PREXTHERM

4

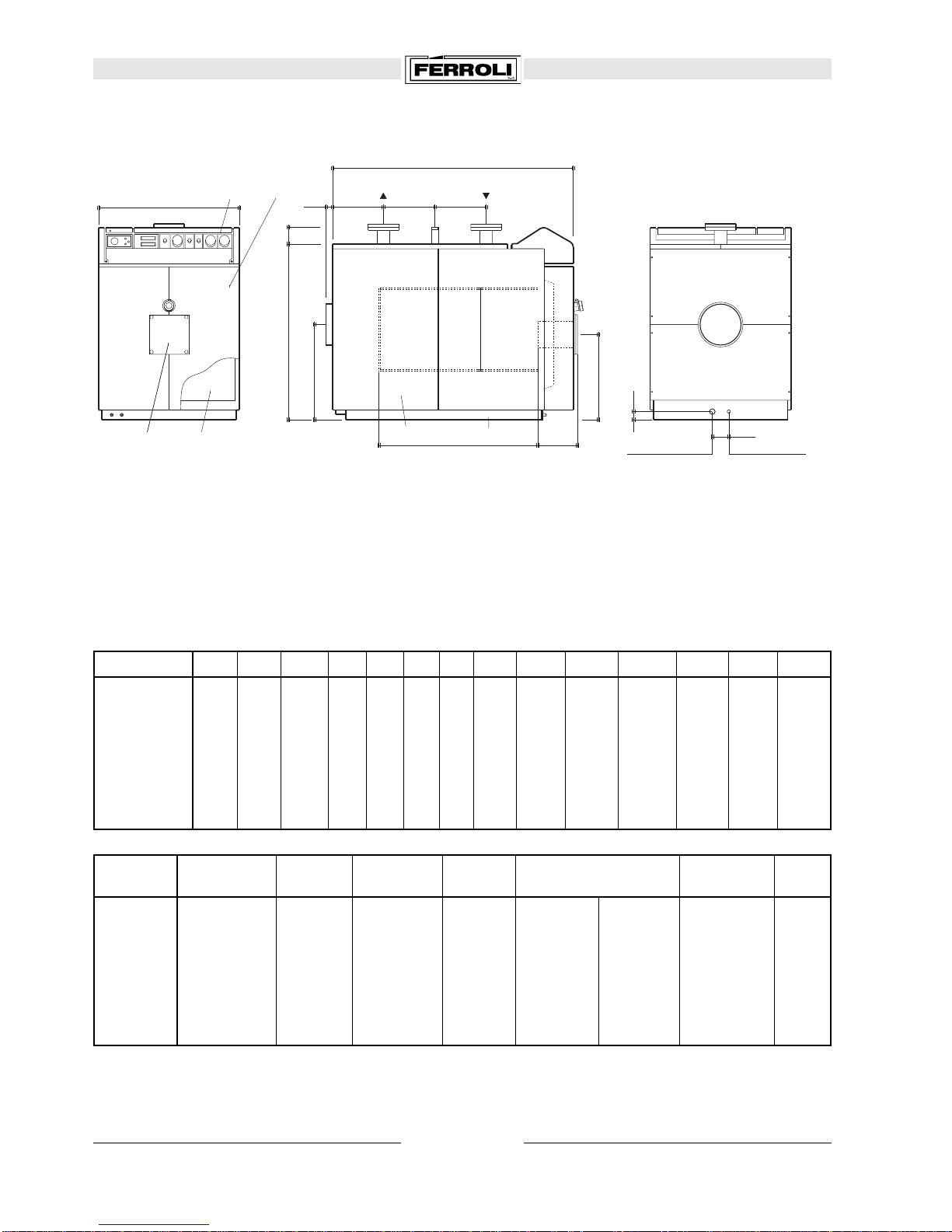

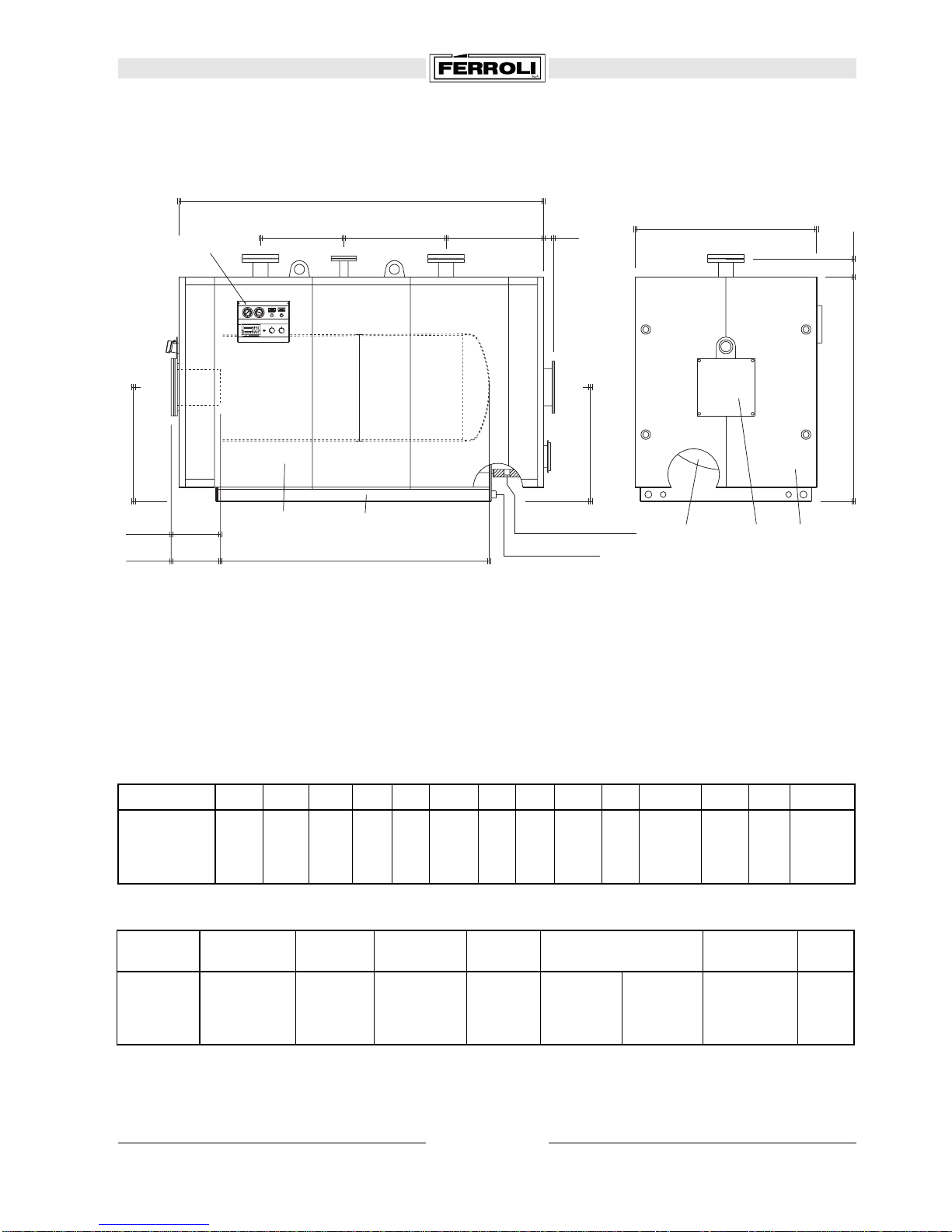

1. DIMENSIONS AND TECHNICAL DATA

A B C D E F G H L M a1 - a2 a3 a4 a5

100 970 760 1110 235 215 145 540 470 660 400 DN 50 1" 1/4 200 160

125 970 760 1260 235 365 145 540 470 810 400 DN 50 1" 1/4 200 160

150 970 760 1410 235 465 195 540 470 960 400 DN 50 1" 1/4 200 160

200 1060 850 1452 306 415 205 585 515 930 480 DN 65 1" 1/4 250 160

250 1060 850 1652 306 515 305 585 515 1130 480 DN 65 1" 1/4 250 160

300 1060 850 1852 306 615 405 585 515 1330 480 DN 65 1" 1/4 250 160

350 1230 1040 1832 484 405 395 670 600 1250 540 DN 80 1" 1/2 300 210

400 1230 1040 2032 484 605 395 670 600 1450 540 DN 80 1" 1/2 300 210

470 1230 1040 2232 484 805 395 670 600 1650 540 DN 80 1" 1/2 300 210

Output kW Input kW Water capac. Pressure drop Working press. Weight

Min. Max. Min. Max. m3dm3*Flue gas mbar **Water mbar bar kg

100 60 100 65 109 0,083 120 0,6 4 5 270

125 75 125 82 136 0,102 142 0,9 7 5 290

150 90 150 98 163 0,124 162 1,1 10 5 320

200 120 200 131 218 0,174 214 0,8 7 5 430

250 150 250 163 272 0,204 247 1,1 10 5 490

300 180 300 196 327 0,241 283 1,4 16 5 560

350 210 350 229 381 0,286 528 1,8 11 5 830

400 240 400 262 436 0,332 598 2,7 15 5 910

470 282 470 307 512 0,378 667 3,6 19 5 980

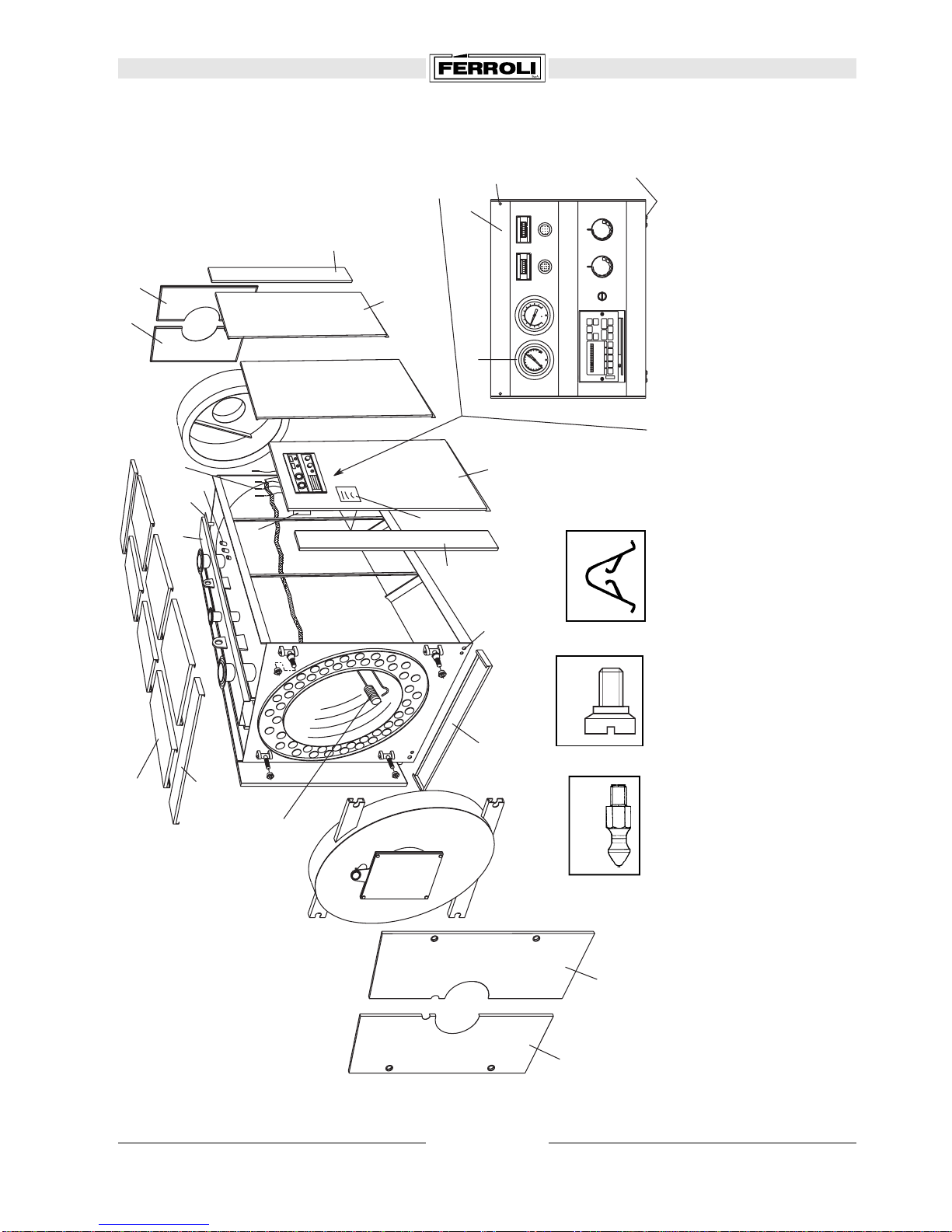

comb. chamber

volume

Legend

1Boiler shell

2Door

3Burner mounting plate

4Casing

5Door insulation

6Control panel

a1 Flow connection

a2 Return connection

a3 Safety valve tapping

a4 Flue outlet

a5 Burner flange

PREXTHERM 100-470

PREXTHERM

PREXTHERM

FERROLI

F

a4

a2

100

B

A

100

40

G

D E F

a1 a3

H

a5

C

FLUE CONDENSE

Ø 3/8

DRAIN OFF Ø 1

50

1

4

23

56

L 240

M

Fig. 1

*technical dates for oil-fired heating; for gas heating you must decrease of 15%

**

∆

t considered: 15

°

C