Fenwal Controls 35-9 Series User manual

F-35-2000

October 2018

1 of 12

Series 35-9X Modulating

Platform Ignition Module (PIM®)

OPERATION AND INSTALLATION INSTRUCTIONS

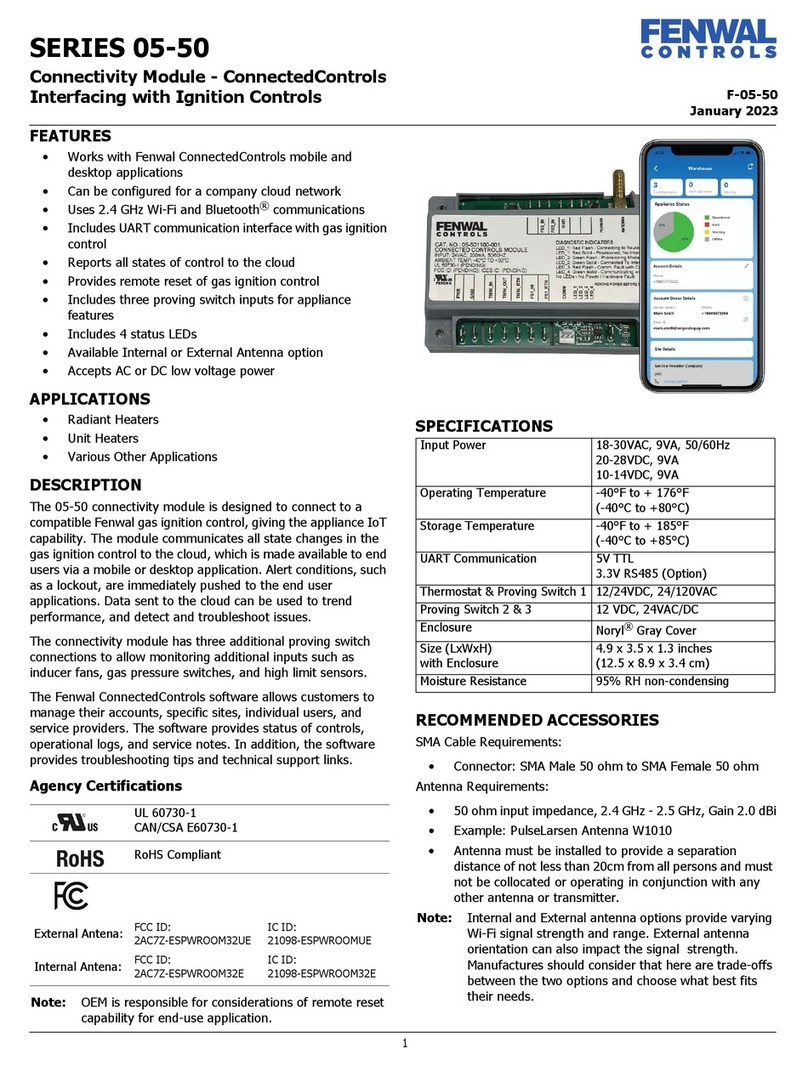

DESCRIPTION

The Fenwal Controls Platform Ignition Module (PIM®) integrates

the functions of Automatic Ignition Control with temperature

regulating and control functions. The PIM is designed for a range

of hydronic boilers including both staged systems and

modulating types. The PIM can be configured as a direct spark

ignition (DSI), intermittent pilot (IP) or Hot Surface Ignition

(HSI) to provide safe lighting and supervision of the burners in

an appliance. The PIM is also designed to connect to and receive

commands from the tekmar®1 Host Controller. When connected

to a Host Controller, the PIM offers expanded control

functionality including Domestic Hot Water, outdoor reset,

diagnostic messages, and other system capabilities.

APPLICATIONS

The PIM and Host Controller system is suited to a wide variety

of gas-fired hydronic heating systems including:

• High-efficiency Modulating Condensing Boilers

• Fan-assisted single and multi-staged Boilers

• Multiple Boiler Installations using intelligent sequencing

• Intermittent Pilot based Hydronic appliances

• Water Heaters

• Pool and Spa Heaters

AGENCY APPROVALS

SPECIFICATIONS

1.The tekmar BTCII Boiler Controller is fully compatible with

the Fenwal PIM and provides complete hydronic boiler

operation. For more information, contact tekmar controls at

(250) 545-7749.

2. EMC Emission testing to be verified after incorporation into

end use appliance.

CSA Design certified to ANSI Z21.20,

CAN/CSA C22.2 No. 199-M99 and ANSI

Z21.20-2014 CAN/CSA C22.2 No.

60730-2-5-14

CE Approved to EN 298-20122

WARNING

Installing or operating the product inconsistent

with these instructions or specifications could

cause serious property damage, injury or death.

Specification Value

Input Power Control: 18-30 VAC 50/60 Hz

(Class 2 Transformer)

Input Current Drain 400 mA @ 24 VAC with gas and

blower relays energized (Control

only)

Gas Valve Relays 5.0A max (continuous)

Combustion Blower 5.0 A max for standard (J2)

connection

15.0 A max for heavy-duty (K5

relay) terminals

Hot Surface Igniter 5.0 A max, 120/240 VAC

Pump Relays 5.0 A max (continuous)

Alarm Relay 2.0 A, 30 VDC or 30 VAC max

Operating Temperature -40°F to + 165°F (-40°C to +74°C)

Storage Temperature -40°F to + 185°F (-40°C to +85°C)

Sensor Temperature Range -22°F to + 260°F (-30°C to

+126°C)

Flame Sensitivity 0.7 μA minimum

Flame Failure Response or

Reignition Time

0.8 seconds maximum

Flame Detector Self-check Rate Once per second minimum

Flame Failure Lockout Time Varies by model

Types of Gas Natural, LP, or manufactured

Spark Rate Remote sense (50/60 Hz)

Local sense (25/30 Hz)

Size (LxWxH) 8.50 x 6.50 x 2.50 inches

(21.59 x 16.51 x 6.35 cm)

Ingress Protection Not rated, protection provided by

appliance in which it is installed.

Moisture Resistance Conformal coated to operate non-

condensing to 95% R.H.

Tries for Ignition One or three try versions available

Trial for Ignition Period 1 to 30 seconds, up to 300 seconds

(IP)

Pre-purge Timings 1 to 255 seconds

Inter-purge Timings 1 to 255 seconds

Effective: October 2018

2 of 12 F-35-2000

FEATURES

The PIM provides the following features:

• Integrated UL353 High Limit using Thermistor Sensor

• Configuration parameters selected through a unique

Identification Card

• Communicates via (RS485) with Host Controller

• Supports tN4 signals when using tekmar Host

Controller

• Measures Inlet, Outlet, Limit, and Vent temperatures

using NTC curve

J Thermistors, 10 KΩ(β3892) at 25°C (12 KΩ

Thermistors optional).

• Optional signals from DHW, System, and Outdoor Air

sensors to Host Controller for Outdoor Reset and DHW

functions.

• Supports external input (0-10 VDC or 4-20 mA) from an

Energy Management System

• Controls the Boiler, System, and DHW pumps

• Controls the gas ignition sequence in response to space

heating or DHW demand

• Pulsed Water Flow sensor input for optimizing DHW

performance

• Modulates the boiler firing rate using combustion

blower speed control, providing a PWM output or a 4-

20 mA signal.

• Closed-loop control of blower speed (RPM) through

tachometer signal monitoring

• Optional support for two-stage blowers by re-assigning

the DHW pump relay

• Low-voltage detection and safe shutdown below

18.0VAC supply input

• Hot Surface or Direct Spark Ignition (also allows for

external HV transformer)

• Intermittent Pilot Ignition (single stage only)

• Fail-safe Control for one or two stages of gas valves

• Optional Isolated (Dry) Contact Gas Valve operation

• Airflow, water flow and gas pressure switch monitoring

and diagnostics

• Optional automatic reset after ignition lockout (one

hour or as defined)

• Safe-Start and full-time Flame sensing

• Local (through the HSI or DSI element) or Remote

Flame sensing

• Configurable as needed to meet CSD-1 applications

• System and Control Diagnostics through use of on-

board or remote LED

• Communication of Diagnostic status to Host Controller

• Manual Reset for Ignition Lockout or Hi-Limit (on-board

or remote)

• Field Test/pump exercise capability

• Dry contact relay output for Alarm and Alert conditions

• Capability of two PIM operation to support up to 4 gas

valve stages using a master/member configuration

SENSORS

The PIM provides standard support for 10K ohm @ 77°F NTC

curve J Thermistor probes (β=3892). Special OEM models may

support other sensor types as outlined in the specific appliance

manuals. Optional 12k Ohm thermistor are available, consult

factory for details.

The Inlet, Outlet, Hi-Limit, and Vent (exhaust stack) sensors are

directly processed by the PIM. The optional System, Outdoor,

and DHW tank sensors are also connected to the PIM but passed

through to the tekmar Host Controller which is required to

provide those additional features.

ID CARD

The PIM determines its operating parameters by reading the

identification code of an external plug-in ID card.

Note: This ID card must be present for the PIM and

appliance to operate.

A total of up to 126 unique codes are supported. This card

selects the proper settings in the PIM's memory for appliance

models. These parameters include ignition timings and

operation; and system and OEM configuration settings.

Fenwal supplies the PIM with its internal ID card settings blank.

The first time a PIM is powered-up attached to an ID card, the

PIM stores the ID card setting in non-volatile memory. Once set,

the PIM only operates with the correct ID card installed that

matches the PIM’s internal ID settings. The PIM verifies the ID

card at power-up.

If a PIM needs to be re-configured for another ID card, such as

during service or replacement, its internal ID card settings must

be cleared. Contact the manufacturer for ID card reset process.

SEQUENCE OF OPERATION

Install the ID Card

The PIM must always have the proper ID card attached for

operation. The ID card is connected to J6 and determines the

correct configuration parameters and system timings for a

particular application. The ID card must always remain with the

appliance, even if the PIM needs to be replaced.

Potentiometer (Operator Setpoint)

The operating setpoint for PIM stand-alone mode is selected by

manually adjusting a potentiometer. The operating point for

outlet water temperature is settable from 110°F to 210°F.

Note: The operating setting used by the software limits the

maximum setpoint to the configured operator

safeguard (delta below the configured high limit

setpoint) to avoid nuisance trips regardless of the

potentiometer position.

WARNING

The ID card must remain with the appliance

for its entire service life. In the event of an ID

Card failure, replacement must be performed

by a qualified technician and must be

replaced with an ID card of the same number.

ID Cards cannot be interchanged between

appliances.

Effective: October 2018

F-35-2000 3 of 12

Configuration (DIP Switch Settings)

The PIM includes an 8-position DIP switch, located near the field

wiring terminals. Use this DIP switch to set field configurable

items when commissioning. The switch positions are listed in the

following table.

The default factory setting for each switch is the second

selection (off position).

Note: When a Host Controller is connected, higher level

functions for these options must be enabled first using

the DIP switch settings.

Start-Up

1. Upon application of 24 VAC power, the PIM resets with

all outputs in the off state.

2. The PIM performs a processor and memory self-test to

insure proper operation.

3. The PIM confirms the presence of a valid ID card which

matches the configuration previously stored in

memory. If the valid ID card is not present, the PIM

generates a diagnostic fault.

4. The PIM reads the DIP switch settings and configures

itself for the desired operation.

5. The Host Controller communications are scanned to

determine if a Host Controller device is present. If

found, system operation is controlled by the Host

Controller.

6. The non-volatile memory is checked for an active

lockout condition. A lockout indicates the previous

attempt to light was unsuccessful, or a hi-limit or other

system fault occurred. The PIM stays in lockout until a

manual reset is performed.

Standby/Call for Heat

1. The PIM continuously monitors the flame status to

verify no flame is present during Standby. If an

erroneous flame is detected, the PIM generates a flame

error fault.

2. The PIM verifies that the optional exhaust vent sensor

below the vent temperature limit before burner

operation can occur. If the vent temperature exceeds

the limit, the PIM performs a Post-purge and proceeds

to a Hard Lockout.

3. A Call for Heat is initiated by the presence of any one

or more of the four sources below:

– A heat demand (contact closure) on the TH field

wiring terminals

– A voltage greater than 0.5Vdc on the analog 0-

10Vdc EMS signal input

– A heat demand present on the DHW field wiring

terminals

– A heat demand from the Host Controller based on

the DHW sensor temperature

4. The PIM initializes the Trial for Ignition (TFI) counter to

the programmed number of trials and proceeds to

Pump Purge mode.

Pump Purging

Note: If a Host Controller is present, the PIM responds to

pump commands via the communication bus. When

the Host Controller determines the boiler needs to fire,

it sends a firing rate command to the PIM and

operation proceeds to Blower Pre-purge.

If the PIM is in stand-alone mode, the pumps operate as follows:

1. A call for space heating energizes the boiler and system

pump outputs.

2. The heat exchanger is purged providing flow past the

water pressure switch.

3. The pump pre-purge time begins after the water

pressure switch is proven.

4. If burner operation is required to meet the operating

setpoint, the PIM proceeds to Blower Pre-purge.

Blower Prepurge

1. The Gas Pressure switch(es) are verified closed.

2. The Airflow switch is verified open (shorted switch

detection).

3. The Combustion Blower is energized, and set to the

purge speed (if modulating).

4. The Airflow switch is verified to close within 60 seconds

to prove flow.

5. The configured ignition pre-purge delay takes place.

6. The voltage level of the 24 VAC supply input is

confirmed to be above 18.0 VAC.

7. If all checks are passed, the PIM proceeds to Ignition.

Table 1-1. DIP Switch Settings

Position Switch Description

1 Operator Differential (Manual/Auto Differential)

2 Analog Input Type (Direct Drive/Target

Temperature)

3PumpPostPurge(On/Off)

4 Pump Exercise Enable (On/Off)

5 EMS/Demands (PIM uses analog input only/

Host Controller or PIM

demands)

6 EMS Signal Type (4-20mA/0-10Vdc) * * 4-

20mA setting requires use of

external 500Ω, 1/2W resistor.

7 Freeze Protection (On/Off)

8 Commission Test (On/Off)

Effective: October 2018

4 of 12 F-35-2000

Ignition (DSI Models)

1. The PIM re-initializes the ignition counter to the

configured number of trials.

2. The High Limit sensor is confirmed to read below the

High Limit Set Point.

3. The blower light-off RPM speed is verified (modulating

type only).

4. The gas valve relay contacts are verified open (except

isolated valve models).

5. The Combustion Blower is set to the Ignition light-off

speed (if modulating).

6. The gas valve output is enabled for the trial for ignition

time to light the burner.

7. The HV spark output is enabled for the configured trial-

for-ignition time.

8. The flame sense is checked for successful lighting of

the burner. When a valid flame is detected during the

TFI period, sparking is terminated and the main gas

valve, operating pumps, and blower relay remain

energized and the PIM proceeds to the Heating mode.

9. If flame is not detected during the TFI period see

“Failure to Light - Lockout”.

Ignition (HSI Models)

1. The PIM re-initializes the ignition counter to the

configured number of trials.

2. The High Limit sensor is confirmed to read below the

High Limit Set Point.

3. The blower light-off RPM speed is verified (modulating

type only).

4. The gas valve relay contacts are verified open (except

isolated valve models).

5. The HSI Element proving current is verified to be above

the configured value. (proven hot-surface models only)

6. The configured heat-up delay takes place to allow the

hot surface element to reach ignition temperature.

7. The gas valve output is enabled for the trial-for-ignition

time to light the burner.

8. The hot surface element is de-energized during the last

second of the TFI period.

9. The flame sense is checked for successful lighting of

the burner. If a valid flame is detected during the TFI

period, the main gas valve, operating pumps, and

blower relay remain energized and the PIM proceeds to

the Heating mode.

10. If flame is not detected during the TFI period see

“Failure to Light - Lockout”.

Ignition (IP Models)

1. The PIM re-initializes the ignition counter to the

configured number of trials.

2. The High Limit sensor is confirmed to read below the

High Limit Set Point.

3. The blower light-off RPM speed is verified (modulating

type only).

4. The gas valve relay contacts are verified open (except

isolated valve models).

5. The Combustion Blower is set to the Ignition light-off

speed (if modulating).

6. The Pilot gas valve output is enabled for the trial for

ignition time.

7. The HV spark output is enabled for the configured trial-

for-ignition time.

8. The flame sense is checked for successful lighting of

the burner. When a valid Pilot flame is detected during

the TFI period, sparking is terminated and the main gas

valve is energized. The Pilot valve, operating pumps,

and blower relay remain energized and the PIM

proceeds to the Heating mode.

9. If flame is not detected during the TFI period see

“Failure to Light - Lockout”.

Heating

1. The flame status, airflow switch, LWCO switch, water

pressure switch and other safety switches are

continually monitored for proper state.

2. The High Limit sensor is confirmed to read below the

High Limit setpoint.

3. The boiler operating water temperature is monitored

against the target temperature to determine the proper

firing rate or staging level.

4. The PIM remains in heating mode until the staging

reaches 0% or the firing rate drops below the

configured minimum value for the burner.

5. A Blower Post-purge is completed and the control

proceeds to Standby mode.

Heat Demand Satisfied

1. The thermostat signal becomes inactive indicating the

call for heat is satisfied.

2. The gas valve(s) are immediately disabled.

3. A Blower and Pump Post-purge is completed before

returning to Standby mode.

FAILURE TO LIGHT - LOCKOUT

Single Trial Model

Should the burner fail to light or if flame is not detected during

the trial for ignition period, the control performs the following:

1. The control enters ignition lockout.

2. The gas valve(s) are de-energized immediately.

3. The LED indicates the fault code for ignition lockout.

Multi Trial Model

Should the burner fail to light or if flame is not detected during

the first trial for ignition period, the control performs the

following actions:

1. The gas valve(s) are de-energized.

2. The control then goes through an interpurge delay

before another ignition attempt.

Effective: October 2018

F-35-2000 5 of 12

3. The control attempts two additional ignition trials

before going into lockout and the gas valve relay(s) are

de-energized immediately.

4. The LED indicates the fault code for ignition lockout.

Lockout Reset

Volatile Reset Models

Recovery from lockout requires either pressing manual reset,

recycling the call for heat, or removing 24 volts for a period of 5

seconds. On models with automatic reset, if the call for heat is

still present after the configured reset time, the control will

automatically reset and attempt to start a new heating cycle.

Manual Reset Models

Recovery from lockout requires activation of the manual reset

switch or remote reset input.

High Limit Fault Reset

If the High Limit sensor detects a temperature above the High

Limit setpoint, the PIM will enter lockout. Recovery from a High

Limit fault requires activation of the manual reset switch or

remote reset input.

FLAME FAILURE RESPONSE

Recycle Mode

With "recycle after loss of flame", upon loss of flame, the gas

valve is de-energized within 0.8 seconds. After the flame recycle

delay, the control attempts to relight the burner. Multi-try

models allow three tries for ignition including inter-purges. If the

pilot burner relights, normal operation resumes. If the burner

does not relight, the control will go into lockout as described in

“Failure to Light - Lockout”.

Re-ignition Mode (Spark Models Only)

If the established flame signal is lost while the burner is

operating, the control responds within 0.8 seconds by energizing

the HV spark for the TFI period in an attempt to relight the

burner. If the flame is re-established, normal operation resumes.

If the burner does not light within the TFI, the gas valve is de-

energized immediately and on multi-try models a new TFI

sequence begins. Multi-try models will make 2 more attempts to

light the burner.

If the burner does not relight, the control will lockout as

previously described in “Failure to Light - Lockout”.

OEM FACTORY WIRING

Supplying Power

The PIM requires 24 VAC on Connector J11 to operate its

microprocessor circuits, the safety switch connections, and the

field demand inputs. An onboard fuse protects the 24 VAC

circuits and if configured for direct gas valve power, the 24 VAC

relay outputs to the gas valves.

Sensor Inputs

The PIM requires an outlet thermistor sensor for burner control

and a high-limit thermistor sensor for the integrated UL353 high-

limit function. These two thermistors must be independent but

co-located so they provide similar readings. The vent sensor and

inlet sensor are optional and if used should be enabled by the

parameter table settings.

Isolated Valve Contacts

If the optional isolated valve configuration is used, the valve

power and return must be separately supplied to J12 and the

valve outputs are not protected.

Combustion Blower Connections

The blower motor is connected to J13 operating off the power

supplied to L1, which can be 120VAC or 240VAC. If a modulating

blower is used, PWM or 4-20 mA signals are provided by

connection to J10. The blower motor tachometer signal is

required when configured for closed-loop fan speed control.

High-Current Blower Option

If provided, the relay contacts of K5 must be used to connect the

blower. The QC dry-contact terminals on top of the relay are

used for the blower output and supply voltage, which may be

120VAC or 240VAC. The maximum current rating is 15.0A.

Pump Outputs

The pump circuits are operated off the power supplied to L1 and

L1-S, which can be 120VAC or 240VAC. The boiler pump and

DHW pump are sourced from L1, while the supply pump (if

used) must be powered by L1-S.

Ignition Outputs

The PIM is capable of DSI, IP, or HSI ignition depending on

configuration. For spark ignition (DSI or IP) the electrode is

connected to the T3 ignition coil. For HSI the igniter element

connects to P1 and is driven off the L1 supply voltage.

If configured, an external spark ignition transformer can be used

by connecting it to P1. It is powered by L1 and the spark output

on T3 will be disabled.

SYSTEM CONNECTIONS (FIELD WIRING)

If used, the Host Controller must be connected to J4. The RJ-45

style 8-pin jack provides power, communications, and sensor

information to the Host Controller.

The PIM also acts as the central wiring point of a hydronic

system. Field wiring terminals on J1 and J2 allow connection of

optional DHW, outdoor, and system sensors, Host Controller,

EMS analog demand signal, LWCO, remote reset, water flow

switch, and the space thermostat and DHW demand inputs.

Effective: October 2018

6 of 12 F-35-2000

LED ERROR CODE LISTING

The following table lists the errors detected by the control and the associated LED indications

Error Mode LED Code Recommended Troubleshooting

Normal Operation Off

ID Card Fault Red LED Steady ON, Green

Power LED OFF

Check that the proper ID card is securely connected.

Perform a power and system reset.

Internal Control Failure Steady ON Perform a power and system reset.

If fault remains, replace the PIM.

Airflow Fault 1 flash Check Blower operation and airflow switch.

False Flame Error 2 flashes Check for proper gas valve closure.

Clean burner and electrodes.

Ignition Lockout Fault 3 flashes Check the gas supply.

Ignition Proving Current

Fault

4 flashes Check HSI element. Replace with a new element of the proper rating.

Low Voltage Fault 5 flashes Check the 24 VAC input voltage. The voltage must be above 18.0 VAC

Vent Temperature Fault 6 flashes Check for a blocked flue. Check the vent sensor and connections.

Hi-Limit Fault 7 flashes Check for proper water flow. Check hi-limit and outlet sensors.

Sensor Fault 8 flashes See Host Controller for fault identification. Check sensors and wiring.

Safety #1 Fault 9 flashes Check gas pressure. Verify proper safety switch operation.

Water Pressure Fault 10 flashes Check piping for leaks. Check pressure switch and connections.

Blower Speed Fault 11 flashes Verify tachometer signal and connection on J5.

LWCO Fault 12 flashes Check LWCO switch and connections. Check the water level.

Hi-Temperature Delta Fault 13 flashes Check pump operation. Confirm proper water flow across heat exchanger.

Ft-bus Communications

Fault

14 flashes Verify Host Controller is connected and operating. Check the cable between the

Host Controller and J1.

Safety #2 Fault 15 flashes Check gas pressure. Verify proper safety switch operation.

MOUNTING AND WIRING

The PIM enclosure is designed to facilitate mounting within a

control box by the appliance OEM.

The PIM is not position sensitive and can be mounted vertically

or horizontally. The case may be mounted on any surface using

four standard #8 sheet metal screws.

HIGH VOLTAGE AND REMOTE SENSE CABLE

REQUIREMENTS

The HV Ignition Cable must meet a voltage rating of 25 KV and

an insulation rating of 200 °C. Recommend length of 3ft (.9m)

or less. Consult factory for longer lengths.

Remote flame sense cable must meet a voltage rating of 250V

and an insulation rating of 200 °C. Recommended length of 10ft

(3m) or less. Consult Factory for longer lengths.

INDICATORS

The PIM has three LED indicators to display operational status

and to help diagnose system error conditions.

•Power: Green LED indicating the PIM module is

receiving 24 VAC power.

•Alarm/Test: Amber LED which indicates the PIM is in

Commission Test Mode or that a diagnostic alarm

(fault) is present.

•Diagnostic Code: Red LED that is normally off.

During a control or system fault condition, this LED

flashes the error codes. Refer to the following table for

additional details.

WARNING

The PIM must be mounted and located in a

manner which protects components from expo-

sure to water (dripping, condensate, spraying,

rain). Any control that has been exposed to

water must be replaced.

WARNING

All wiring must be done in accordance with both

local and national electrical code. Wiring must

be at least #18 AWG rated for 105°C or higher.

WARNING

The PIM uses voltages of shock hazard poten-

tial. Wiring and initial operation must be done by

qualified service technician.

WARNING

Operation outside specifications could result in

failure of the Fenwal product and other equip-

ment with injury to people and property.

Effective: October 2018

F-35-2000 7 of 12

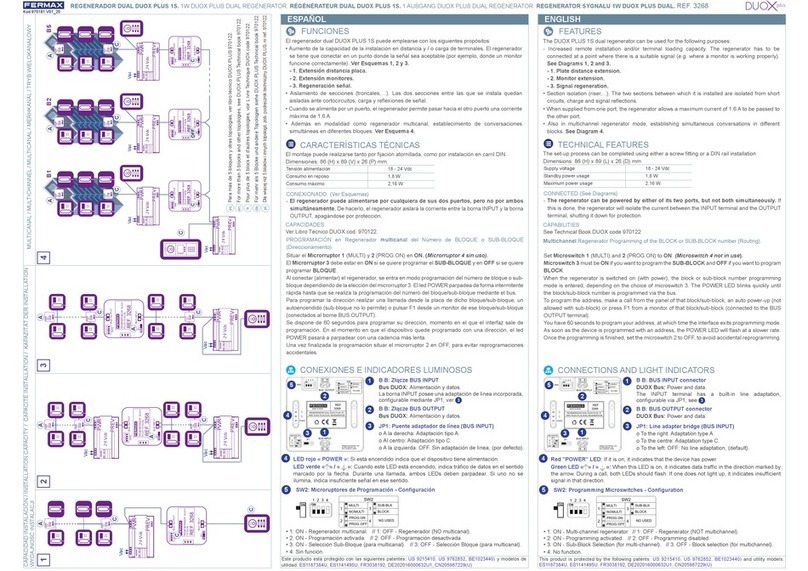

WIRING DIAGRAMS

DSI Wiring Diagram

J4

J2 J1

SW2

For field settings,

see note

Limit

R91

Operator

Se t P oint

SW1

J15

D80

D23

D90

Remote

LED

D

RST

PWR

Reset

F1

T2

FS P2 GND

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

FC-

FC+

Remote Flame

Sense Rod

Host Controller Bus

DHW Sensor

System Sensor

Outdoor Senso

r

tN 4

+ EMS

- 0-10 V DC

Alarm

LWCO

Remote Reset

Flow Swit ch

DHW TH

The rmo st at

Host

Controller

FT -B us B

FT -B us A

PI M

Sla ve

V+

Boiler

Identity Card V in

GN

D

Hi gh Limit

Senso r

Outlet Sen sor

Air Flow

Sa fet y #2

Sa fet y #1

Inlet S ensor

Vent Sensor

4 to 20 MA

Fan Power (18 VDC )

Fan GND

Flow SE N GN D

Flow SEN P W (12 V DC)

PWM-Out

Flow Sens or

Tachometer

To J10 Pin 3

To J10 Pin 4

24 VA C

L1

L2

2 STG / MV

MV / PV

RTN

Hot

Dry

Contact

Blower

System

Pump

B oile r

Pump

DHW

Pump

L1 – S 120 VAC

120 VAC

120 VAC

11091

1

2

1

2

3

1

2

3

4

1

2

3

4

5

6

1

2

3

4

1

2

3

5

6

7

48

1

2

3

5

6

7

48

12

1

25

4

36

1

2

3

4

T3

Spark

Electrode

J3

Effective: October 2018

8 of 12 F-35-2000

HSI Wiring Diagram

J4

J2 J1

SW2

For field settings,

see note

Limit

R91

Op er ato r

Se t P oint

SW1

J15

D80

D23

D90

Remote

LED

D

RST

PWR

Reset

F1

T2

FS P2 GND P1

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

FC-

FC+

S2/FS

S1

Remote Flame

Sense Rod

Hot

Surface

Ignitor

DHW Sensor

Syst em Se nso r

Outdoor Senso r

tN 4

+ EMS

- 0-10 V DC

Alarm

LWCO

Remote Reset

Flow Swit ch

DHW TH

The rmo st at

FT -B us B

FT -B us A

PI M

Sla ve

V+

Boiler

Identity Card

V in

GN

D

Hi gh Limit

Senso r

Outlet Sen sor

Air Flow

Sa fet y #2

Sa fet y #1

Inlet S ensor

Vent Sensor

4 to 20 MA

Fan Power (18 VDC )

Fan GND

Flow SE N GN D

Flow SE N P W (1 2 V DC )

PWM-Out

Flow Sens or

Tachometer

To J10 Pin 3

To J10 Pin 4

24 VA C

L1

L2

2 STG / MV

MV / PV

RTN

Hot

Dry

Contact

Blower

System

Pump

B oile r

Pump

DHW

Pump

L1 – S

120 VAC

120 VAC

120 VAC

11091

1

2

1

2

3

1

2

3

4

1

2

3

4

5

6

1

2

3

4

1

2

3

5

6

7

48

1

2

3

5

6

7

48

12

1

25

4

36

1

2

3

4

J3

Host Controller Bus

Host

Controller

Effective: October 2018

F-35-2000 9 of 12

WIRING TABLES

OEM Factory Low-Voltage Wiring Connections (30 VAC Max)

Connector Pin Function Type and Rating

J5 1 Ft-bus B (PIM to PIM) Molex Micro-Fit, 20-30AWG, 2.0A

J5 2 Ft-bus A (PIM to PIM) Molex Micro-Fit, 20-30AWG, 2.0A

J6 1 ID Card Power (3.3Vdc) Molex Micro-Fit, 20-30AWG, 2.0A

J6 2 ID Card Signal Molex Micro-Fit, 20-30AWG, 2.0A

J6 3 ID Card Ground Molex Micro-Fit, 20-30AWG, 2.0A

J7 1 Hi-Limit Sensor Molex Micro-Fit, 10K Thermistor J curve

J7 2 Sensor Common Molex Micro-Fit, 10K Thermistor J curve

J7 3 Sensor Common Molex Micro-Fit, 10K Thermistor J curve

J7 4 Outlet Sensor Molex Micro-Fit, 10K Thermistor J curve

J8 1 Safety #1 switch Molex Micro-Fit, 20-30AWG, 2.0A

J8 2 Airflow switch Molex Micro-Fit, 20-30AWG, 2.0A

J8 3 Safety #1 return Molex Micro-Fit, 20-30AWG, 2.0A

J8 4 Airflow return Molex Micro-Fit, 20-30AWG, 2.0A

J8 5 Safety #2 switch Molex Micro-Fit, 20-30AWG, 2.0A

J8 6 Safety #2 return Molex Micro-Fit, 20-30AWG, 2.0A

J9 1 Inlet Sensor Molex Micro-Fit, 10K Thermistor J curve

J9 2 Vent Sensor Molex Micro-Fit, 10K Thermistor J curve

J9 3 Sensor Common Molex Micro-Fit, 10K Thermistor J curve

J9 4 Sensor Common Molex Micro-Fit, 10K Thermistor J curve

J10 1 4-20 mA Out (modulation %) Molex Micro-Fit, 20-30AWG, 2.0A

J10 2 PWM Out (modulation %) Molex Micro-Fit, 20-30AWG, 2.0A

J10 3 Flow Sensor Signal Molex Micro-Fit, 20-30AWG, 2.0A

J10 4 Tachometer Input Molex Micro-Fit, 20-30AWG, 2.0A

J10 5 Fan Power (18VDC) Molex Micro-Fit, 20-30AWG, 2.0A

J10 6 Fan Ground Molex Micro-Fit, 20-30AWG, 2.0A

J10 7 Flow Sensor Ground Molex Micro-Fit, 20-30AWG, 2.0A

J10 8 Flow Sensor Power (12VDC) Molex Micro-Fit, 20-30AWG, 2.0A

J11 1 24VAC Power (R) Molex Mini-Fit Jr. 30VAC, 8A

J11 2 24VAC Common Molex Mini-Fit Jr. 30VAC, 8A

Effective: October 2018

10 of 12 F-35-2000

OEM Factory Line-Voltage Wiring Connections

Connector Pin Function Type and Rating

J12 1 Valve common (isolated contact) Molex Mini-Fit Jr. 120/240VAC, 8A

J12 2 2nd stage Valve Molex Mini-Fit Jr. 120/240VAC, 5A

J12 3 Gas Valve Return Molex Mini-Fit Jr. 120/240VAC, 5A

J12 4 2nd Stage Valve Return Molex Mini-Fit Jr. 120/240VAC, 5A

J12 5 Gas Valve (MV/PV) Molex Mini-Fit Jr. 120/240VAC, 5A

J12 6 Valve Power (isolated contact) Molex Mini-Fit Jr. 120/240VAC, 8A

J13 1 Blower Output (L1) Molex Mini-Fit Jr. 120/240VAC, 5A

J13 2 Blower Return (L2) Molex Mini-Fit Jr. 120/240VAC, 5A

J13 3 Blower Ground Molex Mini-Fit Jr. 120/240VAC, 8A

J13 4 L1 supply input Molex Mini-Fit Jr. 120/240VAC, 8A

K5 Relay F1 and F2 terminals .250” QC terminals, 120/240VAC, 15A

J14 1 DHW Pump Molex Mini-Fit Jr. 120/240VAC, 5A

J14 2 Boiler Pump Molex Mini-Fit Jr. 120/240VAC, 5A

J14 3 L1s – System Pump Supply Molex Mini-Fit Jr. 120/240VAC, 8A

J14 4 System Pump Molex Mini-Fit Jr. 120/240VAC, 5A

J14 5 L1 Supply power Molex Mini-Fit Jr. 120/240VAC, 8A

J14 6 Not used Molex Mini-Fit Jr.

J14 7 L2 (neutral) Molex Mini-Fit Jr. 120/240VAC, 8A

J14 8 Pumps GND Molex Mini-Fit Jr. 120/240VAC, 8A

HV Spark Output (T3 coil) .250” QC terminal, 25kV

GND Burner Ground .250” QC terminal

S1 Hot Surface Element .250” QC terminal, 5.0A Max

S1/FS Hot Surface Element .250” QC terminal, 5.0A Max

FS Flame Sense Rod .250” QC terminal

P2 FC+ Flame Current Measurement .156” pin header

P2 FC- Flame Current Measurement .156” pin header

Effective: October 2018

F-35-2000 11 of 12

Low-Voltage Field Wiring Connections (30 VAC Max)

Connector Pin Function Type and Rating

J4 1 DHW sensor (to Host Controller) RJ45

J4 2 System sensor (to Host Controller) RJ45

J4 3 Outdoor sensor (to Host Controller) RJ45

J4 4 Host Controller RJ45

J4 5 Host Controller RJ45

J4 6 Host Controller RJ45

J4 7 24VAC Common RJ45

J4 8 24VAC Power (to Host Controller) RJ45

J3 1 Host Controller Bus 22AWG twisted pair

J3 2 Host Controller Bus 22AWG twisted pair

J2 1 DHW Sensor 10K Thermistor J curve

J2 2 DHW Sensor Common 10K Thermistor J curve

J2 3 System Supply Sensor 10K Thermistor J curve

J2 4 System Sensor Common 10K Thermistor J curve

J2 5 Outdoor Sensor 10K Thermistor J curve

J2 6 Outdoor Sensor Common 10K Thermistor J curve

J2 7 tN4 Communications Network Signal

J2 8 0-10Vdc Analog EMS Input 0-10 VDC or 4-20mA

J2 9 Common GND

J1 1 Alarm Contacts 0-30VAC, 2.0A Max Dry contact

J1 2 Alarm Contacts 0-30VAC, 2.0A Max Dry contact

J1 3 Low Water Switch (LWCO) 0-30VAC, 2.0A Max

J1 4 24VAC out (R) 18-30VAC, 2.0A Max

J1 5 Remote Reset 0-30VAC, 2.0A Max

J1 6 Water Pressure Switch 0-30VAC, 2.0A Max

J1 7 24VAC out (R) 18-30VAC, 2.0A Max

J1 8 DHW Call (DHW) 0-30VAC, 2.0A Max

J1 9 Heat Call (TH) 0-30VAC, 2.0A Max

J1 10 24VAC out (R) 18-30VAC, 2.0A Max

Fenwal Controls, Kidde-Fenwal Inc.

400 Main Street

Ashland, MA 01721

Tel: 800-FENWAL-1

Fax: 508-881-7619

www.fenwal.com

tekmar is a registered trademark of tekmar Control Systems Ltd. and tekmar Control Systems, Inc.

PIM is a registered trademark of Kidde-Fenwal Inc. All other trademarks are the property of their respective owners.

This literature is provided for informational purposes only. KIDDE-FENWAL, INC. believes this data to be accurate, but it is published and presented without any guarantee

or warranty whatsoever. KIDDE-FENWAL, INC. assumes no responsibility for the product's suitability for a particular application. The product must be properly applied to

work correctly. If you need more information on this product, or if you have a particular problem or question, contact KIDDE-FENWAL, INC., Ashland, MA 01721 USA.

Telephone: (508) 881-2000.

F-35-2000 Rev AB

©2018 Kidde-Fenwal, Inc.

12 of 12

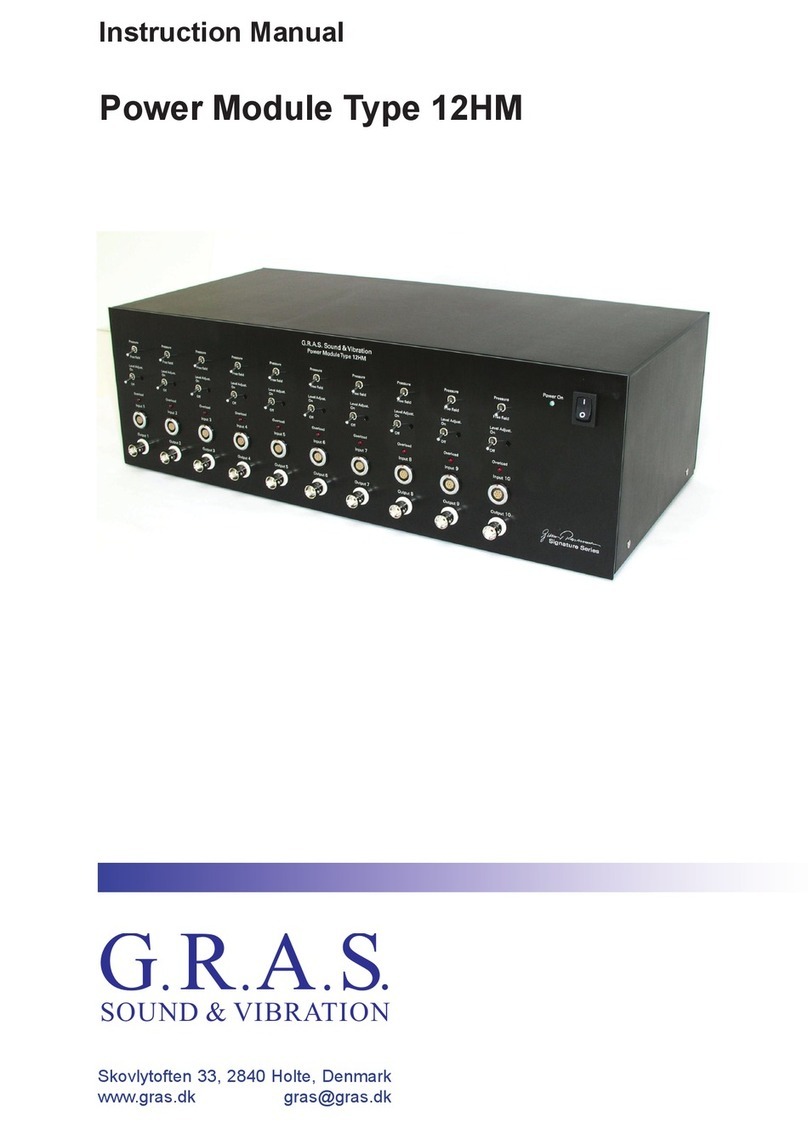

PIM PART NUMBER

The following image explains the meaning of the various digits in the part number. Use this information to order the correct board.

35 – 9 X X X X X X X X–

IGNITION TYPE

1 = Direct Spark

2 = Direct Spark with External Relay

6 = Hot Surface Ignition

7 = Proven Hot Surface Ignition

VALVE/FAN CONFIGURATION

0 = Modulating (1-stage)

1 = One Stage

2 = Two Stage

3 = Intermittent Pilot (PV/MV)

4 = One Stage with Auxiliary

5 = Isolated M odulating (1-stage)

6 = Isolated One Stage

7 = Isolated Two Stage

RESERVED

0 = Standard Model

0-9 = Special Feature Assignment

TERMINAL CONFIGURATION

0 = Standard

1 = Pluggable Field Terminal Blocks

BLOWER RELAY

0 = Standard (5A)

1 = High-Current (15A)

FL AM E SENSE METHOD

0 = Local Sense

1 = Remote Sense

3 = Dual (Local and Remote)

RESERVED

0 = Standard Model

0-9 = Special Feature Assignment

MODEL CONFIGURATION

0 = North American (C22.2-199) Standard Model

2 = CE (EN298 & 60730) Standard Model

3 = CE (EN298 & 60730) OEM Special Feature Model

5 = North American (60730) Standard Model

6 = North American (60730) OEM Special Feature Model

9 =North American (C22.2-199) OEM Special Feature Model

Description

EXPORT INFORMATION (USA)

Jurisdiction: EAR

Classification: EAR99

This document contains technical data subject to the EAR.

Fenwal Controls

400 Main Street

Ashland, MA 01721

Tel. (508) 881-2000

© Kidde-Fenwal Inc. 06-237657-001 Rev AC

EU DECLARATION OF CONFORMITY

We

Company Name: Kidde-Fenwal Inc.

Postal Address: 400 Main Street

City and Post Code: Ashland, MA 01721

Tel: 508-881-2000

Declare that the DoC is issued under sole responsibility and belongs to the following product:

Apparatus Model(s) Series 35-40, 35-53, 35-60, 35-61, 35-63, 35-608, 35-65, 35-66, 35-9X

Type: Fitting

Batch Number Date code and Revision Level Assigned per production lot, (YYWW RR)

Object of the Declaration:

Series 35-40, 12/24Vdc Direct Spark Automatic Gas Ignition Controllers

Series 35-53, 12Vdc Direct Spark Automatic Gas Ignition Controllers

Series 35-60, 35-61, 35-63, 35-608 24Vac Direct Spark Automatic Gas Ignition

Series 35-65 & 35-66 24Vac Hot Surface Automatic Gas Ignition Controllers

Series 35-9X Platform Ignition Module

SERIES 35-40 SERIES 35-53 SERIES 35-60/61/63/608 SERIES 35-65/66

SERIES 35-9X

The object of the declaration described above is in conformity within the relevant union

harmonization legislation:

Gas Appliance Regulation: (EU) 2016/426 Low Voltage Directive: 2014/35/EC

EMC Directive: 2014/30/EC Rohs 2011/65/EU

The following harmonized standards and technical specifications have been applied:

EN298:2012: Automatic Burner Control systems for Burners and appliances burning gaseous or liquid fuels.

EN13611:2007_A2:2011: Safety and control devices for Gas Burners and Gas burning appliances – General Requirements.

Name of Notified Body & Number: BSI Group, 0086, EU Type Examination Certification

Notified Body Certificate No.: Series 35-40: CE682407

Series 35-53 CE682404

Series 35-60/61/63/608 CE682405

Series 35-65/66 CE682406

Series 35-9x CE690652

Surveillance Audit Notified Body: BSI Group

For copies of the Installation Instructions and the EU DoC, got to www.fenwalcontrols.com, - Document Library - Data sheets.

Paul Finn

Kidde-Fenwal, Inc. Ashland, MA USA 01 Oct 2018 Paul Finn, Certification Engineer

Place of Issue: Date of Issue Name

Table of contents

Other Fenwal Controls Control Unit manuals