................................

................................

................................

................................

................................

..........................

................................

................................

General safety rules for machine equipment

................................

................................

Safety regulations for hydraulic pres

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

...............................

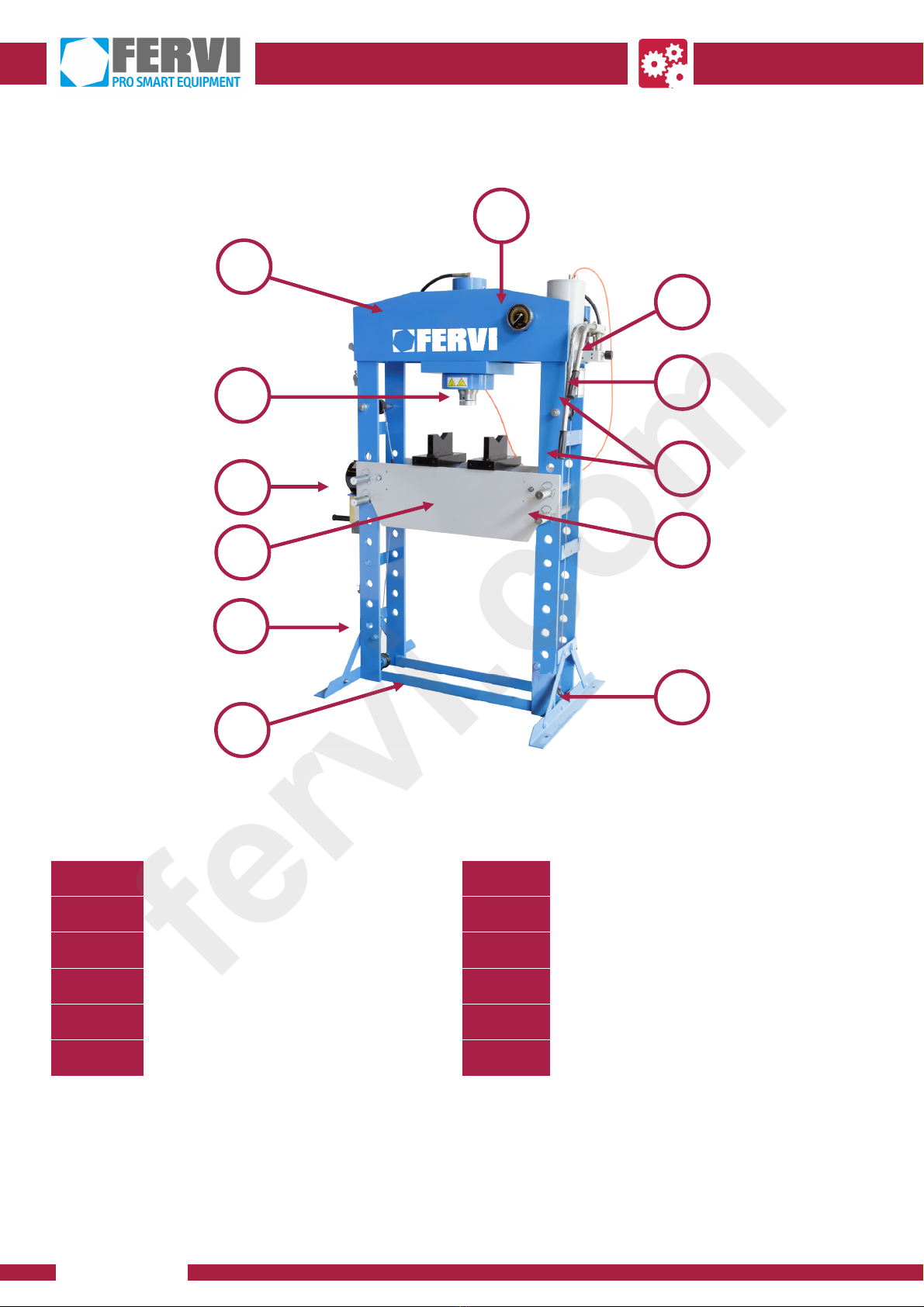

Main parts of the machine

................................

................................

...........................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

..........................

................................

................................

................................

................................

................................

...............................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

Removing air from the circuit

................................

................................

Pressing work with pneumatic energy

................................

................................

................................

................................

................................

................................

................................

................................

................................

...............................

................................

................................

................................

................................

............................