Miller SRL2-M Series

Rodless Cylinders

2

A Series Cylinders

Up to 250 PSI

Permanently lubricated

Series A steel air cylinders are available in bore

sizes from 1

1

⁄

2

"through 20"and up to 250 psi

operating pressure. Standard NFPA dimensions

and proven Miller design features. (File 7619)

AL Series Cylinders

Up to 200 PSI

Permanently lubricated

Our new aluminum AL Series air cylinders are

available in bore sizes from 1

1

⁄

2

"through 8".

Operating pressures up to 200 PSI. Dimensions

are NFPA Standard. (File 8564)

J Series Cylinders

500-2500 PSI

Our popularly-priced line of medium pressure

hydraulic cylinders, with bore sizes from

1

1

⁄

2

"to 20". (File 7620)

H Series Cylinders

3000-5000 PSI

Miller's heavy-duty cylinder line for the most

demanding hydraulic applications. Bore sizes

from 1

1

⁄

2

"to 20". Heavy-duty construction.

(File 7622)

Table Of Contents

Index and Warranty..................................................................................................... Page 2

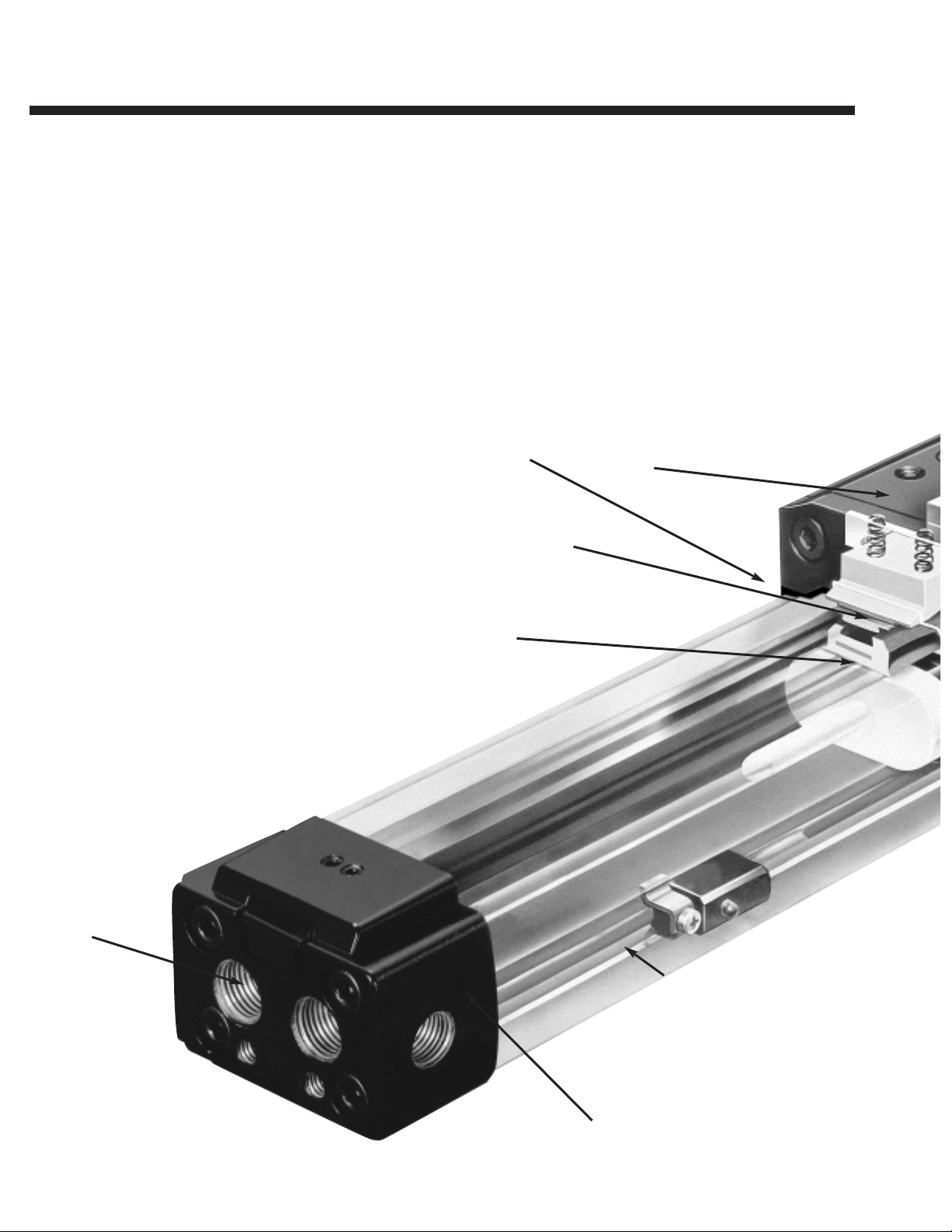

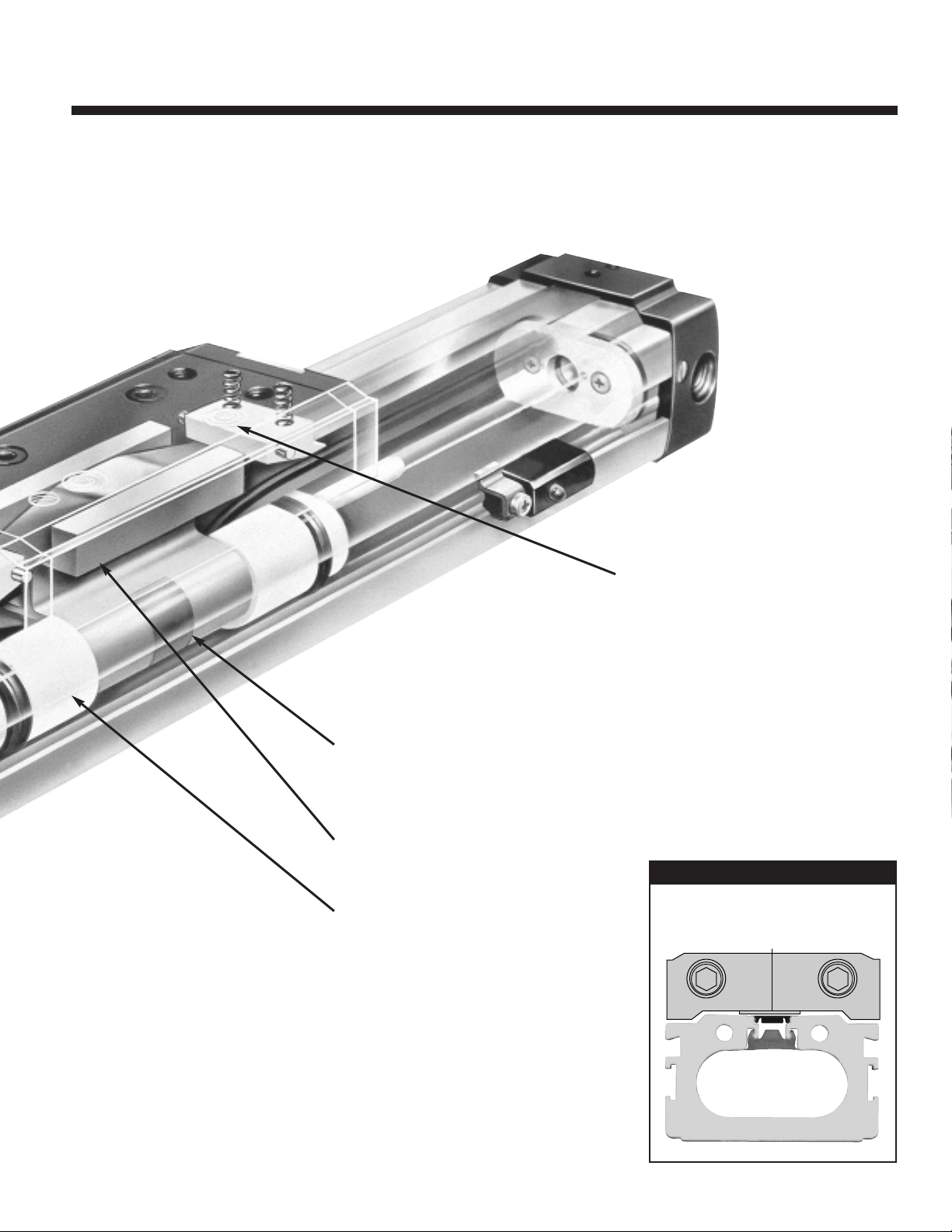

Features and Benefits ....................................................................................................... 3-5

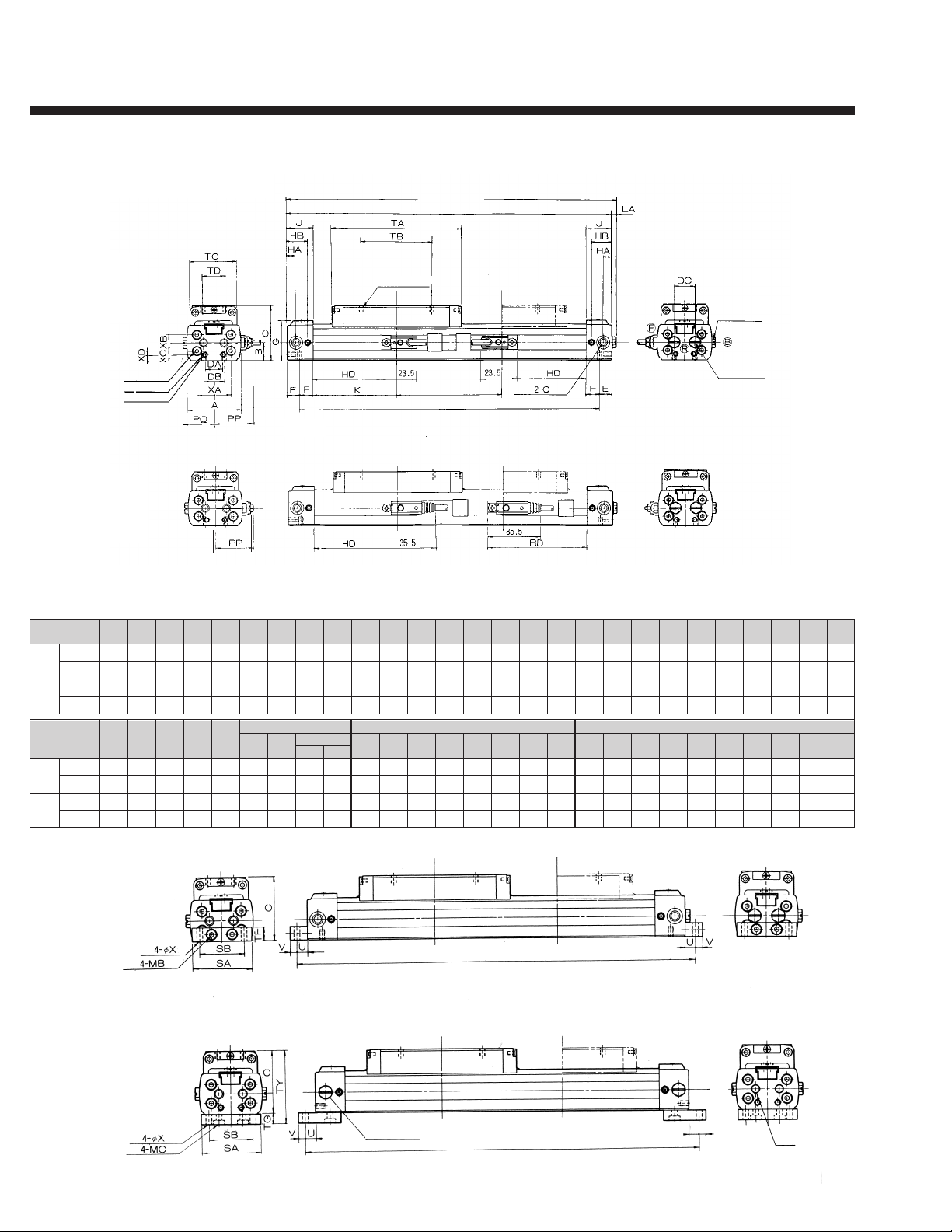

Dimensions....................................................................................................................... 6-7

Switches......................................................................................................................... 8-12

Switch Specifications and How to Order.............................................................................. 9

Switch Operating Range......................................................................................................10

Notes on Switch Usage..................................................................................................11-12

Cylinder Specifications and How To Order..........................................................................13

Accessories and Options ...............................................................................................14-15

Stroke Adjuster and Shock Absorber Dimensions...............................................................16

Technical Information....................................................................................................17-20

Rodless Cylinder Sizing Guide...................................................................................... 21-27

Sizing Forms................................................................................................................. 28-31

Air Consumption Chart....................................................................................................... 31

Plant Locations .................................................................................................................. 32

Miller's Rodless cylinders are warranted for one (1) year to be free from defects in

workmanship and material. Miller will replace, free of charge including lowest transportation

costs, but not including installation or any other charges, any part that Miller's inspection

shows to be defective. All defective parts must be returned to Miller's plant within warranty

period after shipment by Miller. Written permission for such return must first be obtained.

A complete explanation is required of the defects and circumstances. This warranty applies

only if goods fail to function properly under correct use, normal operating conditions, and

proper application because of defects in material or workmanship, and if Miller is notified

promptly in writing of such failure. If goods are in accordance with or in reference to an

engineering drawing specified by or furnished to the customer, these specifications and

information shall be applicable in determining such correct use, operation and application.

MILLER MAKES NO WARRANTY THAT THE GOODS ARE DELIVERED FREE OF THE

RIGHTFUL CLAIM OF ANY THIRD PERSON BY WAY OF INFRINGEMENT OR THE LIKE.

THERE ARE NO WARRANTIES OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR

PURPOSE OR ORDINARY PURPOSE NOT WITHSTANDING ANY DISCLOSURE TO MILLER

OF THE USE TO WHICH THE PRODUCT IS TO BE PUT.

Miller shall never be liable for any consequential or incidental damages. The sale of Miller's

products under any other representation, warranty or guarantee, express or implied, is not

authorized by Miller.

Other Miller Air and Hydraulic

Cylinders.

Order Catalog by File No.

Miller One Year Warranty