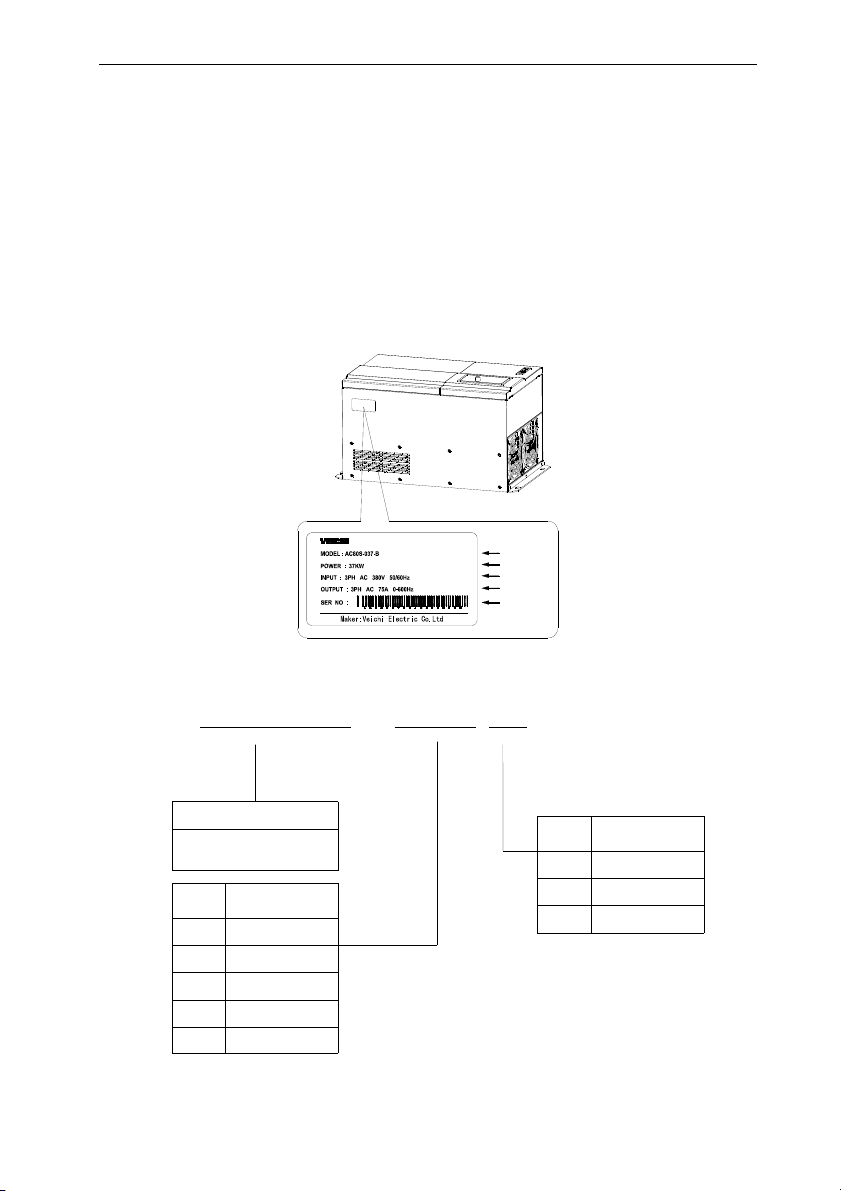

AC80T Tower Crane Purpose VFD Manual

4

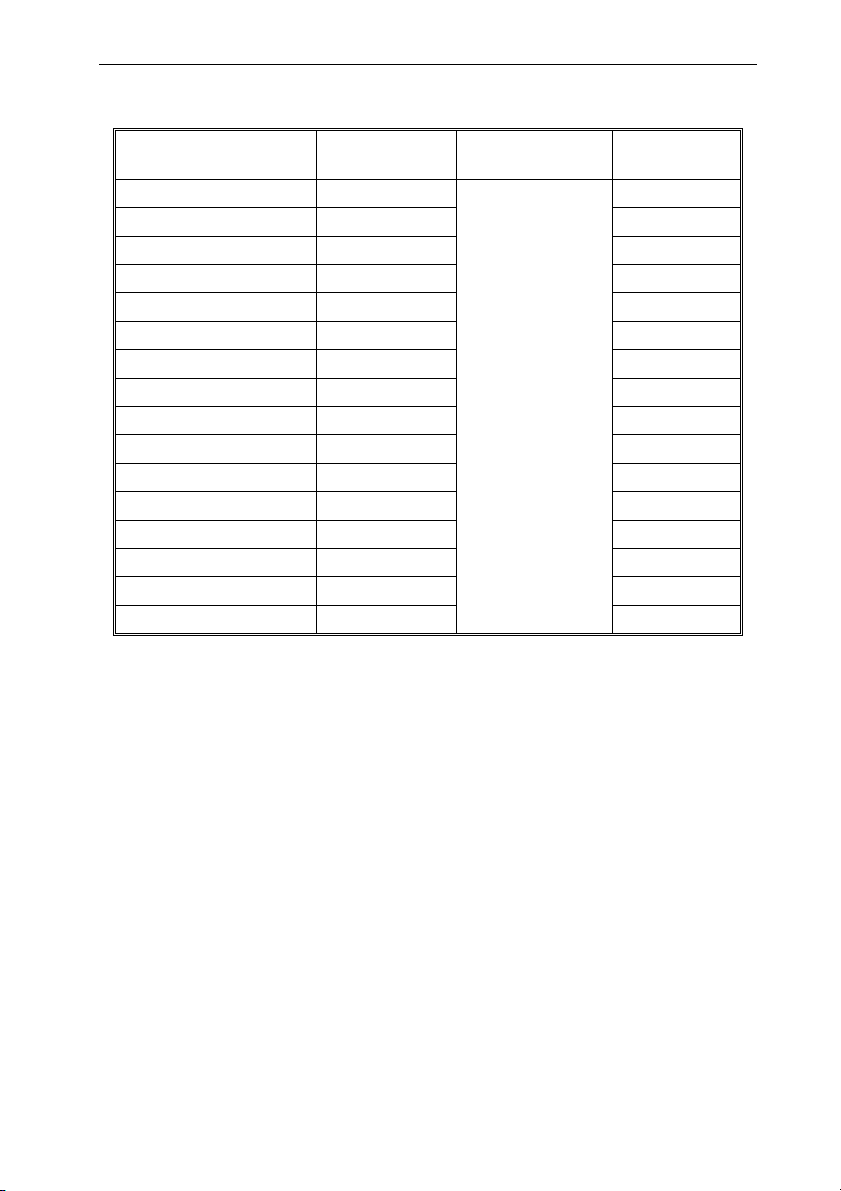

ACC/ DEC curve Two modes: line ACC/ DEC, S curve ACC/ DEC.;

Four sets ACC/ DEC, time unit: 0.01s, maximum: 650.00s.

AVR (Auto Voltage

Regulation)

Auto voltage regulation for keeping output voltage stable when

grid voltage fluctuation.

Auto current limit Auto current limit during running mode to avoid trip occurs

frequently.

Momentary power

loss with no stop

running function

Achieve continuous running through bus voltage control, when

momentary power loss.

Frequency setting

methods

Keypad digital setting, potentiometer of keypad, analog voltage

terminal VS1, analog voltage terminal VS2, analog current

terminal AS, communication given and multiple terminal, main

and auxiliary composition setting.

Feedback input

channel

Voltage terminal VS1, VS2, current terminal AS, communication

given and pulse input PUL.

Running command

channel Keypad given, external terminal given, communication given.

Input command

signal

Start, stop, FEW/REV, JOG, multiple speed, free stop, reset,

ACC/ DEC. Time selection, frequency setting channel selection,

external fault alarm.

External output

signal

1 relay output, 2 collector output, 0~10V output, 4~20mA

output, frequency pulse output.

Protection function

Overvoltage, undervoltage, current limit, overcurrent, overload,

electric thermal relay, overheat, overvoltage stall, data

protection.

Keyboard

display

LED display Double line 4 digital tube

display Can monitor the status of 2 VFD.

Parameter copy Upload & download parameter code of inverter to achieve easy

& fast parameter copy.

Monitor function

Output frequency, given frequency, output current, input voltage,

output voltage, motor speed, PID feedback value, PID given

value, module temperature, input/output terminal status.

Alarm

Overvoltage, undervoltage, overcurrent, short circuit, phase loss,

overload, overheat, overvoltage stall, current limit, parameter

lock damage; Fault running state at present; Fault history.

Environmen

t

Installation site Indoor, altitude ≤1000m, no corrosive gases and direct sunshine

Temperature,

humidity

-10 ~ +40℃(wall-mounted type)

20%~90%RH (no condensation)

Vibration ≤0.5g under 20Hz

Store temperatue -25~+65℃

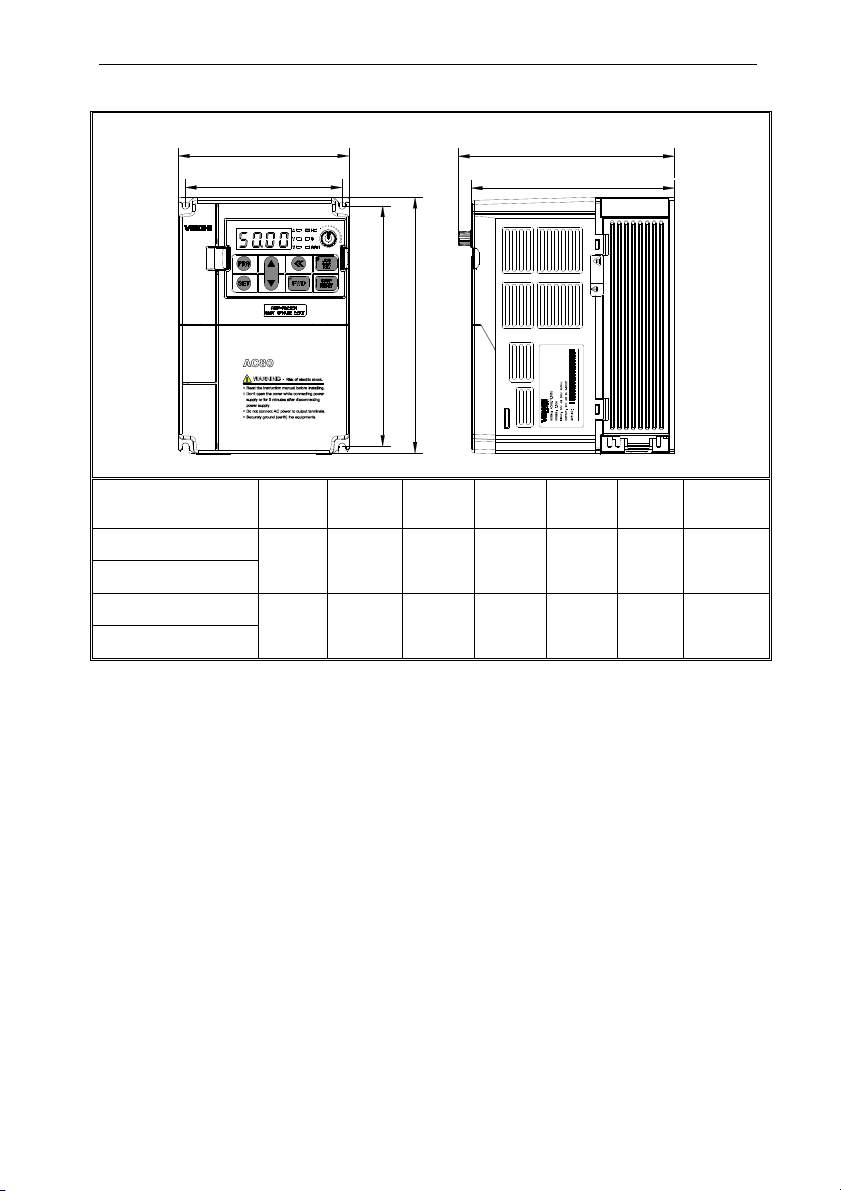

Installation type Wall-mounted type

Protection degress IP20

Cooling method Forced air-cooling