Fenwal Controls 05-50 Series User manual

F-05-50

January 2023

1

FEATURES

• Works with Fenwal ConnectedControls mobile and

desktop applications

• Can be configured for a company cloud network

• Uses 2.4 GHz Wi-Fi and Bluetooth® communications

• Includes UART communication interface with gas ignition

control

• Reports all states of control to the cloud

• Provides remote reset of gas ignition control

• Includes three proving switch inputs for appliance

features

• Includes 4 status LEDs

• Available Internal or External Antenna option

• Accepts AC or DC low voltage power

APPLICATIONS

• Radiant Heaters

• Unit Heaters

• Various Other Applications

DESCRIPTION

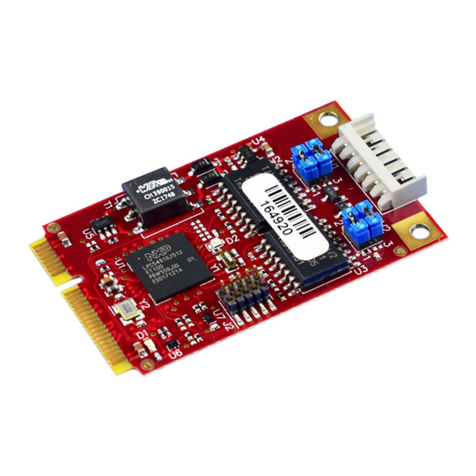

The 05-50 connectivity module is designed to connect to a

compatible Fenwal gas ignition control, giving the appliance IoT

capability. The module communicates all state changes in the

gas ignition control to the cloud, which is made available to end

users via a mobile or desktop application. Alert conditions, such

as a lockout, are immediately pushed to the end user

applications. Data sent to the cloud can be used to trend

performance, and detect and troubleshoot issues.

The connectivity module has three additional proving switch

connections to allow monitoring additional inputs such as

inducer fans, gas pressure switches, and high limit sensors.

The Fenwal ConnectedControls software allows customers to

manage their accounts, specific sites, individual users, and

service providers. The software provides status of controls,

operational logs, and service notes. In addition, the software

provides troubleshooting tips and technical support links.

Agency Certifications

Note: OEM is responsible for considerations of remote reset

capability for end-use application.

SPECIFICATIONS

RECOMMENDED ACCESSORIES

SMA Cable Requirements:

• Connector: SMA Male 50 ohm to SMA Female 50 ohm

Antenna Requirements:

• 50 ohm input impedance, 2.4 GHz - 2.5 GHz, Gain 2.0 dBi

• Example: PulseLarsen Antenna W1010

• Antenna must be installed to provide a separation

distance of not less than 20cm from all persons and must

not be collocated or operating in conjunction with any

other antenna or transmitter.

Note: Internal and External antenna options provide varying

Wi-Fi signal strength and range. External antenna

orientation can also impact the signal strength.

Manufactures should consider that here are trade-offs

between the two options and choose what best fits

their needs.

UL 60730-1

CAN/CSA E60730-1

RoHS Compliant

External Antena: FCC ID:

2AC7Z-ESPWROOM32UE

IC ID:

21098-ESPWROOMUE

Internal Antena: FCC ID:

2AC7Z-ESPWROOM32E

IC ID:

21098-ESPWROOM32E

Input Power 18-30VAC, 9VA, 50/60Hz

20-28VDC, 9VA

10-14VDC, 9VA

Operating Temperature -40°F to + 176°F

(-40°C to +80°C)

Storage Temperature -40°F to + 185°F

(-40°C to +85°C)

UART Communication 5V TTL

3.3V RS485 (Option)

Thermostat & Proving Switch 1 12/24VDC, 24/120VAC

Proving Switch 2 & 3 12 VDC, 24VAC/DC

Enclosure Noryl® Gray Cover

Size (LxWxH)

with Enclosure

4.9 x 3.5 x 1.3 inches

(12.5 x 8.9 x 3.4 cm)

Moisture Resistance 95% RH non-condensing

SERIES 05-50

Connectivity Module - ConnectedControls

Interfacing with Ignition Controls

Effective: January 2023

2 F-05-50

PROVISIONING

Installation and Configuration with Mobile App

During initial power-up, LED2 (Green) flashes to notify user it is

in provisioning mode. The mobile application walks user through

the process of provisioning the appliance. The mobile application

connects to the connectivity module via Bluetooth. Once

securely connected, LED1 (Red) flashes while searching for

available Wi-Fi networks. The user then selects the network they

want to use and enter its password. The connection is then

verified through the cloud and back to the mobile phone via the

Internet. LED2 (Green) changes to a solid on after successfully

connecting to the Internet and authenticating.

OPERATION

Power Up

On powerup, the connectivity module runs diagnostics. After a

successful power up, LED2 (Green) stays solid to indicate secure

connection to the internet. LED4 (Green) stays solid to indicate

successful communication with gas ignition control.

If there is any data in memory of the connectivity module that

has not been previously uploaded to the cloud, that data is

uploaded at this time.

Normal Operation

The connectivity module constantly monitors the gas ignition

control activity and the three proving switches. All data is stored

in the module’s memory during normal operation. At the

completion of a burn cycle, the data is sent to the cloud and then

available in the Fenwal ConnectedControls application.

Alert Conditions

In the event of a gas ignition control alert, such as a lockout, the

connectivity module will immediately send all data in memory

including the alert condition to the cloud. The Fenwal

ConnectedControls application can be configured to notify end-

users of the alert condition.

Refresh Command

Using the Fenwal ConnectedControls mobile application, a

refresh command can be sent to the connectivity module. Upon

receiving this command all available data in memory of the

connectivity module, including the current state, is sent to the

cloud.

Reset Command

Using the Fenwal ConnectedControls application, a reset

command can be sent to the connectivity module during certain

alert conditions. Upon receiving this command, the TH relay is

momentarily opened and then re-closed to cycle the TH signal

to the gas ignition control. The software contains limits

controlling when and how often this reset can be done.

Loss of Power

On a loss of power, any data that has not been sent to the cloud

is written to non-volatile memory for transmission on the next

power up cycle.

MOUNTING AND WIRING

The 05-50 with internal antenna option is position sensitive. The

internal antenna is placed on the right side of the module (as

noted on the label) and must be kept a minimum of 15mm (.6")

away from any metal surface, including below the module. As

such, the connectivity module should not be mounted to a metal

surface without the appropriate spacing.

The 05-50 with external antenna option is not position sensitive

and can be mounted vertically or horizontally. The module may

be mounted on any surface and fastened with #6 sheet metal

screws. Consideration should be taken for mounting the external

antenna to reduce signal blockage by metal surfaces. The Wi-Fi

signal radiates perpendicular to the antenna.

Secure the module in an area that will experience minimum

vibration and remain below the maximum ambient operational

temperature of 176°F (80°C).

All connections should be made with UL approved, 105°C rated,

18 gauge stranded wire with .054" minimum insulation thick-

ness. Refer to the appropriate wiring diagram when connecting

the 05-50 to other components in the system.

CAUTION

Label all wires prior to disconnection when

servicing or replacing controls. Wiring errors can

cause improper and dangerous operation. A

functional checkout of a replacement control

should always be performed.

CAUTION

The control must be mounted and located in a

manner which protects components from

exposure to water (dripping, condensate,

spraying, rain). Any control that has been

exposed to water must be replaced.

WARNING

All wiring must be done in accordance with both

local and national electrical code, and by a

trained service technician. Wiring must be at

least #18 AWG /AWM rated for 105°C or higher.

WARNING

The 05-50 uses voltages of shock hazard

potential. Wiring and initial operation must be

done by qualified service technician.

WARNING

Operation outside specifications could result in

failure of the Fenwal Controls product and other

equipment with injury to people and property.

WARNING

Do not disconnect any electrical loads while the

automatic gas ignition control is powered.

Disconnect power prior to installation or

replacement of the control with the end use

appliance.

Effective: January 2023

F-05-50 3

TERMINAL DESIGNATIONS

WIRING DIAGRAMS

Figure 1. Wired to 24VAC Gas Control with 120VAC Proving Switch 1

Name Description Terminal Type

PWR/R PWR IN 1/4” Male Q.C.

GND PWR GND 1/4” Male Q.C.

TH/W_IN TH In 3/16” Male Q.C.

TH/W_OUT TH Out 3/16” Male Q.C.

TH/W_RT TH RTN 3/16” Male Q.C.

PS1_IN Proving Switch 1 3/16” Male Q.C.

PS1_RTN Proving Switch 1 RTN 3/16” Male Q.C.

PS2_IN Proving Switch 2 1/4” Male Q.C.

PS3_IN Proving Switch 3 1/4” Male Q.C.

GND GND 1/4” Male Q.C.

COMM 1 Comm. Rx-Receive .100 pin (1)

COMM 2 Comm. TX-Transmit .100 pin (2)

COMM 3 Comm. GND .100 pin (3)

Antenna External antenna option SMA Female

Notes:

• If the Thermostat (TH/W_IN) is 24VAC/DC, (TH/W_RT)

should be GND. If Thermostat (TH/W_IN) is 120VAC, (TH/

W_RT) should be L2.

• If Proving Switch 1(PS1_IN) is 24VAC/DC, (PS1_RTN) should

be GND. If Proving Switch 1(PS1_IN) is 120VAC, (PS1_RTN)

should be L2.

• TACO, THER, TOG, and 0-10V are NOT used at this time.

Effective: January 2023

4 F-05-50

Figure 2. Wired to 120VAC Gas Control

LED DESIGNATIONS

TROUBLESHOOTING

Disposal

Do not discard the connectivity module in the trash, recycle per

local guidance.

Wi-Fi Network Change

If the connectivity module must be connected to a new network

or the network password changes, the module will need be re-

provisioned again. This can be accomplished by pressing the

Reset button on the connectibity module. Alternatively, on

power up, if the module cannot connect to the router there is a

brief period where the provisioning mode is open.

Internal Control Failure

If the connectivity module detects a software or hardware error,

all outputs are turned off. If this condition persists after an

attempt to restart, then the control must be replaced.

LED Condition/Mode

LED 1 Flashing Red Connecting to Local Router

LED 1 Solid Red Provisioned, No Internet

LED 2 Flashing Green Provisioning Mode

LED 2 Solid Green Connected to Internet

LED 3 Flashing Red Communication Fault with Control

LED 4 Solid Green Communicating with Control

No LEDs No Power / Hardware Fault

WARNING

Risk of Explosion or Fire

The 05-50 cannot be service by the user, this can

lead to risk of fire and voids warranty. If controls

faults are detected the 05-50 must only be

replaced by a qualified service personnel.

Do not use aluminum wire, this can also lead to

risk of fire.

WARNING

This product can expose you to chemicals

including Lead and Nickel which are know to the

State of California to cause Cancer and Birth

defects or other Reproductive Harm. For more

information, go to www.P65Warnings.ca.gov

Troubleshooting Guide

Symptom Recommended Actions

1.Dead

(No LED’s after power up.)

A. Miswired

B. Fuse/circuit breaker fault

C. No voltage at PWR

D. Faulty control

2. No Internet

(LED1 Solid Red)

A. Restart Router

B. Restart Modem

C. Reposition Antenna

This literature is provided for informational purposes only.

KIDDE-FENWAL, INC. assumes no responsibility for the prod-

uct’s suitability for a particular application. The product must be

properly applied to work correctly. If you need more informa-

tion on this product, or if you have a particular problem or

question, contact KIDDE-FENWAL, INC., Ashland, MA 01721.

© 2023 Carrier P/N F-05-50 Rev AC

Fenwal Controls, Kidde-Fenwal Inc.

400 Main Street

Ashland, MA 01721

Tel: 800-FENWAL-1

Fax: 508-881-7619

fenwalcontrols.com

Bluetooth is a registered trademark of Bluetooth SIG, Inc.

NORYL is a registered trademark of SABIC Innovative Plastics IP B.V.

All trademarks are property of their respective owners.

EXP OR T INFOR M ATI ON (U SA)

Jurisdiction: EAR

ECCN: 5A991.g

This document contains technical data subject to the EAR.

DIMENSIONS

Figure 3. Control with Cover

STANDARD PART NUMBER CONFIGURATION

Table of contents

Other Fenwal Controls Control Unit manuals

Popular Control Unit manuals by other brands

schmersal

schmersal PSC1-C-10 Series installation manual

Nordson EFD

Nordson EFD 754V-SS installation guide

Philips

Philips Hadco ZoneScape 1-A Documentation

SSS Siedle

SSS Siedle NG 602-01 Product information

Perry Electric

Perry Electric Smartbox Wi-Fi user manual

Honeywell

Honeywell S8921D installation instructions