Installation Instructions

WARNING

HAZARDOUS VOLTAGE CAN SHOCK AND CAUSE SEVERE INJURY

Disconnect power before making any electrical connections

or performing maintenance.

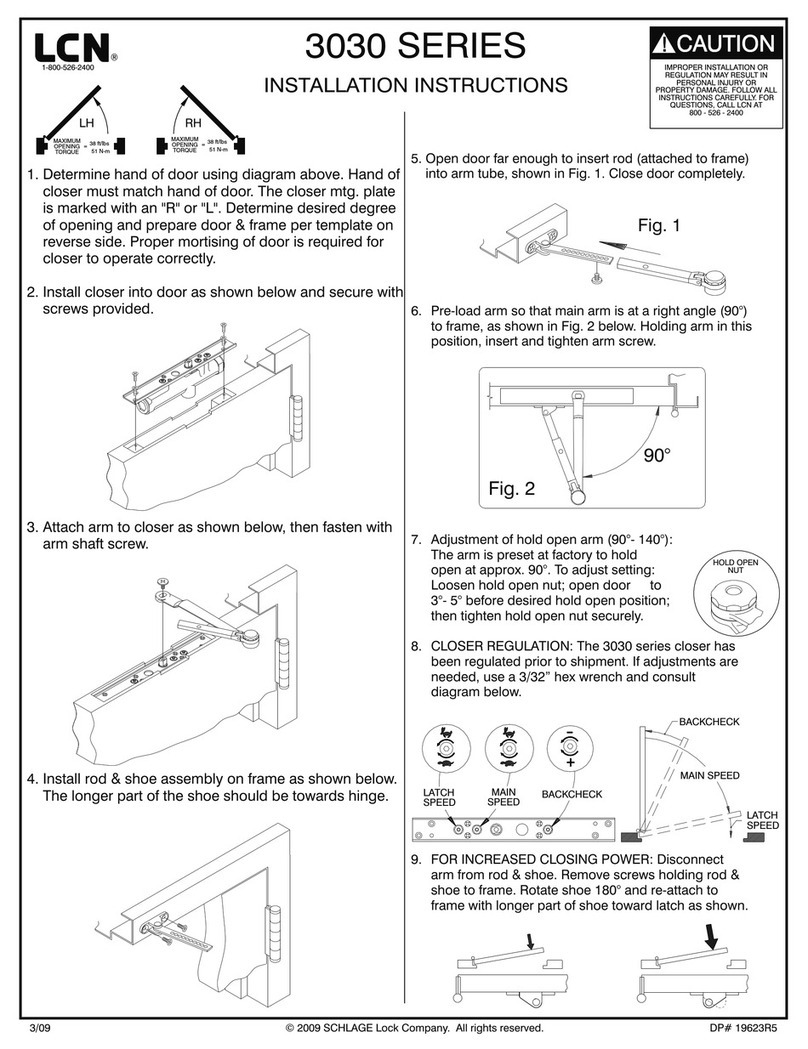

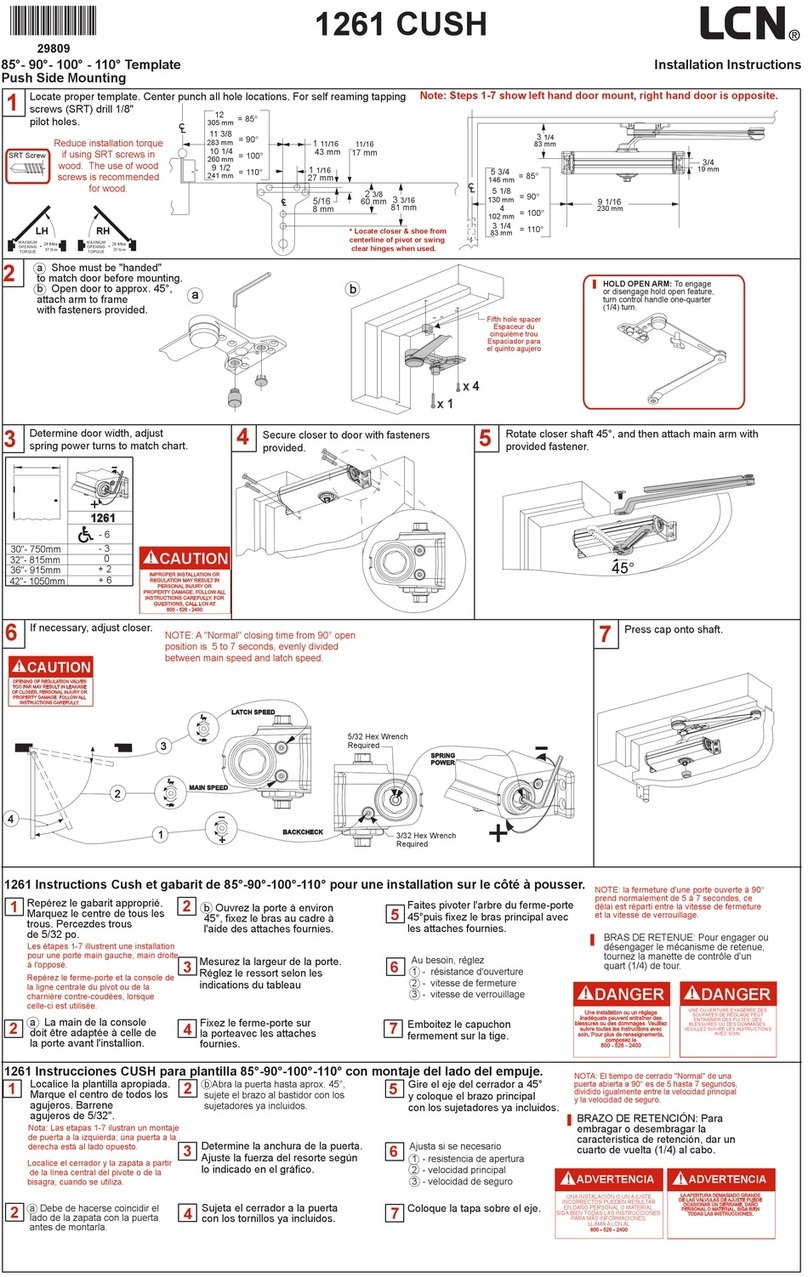

1 Closer

The closer is handed at the factory, and marked with an “R” or “L”

on top of the packing nut. The hand of the closer must match the

handing of the door (see the door handing diagram on page 1).

2 Input Voltage

Input voltage supplied to the door frame must be 24V. Determine

whether the wiring will be concealed or surface-run, and follow the

remaining instructions carefully.

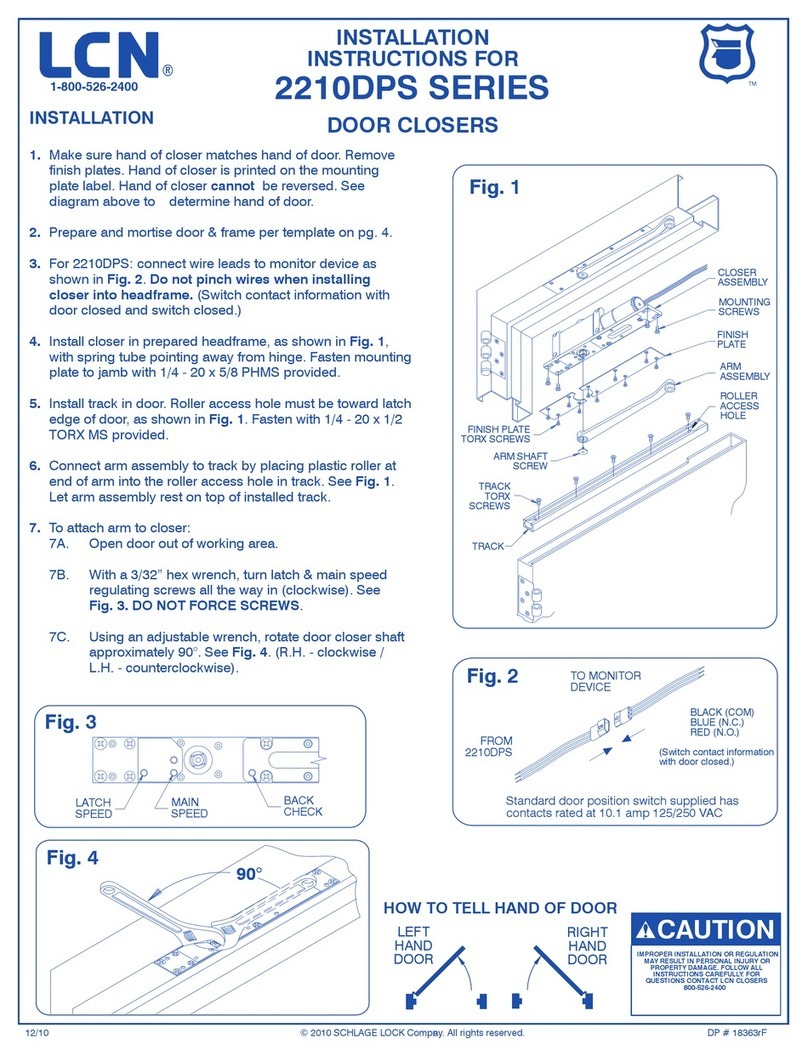

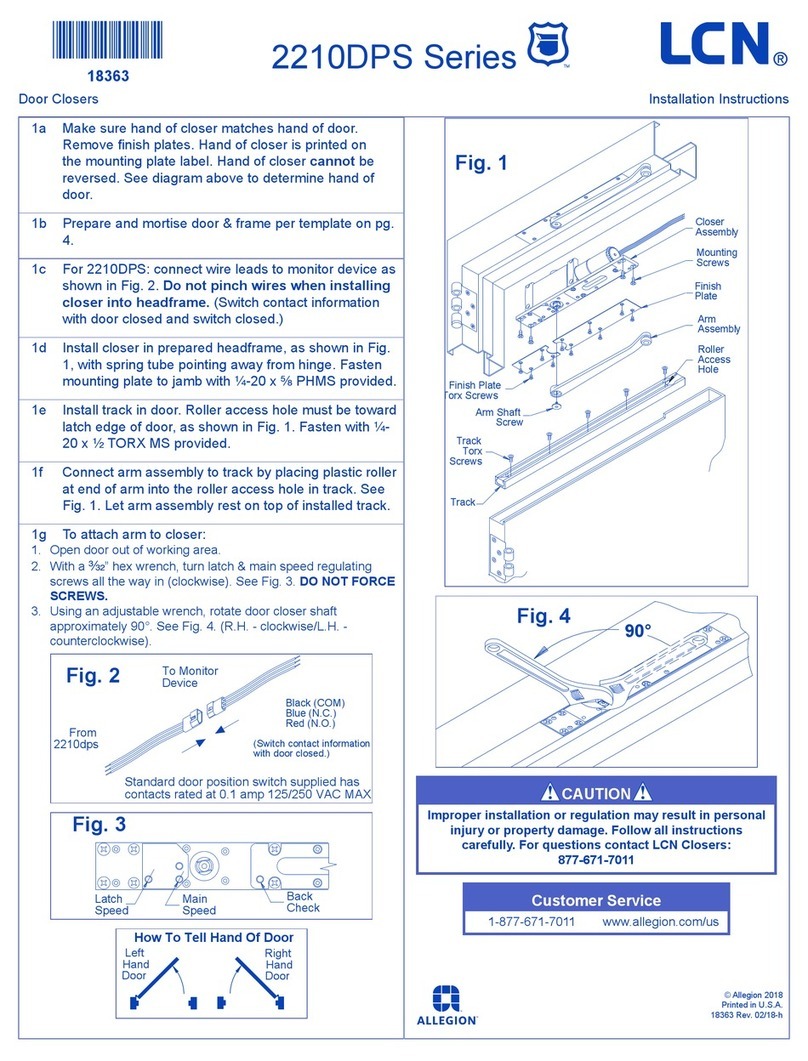

3 Wiring

3a For concealed wiring:

See Figure 2 on page 3.

1. Prepare the frame with the proper template on page 6. Be sure

all of the holes are dimensioned correctly before drilling and

tapping.

2. Assemble the conduit connector provided to the exible

conduit, then attache to the hole in the mounting plate.

3. Secure the mounting plate to the frame with the screws

provided.

3b For surface wiring:

See Figure 3 on page 3.

LNOTE: Remove the knockout in the top of the cover.

1. Prepare the frame with the proper template on page 6. Be sure

all of the holes are dimensioned correctly before drilling and

tapping.

2. Secure the mounting plate to the frame with the screws

provided.

3. Attach the surface run Z\x” EMT conduit to the hole in the

bracket on the mounting plate. Be sure the conduit is securely

attached to the bracket.

4 Wiring Connections

Make your wiring connections at this time. Connect two black wires

to the 24V input voltage. The green wire MUST be connected to an

earth ground. See Figures 2 & 3 on page 3.

5 Arm Shaft

Place the main arm on the closer shaft, 90° to the closer body, and

secure with the arm shaft screw.

6 Track Setup

Attach the rod & shoe to the door (per the template on page 5) with

the screws provided.

7 Set Screw

Open the door partway, insert the rod into the forearm, then close

the door. With the main arm at a right angle (90°) to the door, insert

the arm set screw, and tighten securely.

8 Spring Power Adjustment

See Figure 1 for the spring power adjustment diagram. To adjust

the spring power, use a B\cx” allen wrench provided to turn the

spring adjustment nut clockwise or counterclockwise the required

number of turns to match the door width in the spring adjustment

chart on page 6. DO NOT exceed 7 turns clockwise or 8 turns

counterclockwise.

9 Closing Speed Regulation

The closing speed regulation is preset at the factory. Normally

no adjustment is required. If adjustment is needed or desired,

adjust the main speed and latch speed by turning the proper

regulating screw for each (see Figure 1) clockwise to slow or

counterclockwise to increase the speed. Do not allow the door to

slam into the frame. A “normal” closing time from a 90° position is

5 to 7 seconds, equally divided between the main and latch speed.

When adjusting the backcheck, use the least amount of force

necessary to sufciently slow the swing of the door. To adjust the

backcheck, turn the regulating screw clockwise to increase the

amount of force, or counterclockwise to reduce the amount of force.

DO NOT USE AN ABRUPT BACKCHECK SETTING OR EXPECT

THE CLOSER TO ACT AS A STOP!

10 Electrical Checkout

Perform the electrical checkout on page 4 before installing the

closer cover.

CAUTION

Improper installation or regulation may result in personal

injury or property damage! Follow all instructions

carefully.

For questions, call LCN at

1-877-671-7011.