Fenwal Controls FC1 Administrator Guide

1

Page

Control Unit

FC1

Operation Instruction Manual

Thank you for purchasing this product.

In this manual, we have shown the important notice in order for you to use the

device just and the method of handling this system.

In addition to you read this manual well before the utilization, understanding

well, and use.

A

fter you read, in the place where it is seen with anytime, please be sure to

keep.

ES0911 K5

730110 K0

2

ES0911

Page

Table of contents

1. Safety instructions.................................................................... 3

2. Installation........................................................................... 5

2.2. Installation of control unit...................................................... 6

2.3. Installation of detector.......................................................... 7

2.4. Wiring............................................................................ 8

3. Starting the system.................................................................... 9

3.2. Control unit..................................................................... 10

3.3. Dimensions....................................................................... 16

3.4. Electric specifications.......................................................... 17

3.5. Environmental specifications..................................................... 19

3.6. Mechanical specifications........................................................ 19

4. Procedures/steps to be taken in the event of alarm occurrence ......................... 20

4.1. Alarm............................................................................ 20

4.2. Zone Alarm...................................................................... 20

5. Indication of the time of trouble..................................................... 21

6. Procedures/steps to be taken in the event of trouble occurrence ....................... 22

7. Detector.............................................................................. 23

7.1. Connectable detector............................................................. 23

8. Serial communication facility......................................................... 24

9. Maintenance and Inspection............................................................ 25

9.1. Daily Inspection................................................................. 25

9.2. Periodically Inspection.......................................................... 26

9.3. Functional Inspection............................................................ 28

10. Disposal............................................................................ 30

11. Support............................................................................. 30

730110 K0

3

ES0911

Page

1

11

1.

Safety instructions

Safety instructionsSafety instructions

Safety instructions

・ Before the using, read this chapter and use correctly.

・ The contents which it occurs when you handle erroneously are divided in two of “warning”

and “caution”. This division states clearly the size and impendence of the harm and the

damage.

・ Please keep below rules for safety.

!

!!

!

Warning

・Do not disassemble a control unit. It causes trouble.

・Do not remove a control unit and detector, Fire can not detect.

・

Do not use a control unit which has impacted. And also do not paint

a control unit.

・

Do not soak a control unit in water, and do not put a control unit

into water. It causes electric shock.

・

Do not use the method that not listed in this manual, It causes

trouble.

Caution

!

!!

!

・

This system only tells the outbreak of a fire. This system is not

Fire prevention systems. And Fire extinguishing system.

・

Do not use at the place where it exceeds environmental

specification. It causes trouble.

The Warning symbol is

used to indicate situations and conditions that

can cause operator serious injury and/or equipment damage.

The Caution symbol is

used to indicate situations and conditions that

can cause operator injury and/or equipment damage.

!

!!

!

Warning

Caution

!

!!

!

730110 K0

4

ES0911

Page

・ A term of a guarantee and a guarantee range

【A term of a guarantee】

In regard to the guarantee of this product, the designated payment of the order main thing

after the paying 1 years you guarantee first only the breakdown which occurs in the normal

busy condition which you follow the instruction manual.

【guarantee range】

In regard to the breakdown which it occurs in this product with the criticism of payment

person side during the above-mentioned guarantee period, it does returns repair in the

responsibility of payment person side. However, when it corresponds next, you exclude from

the object of this guarantee.

① Fire, earthquake and the damage by wind and flood, breakdown and the loss by the

thunderbolt and other natural disasters etc.

② After the shipping, transporting and moving and falling etc at your corporation,

breakdown and the loss with inadequate handling.

③ When cause of breakdown due to the reason other than the payment item.

④ Error in regard to use of the consumer, breakdown and the loss with repairing,

remodeling other than our company and error connecting.

⑤ In case of life of the relay part by wearing and depositing of the relay contact.

Furthermore, the guarantee referred to here being something which means the guarantee of

the payment item single unit, pardons the damage which is induced by the breakdown of the

payment item.

730110 K0

5

ES0911

Page

2

22

2.

I

II

Installation

nstallationnstallation

nstallation

2.1.1. System configuration & Connection

This control unit receives the information of warning or breakdown from the detector which

is connected. In addition, it is the equipment which informs outside with the indication

LED and the warning buzzer and the signal contact.

① Control unit : Control unit communicates with the detector,

Control unit controls the indicating LED and 7seg. LED and

the buzzer and signal contact according to the state of the

detector and itself.

FC1-DY:DIN rail mount type

FC1-HY:Surface mount type

② Communication line : It is the line which shares the power supply and the

communication line of the detector.

③ Detector : The connectable detector is shown with the 7th section.

2.1.2. Power Supply

Power supply of the control unit is DC24V±10%.

・

Please prepare for the control unit exclusive power supply as much

as possible.

・Please reduce the electrical noises on power supply.(Bellow 1Vp-p)

・If necessary, attach a proper noise filter to the power supply line.

Caution

!

!!

!

730110 K0

6

ES0911

Page

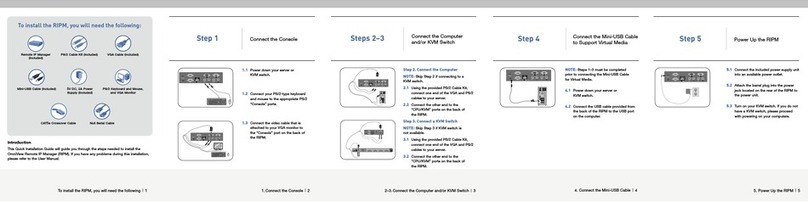

2.2. Installation of control unit

2.2.1. FC1-DY

FC1-DY is DIN rail mount type.

Loosen the screw of the metallic parts for the installation of 2 places which are on the

side of control unit itself. And put the control unit to the fixed 35mm width DIN rail.

Tighten the screw in the specified torque range. Please ensure that equipment installed

correctly.

(torque 1.00~1.35N・m: Reference value)

2.2.2. FC1-HY

FC1-HY is surface mount type.

Using the two screw holes of the metallic parts for the installation of 2 places which are

on the both side of control unit itself, please install securely in the equipment.

Tighten the screw in the specified torque range. Please ensure that equipment installed

correctly.

Please you have to match the screw installations environments.

・

Incorrect loading of the equipments can cause a malfunction,

failure or drop.

・Tighten the screw in the specified torque range.

・Under tightening can cause a drop, malfunction.

・

Over tightening can cause a drop, malfunction due to damage to

the screw or he equipments and malfunction.

!

!!

!

Warning

730110 K0

7

ES0911

Page

2.2.3. Installation places

The control unit must be installed on conductive place where is grounded. And must be used,

When it covers around control unit, electronic buzzer sound hears and becomes difficult to

take. In addition, also heat dissipation becomes bad, becomes cause of breakdown.

Because of this, usually at least please guarantee the space of width above 10mm substance

control unit top and around the guaranty of the passage of air current for heat dissipation

as a purpose.

2.3. Installation of detector

Install the mounting base for detector installation with the two screws M3 which is more

than 15mm length.

And install the detector just in the mounting base.

Caution

!

!!

!

Caution

!

!!

!

・

Install and use with environmental temperature and the humidity

which are within specification value.

・If the

control unit is not correctly installed, it causes the

malfunction, the breakdown, and the fall.

Please note it especially when using it with a lot of vibrations.

・

When the installation screw is loose, it causes the fall, the

short-circuit, and the malfunction.

・

When the installation screw is tightened too much, it causes the

fall, the short-

circuits, and malfunctions by the damage of the

screw and the control unit.

Install and use with environmental temperature and the humidity which

are within specification value.

730110 K0

8

ES0911

Page

2.4. Wiring

2.4.1. Power Supply

When turning on power source, rush current is between several mS, but above 10A it flows.

Wiring please tries to withstand this.

Earthing connection of the ground terminal please goes in order to protect the equipment

from electric shock accident prevention and electric noise, securely.

2.4.2. Communication line

The communication line is connected with control unit and detector as the power line and

the signal line. Therefore, use the shield cable of 0.5mm

2

, and connect the shield part in

the shield cable with the terminal FG.

Divergence wiring is possible concerning wiring. In addition also polarity is nonpolar

characteristics.

Do not bundle with line which gives out other electric noise and separate from it.

・Please do the wiring after the external power supply off. It may

get

an electric shock or the control unit may break down.

・Please use the terminal cover for the control unit when the unit

is

energized, after do the wiring.

If the terminal cover is not used, it may get an electric shock.

・When miss-

wiring or connecting to a power supply different from

ratings, it causes a fire and the breakdown.

・Please give the noise of power supply (DC24V±

10%) to the control

unit as 1Vp-p or less.

Please decrease with the power supply filter etc, whe

n the influence

of the noise is strong.

Caution

!

!!

!

!

!!

!

Warning

Caution

!

!!

!

[

Isolation from electric noise source such as power line

]

The signal conductor which is connected to the receiver and the receiver please wires

above 20cm separating from the power line.

Case it is not possible, please pass in the metallic conduit which the power line is

grounded.

730110 K0

9

ES0911

Page

3

33

3.

Starting the system

Starting the systemStarting the system

Starting the system

3.1.1. Setting of control unit

Please verify whether the number of detectors which it is connected with the DET. NUMBERS

switch which is on the panel front is same.

When setting is different, trouble indication is lighting.

3.1.2. Power on

When the supply of power or power switch is pushed, the power light(green LED) lights up,

the system operates starts.

3.1.3. Register at time of power on

ON

Power supply

OFF

Maximum 120 seconds

State of

Control unit

Initialize

※1

,Wait・Registration

※2

Supervision

※1 After power on, the alarm LED and the trouble LED blink sequentially.

※2 Control unit supplying power to the detector which is connected, starts communication.

Control unit inspects the address of all detectors which are connected, registers the detector

automatically.

When detectors of a quantity which is set in 120 seconds are registered, supervision is started.

When a quantity which is set with control unit and the number of detectors which are registered

are different it makes trouble.

Caution

!

!!

!

・

Pay attention to the sharp edge and the like when you handle control

unit. It becomes cause of the wound.

・

Do not operate switch with sharp and hard ones like a ball pen top.

It makes surface sheet make a tears.

・

Do not touch by hand where the oil is attached and the chemicals are

attached. The surface seat deteriorates and softens.

730110 K0

10

ES0911

Page

3.2. Control unit

3.2.1. Name and function of each section

① Operation panel

a. POWER : Power supply switch (White)

Supply of power supply is started, or the each operation of POWER switch turns on/off the

system.

b. RESET : Reset switch(Blue)

Operation of reset switch resets the alarm LED, alarm signal contact output and buzzer rumble

(continual sound).

However, when the detector still has alarm state, control unit for the second time becomes

alarm state.

The alarm LED and the trouble LED blink sequentially while resetting the alarm one by one.

Also, each segment LED of 7seg LED blinks in order one at a time.

c. DET. NUMBERS×10 : Detector numbers switch(X10)

This is the switch whereby to set the connectable detector numbers by ten digits. (X10)

Caution

!

!!

!

Caution

!

!!

!

After turning off the system, until it turns on power supply again,

please provide the interval of a minute o

r more. There are times when

the system does not start normally.

Since the setting of this switch is re

cognized only at the time of

turning the power on, the power is to be off in the event of changing

the setting.

730110 K0

11

ES0911

Page

d. DET. NUMBERS×1 : Detector numbers switch (X1)

This is the switch whereby to set the connectable detector numbers by ten digits. (X1)

e. POWER: Power Supply indication LED (Green)

While power has been turned on, the power light has lit up.

When control unit CPU error occurs, the power light it goes out and `E' or `E. 'is indicated

in 7Seg LED.

f. ALARM: Alarm indication LED (Red)

When the detectors are in alarm state, it lights up.

Control unit keeps alarm state. Control unit until reset switch is pushed even with when

the smoke of the smoke detector is gone, continues to indicate alarm state.

However, at the time of zone alarm occurrence, as for the alarm LED blinks. Concerning

“4.2.Zone alarm “. The zone alarm does not keep with control unit.

When the alarm occurs, alarm LED is indicated in preferentially from indication of other

things.

g. TROUBLE: Trouble indication LED (Yellow)

While trouble occurs in the system, the trouble LED which corresponds to the contents of

trouble lights up or blinks.

Details of trouble contents please refer to “6. Procedures/steps to be taken in the event

of trouble mode”.

h. Buzzer (Embedded)

In case of alarm state it rumbles with continual sound. In case of trouble state it rumbles

with intermittent sound.

However, at the time of control unit CPU error to continue rumble, the contents are indicated

in 7Seg LED.

Caution

!

!!

!

Caution

!

!!

!

Since the setting of this switch is recogni

zed only at the time of

turning the power on, the power is to be off in the event of changing

the setting.

When the alarm occurs in a trouble state where control unit CPU error

is excluded, rumble of the buzzer changes to continual sound from

intermittent sound because of alarm priority indication.

730110 K0

12

ES0911

Page

i. 7 Segment LED (Red)

Address of the detector where the alarm occurs is indicated.

When the alarm occurs with the plural detectors, the scroll it indicates in the order where

the alarm generates the address which is in the midst of alarm occurring 2 seconds.

First address indicates the decimal point in simultaneously

Address of the detector where trouble occurs is indicated.

When the trouble occurs with the plural detectors, the scroll it indicates in the order where

the trouble generates the address which is in the midst of alarm occurring 2 seconds.

First address indicates the decimal point in simultaneously

At the time of zone alarm occurrence “00” is indicated.

In addition, As for 7seg. LED indication “00” the scroll it indicates in the order where

the alarm generates indication and the address indication to which the alarm occurs.

When control unit CPU error occurs, “E” or “E.” indicates.

Because this indication is breakdown of control unit, please exchange.

Caution

!

!!

!

Caution

!

!!

!

Caution

!

!!

!

When trouble occurs in alarm state, for alarm priority indication,

the address where trouble occurs is not indicated.

When trouble occurs in alarm state, for alarm priority indication,

the address where trouble occurs is not indicated.

When the alarm occurs in zone alarm state, the alarm LED from blinking

becomes lighting because of alarm priority indication.

In addition, As for 7seg. LED indication “00”

the scroll it indicates

in the order where the alarm generates indication and the address

indication to which the alarm occurs.

730110 K0

13

ES0911

Page

② Terminal section

a. DC24V(+,-),

It is the terminal which connects the DC 24V power line.

b. FG

It is the terminal which connects the ground line.

c. Power Communication Line (L, C)

It is the terminal which connects the communication line.

Conformity wire

18-26AWG

Screw

M3×6L

Tightening torque

0.5 N・m

Caution

!

!!

!

!

!!

!

Warning

!

!!

!

Warning

!

!!

!

Warning

Please install the bundled terminal cover in order to prevent accident

such as electric shock.

Use the proper screw driver bit for screw size. Tig

hten inside of

torque.

Do not input the power source other than DC 24V to the terminal.

Do not exceed the service voltage range. It becomes cause of accident

such as fire.

Making a mistake in polarity and connect, the equipment breaks down.

Do not conn

ect wiring other than the communication line to this

terminal absolutely.

It becomes cause of breakdown such that it stops starting normally.

730110 K0

14

ES0911

Page

d. ALARM(COM,NO,NC)

At the time of alarm state and power supply stopping/deciding, the alarm contact signal

operates.

However, at the time of zone alarm occurrence, as for the alarm contact signal it does not

operate.

Alarm contact

State of control unit

Between

COM and NO

Between

COM and NC

Normal supervise Close Open

Alarm or Power supply stop

Open Close

Zone alarm Close Open

e. TROUBLE(COM,NO,NC)

At the time of trouble state and power source stopping/deciding, trouble contact signal

operates.

Trouble contact

State of control unit

Between

COM and NO

Between

COM and NC

Normal supervise Close Open

Trouble or Power supply stop

Open Close

f. RESET

With external non voltage contact input, control unit resets.

g. P-off

When power source of control unit is off, the non voltage contact point is output.

State of control unit contact

Power on Open

Power off Close

Caution

!

!!

!

Caution

!

!!

!

Caution

!

!!

!

!

!!

!

Warning

Do not exceed the maximum of contact point voltage and the maximum

of contact point electric current in this terminal. It becomes cause

of breakdown such as contact point depositing.

Do not exceed the maximum of contact point voltage and the maximum

of contact point electric current in this terminal. It becomes cause

of breakdown such as contact point depositing.

・

Do not connect other than the non voltage contact point to this

terminal absolutely. It becomes cause of breakdown such that it stops

starting normally.

・During signal inputting, control unit becomes non supervisory state

.

When reset action is verified, please stop the input of the signal.

Do not exceed the maximum of contact point voltage and the maximum

of contact point electric current in this terminal. It becomes cause

of breakdown such as contact point depositing.

730110 K0

15

ES0911

Page

③ About Trouble indication

a. DETECTOR

It lights up when sensitivity revision over or inside the detector, trouble occurs in the

detector. (Refer to “6.

Procedures/steps to be taken in the event of trouble occurrence”)

In addition, address of the detector where trouble occurs is indicated in 7seg LED.

b. DET.O V E R

It lights up when the number of detectors which have been recognized is greater than

specification at the detector number switch of control unit

c. DET.UNDER

It lights up when the number of detectors which have been recognized is less than specification

at the detector number switch of control unit.

Control unit, the numbers of detectors recognizing few, lights up similarly even when being

disconnected of the communication line and broken wire inside the detector.

d. PCL.SHORT

When the communication line is short, it lights up.

e. RECEIVER

It lights up when specification of detector number switches of control unit 0 or 32 or more.

In this case of control unit trouble, please exchange.

730110 K0

16

ES0911

Page

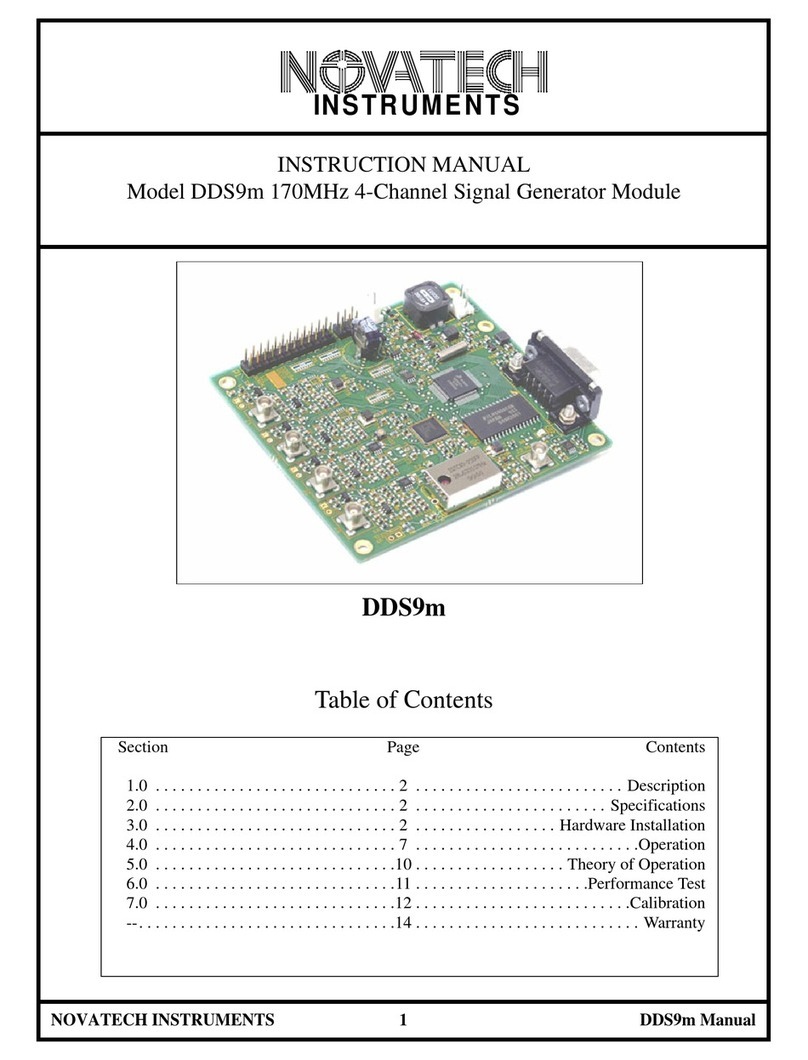

3.3. Dimensions

3.3.1. FC1-DY

3.3.2. FC1-HY

730110 K0

17

ES0911

Page

3.4. Electric specifications

(1) Name of item :

Control unit

(2) model :

FC1-DY

:

FC1-HY

(3) Rating :

DC24V 0.15A

(4) Range of working

voltage

:

DC24V ±10%

(5) Connectable detector

Numbers

:

Up to 31.

(6) Method of setting up

connectable detector

counts

:

It sets making use of the driver from the operation

panel.

When setting up 0 or 32, the trouble LED is made to light

up as a trouble state.

(7) Set up for receiving

the alarm signals

:

5%/m

(8) External wiring

resistance

:

Less than 10Ω

(9) Start up time :

After the power on and after the maximum of 2 minutes

start of supervision.

(10) Signal contact output

:

Alarm contact output

Contact type

State

Between

COM and NO

Between

COM and NC

Normal supervision Close Open

Alarm or Power off Open Close

Zone alarm Close Open

:

Trouble contact output

Contact type

State

Between

COM and NO

Between

COM and NC

Normal supervision Close Open

Trouble occurs or Power off

Open Close

・

Please install the power supply only for the control unit as

much as possible.

・

Please give the noise in the power supply to the control unit

as 1Vp-p or less.

・Please correspond with the power supply f

ilter etc, when there

is a noise.

!

!!

!

Warning

Caution

!

!!

!

Caution

!

!!

!

Please do not connect the detector of the same address. It becomes

not be able to watch normally.

External wiring value of resistance please do not wire above 10

Ω. Supervision stops impossible normally.

730110 K0

18

ES0911

Page

:

Power off contact output

State Contact

Power on Open

Power off Close

Capacity of contact DC30V 1A AC125V 0.3A Resistance

loading

(11) S o u n d o f a l e r t

:

Electronic buzzer.

Alarm sound : Continual sound

trouble sound : Intermittent sound(continual sound

priority)

(12) On/off of power

switch

:

At the time of power switch operating, when power source

is turned on again, please take the interval of 1 minute

or more.

When while the power switch is on main power source is

stopped directly, when main power source is turned on

again, please take the interval of 1 minute or more.

!

!!

!

Warning

Do not disassemble the equipment.

Electric shock, short circuit, there are times when it become

s cause

of fire and breakdown.

730110 K0

19

ES0911

Page

3.5. Environmental specifications

(1) Working temperature range

: 0℃~60℃

(2) Storage temperature range

: -20℃~70℃

(3) Working humidity range : 30~85%RH

3.6. Mechanical specifications

(1) External form : W125×D104×H40(FC1-DY)

: W121×D104×H40(FC1-HY)

(2) Main material : SPCC t1.0 black paint

(3) Mass : Approximately 420g

!

!!

!

Warning

Do not use at the place where it exceeds environmental specification

and the place where the volatilization gas and the corrosiveness gas

occur.

It becomes cause of breakdown such that it stops operating normally.

730110 K0

20

ES0911

Page

4

44

4.

Procedures/steps to be taken in the event of alarm occurrence

Procedures/steps to be taken in the event of alarm occurrenceProcedures/steps to be taken in the event of alarm occurrence

Procedures/steps to be taken in the event of alarm occurrence

When this system inspects abnormality, the following warning is output from control unit.

When warning is output, verifying circumstance, please do necessary disposal.

4.1. Alarm

The alarm occurs when the alarm signal (AON) from the detector is received by the control

unit.

(1) The alarm LED lights up.

(2) The buzzer (continual sound) rumbles.

(3) The alarm signal contact is output.

(4)The alarm detector address is indicated in 7seg LED indication.

4.2. Zone Alarm

The zone alarm is one of alarm information. That occurs when address recognition becomes

impossible in communication obstacle and control unit or breakdown of the detector,

(1) The alarm LED blinks.

(2) The buzzer (continual sound) rumbles.

(3) “00” is indicated in 7seg LED indication.

The state indicating LED of the detector at the time of alarm state and zone alarm state

blinks 1 times at a time in 2 seconds.

Table of contents

Other Fenwal Controls Control Unit manuals