Feuling Parts 4095 User manual

INSTALLATION INSTRUCTIONS FEULING® QUICK INSTALL ADJUSTABLE PUSHRODS

#4095 #4096 #4097 4/23/19

FEULING® Quick Install Adjustable pushrods are the strongest ‘Quick’ install pushrods on the market! The strength and rigidity of this quick

install pushrod design is second only to heavy duty one piece pushrods. Our tube material starts out as 7/16” rod OD, gets turned down to

3/8” OD leaving 0.134” wall thickness and heavy duty 7/16” – 20 threads for the base and jam nut. The jam nut slides up the pushrod, the base

then loosens up into the pushrod to allow quick install access.

Part #’s available as just pushrods #4096 or pushrod and tube kit #4097, kit’s include set of 4 pushrods, individual length exhaust and intake,

pushrods install WITHOUT the removal of rocker covers but require the short quick install tubes - see Feuling #4095 for tubes only or Feuling

#4097 for pushrod + tube kit.

The chrome tubes/clips included in #4095 and kit #4097 are used conjunction with your factory inner/upper tubes, cups, springs and washers.

IMPORTANT NOTICE

This installation should be done by an experienced mechanic who has access to a factory service manual and all required tools.

NOTE

QUICK INSTALL pushrods can be adjusted 0.225” longer than stock to accommodate longer cylinder and smaller base circle camshafts

CAUTION

Incorrect installation can cause engine damage not covered under warranty. Failure to install components correctly can cause engine seizure. Engine seizure may result

in serious injury to motorcycle, operator, passenger, and/or others. Removal of the rocker arms and or pushrods with the valve train loaded can damage rocker arms,

push rods, bushings and or camplate. Rotate engine to TDC of compression stroke on the servicing cylinder.

IMPORTANT NOTICE

Measure flywheel pinion shaft run out. Excessive pinion shaft run out will cause camplate and oil pump damage and or failure. Excessive pinion shaft run out will void

manufacturer’s warranty.

WARRANTY NOTE

Feuling offers an additional 12 month warranty for a total of 2 years if product is installed by a professional V-Twin installer, oil tank is dropped and cleaned at time of

install and the WARRANTY REGISTRATION form is filled out - form can be found on www.Feulingparts.com

Required Tools: (1) 3/8” open end wrench (2) 1/2” open end wrenches (1 being thin is advised)

1. Refer to the proper factory service manual for your model and year of engine, for removal of existing pushrods.

2. The Feuling® Quick install pushrods are designed to install without removing the rocker box covers or rocker arms etc. but do require quick

install pushrod tubes.

3. Clean and inspect each new Feuling® pushrod including center oil hole

4. Feuling® Quick install pushrods are marked Intake and Exhaust. The shorter pushrods are Intake and the longer pushrods Exhaust.

5. Feuling® recommends using new O-rings and gaskets where applicable to prevent oil leaks

6. Always pump up hydraulic lifters before installing them. Use an oil squirt can to fill the lifter with oil through the feed hole on the side of the

lifter, push oil through the feed hole until the air bubbles are gone. If needed work the oil back and forth through the feed hole and pushrod

seat with the squirt can. Light weight oil can be helpful.

7. Assemble and adjust one cylinder at a time, the servicing cylinder needs to be on TDC of compression stroke so the cam lobes and lifters are

at their lowest point.

8. To collapse pushrods for installation screw the jam nut up towards the rocker end side of rod until it disengages from the threads. Screw the

base up towards the same direction and it will disengage and slide up after the last thread. Now the pushrods are fully collapsed and ready for

install.

PUSHROD BREAKDOWN FULLY COLLASPED

9. Install pushrods into proper locations with the adjusting side of the pushrod down, towards the lifter. Pushrods are marked, separate length

pushrods for Intake and Exhaust. NOTE: These pushrods do install with lifter blocks installed, pushrods need to be maneuvered around in

order to fit up into rocker arm and in between lifter block.

10. Slide the pushrods through the QUICK install tube covers and up into the rocker housing and set the pushrod on the seat of the lifter. We

recommend filling the pushrods with oil then maneuver the pushrod up into the rocker arm seat. Pivot the pushrod and cover over the lifter

block and hold the pushrod cover up out of the way as you let the pushrod base slide down and contact the top of the threads.

INTAKE: Install pushrod/tube with the lifter side of pushrod from outside of engine and swing inward after you insert the ball end up into the

rocker arm socket.

EXHAUST: Install Exh pushrod/tube with the lifter side of pushrod from inside of the engine and swing outward after you insert the ball end up

into the rocker arm socket

INTAKE INSTALL EXHAUST INSTALL

11. Holding the pushrod body just below the cover begin to turn the base (clockwise looking down) and when it gets far enough out that it begins to

seat in the lifter stop and make sure the top is still seated in the rocker arm. Continue extending the base until there is no play in the pushrod,

lifter, rocker contact. The jam nut will still be up above the threads. Thread the jam nut down towards the base but don’t tighten it.

Once pushrod is installed, thread

lower base down onto rod.

Pull up on tube to compress spring

to give you more working room.

Hold rod and pull down on lower

base and rotate to adjust

downward.

12. Place the 3/8” open end wrench on the flats near the top of the threads to keep the body of the pushrod from turning. Place a THIN ½”

open end wrenches on the hex of the base and continue to extend the base to get the proper preload. Each full turn of the base is .050” (7/16

X 20 tpi) so for .100” preload its 2 full turns. Each flat of the hex is just over .008”

13. We recommend starting from zero lash with a fully pumped up lifter and adjusting the pushrod longer crushing the lifter. We DO NOT

recommend bottoming the lifter and adjusting backwards. To find zero lash it is best to have the rocker arm in hand to feel and verify zero lash

position.

14. Feuling® QUICK INSTALL pushrods have 20 threads per inch and 1 full turn equals .0500” of adjustment. When adjusting Feuling Pushrods on

Feuling lifters from zero lash, 2 turns will put .100” of crush on the lifter. The loose jam nut tightens to the bottom.

15. Once the preload has been adjusted screw the nut down against the base and using both ½” wrenches tighten them against each other. (If you

have a thin ½” wrench for the base it will work best) Don’t try to over-tighten. If you start to round the corners on the jam nut you’re trying to over-

tighten. Repeat the process on the other 3 locations. Be sure to let the lifters bleed down before rotating the engine or damage may occur. You’ll

know it’s safe when you can spin the pushrod by hand.

16. Final install of tubes/clips after lifters have bleed down and you can rotate the pushrods

Example of assembled

and adjusted pushrod

With lower base loosely into

position on top of lifter.

rotate the jam nut downward,

pull up on tubes compressing

spring to give you more working

room.

set jam nut into position allow

room for lifter adjustment

With lower base and jam nut

into finger tight positions lower

base to zero lash then using a

THIN ½” wrench and 3/8”

wrench make the 2 turn

adjustment to achieve 0.100”

pre-load on lifter.

Once 0.100” of pre-load is

adjusted

Using the THIN ½” wrench on

lower base, 3/8 wrench on rod

and ½” wrench on jam nut

torque jam nut into position

without adjusting pushrod

longer.

FEULING® QUICK INSTALL Pushrods have 20 threads per inch

Distance per turn = .050”2 Turns = 0.100”

CORRECT PUSHROD/LIFTER ADJUSTMENT REQUIRES STARTING WITH FULLY PUMPED UP LIFTERS!

TROUBLE SHOOTING NOISY VALVE-TRAIN

1. Lifter adjustment - Starting with a fully pumped up lifter, from zero lash put 0.90” - 0.100” of pre-load on Feuling® hydraulic lifters

2. Lifter to lifter bore clearance out of spec, Feuling® recommends a clearance of 0.001” - 0.0015” for proper oil psi at lifter

3. Pushrods flexing and hitting pushrod tubes - look for a shiny ring witness mark around pushrod normally seen up towards the cylinder head

4. Low oil pressure - inspect pressure relief valve in camplate, oil pump/camplate wear

5. Pushrod center oil hole plugged

6. Clearance for roller rocker arms on under side of rocker box covers

7. Steep ramped camshafts, valves closing so fast the valves bounce off valve seats - see Feuling® Beehive® valve springs

8. Excessive crankshaft runout

9. Gear drive camshafts, excessive gear drive backlash or excessive crankshaft runout

10. Rocker arms/bushings out of tolerance

11. Valve spring clearance to lower rocker box housing

12. Valve spring coil bind and or valve spring harmonics - match up valve spring open height with camshaft peak lift

13. Leaky/broken piston cooling jets

*CORRECT PUSHROD/LIFTER ADJUSTMENT REQUIRES STARTING WITH FULLY PUMPED UP LIFTERS!

WARRANTY:

All parts are guaranteed to the original purchaser to be free of manufacturing defects in materials and workmanship for a period of twelve (12) months from the date of purchase.

Merchandise that fails to conform to these conditions will be repaired or replaced at FOP’s option if the parts are returned to FOP by the purchaser within the (12) month warranty

period. In the event warranty service is required, the original purchaser must notify FOP of the problem immediately. Some problems may be rectified by a telephone call and need no

further action. A part that is suspect of being defective must not be replaced without prior authorization from FOP. If it is deemed necessary for FOP to make an evaluation to

determine whether the part was defective, it must be packaged properly to avoid further damage, and be returned prepaid to FOP with a copy of the original invoice of purchase and a

detailed letter outlining the nature of the problem, how the part was used and the circumstances at the time of failure. After an evaluation has been made by FOP and the part was found

to be defective, repair, replacement or refund will be granted. Excessive flywheel pinion shaft run out will damage camplate and oil pump and or cause engine damage and or failure.

Damage to Feuling oil pump corporation products from excessive pinion shaft run out will void manufacturer’s warranty.

ADDITIONAL WARRANTY NOTE

Feuling offers an additional 12 month warranty for a total of 2 years if product is installed by a professional V-Twin installer, oil tank is dropped and cleaned at time of install and the

WARRANTY REGISTRATION form is filled out - form can be found on www.Feulingparts.com

ADDITIONAL WARRANTY PROVISIONS:

FOP shall have no obligation in the event an FOP part is modified by any other person or organization, or if another manufacturer’s part is substituted for one provided by FOP. FOP

shall have no obligation if an FOP part becomes defective in whole or in part as a result of improper installation, improper break-in or maintenance, improper use, abnormal operation,

or any other misuse or mistreatment. FOP shall not be liable for any consequential or incidental damages resulting from the failure of an FOP part, the breach of any warranties, the

failure to deliver, delay in delivery, delivery in non-conforming condition, or any other breach of contract or duty between FOP and the customer.

The installation of parts may void or otherwise adversely affect your factory warranty. In addition, such installation and use may violate certain federal, state and local laws, rules and

ordinances as well as other laws when used on motor vehicles operated on public highways, especially in states where pollution laws may apply. Always check with federal, state, and

local laws before modifying your motorcycle. It is the sole and exclusive responsibility of the user to determine the suitability of the product for his/her use, and the user shall assume

all legal, personal injury risk and liability and all other obligations, duties and risks associated therewith. Our high performance parts, engines and motorcycles are intended for

experienced riders only. Feuling Oil Pump Corporation reserves the right to change prices and/or discounts without notice and to bill at the prevailing prices at the time of shipments.

The words Harley®, Harley-Davidson®and H-D®and all H-D®part numbers and model designations are used in reference only. Feuling Oil Pump Corporation is in no way

associated with, or authorized by Harley-Davidson Motor Co®. To manufacture and sell any of the engine parts described in this instruction sheet. 4/28/19

3740 Oceanic Way, 304, Oceanside, CA 92056 Ph. 619-917-6222 Fax 760-487-1545, www.feulingparts.com

This manual suits for next models

3

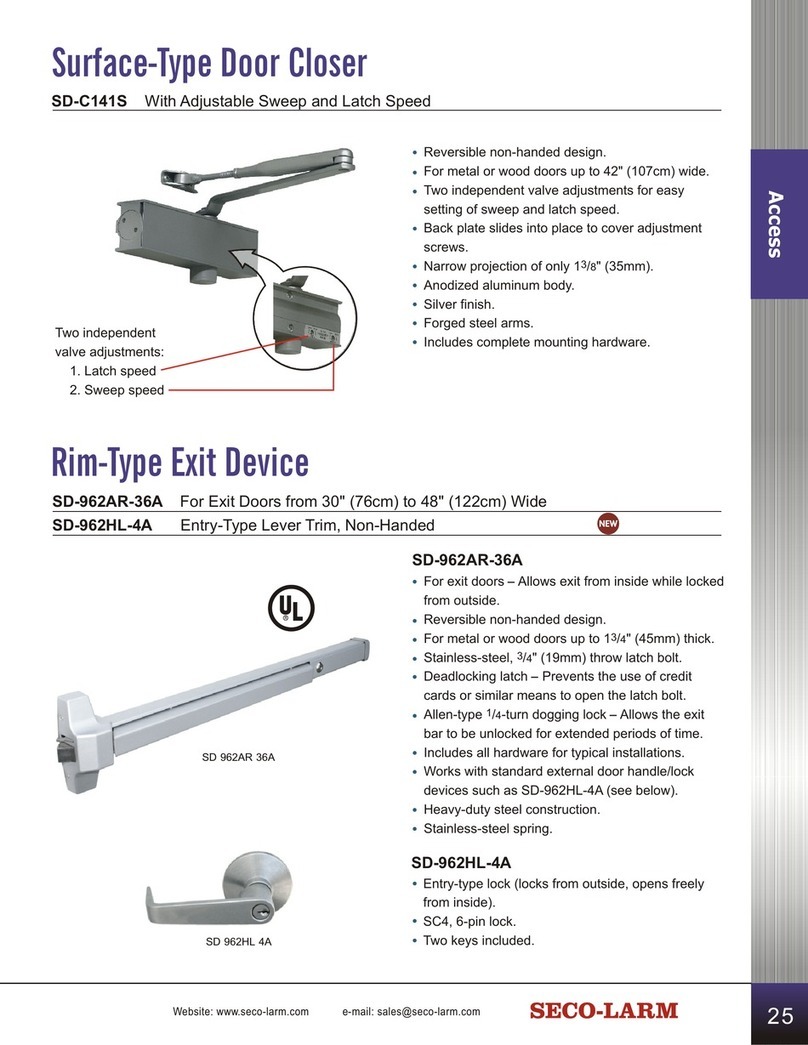

Popular Door Opening System manuals by other brands

Yale

Yale 6116 Series installation instructions

Dorma

Dorma 8916 FT manual

Roger Technology

Roger Technology H85/TDR/E Instruction and warnings for the installer

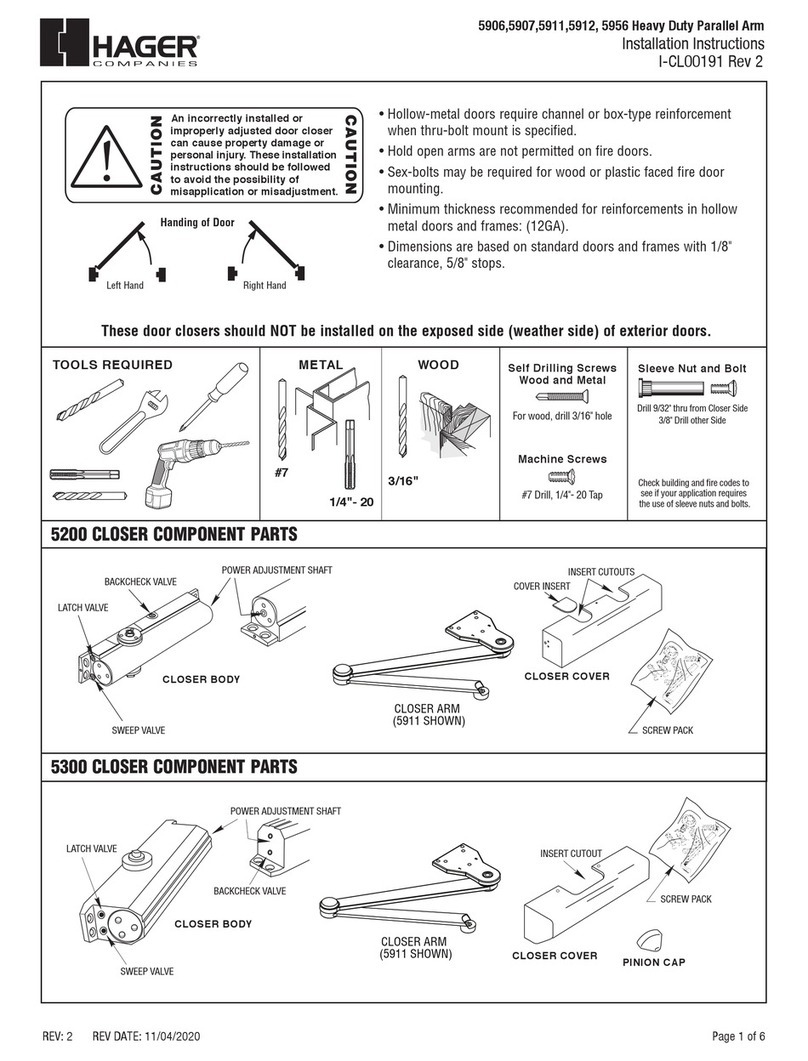

hager

hager 5906 installation instructions

Dormakaba

Dormakaba ED900 installation instructions

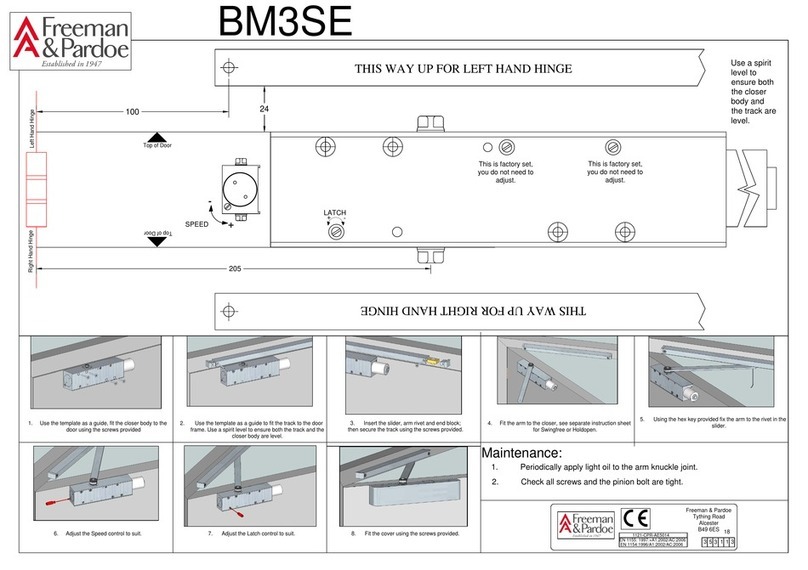

Freeman & Pardoe

Freeman & Pardoe BM3SE quick start guide