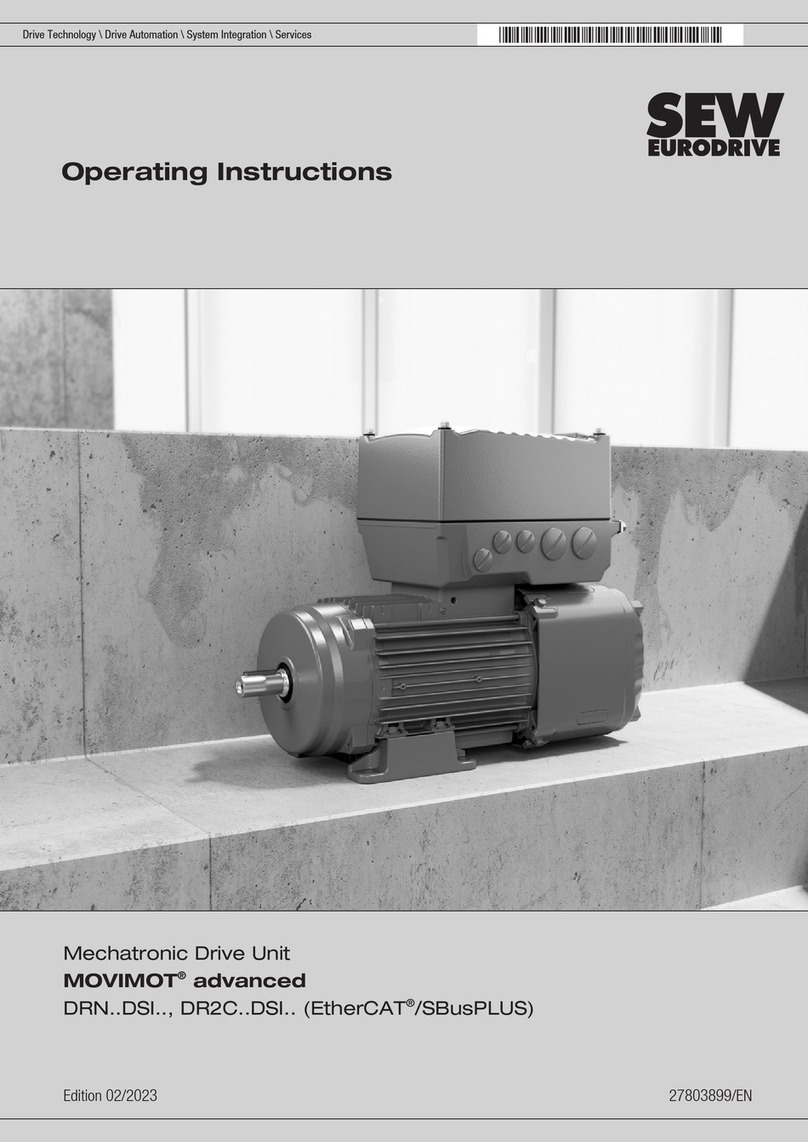

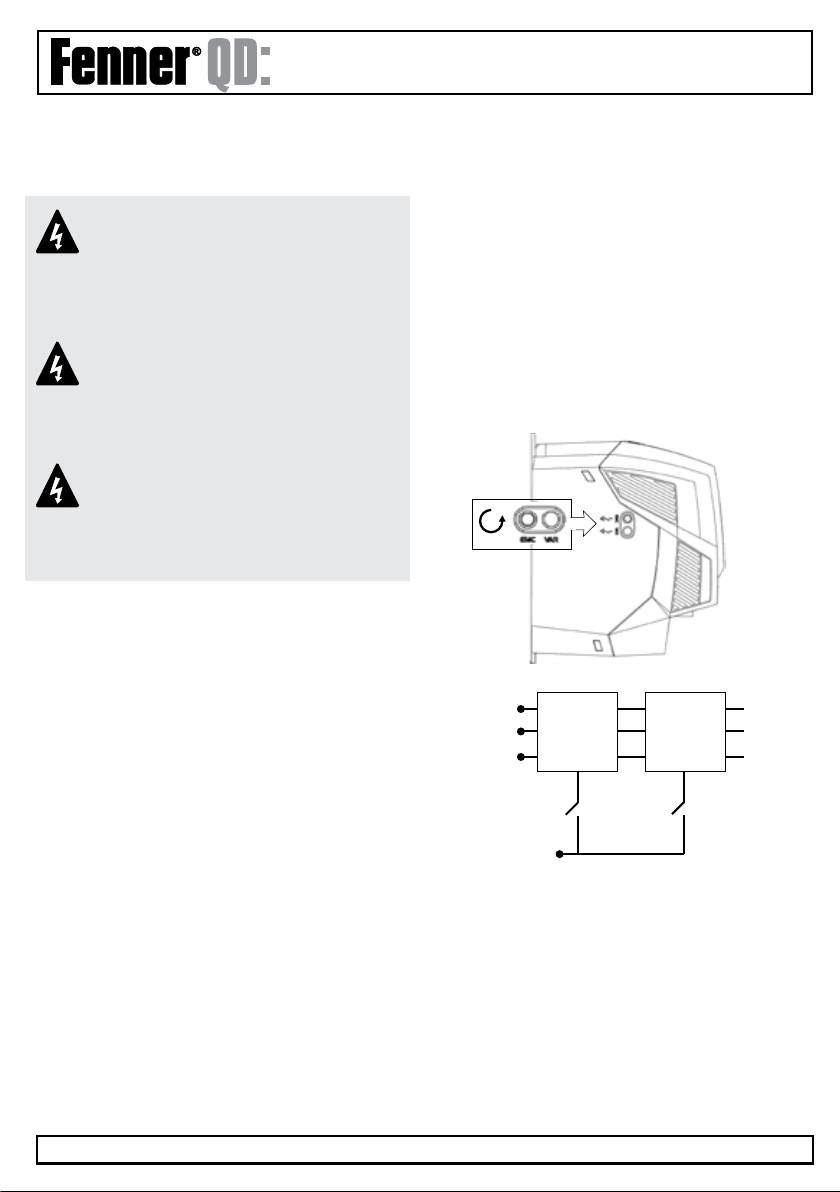

Mechanical Mounting

Information can be found on page 12

HVAC Display

(Status, diagnostics and programming)

1 2 5 6 7

SafeTorque Off (STO)

Link the terminals as shown, through the emergency

stop circuit contacts

Run - Stop 10K Pot

Motor Cable

For correct cable size, see technical data on page 66

Observe the maximum permissible motor cable length

For motor cable lengths > 50 metres, an output filter

is recommended

Use a screened (shielded cable). The shield should be

bonded to earth at both ends.

Motor Connection

Check for Star or Delta Connection

Enter the Motor Nameplate data into the drive param-

eters as follows:

lMotor Rated Voltage : P1-07

lMotor Rated Current : P1-08

lMotor Rated Frequency : P1-09

lMotor Rated Speed (Optional) : P1-10

Keypad Operation can be found on page 21

Close the switch to run (enable),

Open to stop

M

AC Supply Connections

200-240 Volts +/- -10%

380-480 Volts +/- -10%

Check drive rating info on page 63

PE L1 L2 L3

Fuses or

MCB

Check

drive rating

information

on page 64

Easy Start Up Guide: QD:HVAC IP55

Control Terminals

Configuration based on factory settings.

1 9 12 13 Inhbit

stop

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 3

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

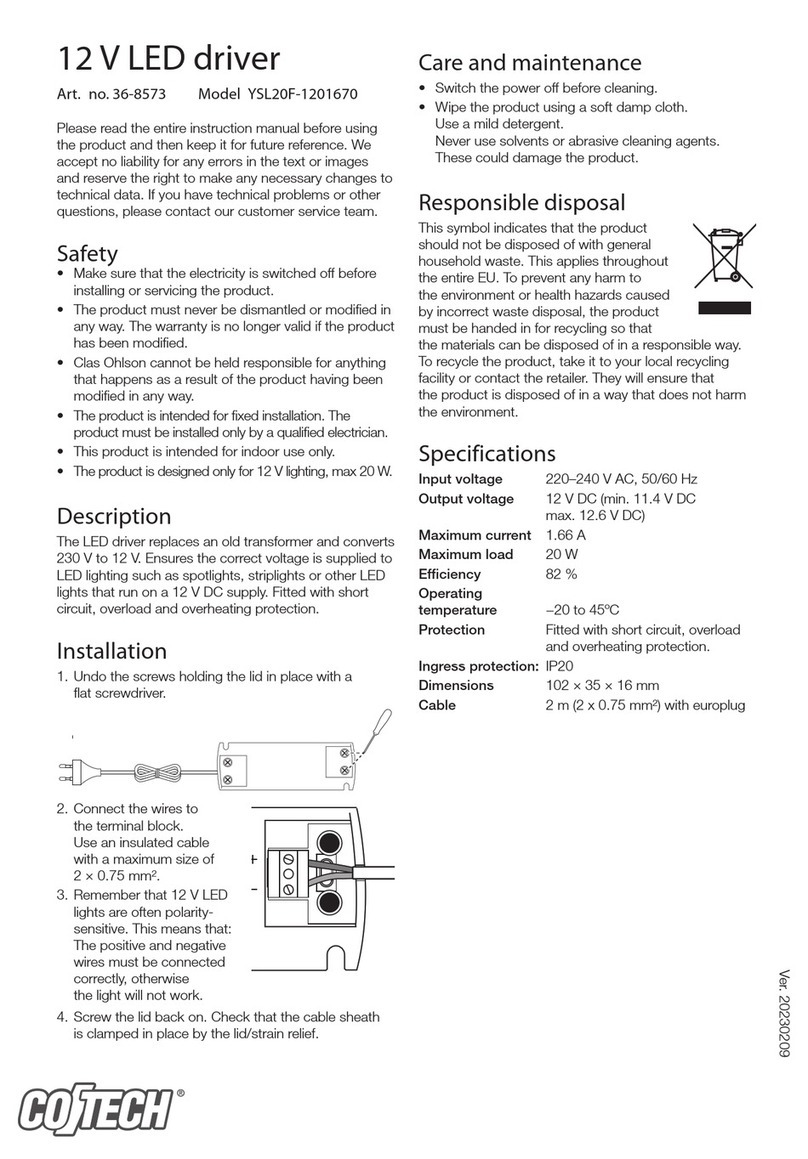

Page 3

www.fptgroup.com

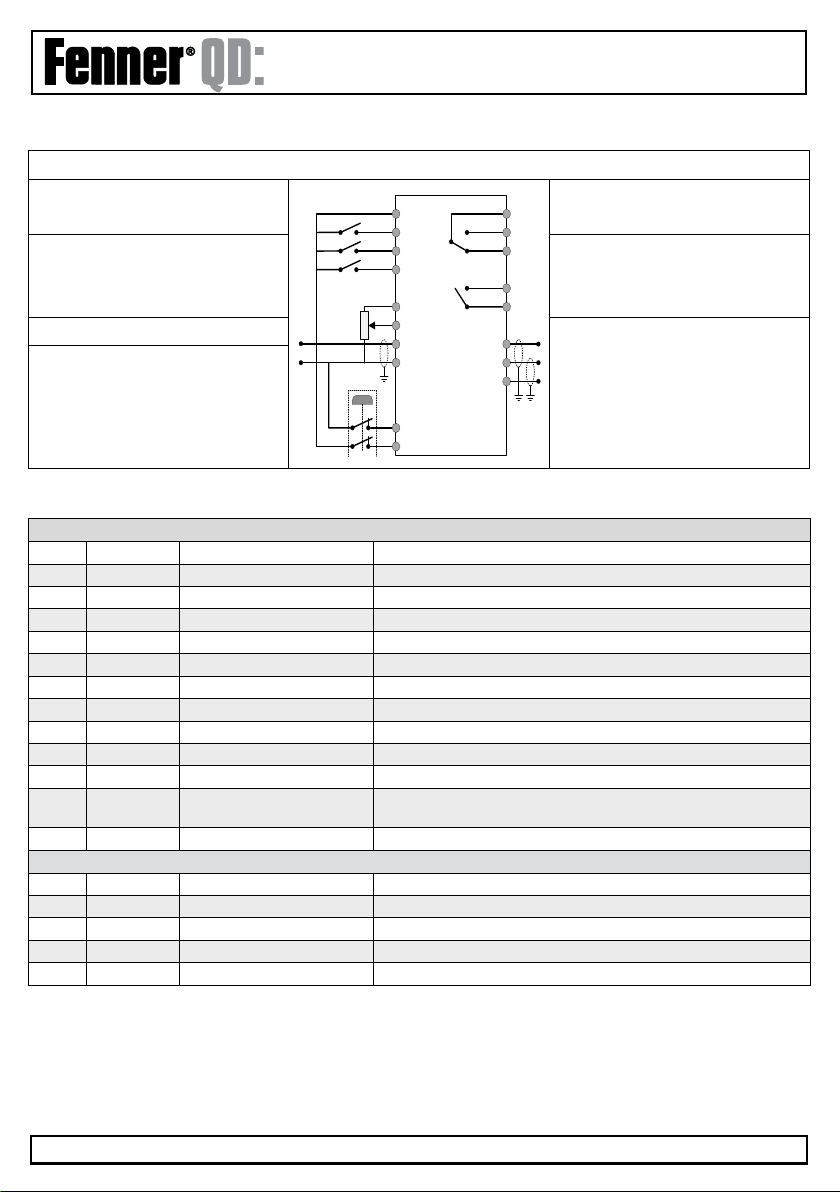

HVAC Display

Status, Diagnostics and

Programming

Control terminals

Based on factory settings

1 2 5 6 7

1 9 12 13

SafeTorque Off (STO)

Link the terminals as shown,

through the emergency stop

circuit contacts

10K Speed

Pot

Run - Stop

M

Motor Cable

Check the rating information on

page 64

Motor Connection

Check for Star or Delta Connection

according to the motor voltage

rating - see page 17

Enter the Motor Nameplate data

into the drive parameters as

follows:

lMotor Rated Voltage : P1-07

lMotor Rated Current : P1-08

lMotor Rated Frequency : P1-09

lMotor Rated Speed (Optional) : P1-10

AC Supply Connection

200 - 240 Volts +/- 10%

380 - 480 Volts +/- 10%

Check the drive rating

information on page 63

L3L1 L2

Mechanical Mounting

Information can be found on

page 9

Keypad Operation can be

found on page 21

Close the switch to run (enable),

Open the switch to stop

PE

Fuses or

MCB

Check the

drive rating

information

on page 65

Applies to switched

version only in-built

isolator:

Mains power On/Off

Easy Start Up Guide: QD:HVAC IP66

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 4

Declaration of Conformity

ERIKS Industrial Services Ltd hereby states that the

Fenner QD product range conforms to the relevant

safety provisions of the Low Voltage Directive

2006/95/EC and the EMC Directive 2004/108/EC and

has been designed and manufactured in accordance

with the following harmonised European standards:

EN 61800-5-1: 2003 Adjustable speed electrical

power drive systems. Safety

requirements. Electrical,

thermal and energy.

EN 61800-3 2nd Ed: 2004 Adjustable speed electrical

power drive systems. EMC

requirements and specific test

methods.

EN 55011:2007 Limits and Methods of

measurement of radio

disturbance characteristics

of industrial, scientific and

medical (ISM) radio-frequency

equipment (EMC).

EN60529:1992 Specifications for degrees

of protection provided by

enclosures.

Electromagnetic Compatibility

All Fenner drives are designed with high standards of

EMC in mind. All versions suitable for operation on

Single Phase 230 volt and Three Phase 400 volt

supplies and intended for use within the European

Union are fitted with an internal EMC filter. This EMC

filter is designed to reduce the conducted emissions

back into the supply via the power cables for

compliance with harmonised European standards.

It is the responsibility of the installer to ensure that the

equipment or system into which the product is

incorporated complies with the EMC legislation of the

country of use. Within the European Union, equipment

into which this product is incorporated must comply

with the EMC Directive 2004/108/EC. When using an

Fenner drive with an internal or optional external filter,

compliance with the following EMC Categories, as

defined by EN61800-3:2004 can be achieved:

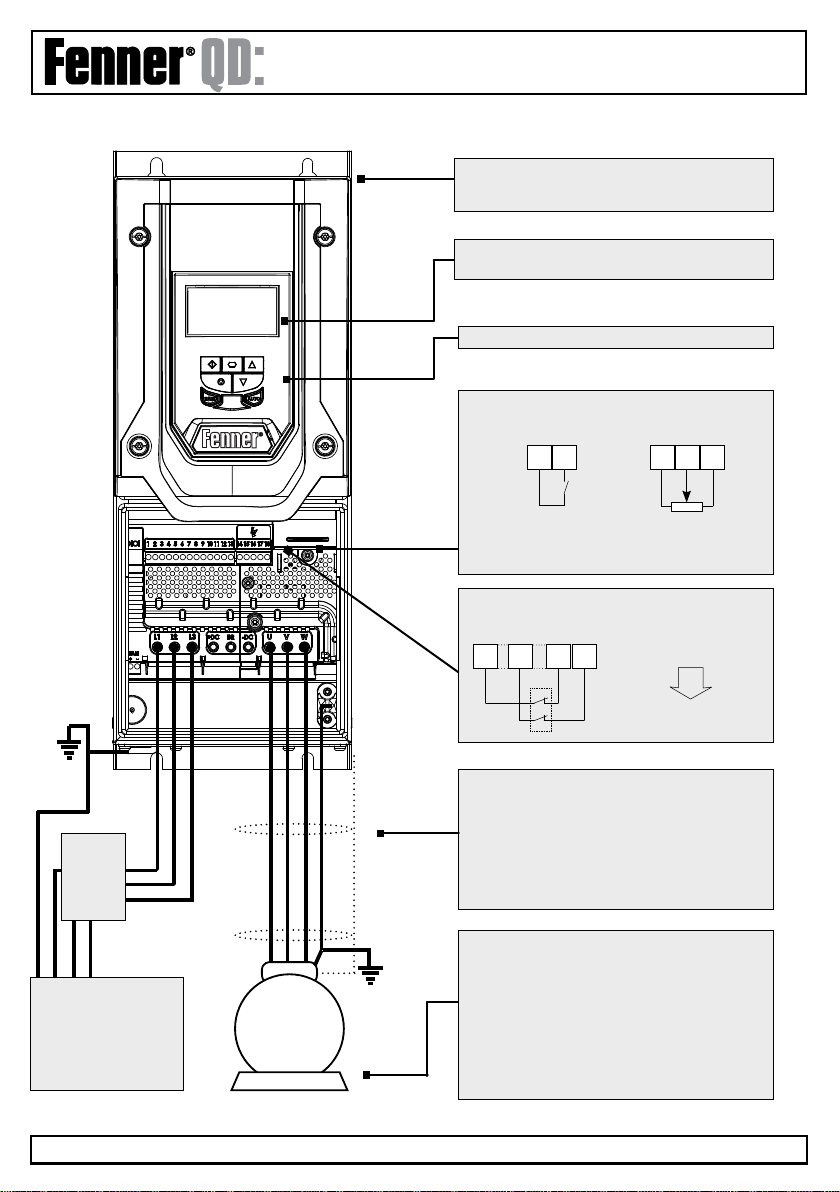

Drive Type /

Rating

EMC Category

Cat C1 Cat C2 Cat C3

1 Phase,

230 Volt

Input

No additional filtering required.

Use shielded motor cable.

3 Phase,

400 Volt

Input

Use external

filter

No additional filtering

required

Use shielded motor cable

Note

For motor cable lengths greater than

100m, an output dv / dt filter must be

used. For further information contact

your Fenner distributor.

All rights reserved. No part of this User Guide may be

reproduced or transmitted in any form or by any means,

electrical or mechanical including photocopying, recording or

by any information storage or retrieval system without

permission in writing from the publisher.

Copyright ERIKS Industrial Services Ltd © 2012

ERIKS Industrial Services Ltd, Amber Way, Halesowen,

West Midlands, B62 8WG

The manufacturer accepts no liability for any consequences

resulting from inappropriate, negligent or incorrect

installation, or adjustment of the optional operating

parameters of the drive or from mismatching of the drive to

the motor.

The contents of this User Guide are believed to be correct

at the time of printing. In the interest of a commitment to a

policy of continuous improvement, the manufacturer

reserves the right to change the specification of the product

or its performance or the contents of the User Guide

without notice.

All Fenner QD Series products carry a 2-year warranty, valid

from the date of manufacture. This date is clearly visible on

the product rating label.

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 5

1. IntroductIon

1.1 Important Safety Information 4

2. General InformatIon and ratInGs 7

3. mechanIcal InstallatIon 9

3.1 General 9

3.2 Before Installation 9

3.3 UL Compliant Installation 9

3.4 Mechanical dimensons and mounting IP66 9

3.5 Mechnical dimensions and mounting IP55 10

3.6 Guidelines for enclosure moutning IP55 & 66 11

3.7 Removing the Terminal Cover 11

3.8 Lock off 14

4. electrIcal InstallatIon 15

4.1 Grounding the Drive 15

4.2 Wiring Precautions 16

4.3 Incoming Power Connection 16

4.4 Drive and motor connection 16

4.5 Motor Terminal Box Connections 17

4.6 Motor Thermistor Connection 17

4.7 Control Terminal Wiring 17

4.8 Control Terminals Connection Diagram 18

4.9 Control Terminal Connections 18

5. manaGInG the Keypad 19

5.1 Keypad Layout and Function 19

5.2 Changing Parameters 19

5.3 Accessing and changing parameter values 20

5.4 Keypad Layout and Function OLED 21

5.5 Drive Operating Display OLED 21

5.6 Accessing and Changing Parameter Values OLED 21

5.7 Resetting Parameters to Factory Default OLED 22

5.8 Resetting Parameter to Use Default Settings 22

5.9 Changing the Language on OLED Display 23

5.10 Selecting between Hand and Auto Control OLED 23

6. commIssIonInG 24

7. hVac specIfIc feature setup 25

7.1 Pump Staging DOL Cascade 25

7.2 Pump Staging Multiple Drive Cascade 27

7.3 Maintenance Internal Set-up & Reset 28

7.4 Load Profile Monitoring Function 30

7.5 Pump Clean Function 31

7.6 Pump Stir Function 33

7.7 Bypass Control Fuction 33

7.8 Fire Mode Function 35

7.9 Motor Pre-heat Function & DC Injection 37

8 pId control applIcatIons 39

8.1 Overview 39

8.2 PID Function Set-Up 39

8.3 Application Example 43

9. parameters 44

10.dIGItal Input functIons 46

10.1 Digital Input Configuration Parameter P1-13 46

11. extened parameters 47

11.1 Parameter Group 2 - Extended 47

11.2 Parameter Group 3 - PID Control 52

11.3 Parameter Group 4 - Motor Control 53

11.4 Parameter Group 5 - Communication 53

11.5 Parameter Group 6 - Advanced Features 54

11.6 Parameter Group 8 - HVAC Functions 55

11.7 Parameter Group 9 - Advanced Control Logic 57

11.8 Parameter Group 0 - Monitoring 57

12. serIal communIcatIons 61

12.1 RS-485 Communications 61

12.2 Modbus RTU Communications 61

13.technIcal data 63

13.1 Environmental 63

13.2 Input Voltage Ranges 63

13.3 Maximum Supply Ratings for UL Compliance 63

13.4 Output Power & Current Ratings 64

13.5 Additional Information for UL Approved 65

14.parameter chanGe tables 66

15.troubleshootInG 67

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 6

Danger: Indicates a potentially hazardous

situation other than electrical, which if not

avoided, could result in damage to property.

Within the European Union, all machinery in which this product

is used must comply with Directive 98/37/EC, Safety of Machin-

ery. In particular, the machine manufacturer is responsible for

providing a main switch and ensuring the electrical equipment

complies with EN60204-1.

The level of integrity offered by the Fenner QD:HVAC control input

functions (excluding the ‘Safe Torque Free Input’) – for example

stop/start, forward/reverse and maximum speed, is not sufficient

for use in safety-critical applications without independent channels

of protection. All applications where malfunction could cause injury

or loss of life must be subject to a risk assessment and further

protection provided where needed.

The driven motor can start at power up if the enable input

signal is present.

The STOP function does not remove potentially lethal high

voltages. ISOLATE the drive and wait 10 minutes before starting

any work on it. Never carry out any work on the Drive, Motor or

Motor cable whilst the input power is still applied.

The drive can be programmed to operate the driven motor at

speeds above or below the speed achieved when connecting

the motor directly to the mains supply. Obtain confirmation

from the manufacturers of the motor and the driven machine

about suitability for operation over the intended speed range

prior to machine start up.

Do not activate the automatic fault reset function on any systems

whereby this may cause a potentially dangerous situation.

The Fenner QD:HVAC has an Ingress Protection rating of IP20

or IP55 depending on the model. IP20 units must be installed

in a suitable enclosure.

Fenner QD: HVAC drives are intended for indoor use only.

When mounting the drive, ensure that sufficient cooling is

provided. Do not carry out drilling operations with the drive in

place, dust and swarf from drilling may lead to damage.

The entry of conductive or flammable foreign bodies should be

prevented. Flammable material should not be placed close to

the drive

Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and no. of phases (1

or 3 phase) correspond to the rating of the drive as delivered.

Never connect the mains power supply to the Output

terminals U, V, W.

Do not install any type of automatic switchgear between the

drive and the motor

Wherever control cabling is close to power cabling, maintain a

minimum separation of 100 mm and arrange crossings at 90

degrees

Ensure that all terminals are tightened to the appropriate

torque setting

Do not attempt to carry out any repair of the Fenner QD:HVAC

In the case of suspected fault or malfunction, contact your

local Fenner distributor.

1. Introduction

1.1 Important Safety Information

Please read the important safety information

below, and all Warning and Caution Information

elsewhere in this manual.

Danger: Indicates a risk of electric shock,

which, if not avoided, could result in

damage to the equipment and possible

injury or death.

This variable speed drive product (Fenner QD:HVAC) is

intended for professional incorporation into complete

equipment or systems as part of a fixed installation. If installed

incorrectly it may present a safety hazard. The Fenner

QD:HVAC uses high voltages and currents, carries a high level

of stored electrical energy, and is used to control mechanical

plant that may cause injury. Close attention is required to

system design and electrical installation to avoid hazards in

either normal operation or in the event of equipment

malfunction. Only qualified electricians are allowed to install

and maintain this product.

System design, installation, commissioning and maintenance

must be carried out only by personnel who have the necessary

training and experience. They must carefully read this safety

information and the instructions in this Guide and follow all

information regarding transport, storage, installation and use of

the drive, including the specified environmental limitations.

Do not perform any flash test or voltage withstand test on the

drive. Any electrical measurements required should be carried

out with the drive disconnected.

Electric shock hazard! Disconnect and ISOLATE the Fenner

QD:HVAC before attempting any work on it. High voltages are

present at the terminals and within the drive for up to 10

minutes after disconnection of the electrical supply. Always

ensure by using a suitable multimeter that no voltage is present

on any drive power terminals prior to commencing any work.

Where supply to the drive is through a plug and socket

connector, do not disconnect until 10 minutes have elapsed

after turning off the supply.

Ensure correct earthing connections. The earth cable must

be sufficient to carry the maximum supply fault current which

normally will be limited by the fuses or MCB. Suitably rated

fuses or MCB should be fitted in the mains supply to the

drive, according to any local legislation or codes.

Do not carry out any work on the drive control cables whilst

power is applied to the drive or to the external control circuits.

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 7

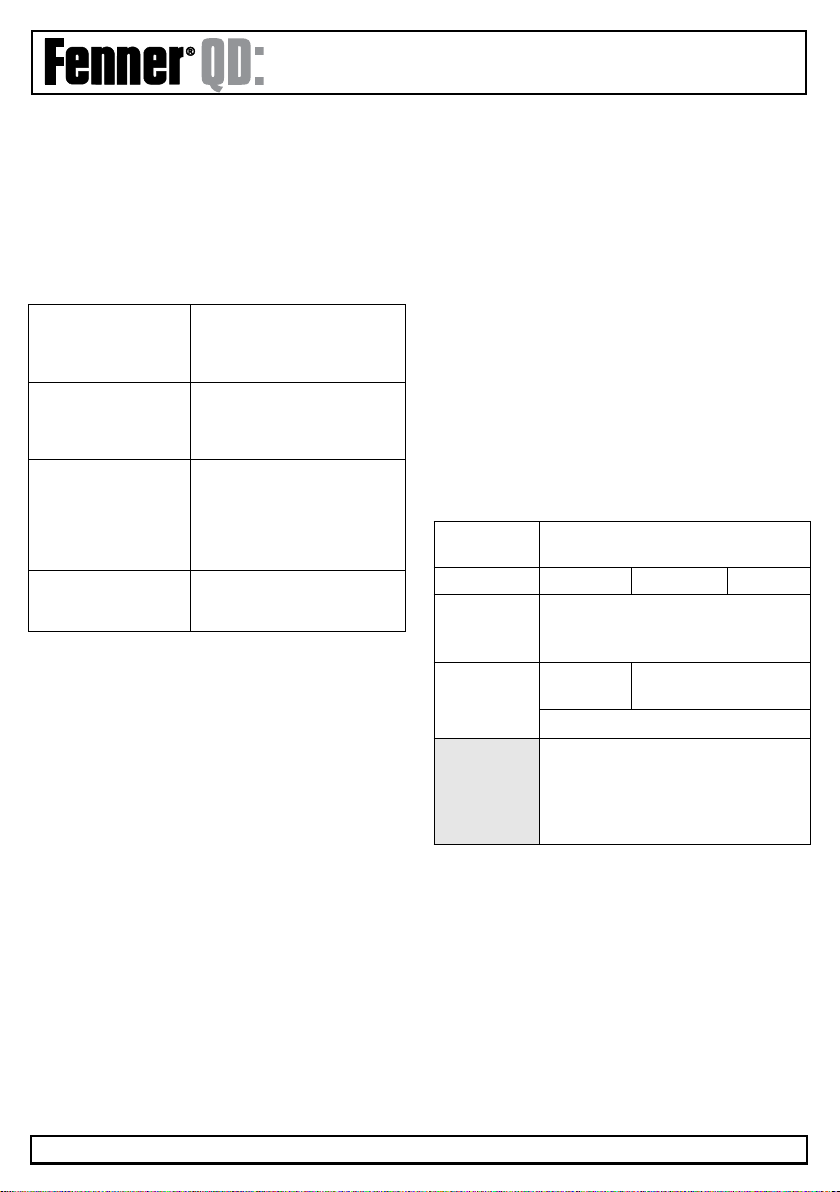

2. General Information and Ratings

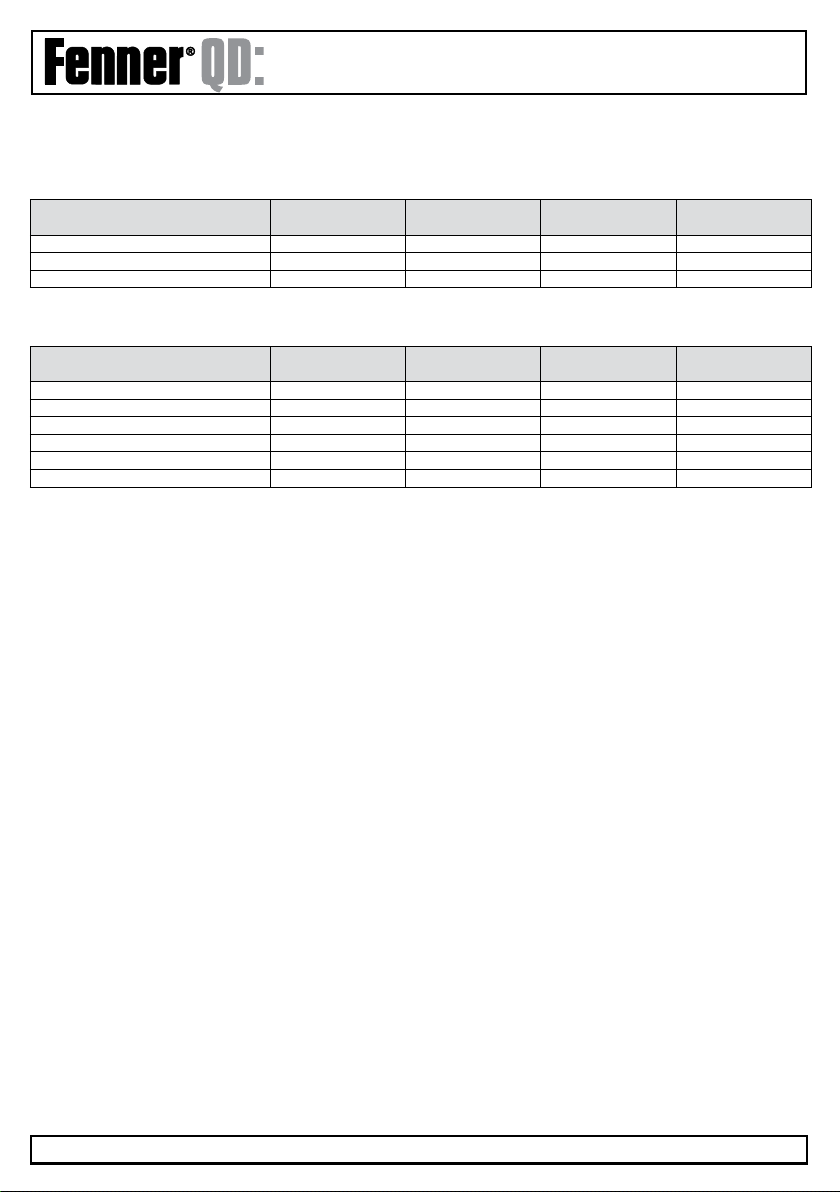

2.1 Drive Model Numbers IP55

kW Model with Filter kW HP Output

Current (A)

Frame Size

575F20P7 0.75 1 4.3 2

575F21P5 1. 5 272

575F22P2 2.2 3 10.5 2

kW Model with Filter kW HP Output

Current (A)

Frame Size

575F30P7 0.75 1 4.3 2

575F31P5 1. 5 272

575F32P2 2.2 3 10.5 2

575F34P0 4 5 18 3

575F35P5 5.5 7. 5 25 3

575F37P5 7. 5 10 39 4

575F3011 11 15 46 4

575F3015 15 20 61 5

575F3018 18.5 25 72 5

575F3022 22 30 90 5

575F3030 30 40 110 6

575F3037 37 50 150 6

575F3045 45 60 180 6

575F3055 55 75 202 6

575F3075 75 100 240 7

575F3090 90 120 300 7

kW Model with Filter 22kW HP Output

Current (A)

Frame Size

575F40P7 0.75 1 2.2 2

575F41P5 1. 5 2 4.1 2

575F42P2 2.2 3 5.8 2

575F44P0 4 5 9.5 2

575F45P5 5.5 7. 5 14 3

575F47P5 7. 5 10 18 3

575F4011 11 15 25 4

575F4015 15 20 30 4

575F4018 18.5 25 39 4

575F4022 22 30 46 4

575F4030 30 40 61 5

575F4037 37 50 72 5

575F4045 45 60 90 5

575F4055 55 75 110 6

575F4075 75 120 150 6

575F4090 90 150 180 6

575F4110 110 175 202 6

575F4132 132 200 240 7

575F4160 160 250 300 7

200-240V 10% - 1 Phase Input

200-240V 10% - 3 Phase Input

380-400V 10% - 3 Phase Input

575F20P7

Series &

Enclosure

Inverter

Type

Supply

Voltage

Rated

Power

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 8

2.2 Drive Model Numbers IP66

kW Model with Filter kW HP Output

Current (A)

Frame Size

576F20P7 0.75 1 4.3 2

576F21P5 1. 5 272

576F22P2 2.2 3 10.5 2

kW Model with Filter kW HP Output

Current (A)

Frame Size

576F40P7 0.75 1 2.2 2

576F41P5 1. 5 2 4.1 2

576F42P2 2.2 3 5.8 2

576F44P0 4 5 9.5 2

576F45P5 5.5 7. 5 14 3

576F47P5 7. 5 10 18 3

200-240V 10% - 1 Phase Input

380-480VV 10% - 3 Phase Input

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 9

3. Mechanical Installation

3.1. General

• The Fenner QD:HVAC should be mounted in a vertical position only on a flat, flame resistant vibration free mounting using

the integral holes.

• The Fenner QD:HVAC must be installed in a pollution degree 1 or 2 environment only.

• Do not mount flammable material close to the drive

• Ensure that the minimum cooling air gaps, as detailed in section 3.7 are left clear

• Ensure that the ambient temperature range does not exceed the permissible limits for the Fenner QD:HVAC given in

section 13.1

• Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the Fenner

QD:HVAC according to section 13.1

3.2. Before Installation

• Carefully unpack the QD:HVAC and check for any signs of damage. Notify the shipper immediately if any exist.

• Check the drive rating label to ensure it is of the correct type and power requirements for the application.

• Store the QD:HVAC in its box until required. Storage should be clean and dry and within the temperature range –40°C to +60°C

3.3. UL Compliant Installation

Note the following for UL compliant installation:

• For an up to date list of UL compliant products, please refer to UL listing NMMS.E226333

• The drive can be operated within an ambient temperature range as stated in section 13.1

• For IP20 units, installation is required in a pollution degree 1 environment

• For IP55 & IP66 units, installation in a pollution degree 2 environment is permissible

• UL Listed ring terminals / lugs must be used for all bus bar and grounding connections

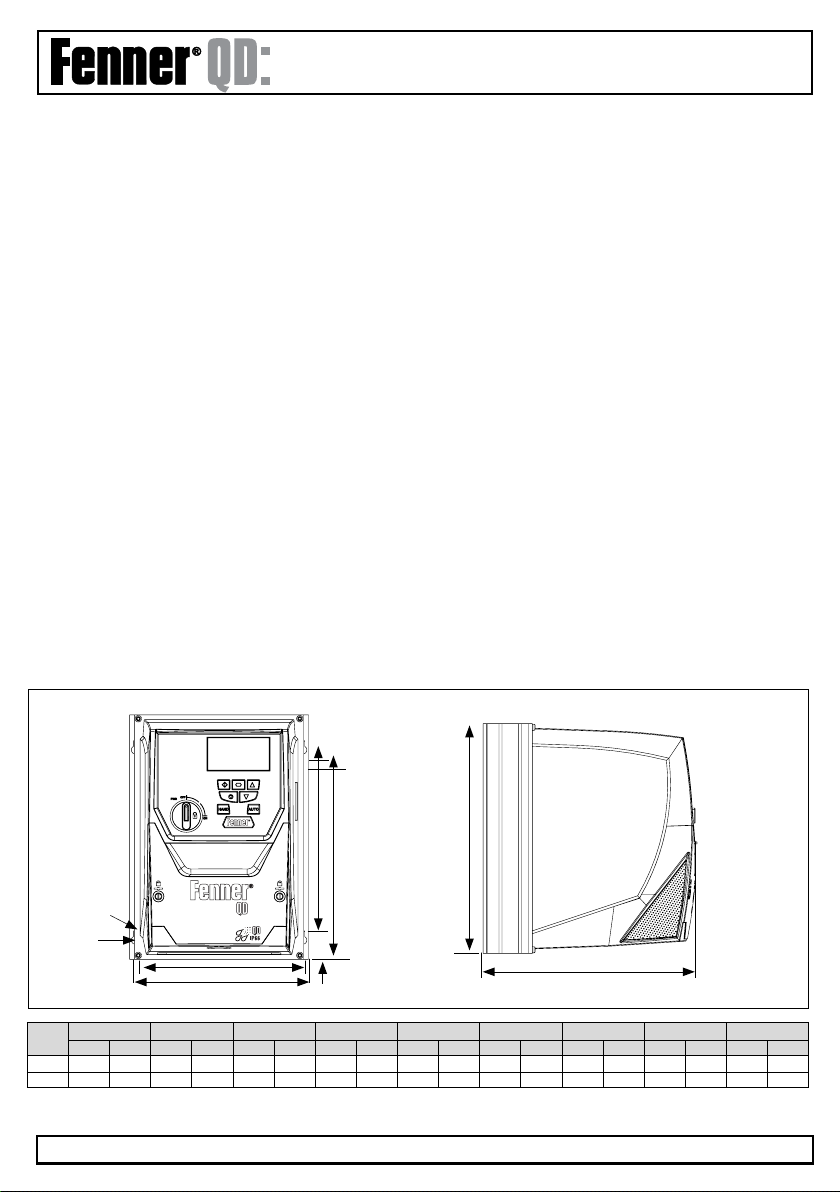

3.4 Mechanical Dimensions and Mounting - IP66 Units

Drive

Size

A B D E F G H I J

mm in mm in mm in mm in mm in mm in mm in mm in mm in

2257.0 10.12 220.0 8.67 28.5 1. 12 28.5 1. 12 238 9.37 188.0 7. 4 176.0 6.93 4.2 0.17 8.5 0.33

3310.0 12.20 276.5 10.89 251.5 9.90 33.4 1.31 256 10.08 210.5 8.29 197.5 7.78 4.2 0.17 8.5 0.33

Control terminal torque settings: All Sizes: 0.8Nm

Power terminal torque settings: All Sizes: 1Nm

I

J

D

B

E

H

G

A

F

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 10

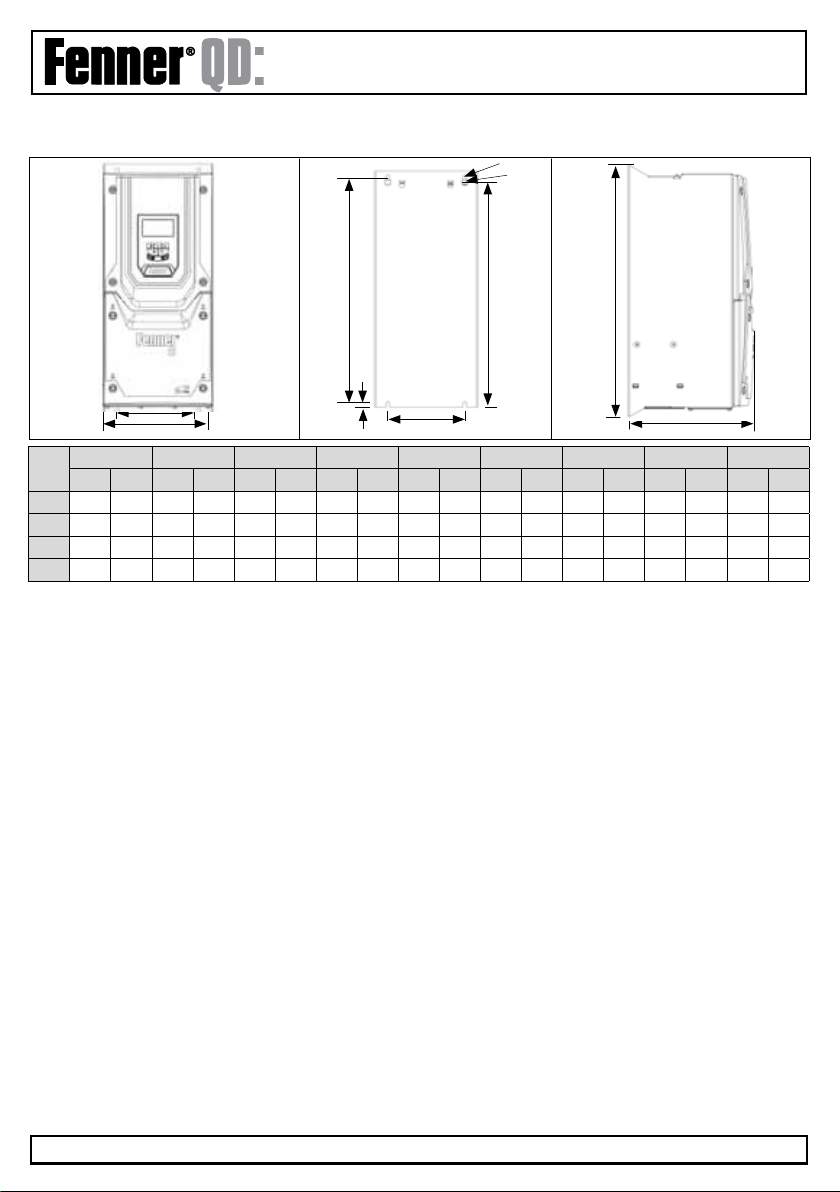

3.5 Mechanical Dimensions and Mounting - IP55

Drive

Size

A B C D E F G H I

mm in mm in mm in mm in mm in mm in mm in mm in mm in

4440 17.32 418 16.46 423 16.65 8 0.315 230 9.06 173 6.81 110 4.33 4.25 0.167 7. 5 0.295

5540 21.26 515 20.28 520 20.47 8 0.315 270 10.63 235 9.25 175 6.89 4.25 0.167 7. 5 0.295

6865 34.06 830 32.68 840 33.07 10 0.394 340 13.39 290 11.42 200 7.87 5.5 0.217 11 0.433

71280 50.39 1245 49.02 1255 49.41 10 0.394 370 14.57 330 12.99 200 7.87 5.5 0.217 11 0.433

Control terminal torque settings: All sizes: 0.8Nm

Power terminal torque settings: Frame size 4: 1.2-1.5Nm

Frame size 5: 2.5 - 4.5Nm

Frame size 6 & 7: 8Nm

G

F

CA

E

H

G

D

B

I

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 11

3.6 Guidelines for enclosure mounting IP55 and IP66 units

• Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive

shown in section 13.1

• The drive must be mounted vertically, on a suitable at surface

• The minimum mounting clearances as shown in the table below must be observed

• The mounting site and chosen mountings should be sufcient to support the weight of the drives

Drive Size X Above & Below Y Either Side

mm in mm in

2 (IP66) 150 5.9 10 0.394

3 (IP66) 150 5.9 10 0.394

4 (IP55) 200 7. 9 10 0.394

5 (IP55) 200 7. 9 10 0.394

6 (IP55) 200 7. 9 10 0.394

7 (IP55) 200 7. 9 10 0.394

Note:

Typical drive heat losses are 3% of operating load conditions

Above are guidelines only and the operating ambient temperature

of the drive MUST be maintained at all times.

3.7 Removing the Terminal Cover

3.7.1 Frame Size 2

Terminal Cover Release Screws

3.7.2 Frame Size 3

Using a suitable

flat blade

screwdriver,

rotate the four

retaining screws

indicated until the

screw slot is

vertical

Using a suitable

flat blade

screwdriver,

rotate the four

retaining screws

indicated until the

screw slot is

vertical

X

X

YY

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 12

3.7.3 Frame Size 6

Remove the two screws

indicated, lift the cover

forwards and off. To refit

the cover, slide the top

locating lugs upwards

under the top cover, then

re-fasten the lower cover

screws.

3.7.3 Frame Size 4 3.7.2 Frame Size 5

Using a suitable

flat blade

screwdriver,

rotate the four

retaining screws

indicated until the

screw slot is

vertical.

Using a suitable

flat blade

screwdriver,

rotate the four

retaining screws

indicated until the

screw slot is

vertical

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 13

3.7.4 Frame Size 7

Using a suitable flat blade

screwdriver, rotate the four

retaining screws indicated

until the screw slot is vertical.

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 14

3.8 Lock Off

Power Isolator Lock Off - IP66 with Built in Isolater Option

On the switched models the main power islator switch can be locked in the ‘off’ position using a 20mm standrad shackle

padlock (not supplied)

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 15

4. Electrical Installation

4.1 Grounding the Drive

This manual is intended as a guide for proper

installation. ERIKS Industrial Services cannot

assume responsibility for the compliance or the

non-compliance to any code, national, local or

otherwise, for the proper installation of this drive or

associated equipment. A hazard of personal injury and/or

equipment damage exists if codes are ignored during

installation.

This Fenner QD drive contains high voltage

capacitors that take time to discharge after

removal of the main supply. Before working on the

drive, ensure isolation of the main supply from line

inputs. Wait ten (10) minutes for the capacitors to discharge

to safe voltage levels. Failure to observe this precaution

could result in severe bodily injury or loss of life.

Only qualified electrical personnel familiar with the

construction and operation of this equipment and

the hazards involved should install, adjust, operate,

or service this equipment. Read and understand

this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could

result in severe bodily injury or loss of life.

4.1.1 Grounding Guidelines

The ground terminal of each Fenner QD:HVAC should be

individually connected DIRECTLY to the site ground bus bar

(through the filter if installed). Fenner QD ground

connections should not loop from one drive to another, or

to, or from any other equipment. Ground loop impedance

must confirm to local industrial safety regulations. To meet

UL regulations, UL approved ring crimp terminals should be

used for all ground wiring connections. The drive Safety

Ground must be connected to system ground. Ground

impedance must conform to the requirements of national

and local industrial safety regulations and/or electrical

codes. The integrity of all ground connections should be

checked periodically.

4.1.2. Protective Earth Connector

The cross sectional area of the PE Conductor must be at

least equal to that of the incoming supply conductor.

4.13 Safety Ground

This is the safety ground for the drive that is required by

code. One of these points must be connected to adjacent

building steel (girder, joist), a floor ground rod, or bus bar.

Grounding points must comply with national and local

industrial safety regulations and/or electrical codes.

4.1.4. Motor Ground

The motor ground must be connected to one of the ground

terminals on the drive.

4.1.5. Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist.

The Fenner QD:HVAC is designed to produce the minimum

possible leakage current whilst complying with worldwide

standards. The level of current is affected by motor cable

length and type, the effective switching frequency, the earth

connections used and the type of RFI filter installed. If an

ELCB (Earth Leakage Circuit Breaker) is to be used, the

following conditions apply:

• A Type B Device must be used

• The device must be suitable for protecting equipment

with a DC component in the leakage current

• Individual ELCBs should be used for each Fenner drive

Drives with a EMC filter have an inherently higher leakage

current to ground (Earth). For applications where tripping

occurs the EMC filter can be disconnected (on IP20 units

only) by removing the EMC screws on the side of the

product.

The Fenner QD:HVAC range has input supply voltage surge

supression components fitted to protect the drive from

voltage transients, typically originating from lightening

strikes or switching of high power equipment on the same

supply.

4.1.6. Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for

the motor cable shield. The motor cable shield connected to

this terminal (drive end) should also be connected to the

motor frame (motor end). Use a shield terminating or EMI

clamp to connect the shield to the safety ground terminal.

Internal

EMC

Filter

Internal

Surge

Protection

EMC VAR

Earth

L/L1

N/L2

L3

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 16

4.2. Wiring Precautions

Connect the Fenner QD:HVAC according to section 4.3 and

4.4, ensuring that motor terminal box connections are

correct. There are two connections in general: Star and

Delta. It is essential to ensure that the motor is connected

in accordance with the voltage at which it will be operated.

For more information, refer to section 4.5 Motor Terminal

Box Connections.

It is recommended that the power cabling should be 4-core

PVC-insulated screened cable, laid in accordance with local

industrial regulations and codes of practice.

4.3 Incoming Power Connection

• For a single phase supply, power should be connected to

L1/L, L2/N.

• For 3 phase supplies power should be connected to L1,

L2, and L3. Phase sequence is not important.

• For compliance with CE and C Tick EMC requirements, a

symmetrical shielded cable is recommended.

• A fixed installation is required according to IEC61800-5-1

with a suitable disconnecting device installed between

the Fenner drive and the AC Power Source. The

disconnecting device must conform to the local safety

code / regulations (e.g. within Europe, EN60204-1, Safety

of machinery).

• The cables should be dimensions according to any local

codes or regulations. Guideline dimensions are given in

section13.4.

• Suitable fuses to provide wiring protection of the input

power cable should be installed in the incoming supply

line, according to the data in section 13.4. The fuses must

comply with any local codes or regulations in place. In

general, type gG (IEC 60269) or UL type T fuses are

suitable; however in some cases type aR fuses may be

required. The operating time of the fuses must be below

0.5 seconds.

• Where allowed by local regulations, suitably dimensioned

type B MCB circuit breakers of equivalent rating may be

utilised in place of fuses, providing that the clearing

capacity is sufficient for the installation.

• When the power supply is removed from the drive, a

minimum of 30 seconds should be allowed before

re-applying the power. A minimum of 10 minutes should

be allowed before removing the terminal covers or

connection.

• The maximum permissible short circuit current at the Fenner

drive Power terminals as defined in IEC60439-1 is 100kA.

• An optional Input Choke is recommended to be installed

in the supply line for drives where any of the following

conditions occur:-

• The incoming supply impedance is low or the fault

level / short circuit current is high

• The supply is prone to dips or brown outs

• An imbalance exists on the supply (3 phase drives)

• The power supply to the drive is via a bus-bar and

brush gear system (typically overhead Cranes).

• In all other installations, an input choke is recommended

to ensure protection of the drive against power supply

faults. Refer to your local Fenner Authorised Distributor

for available options

• Fenner QD:HVAC models in frame sizes 4 to 8 are factory

fitted with an Input choke as standard.

4.4 Drive and Motor Connection

• The motor should be connected to the Fenner drive U, V,

and W terminals using a suitable 3 or 4 core cable. Where

a 3 core cable is utilised, with the shield operating as an

earth conductor, the shield must have a cross sectional

area at least equal to the phase conductors when they

are made from the same material. Where a 4 core cable

is utilised, the earth conductor must be of at least equal

cross sectional area and manufactured from the same

material as the phase conductors.

• The motor earth must be connected to one of the drive

earth terminals.

• For compliance with the European EMC directive, a

suitable screened (shielded) cable should be used.

Braided or twisted type screened cable where the screen

covers at least 85% of the cable surface area, designed

with low impedance to HF signals are recommended as a

minimum. Installation within a suitable steel or copper

tube is generally also acceptable.

• The cable screen should be terminated at the motor end

using an EMC type gland allowing connection to the

motor body through the largest possible surface area

• Where drives are mounted in a steel control panel

enclosure, the cable screen may be terminated directly to

the control panel using a suitable EMC clamp or gland, as

close to the drive as possible.

• For IP55 drives, connect the motor cable screen to the

internal ground clamp

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 17

4.5. Motor Terminal Box Connections

Most general purpose motors are wound for operation on dual voltage supplies. This is indicated on the nameplate of the motor.

This operational voltage is normally selected when installing the motor by selecting either STAR or DELTA connection. STAR

always gives the higher of the two voltage ratings.

Incoming Sup-

ply Voltage

Motor Nameplate

Voltages

Connection

230 230/400

Delta

400 400/690

400 230/400 Star

4.6. Motor Thermistor Connection

Where a motor thermistor is to be used, it should be connected as follows:

1 2 876543 109

Control Terminal Strip

Additional Information

Compatible Thermistor : PTC Type, 2.5kΩtrip level

Use a setting of P1-13 that have Input 5 function as External Trip, e.g. P1-13 = 6. Refer to section 7 for further details.

4.7 Control Terminal Wiring

• All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

• Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other

• Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC, should not be routed in the same cable.

• Maximum control terminal tightening torque is 0.5Nm

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 18

4.8 Control Terminals Connection Diagram

Control Terminal Designations and Default Function Assignments

+24 Volt Control Circuit Supply or

external 24 Volt Power Supply

Programmable Relay Output

Drive Healthy

Run / Enable

Fwd/Reverse

Analog/Preset Speed

Programmable Relay Output

Drive Running

Programmable Analog Inputs Programmable Analog Output

Output Speed

Output Current

External Safety Circuit for Safe Torque

Off Function

4.9 Control Terminal Connections

Main Terminal Strip

1 +24V + 24V User Output (Input) 100mA User Output or +24V back up supply

2 DI 1 Input 1 Digital 8 – 30 Volt DC

3 DI 2 Input 2 Digital 8 – 30 Volt DC

4 DI 3 Input 3 Digital 8 – 30 Volt DC

5 +10V +10 Volt user output 10mA for user potentiometer

6 AI 1 Input 4 Digital 8 - 30V DC / Analog Input 1,-10 to +10V, 0 / 4 to 20mA

7 0V 0 Volt Common

8AO1 Output 1 1st Analog / Digital Output, 0 to 10V, 4 to 20mA or +24VDC Digital

9 0V 0 Volt Common

10 AI 2 Input 5 Digital 8 - 30V DC / Analog Input 2, 0 to 10V, 0 / 4 to 20mA or Motor PTC

11 AO2 Output 2 2nd Analog / Digital Output, 0 to 10V, 4 to 20mA or +24VDC Digital

12 STO+ Drive hardware inhibit “Safe” 24V input - must be linked to ext +24 Volt (18 – 30 Volt) DC to

enable power stage

13 STO- Inhibit 0V input 0V return for the 24V “Safe” (STO)

Additional Terminal Strip

14 RL1-C Relay output 1 common Relay contacts, 250V AC, 30V DC, 5A

15 RL1-NO Relay output 1 NO Relay contacts, 250V AC, 30V DC, 5A

16 RL1-NC Relay output 1 NC Relay contacts, 250V AC, 30V DC, 5A

17 RL2-A Relay output 2 common Relay contacts, 250V AC, 30V DC, 5A

18 RL2-B Relay output 2 NO Relay contacts, 250V AC, 30V DC, 5A

AO2

0V

AO1

RL2-NO

RL2-C

RL1-C

RL1-NO

RL1-NC

STO+

STO-

0V

AI2

AI1

+10V

+24V

DI1

DI2

DI3

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 19

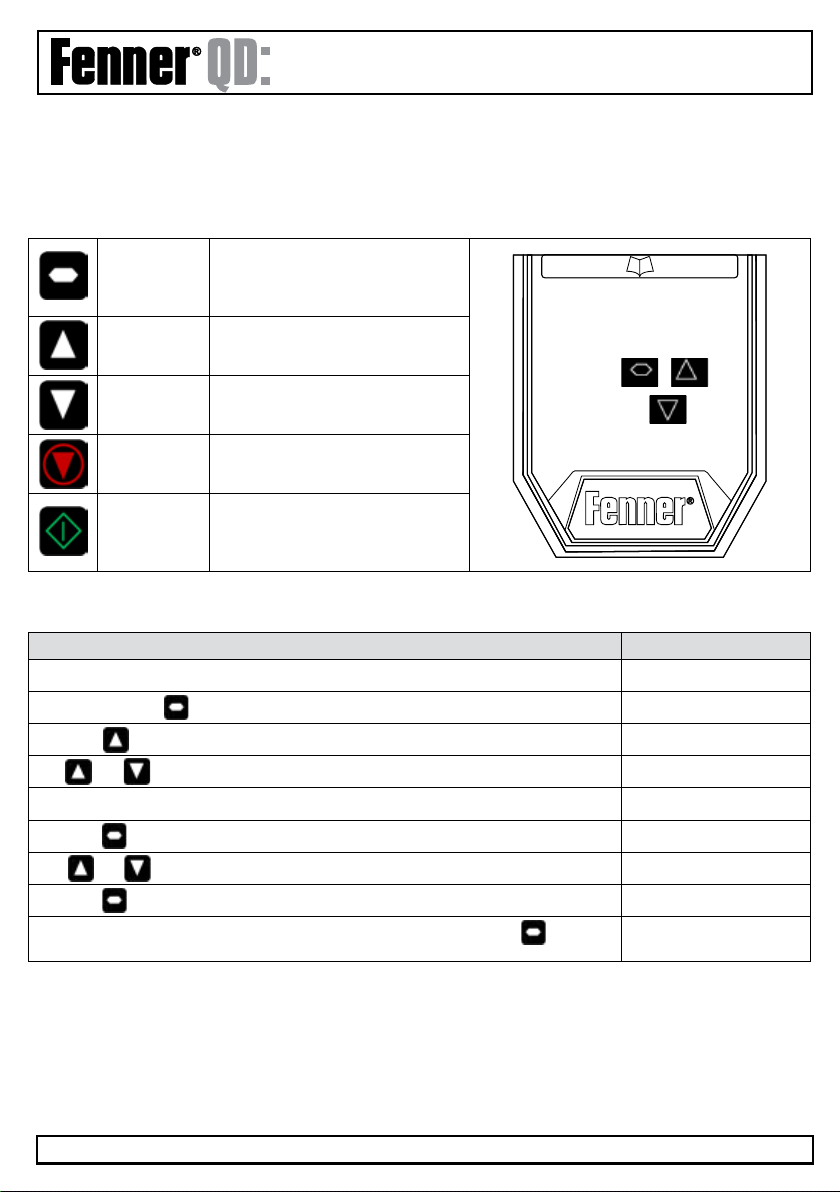

5. Managing the Keypad

The drive is configured and its operation monitored via the built in keypad and display.

IP20 Drives: IP20 rated drives are supplied with a 7 segment LED display and a five button keypad

IP55 & IP66 Drives are supplied with an OLED multi-line text display and a seven button keypad

5.1 Keypad layout and Function - Standard LED Keypad (IP20 Drives)

NAVIGATE

Used to display real-time informa-

tion, to access and exit parameter

edit mode and to store parameter

changes

UP

Used to increase speed in real-time

mode or to increase parameter

values in parameter edit mode

DOWN

Used to decrease speed in real-time

mode or to decrease parameter

values in parameter edit mode

RESET/STOP

Used to reset a tripped drive. When

in keypad mode is used to Stop a

running drive

START

When in keypad mode, used to start

a stopped drive to reverse the direc-

tion of rotation if bidirectional keypad

mode is enabled

5.2. Changing Parameters - Standard LED Keypad (IP20 Drives)

Procedure Display Shows...

Power on Drive stop

Press and hold the for >2 seconds P1-01

Press the key P1-02

The and can be used to select the desired parameter P1-03

Select the required parameter, e.g. P1-02 P1-02

Press the button 0.0

Use the and keys to adjust the value e.g. set to 10 10.0

Press the key P1-02

The parameter value is now adjusted and automatically stored. Press the key for

>2 seconds to return to operating mode

stop

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

www.fptgroup.com

HVAC

Installation & Operating Instructions

Page 20

5.3 Accessing and Changing Parameter Values

Function When Display

Shows

Press Result Example

Fast selection of

Parameter Groups

Note: Parameter

Group Access must

be enabled

P1-14=101

Px-xx The next highest

Parameter group is

selected

Display shows P1-10

Press

Display shows P2-01

Px-xx The next lowest

Parameter group is

selected

Display shows P2-26

Press

Display shows P1-01

Select lowest Group

Parameter

Px-xx The first parameter of

a group is selected

Display shows P1-10

Press

Display shows P1-01

Set Parameter to

minimum value

Any numerical value

(whilst editing a

parameter value)

The parameter is set

to the minimum value

When editing P1-01

Display shows 50.0

Press

Display shows 0.0

Adjusting individual

digits within a

parameter value

Any numerical value

(whilst editing a

parameter value)

Individual parameter

digits can be adjusted

When editing P1-10

Display shows 0

Press

Display shows .0

Press

Display shows 10

Press

Display shows .1 0

Press

Display shows 1 10

etc

+

+

+

+

+

+

+

+

+

+

+

Table of contents

Popular DC Drive manuals by other brands

Franklin Electric

Franklin Electric MONODRIVE UTILITY UT3W owner's manual

East Coast Datacom

East Coast Datacom ALD-19.2 installation guide

Motor City Wash Works

Motor City Wash Works ROCKRHYD Series installation manual

LSIS

LSIS S100 Series quick start guide

Bosch

Bosch Active Line Plus BDU 350 Original operating instructions

Eaton

Eaton PowerXL DM1 Series quick start guide

Siemens

Siemens SINAMICS V20 Series Easy start guide

Allen-Bradley

Allen-Bradley PowerFlex 520 Series Original instructions

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 7000 user manual

Veichi

Veichi AC80T manual

REDEX ANDANTEX

REDEX ANDANTEX Z Series Setup and maintenance instructions

Johnson Controls

Johnson Controls VFD Series Installation & operation