Ferret Leak Locator User manual

TM 1

Ferret Leak Locator

User Manual

TM

ferret-technology.com

Ferret

Blocks the flow in the leaking

pipe when inflated

TM 3

1.1 Ferret Controls: how to adjust

the pressure in the Ferret.

Controls

Ferret Pump

Inflates/deflates the Ferret

Ferret Pressure Gauge

Shows the pressure inside the Ferret

TM 4

1.2 Leaking Pipe Controls: how to

adjust the flow in the leaking pipe.

Controls

Flow Gauge

Shows when water is flowing through

the Ferret Leak Locator

Pipe Pressure Gauge

Shows the pressure inside the leaking pipe

Flow Valve

Turns flow to the leaking pipe on and off

TM 5

1.3 Leaking Pipe Controls: how to adjust

the working pressure in the leaking pipe.

Controls

Pressure Regulator

Controls the working pressure.

Pull out to adjust and push in to lock

Inlet Pressure Gauge

Shows the pressure within the

incoming water supply

Set Pressure Gauge

Shows the working pressure

in the leaking pipe

TM 6

Connecting the Ferret Leak Locator

2.1 Connecting a water supply

Step 1.

Turn o the incoming water supply.

Remove a fitting or cut the pipe, then use

the black Inlet Hose and a suitable fitting

to connect the incoming water supply to the

inlet on the Ferret Leak Locator.

The connection hoses have internal O-ring

seals at the ends that connect to the Ferret

Leak Locator. They should only be hand

tightened.

Do not use a wrench

Incoming water supply

TM 7

Connecting the Ferret Leak Locator

2.1 Connecting a water supply

Step 2.

Make sure the Flow Valve is in the o

position and then turn the incoming

water supply back on.

You should now see pressure registering

on the Set and Inlet Pressure Gauges.

TM 8

Connecting the Ferret Leak Locator

2.2 Fitting the Ferret to the Ferret Leak Locator

Step 1.

Pass the yellow Ferret Pipe through

the Outlet Hose and connection

fitting, then connect the Outlet Hose

to the Ferret Leak Locator.

Step 2.

Remove the Green Cap from

the end of the Ferret Pipe and

put it here for safe keeping.

IMPORTANT:

Always replace the Green

Cap as soon as the Ferret

is removed to prevent air

and dirt from getting into

the Ferret inflation system.

Step 3.

Screw the Ferret on

hand tight.

TM 9

Connecting the Ferret Leak Locator

2.3 Stretch and test the Ferret.

Use the Ferret Pump to inflate the Ferret to

check it is not damaged. Then deflate the Ferret.

IMPORTANT:

A new Ferret must first be stretched to a larger

diameter than the internal bore of the leaking pipe.

TM 10

Connecting the Ferret Leak Locator

2.4 Connecting to the leaking pipe

Step 1.

Feed the Ferret into the

leaking pipe and then

connect the Outlet Hose

to the leaking pipe.

Step 2.

Open the Flow Valve

and wait for the pipe

pressure to register.

Step 3.

You should now see the

leak flow registering

on the Flow Gauge.

Step 4.

Open a vent at the far

end of the leaking pipe.

The Flow Gauge will

now spin faster.

IMPORTANT:

If there is no flow you

will need to use the

Pressure Regulator to

increase the pressure

in the leaking pipe until

the leak flow registers

TM 11

Moving the Ferret along the leaking pipe

3.1 Inflating the Ferret to block the pipe

Step 1.

Turn the Flow Valve o.

Step 2.

Turn the Ferret Pump to

inflate the Ferret to

approximately 1bar (15psi)

above the working pressure.

Step 3.

Turn the Flow Valve back

on and wait for the Flow

Gauge to stop.

IMPORTANT:

If the Ferret starts to move or the Ferret

Winder turns, close the Flow Valve and

increase the pressure in the Ferret,

then

open Flow Valve again.

TM 12

Moving the Ferret along the leaking pipe

Step 1.

Slowly turn the Ferret Pump

to deflate the Ferret.

Step 2.

At the same time watch the

Ferret Pipe and Ferret Winder

to see when they start to move.

As soon as they start to move

stop deflating the Ferret.

3.2 Moving the Ferret forwards

IMPORTANT:

Always make sure the

Ferret pipe is moving

through the Outlet Hose

when you are turning the

Ferret Winder clockwise

or the Ferret Pipe could

become tangled inside

the Ferret Leak Locator

.

Note.

When working with smaller

Ferrets and in metallic pipes

you may need to help the

Ferret Winder turn to allow

the Ferret to move freely.

TM 13

Moving the Ferret along the leaking pipe

3.3 Restrictions in the pipe

The Ferret will stop if it meets

a restriction in the pipe before

it gets to the leak.

Note.

You will see the Ferret Winder stop turning

and no flow registering on the Flow Gauge.

TM 14

Moving the Ferret along the leaking pipe

3.4 Passing through a restriction

Step 1.

Locate a reference point

on the Ferret Pipe.

Step 2.

Turn the Ferret Winder in the Rewind

direction (A) to tension the Ferret Pipe and

then turn the Ferret Winder back a quarter

turn (B) to put some slack in the Ferret Pipe.

Step 3.

Slowly reduce the pressure

in the Ferret until the water

in the pipe pushes it through

the restriction. Watch the

reference point to see when

this happens.

REFERENCE

IMPORTANT:

Once the deflated Ferret

is back in the larger diameter

pipe it will stop but the

Flow Gauge will register

the water flowing past it.

REFERENCE

(B)

(A)

TM 15

Moving the Ferret along the leaking pipe

Step 1.

Turn the Flow Valve o

to stop the Ferret.

Step 2.

Turn the Ferret Pump to

deflate the Ferret.

Step 3.

Turn the Ferret Winder anti-clockwise,

as shown on the label, to move the

Ferret backwards along the leaking pipe.

IMPORTANT:

If the Ferret gets stuck don’t

force the Ferret Winder,

disconnect the clear Outlet

Hose and pull directly on the

yellow Ferret Pipe instead.

3.5 Stopping the Ferret and moving it backwards

TM 16

Locating the leak

4.1 Leak testing a section of pipe

Step 1.

Stop the Ferret by closing

the Flow Valve and inflate the

Ferret so it blocks the pipe

Step 2.

Turn the flow back on to the pipe.

• If the Ferret is before the leak the flow gauge will stop.

• If it keeps turning the Ferret is after the leak.

IMPORTANT:

Check that no water is

flowing through the open

vent. This confirms that the

Ferret is blocking the pipe

and that the Flow Gauge is

registering the flow of

water escaping from the

pipe through the leak.

TM 17

4.2 Pinpointing the leak

Step 1.

Move the Ferret backwards

or forwards as required and

repeat the leak test on the

previous page.

Locating the leak

Step 2.

Repeat this process until

the leak is pinpointed to

within a quarter turn of

the Ferret Winder

4.2 Pinpointing the leak

TM 18

Locating the Ferret from above ground

5.1 Tracing the line of the pipe (without sonde)

Step 1.

Connect a signal generator to the

terminal on the Ferret Winder.

Step 2.

Trace the line of the pipe as per the

manufacturer’s instructions for

your tracing device.

TM 19

Locating the Ferret from above ground

5.2 Tracing the line of the pipe (with sonde)

Step 1.

Connect the Trace Lead supplied with

the Ferret Leak Locator to the terminal

on the Ferret Winder.

Step 2.

Connect a 33kHz signal generator

to the red Trace Lead.

Step 3.

Trace the line of the pipe as per the

manufacturer’s instructions for

your tracing device.

TM 20

Locating the Ferret from above ground

5.3 Measuring the distance to the Ferret

Step 1.

Find a distance mark on the

yellow Ferret Pipe inside the

clear Outlet Hose.

IMPORTANT:

Always rewind the

Ferret before you start

digging. You might forget

later and then cut the

Ferret Pipe when making

the repair!

Step 2.

Place a measuring wheel on the Outlet Hose so it lines up

with the distance mark and then measure out the indicated

distance along the traced line of the pipe

Table of contents

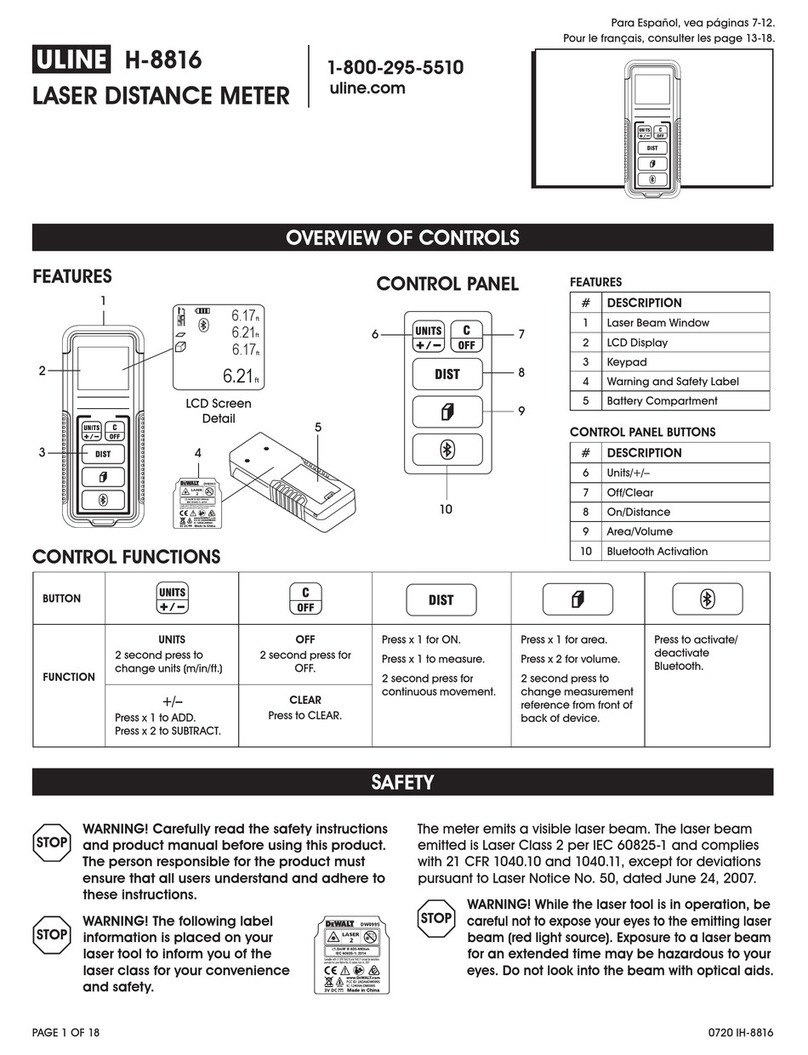

Other Ferret Analytical Instrument manuals

Popular Analytical Instrument manuals by other brands

R&S

R&S ZN-Z15 Series user manual

Leica Geosystems

Leica Geosystems DISTO plus user manual

Artistic License

Artistic License Commissioner dali user guide

Parkside

Parkside PLEM 50 A1 Operation and safety notes

ADA INSTRUMENTS

ADA INSTRUMENTS COSMO 120 video operating manual

Co2meter

Co2meter TecPen MAP user manual