Ferlin One User manual

Page 1of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

User manual

Ferlin One

Revision: 1.2

Release date: 14-6-2023

Page 2of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Contents

General information................................................................................................................................ 3

Details and identification .................................................................................................................... 3

Intended use........................................................................................................................................ 3

Safety instructions................................................................................................................................... 3

Ferlin One................................................................................................................................................ 7

Parts overview..................................................................................................................................... 7

Controller............................................................................................................................................. 8

Help function........................................................................................................................................... 8

Setting up the One .................................................................................................................................. 8

Dosing signal........................................................................................................................................ 9

External alarm signal ......................................................................................................................... 10

Start and stop........................................................................................................................................ 11

This turns the start button into a stop button. The Ferlin One can be stopped by pressing this button.

............................................................................................................................................................... 11

Recipe change........................................................................................................................................ 12

Cleaning................................................................................................................................................. 13

Alarms.................................................................................................................................................... 14

Problem solving..................................................................................................................................... 16

Login ...................................................................................................................................................... 17

Page 3of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

General information

Function and content of this manual.

These operating instructions are intended for qualified personnel using the dosing unit in the

intended industrial application. This manual must be read before installing and using the Ferlin ONE

dosing unit. In addition, the safety instructions provided must be observed at all times. Keep these

operating instructions and the safety instructions in an easily accessible place for qualified personnel.

Ferlin reserves the right to update this manual at any time without prior notice. Ferlin has made

every effort to ensure that these operating instructions are accurate. Ferlin disclaims liability for any

inaccuracies or omissions.

Should you require further information not described in this user manual, please contact your Ferlin

dealer.

Details and identification

Supplier details:

The CE mark is located on the specification plate of the dosing unit.

Type: Ferlin ONE

Electrical connection:

- 100-240 V AC

- 50-60 hz

- 45 W

Pneumatic connections:

- 0.4-0.6 MPa (4-6 bar)

- Dried compressed air (dew point <3°C); Technically oil- and water-free

Operating conditions:

- The unit must be protected from weather conditions

- Operating temperature -0 to + 80°C

Intended use

The Ferlin ONE dosing unit is designed only for dosing free-flowing plastic granules. It is strictly

forbidden to use this system for powdered or liquid materials. Any use that does not comply with

these operating instructions is deemed improper and releases the manufacturer from any liability for

damage to objects and/or persons. In addition, the product warranty will be voided.

Safety instructions

Safety instructions and warnings to protect against danger to life (from users or maintenance

personnel) or to protect against material damage are emphasised in this document by the terms and

pictograms defined here. The terms used in this document and indicated on the device itself have the

following meanings:

Symbool

This symbol warns of the risk of serious injury or death. Warnings related to this symbol

must be observed to avoid personal injury and property damage

This symbol warns of the risk of injury or death from electric shock. Warnings related to

this symbol must be observed to prevent personal injury and property damage.

Page 4of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

This symbol indicates a prohibition.

This symbol indicates that respiratory protection must be worn.

This symbol indicates that safety glasses should be worn.

This symbol indicates that protective safety shoes are required.

This symbol indicates that protective gloves should be worn.

Before anyone is allowed to use or install the dosing unit, the operating instructions must be read

and understood. Qualified personnel working with the dosing unit must understand the function and

operation of the dosing unit and observe the associated safety and maintenance instructions.

Please note the following instructions when using the Ferlin One:

General:

•The company, which owns the FERLIN ONE, needs to guarantee that its co-workers working

with the FERLIN ONE are aware of the safety instructions and have read and understood the

safety instructions and manual.

•With the execution of maintenance near or with the FERLIN ONE the safety instructions and

the manual should be available for the co-worker.

•Any maintenance workings on or around the FERLIN ONE should only be executed by

technical educated co-workers.

•It’s prohibited to install the FERLIN ONE in an explosive dangerous environment.

•It’s prohibited to remove or manipulate the safety instructions or machine parts.

•The workplace in which the FERLIN ONE is installed should be executed with precautions

for good ventilation and co-workers must have the possibility to use breathing protective

gear.

•In case the FELIN ONE needs to be disconnected from the power supply please make sure

that the following actions

are taken care of:

oPress the “stop” button on the controller.

Page 5of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Installation:

•Remove the dosing part and main hopper before installation.

•Connect power supply and compressed air only when installation on the right place is

completed.

•The following should be available:

o110-240V 50/60Hz (P+N+E)

oClean and dry compressed air with a constant

pressure of minimal 4 and maximum 6 bar.

•When installing the FERLIN ONE directly on the feed throat of the injection, extrusion, blow

moulding or other plastic processing machine, the owner of the FERLIN ONE should

provide a flat and save surface surrounding the FERLIN ONE for performing maintenance.

•It must be ensured that the Ferlin ONE is not subject to collision hazard. If this cannot be

guaranteed, installation on input zone is prohibited.

•The FELIN ONE should be installed with a minimum of 4 bolts class 8.8. All parts should be

aligned and securely tightened.

•After installation of the FELIN ONE the dosing part and main hopper can be put back on the

machine.

•The FERLIN ONE may only be made operational when fully assembled.

•The FELIN ONE needs to be well grounded.

Maintenance:

•All maintenance actions should be executed by well-trained co-workers.

•Electric maintenance is only allowed to be executed by qualified staff.

•While performing maintenance always disconnect the FERLIN ONE from the power supply by

removing the power plug.

•While performing maintenance always disconnect the FERLIN ONE from the compressed air

connection.

•Wear eye protection while performing maintenance on the FERLIN ONE.

•In case of replacement of any of the electronic components inside the control box the co-

worker is obligated to wear a wristband which is well grounded to prevent static electricity.

•In case of maintenance actions which can cause dust to get free, the co-worker should wear

breathing protection.

Cleaning:

•Before cleaning, always disconnect the FERLIN ONE from the power supply by removing the

power plug.

•Before cleaning, always disconnect the FERLINE ONE from the compressed air connection.

•Wear eye protection while cleaning the FERLIN ONE.

•Wear breathing protection while cleaning the FERLIN ONE.

Page 6of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Transport:

•Please disconnect FERLIN ONE from power supply and compressed air before disassembling.

•Always use hand and feet protection while moving the FERLIN ONE.

•All lifting materials and tools should be designed to carry the weight of the FERLIN ONE.

•Please make sure that weight is in balance while lifting the FERLIN ONE.

•Attention, it is not allowed to walk underneath the lifted FERLIN ONE.

•Make sure that the FERLIN ONE is prevented from falling or tilting.

•Make sure the door of the FERLIN ONE is closed and the dosing part and main hopper are

removed before transport.

Page 7of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

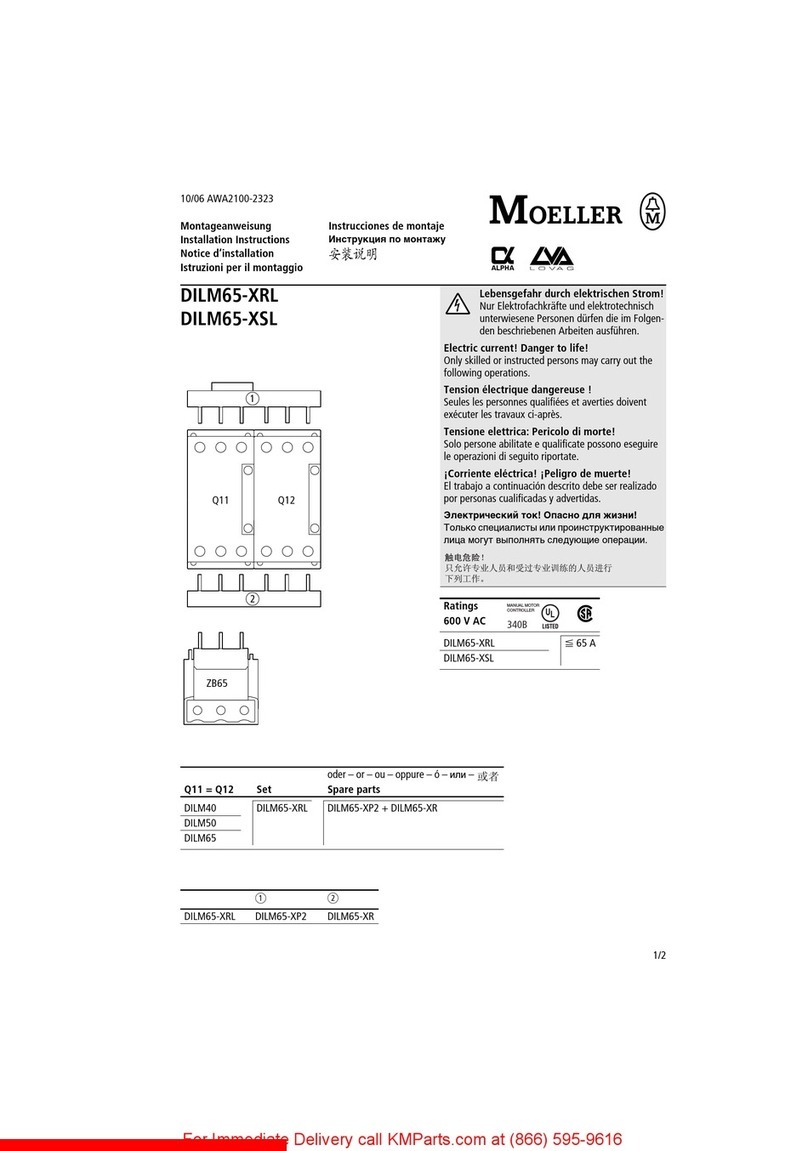

Ferlin One

Parts overview

1- Neck piece

2- Housing

3- Door

4- Main hopper

5- Clamping levers

6- Dosing part

7- Filter pressure regulator (optional)

8- Alarm lamp (optional)

8

Page 8of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

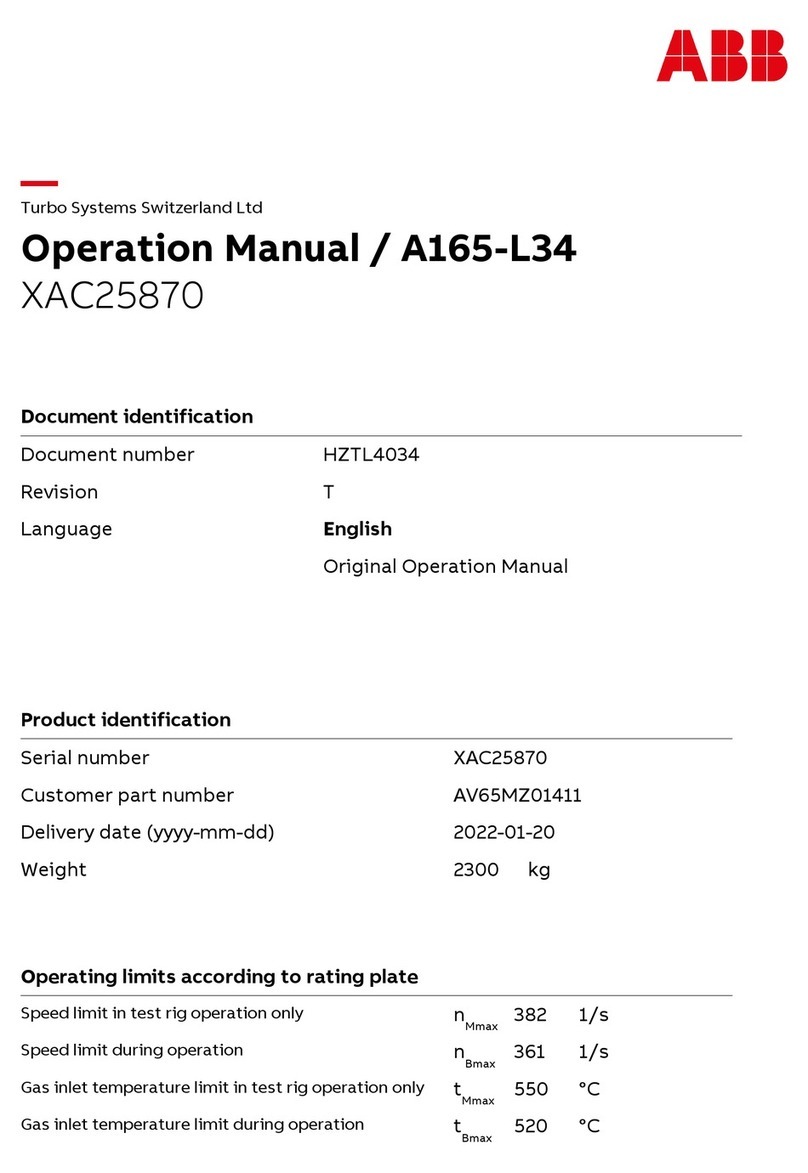

Controller

The controller is displayed below:

Help function

The Ferlin One features a help function. Press the question mark in the top right corner to get

explanations about the content on the screen.

Setting up the One

The Ferlin One controller should be connected to the dosing section via 3 cables. Connect the 9, 15

and 25-pole d-sub connectors to the controller and the housing (2). Then connect the power cable to

the controller. In addition, the Ferlin One needs to be supplied with compressed air. This connection

is located on the side of the housing (2). In the following section the explanation of how to connect

the dosing signal and (optionally) connect the potential-free alarm contact is treated.

Page 9of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Dosing signal

De The controller of the Ferlin One has an M12 connector on the back that has 8 poles. The

potential-free dosing contact of the injection moulding machine must be connected to this. A screw

connector is supplied with the Ferlin One. Additionally the injection signal can also be connected to

also configure dosing during injection.

Connections:

Pin 3 - 24 v outgoing signal

Pin 4 - returning dosing signal

Pin 5 –returning injection signal

Page 10 of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

External alarm signal

The Ferlin One controller also includes a potential-free alarm contact. This contains a NO and NC

connection. These can be connected via the 5-pin M12 connector. A screw connector is supplied with

the Ferlin One. Connecting is as follows:

Pin 1 - Com

Pin 2 - NC

Pin 3 - NO

Page 11 of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Start and stop

The Ferlin One can be started by pressing the start button:

This turns the start button into a stop button. The Ferlin One can be stopped by pressing this button.

Injection moulding machine start-up

When starting up the injection moulding machine (and flushing), the Ferlin One should be set to stop.

This means that the start button should be visible. (If the stop button is visible, the Ferlin One is still

in run mode).

When starting automatic production with the injection moulding machine, the Ferlin One should also

be started by pressing the start button.

Page 12 of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

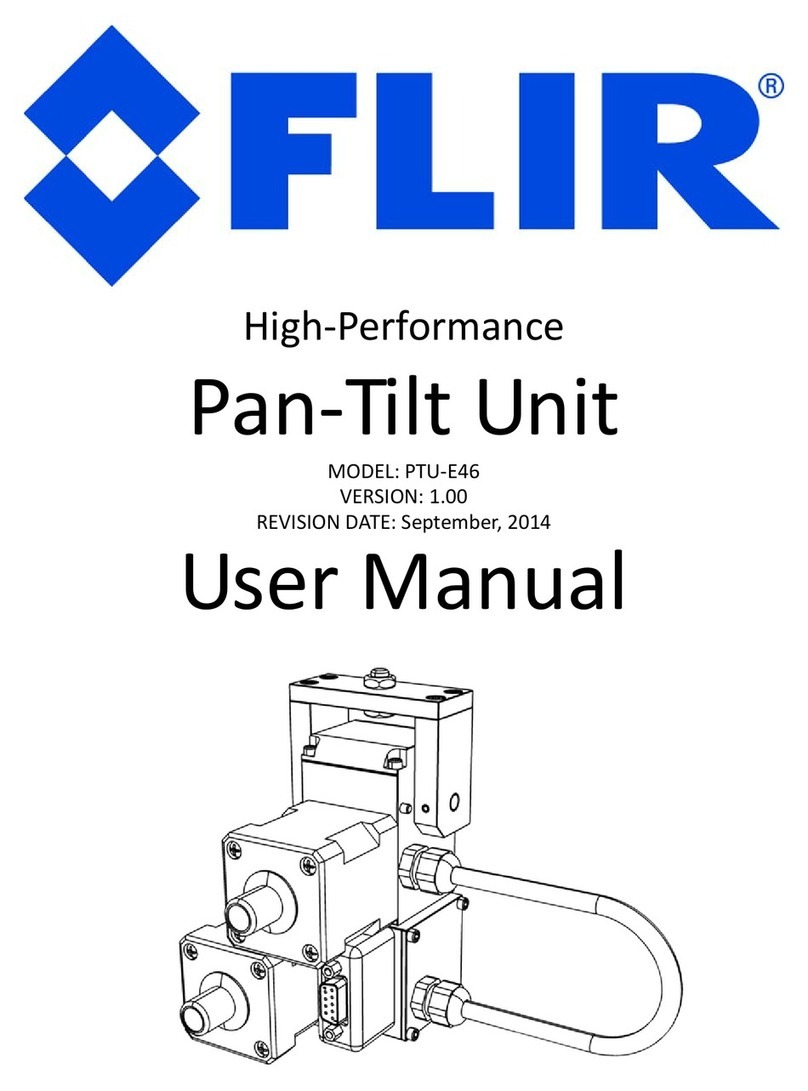

Recipe change

The recipe can be modified by clicking on the recipe name:

After this, the recipe screen opens, which looks as follows:

Shot weight and percentage can be entered here. Press the pencil to adjust the values.

Press previous to return to the main screen.

Page 13 of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Cleaning

-First read the safety instructions for cleaning on page 5 of this manual.

-Open the clamping levers (5) and disconnect the air couplings of the main hopper(4). Slide

the main hopper(4) backwards to take it out. The main hopper (4) can now be cleaned.

CAUTION: use safety goggles when cleaning the hopper with compressed air.

-Reinstall the main hopper(4) and close the clamping levers (5). Then reconnect the air

couplings.

-Open the door(3). Disconnect the large white connector off the motor cable. Then pull the

dosing part (6) backwards. The dosing part (6) can now be cleaned. CAUTION: use safety

goggles when cleaning the hopper with compressed air.

-Place the dosing part(3) back into the housing (2). Reconnect the motor cable to the

connector. Close the door(3).

Page 14 of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Alarms

The alarms appear through a pop-up. Go to settings (Gears on main screen) -> Alarms to view the list

of alarms.

Here is a list of the possible alarms with causes and solutions:

Please keep the safety instruction on page 5 in mind when performing any action on the Ferlin One.

1. Door open.

a. The door(3) of the Ferlin One is open. It must be closed to start the Ferlin One.

2. Main hopper(4) almost empty.

a. The main hopper is almost empty. This alarm only occurs if a sensor is fitted in the

sight glass of the hopper. Open the cover to refill the hopper.

3. Main hopper(4) empty.

a. The main hopper is empty. Open the cover to refill it.

4. Small hopper empty.

a. The small hopper of the dosing section(3) is empty. Refill the main hopper (4), the

Ferlin One fills the small hopper itself.

b. If the main hopper (4) is still full check that the 2 air hoses between the hopper and

the housing are connected. Also check that the air supply is connected to the

connector on the housing or filter pressure regulator (7). (pressure should be

between 4 and 6 bar)

5. Not dosing enough.

a. Little to no weight reduction

is detected. There are 4

possible causes.

i. Check that the

motor's large white

connector is

connected, see

picture on the right.

ii. Check that the d-sub

15 cable (grey cable)

is connected to the

housing(2) and to the

control.

iii. Check that the d-sub 9 cable (black cable) is connected to the housing(2) and

to the controller.

iv. Take out the dosing part (6) (disconnect large white connector first) and

check for a build-up of material. Break through this build-up and replace the

dosing part (6).

6. Calculated speed too high.

a. The Ferlin One cannot dose the requested weight in dosing time.

i. Check whether the requested dosage is feasible in the dosing time. The

maximum throughput of the Ferlin One is around 30 kg per hour (8 grams

per second)

Page 15 of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

ii. If point i. is correct, check the measured dosing time. Go to the recipe screen

and check the value for the dosing time. Does it match the dosing time on

the injection moulding machine? If not, the Ferlin One can be set to a fixed

dosing time. Go to Settings -> General -> production mode -> injection

moulding and select fixed time. Go back to the main screen and then to the

recipe. Enter the desired dosing time here.

7. Unstable dosing weight

a. This alarm appears when the Ferlin One has not been able to perform a stable

weighing for 2 consecutive cycles. This alarm disappears automatically when another

stable weighing has taken place.

i. This alarm does not affect the dosing behaviour if it occurs occasionally.

ii. Should the alarm not go away after a longer period please contact Ferlin.

8. No material selected.

a. No material is selected in the recipe. Click the button with (UNKNOWN MATERIAL)

and select a material.

b. Is the list of materials empty? Then go to settings -> material database and press + to

create a material. Try a. again

9. Trigger time too long.

a. The dosing signal from the injection moulding machine took a lot longer than the

previous cycle. This may be caused by a change on the injection moulding machine or

by manual operation of the injection moulding machine. You do not need to do

anything with this alarm then. Starting an stopping the Ferlin One will cause it to

learn a new time.

i. Should this occur outside the above situation, check whether the alarm

occurs more frequently. If so, the Ferlin One can be set to a fixed dosing

time. Go to Settings -> General -> production mode -> injection moulding

and select fixed time. Go back to the main screen and then to the recipe.

Enter the desired dosing time here.

10. USB full

a. The plugged-in USB is full. Plug in another USB or make room on the existing USB.

11. SD full

a. The Ferlin One's internal storage is full.

i. Please contact Ferlin

12. Backup battery voltage low

a. The Ferlin One's internal battery is low.

i. Please contact Ferlin

Page 16 of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Problem solving

1. Screen of the controller stays black:

a. Check that the black 240v power cable is connected to the back of the control

and in the socket. Check voltage at the socket.

2. Colour of final product disappears.

a. Check that material is present in the main hopper and in the small hopper.

i. Main hopper refilled but still no colour in finished product? Wait at least 10

cycles. Then check that the small hopper has material. Open the door (3) and

take out the dosing part (6) (Disconnect the large white connector first).

Continue to ii. Or iii.

ii. Small hopper full?

1. Check for accumulation (bridging) of material. Remove this.

2. Check whether belt runs smoothly. If not: replace dosing part.

iii. Small hopper empty?

1. Then check that the 2 air hoses between the hopper and housing are

connected. Also check that the air supply is connected to the housing

or the filter pressure regulator (7). (pressure should be between 4

and 6bar)

2. Air hoses present? Re-install dosing part (6), reconnect connector

and close door (3). Perform a tarration. Go to settings -> loadcell ->

tarration and start taring.

Taring and calibration

Go to settings (gears on main screen) -> loadcell. Then open the tare or calibrate screen. Follow the

on-screen instructions to tare or calibrate.

Page 17 of 17

Rudolf Dieselstraat 15A, Nijverdal, Nederland. +31 523 0613439. Mail: Info@ferlin.nl

Login

To log in, click on the lock at the top left of the main screen:

Then choose the desired login level and enter the password.

Passwords are by default:

1111 for supervisor

2222 for technician

Table of contents

Other Ferlin Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Reich Kupplungen

Reich Kupplungen ARCUSAFLEX AC F2 Series English translation of the original German Operating Manual

Shini

Shini SAL-810 manual

Simplex

Simplex STS DAY TANK manual

KTR-Group

KTR-Group CLAMPEX KTR 125 Operating & assembly instructions

Siemens

Siemens Sivacon S8 operating instructions

KLR

KLR 5050-16 manual