FHC FHC96 User manual

AX96 Hot Melt Unit

Cat. No. AX96

GLASS DRILL INSTRUCTION MANUAL

PRODUCT MANUAL

FHC PRODUCT MANUAL Item No. FHC96

4361 FIRESTONE BLVD. SOUTH GATE CA 90280 TOLL FREE: (888) 295-4531 FAX: (323) 336-8307

GLAZING SUPPLIES

SHOWER DOOR HARDWARE

ARCHITECTURAL HARDWARE

RAILING HARDWARE

TRANSACTION HARDWARE

ME TAL EXTRUSIONS

4361 FIRESTONE BLVD.

SOUTH GATE CA 90280

TOLL FREE: (888) 295-4531

FAX: (323) 336-8307

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 1 OF 31

EXPERIENCE AND INNOVATION

ITEM NO. FHC96

GLASS DRILL INSTRUCTION MANUAL

P. 2

ɸ To avoid personal injury and damage to equipment and property, read the product manual completely before installing,

operating or servicing this equipment.

ɸ Follow all safety warnings located on this product and in the product manual. Consult the safety precautions section of

the product manual for an explanation of all safety symbols used on this equipment.

ɸ Retain the product manual for the life of this product.

ɸ After reading this manual, if further assistance is needed, contact your factory authorized sales or service representative.

WARNING:

NOTE CONCERNING ILLUSTRATIONS: All illustrations within this product manual should be considered as general

representations of the parts or assemblies depicted, and should not serve as mechanical drawings, nor be consulted

for scope or scale. They are for reference only.

12 SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

DANGER: To avoid personal injury, follow all

safety labels. Failure to properly operate and

maintain equipment can lead to serious injury.

•Wear protective clothing, safety goggles and

safety gloves. Hot melt materials can cause

severe burns resulting in disfigurement or

blindness.

•Use only manufacturer recommended materials

in this system. Fire, explosion, personal injury,

property and equipment damage can result if

improper or unsafe materials are used.

•Disconnect electrical power from external

source to melt unit before undertaking

maintenance or troubleshooting. Failure to

disconnect power can result in fatal electrical

shock.

•Depressurize system before performing any

maintenance to pump, pump filter, flow control

valve or hose. Turn pump switch off and

depress trigger on handgun until there is no

flow. Air trapped in the system or in a

component can form a pressure pocket.

Loosen fittings cautiously. Adhesive under

pressure can cause severe burns and

blindness.

•Always read the manufacturer’s recommended

use of the material.

5.2 Startup Instructions

1. Become familiar with Section 5.1, Controls and Indicators.

2. Install melt unit as specified in Section 4, Installation.

3. Fill tank with hot melt material.

4. Turn melt unit on and allow sufficient warmup time for hot

melt material to thoroughly melt.

5. Align motor on receipt of a new unit or after transportation.

a. Loosen four screws holding motor pan to side of melt

unit.

b. Heat melt unit and run motor. This centers the motor.

c. With motor running, tighten four screws in a crisscross

pattern.

6. Set hose and tank temperatures to desired settings. Lower

settings increase pot life of the material. Materials degrade

over time due to oxidation.

7. To prevent motor stalling, adjust flow control valve to the

minimum flow requirement.

!

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 2 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 3

TABLE OF CONTENTS

1 SAFETY PRECAUTIONS FOR HOT MELT APPLICATOR EQUIPMENT ..............................................................................5

1.1 INTENDED USE ..........................................................................................................................................................................................5

1.2 PERSONAL SAFETY ...............................................................................................................................................................................5

1.3 ELECTRICAL SAFETY ...........................................................................................................................................................................5

1.4 EMERGENCY POWER DISCONNECT ..........................................................................................................................................6

1.5 FOLLOW DIRECTIONS ..........................................................................................................................................................................6

1.6 SAFETY SYMBOLS AND SIGNAL WORDS ...............................................................................................................................6

2 INTRODUCTION .....................................................................................................................................................................................................7

2.1 DESCRIPTION .............................................................................................................................................................................................7

2.2 FEATURES .....................................................................................................................................................................................................7

3 SPECIFICATIONS ....................................................................................................................................................................................................8

3.1 ELECTRICAL ...............................................................................................................................................................................................8

3.2 PHYSICAL .....................................................................................................................................................................................................8

3.3 PERFORMANCE ........................................................................................................................................................................................8

3.4 ENVIRONMENTAL ...................................................................................................................................................................................8

3.5 DIMENSIONS ...............................................................................................................................................................................................9

4 INSTALLATION .........................................................................................................................................................................................................9

4.1 SETUP........................... ...................................................................................................................................................................................9

4.2 COMPONENT INSTALLATION .........................................................................................................................................................9

4.3 ELECTRICAL CIRCUITS AND WIRING .........................................................................................................................................10

4.3.1 POWER CORD........................... ................................................................................................................................................................. 10

4.3.2 SWITCHED HANDGUN PUMP MOTOR CIRCUIT........................... ........................................................................................10

5 OPERATION........................... .....................................................................................................................................................................................11

5.1 CONTROLS AND INDICATORS........................... ..................................................................................................................................11

[1] SYSTEM POWER SWITCH/CIRCUIT BREAKER AND INDICATOR .............................................................................11

[2] PUMP ON/OFF BREAKER SWITCH .............................................................................................................................................11

[3] TANK THERMOMETER ........................................................................................................................................................................11

[4] TANK HEATING INDICATOR ............................................................................................................ ................................................11

[5] TANK OVER TEMPERATURE INDICATOR ................................................................................................................................11

[6] APPLICATOR .............................................................................................................................................................................................11

[7] FLOW CONTROL VALVE (NOT SHOWN) ................................................................................................................................11

[8] TANK TEMPERATURE CONTROLLER (NOT SHOWN) ...................................................................................................11

[9] HOSE TEMPERATURE CONTROLLER (NOT SHOWN) ..................................................................................................11

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 3 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 4

TABLE OF CONTENTS (CONT.)

5.2 STARTUP INSTRUCTIONS ..................................................................................................................................................................12

5.3 ADJUSTMENTS ........................................................................................................................................................................................12

5.3.1 TANK TEMPERATURE CONTROLLER ........................................................................................................................................12

5.3.2 HOSE TEMPERATURE CONTROLLER ......................................................................................................................................13

5.3.3 ADHESIVE FLOW ADJUSTMENT ...................................................................................................................................................13

6 MAINTENANCE ........................................................................................................................................................................................................14

6.1 PREVENTIVE MAINTENANCE ..........................................................................................................................................................15

6.1.1 MONTHLY INSPECTION PROCEDURE .......................................................................................................................................15

7 TROUBLESHOOTING ..........................................................................................................................................................................................15

8 REPAIR AND REPLACEMENT ........................................................................................................................................................................17

8.1 HOSE REPLACEMENT ..........................................................................................................................................................................17

8.1.1 REMOVAL OF EXISTING HOSE .......................................................................................................................................................17

8.1.2 INSTALLATION OF NEW HOSE ........................................................................................................................................................18

8.2 HOSE CONTROLLER REPLACEMENT .......................................................................................................................................19

8.3 PUMP AND FLOW CONTROL REPLACEMENT .................................................................................................................... 20

8.4 PUMP MOTOR REPLACEMENT ......................................................................................................................................................21

8.5 TANK TEMPERATURE CONTROLLER REPLACEMENT ...................................................................................................22

8.6 TANK HEATER REPLACEMENT ....................................................................................................................................................... 23

9 PARTS LIST ...............................................................................................................................................................................................................24

9.1 96 ASSEMBLY DRAWING .............................................................................................................................................................24

9.2 FLOW CONTROL VALVE ASSEMBLY ...........................................................................................................................................25

9.3 V1 PUMP ASSEMBLY...............................................................................................................................................................................26

9.4 MOTOR ASSEMBLY ...............................................................................................................................................................................27

9.5 L2 HANDGUN NOZZLES. ...................................................................................................................................................................28

9.6 RECOMMENDED SPARES ...................................................................................................................................................................29

FHC96

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 4 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 5

1 . SAFETY PRECAUTIONS FOR HOT MELT APPLICATOR EQUIPMENT

This manual contains important safety information and instructions. Failure to comply with these instructions can result in

death, injury or permanent damage to this equipment and will void the warranty.

1.1 Intended Use

This equipment is designed for use with standard adhesive and sealant materials with flash points above 232 °C (450 °F).

Use of flammable material or material not compatible with the specifications of this equipment can cause injury to opera-

tor and damage to equipment.

The manufacturer has designed this equipment for safe operation. Specified models are in compliance with EN 60204-

1:1997. However, heated thermoplastics and other hot melt materials are dangerous and care must be exercised to ensure

operational safety. Handling must be in accordance with hot melt manufacturer specifications. Never exceed the maximum

application temperature recommended by the adhesive manufacturer.

Dispose of hot melt properly. Refer to the Safety Data Sheet (SDS) of the hot melt for recommended disposal methods.

1.2 Personal Safety

Wear the following protection when working on or around this equipment:

Always wear heat resistant gloves rated to 205 °C (400 °F) and allow all system temperatures to stabilize below 193 °C

(380 °F) before servicing. Properly ventilate equipment according to MSDS of equipment.

Trained operators and service technicians should be aware of exposed surfaces of the unit that cannot be practically

safeguarded. These exposed surfaces may be hot and take time to cool after the unit has been operating.

Keep parts of the body away from rotating parts. Do not wear loose articles of clothing when operating or servicing units

with rotating parts. Remove wristwatches, rings, necklaces, or other jewelry and cover or pin up long hair before performing

any work on or with the unit.

Trained operators may perform only external equipment adjustments. Trained service technicians must perform internal

adjustments and service.

1.3 Electrical Safety

Determine voltage of this equipment before installation and confirm compatibility with available power. Equipment must

be connected to a properly grounded circuit and installed in accordance with all applicable electrical codes. Ground fault

protection must be provided in supply circuitry at site installation.

Models designed to EN60204-1: 1997 require power cords be approved to a harmonized (HAR) standard and rated for 70

°C (158 °F). A HAR approved Type B plug and strain relief for power cord are required to meet standard IEC 309. Power

conducting wires must be nominal 5.3 mm2 (10 AWG) maximum and nominal 2.1 mm2 (14 AWG) minimum.

SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00 1

1 Safety Precautions for Hot Melt Applicator Equipment

This manual contains important safety information and instructions.

Failure to comply with these instructions can result in death, injury or

permanent damage to this equipment and will void the warranty.

1.1 Intended Use This equipment is designed for use with standard adhesive and sealant

materials with flash points above 232 °C (450 °F). Use of flammable

material or material not compatible with the specifications of this

equipment can cause injury to operator and damage to equipment.

The manufacturer has designed this equipment for safe operation.

Specified models are in compliance with EN 60204-1:1997. However,

heated thermoplastics and other hot melt materials are dangerous and

care must be exercised to ensure operational safety. Handling must be in

accordance with hot melt manufacturer specifications. Never exceed the

maximum application temperature recommended by the adhesive

manufacturer.

Dispose of hot melt properly. Refer to the Materials Safety Data Sheet

(MSDS) of the hot melt for recommended disposal methods.

1.2 Personal Safety Wear the following protection when working on or around this equipment:

Always wear heat resistant gloves rated to 205 °C (400 °F) and allow all

system temperatures to stabilize below 193 °C (380 °F) before servicing.

Properly ventilate equipment according to MSDS of equipment.

Trained operators and service technicians should be aware of exposed

surfaces of the unit that cannot be practically safeguarded. These

exposed surfaces may be hot and take time to cool after the unit has

been operating.

Keep parts of the body away from rotating parts. Do not wear loose

articles of clothing when operating or servicing units with rotating parts.

Remove wristwatches, rings, necklaces, or other jewelry and cover or pin

up long hair before performing any work on or with the unit.

Trained operators may perform only external equipment adjustments.

Trained service technicians must perform internal adjustments and

service.

1.3 Electrical Safety Determine voltage of this equipment before installation and confirm

compatibility with available power. Equipment must be connected to a

properly grounded circuit and installed in accordance with all applicable

electrical codes. Ground fault protection must be provided in supply

circuitry at site installation.

Models designed to EN60204-1: 1997 require power cords be approved

to a harmonized (HAR) standard and rated for 70 °C (158 °F). A HAR

approved Type B plug and strain relief for power cord are required to

meet standard IEC 309. Power conducting wires must be nominal

5.3 mm2(10 AWG) maximum and nominal 2.1 mm2(14 AWG) minimum.

1.4 Emergency Power Disconnect

In the event of a malfunction, turn off power to the equipment at the

power off switch and remove source power to the system at the nearest

main disconnect.

1.5 Follow Directions Read the product manual thoroughly before installation, operation or

maintenance. Failure to do so can result in a serious accident or

equipment malfunction. The manufacturer will not be held liable for

injuries or damage caused by misuse of this equipment.

Wear Safety Goggles

Wear Heat-Resistant

Safety Gloves

Wear Protective Clothing

SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00 1

1 Safety Precautions for Hot Melt Applicator Equipment

This manual contains important safety information and instructions.

Failure to comply with these instructions can result in death, injury or

permanent damage to this equipment and will void the warranty.

1.1 Intended Use This equipment is designed for use with standard adhesive and sealant

materials with flash points above 232 °C (450 °F). Use of flammable

material or material not compatible with the specifications of this

equipment can cause injury to operator and damage to equipment.

The manufacturer has designed this equipment for safe operation.

Specified models are in compliance with EN 60204-1:1997. However,

heated thermoplastics and other hot melt materials are dangerous and

care must be exercised to ensure operational safety. Handling must be in

accordance with hot melt manufacturer specifications. Never exceed the

maximum application temperature recommended by the adhesive

manufacturer.

Dispose of hot melt properly. Refer to the Materials Safety Data Sheet

(MSDS) of the hot melt for recommended disposal methods.

1.2 Personal Safety Wear the following protection when working on or around this equipment:

Always wear heat resistant gloves rated to 205 °C (400 °F) and allow all

system temperatures to stabilize below 193 °C (380 °F) before servicing.

Properly ventilate equipment according to MSDS of equipment.

Trained operators and service technicians should be aware of exposed

surfaces of the unit that cannot be practically safeguarded. These

exposed surfaces may be hot and take time to cool after the unit has

been operating.

Keep parts of the body away from rotating parts. Do not wear loose

articles of clothing when operating or servicing units with rotating parts.

Remove wristwatches, rings, necklaces, or other jewelry and cover or pin

up long hair before performing any work on or with the unit.

Trained operators may perform only external equipment adjustments.

Trained service technicians must perform internal adjustments and

service.

1.3 Electrical Safety Determine voltage of this equipment before installation and confirm

compatibility with available power. Equipment must be connected to a

properly grounded circuit and installed in accordance with all applicable

electrical codes. Ground fault protection must be provided in supply

circuitry at site installation.

Models designed to EN60204-1: 1997 require power cords be approved

to a harmonized (HAR) standard and rated for 70 °C (158 °F). A HAR

approved Type B plug and strain relief for power cord are required to

meet standard IEC 309. Power conducting wires must be nominal

5.3 mm2(10 AWG) maximum and nominal 2.1 mm2(14 AWG) minimum.

1.4 Emergency Power Disconnect

In the event of a malfunction, turn off power to the equipment at the

power off switch and remove source power to the system at the nearest

main disconnect.

1.5 Follow Directions Read the product manual thoroughly before installation, operation or

maintenance. Failure to do so can result in a serious accident or

equipment malfunction. The manufacturer will not be held liable for

injuries or damage caused by misuse of this equipment.

Wear Safety Goggles

Wear Heat-Resistant

Safety Gloves

Wear Protective Clothing

SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00 1

1 Safety Precautions for Hot Melt Applicator Equipment

This manual contains important safety information and instructions.

Failure to comply with these instructions can result in death, injury or

permanent damage to this equipment and will void the warranty.

1.1 Intended Use This equipment is designed for use with standard adhesive and sealant

materials with flash points above 232 °C (450 °F). Use of flammable

material or material not compatible with the specifications of this

equipment can cause injury to operator and damage to equipment.

The manufacturer has designed this equipment for safe operation.

Specified models are in compliance with EN 60204-1:1997. However,

heated thermoplastics and other hot melt materials are dangerous and

care must be exercised to ensure operational safety. Handling must be in

accordance with hot melt manufacturer specifications. Never exceed the

maximum application temperature recommended by the adhesive

manufacturer.

Dispose of hot melt properly. Refer to the Materials Safety Data Sheet

(MSDS) of the hot melt for recommended disposal methods.

1.2 Personal Safety Wear the following protection when working on or around this equipment:

Always wear heat resistant gloves rated to 205 °C (400 °F) and allow all

system temperatures to stabilize below 193 °C (380 °F) before servicing.

Properly ventilate equipment according to MSDS of equipment.

Trained operators and service technicians should be aware of exposed

surfaces of the unit that cannot be practically safeguarded. These

exposed surfaces may be hot and take time to cool after the unit has

been operating.

Keep parts of the body away from rotating parts. Do not wear loose

articles of clothing when operating or servicing units with rotating parts.

Remove wristwatches, rings, necklaces, or other jewelry and cover or pin

up long hair before performing any work on or with the unit.

Trained operators may perform only external equipment adjustments.

Trained service technicians must perform internal adjustments and

service.

1.3 Electrical Safety Determine voltage of this equipment before installation and confirm

compatibility with available power. Equipment must be connected to a

properly grounded circuit and installed in accordance with all applicable

electrical codes. Ground fault protection must be provided in supply

circuitry at site installation.

Models designed to EN60204-1: 1997 require power cords be approved

to a harmonized (HAR) standard and rated for 70 °C (158 °F). A HAR

approved Type B plug and strain relief for power cord are required to

meet standard IEC 309. Power conducting wires must be nominal

5.3 mm2(10 AWG) maximum and nominal 2.1 mm2(14 AWG) minimum.

1.4 Emergency Power Disconnect

In the event of a malfunction, turn off power to the equipment at the

power off switch and remove source power to the system at the nearest

main disconnect.

1.5 Follow Directions Read the product manual thoroughly before installation, operation or

maintenance. Failure to do so can result in a serious accident or

equipment malfunction. The manufacturer will not be held liable for

injuries or damage caused by misuse of this equipment.

Wear Safety Goggles

Wear Heat-Resistant

Safety Gloves

Wear Protective Clothing

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 5 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 6

1 . SAFETY PRECAUTIONS FOR HOT MELT APPLICATOR EQUIPMENT (CONT.)

1.4 Emergency Power Disconnect

In the event of a malfunction, turn off power to the equipment at the power off switch and remove source power to the

system at the nearest main disconnect.

1.5 Follow Directions

Read the product manual thoroughly before installation, operation or maintenance. Failure to do so can result in a serious

accident or equipment malfunction. The manufacturer will not be held liable for injuries or damage caused by misuse of

this equipment.

1.6 Safety Symbols and Signal Words

The following safety symbols and signal words are used throughout the manual and on the product to alert the reader and

operator to personal safety hazards or to identify conditions that may result in equipment or property damage.

General Safety Symbols

Specific Symbols and Signal Words

Other Product Symbols

The manufacturer reserves the right to make design changes for product improvement. This manual may not

reflect all details of these improvements.

2SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

1.6 Safety Symbols and Signal Words

The following safety symbols and signal words are used throughout the

manual and on the product to alert the reader and operator to personal

safety hazards or to identify conditions that may result in equipment or

property damage.

General Safety Symbols

Specific Symbols and Signal Words

Other Product Symbols

The manufacturer reserves the right to make design changes for product

improvement. This manual may not reflect all details of these

improvements.

DANGER: Indicates a hazard, which, if not avoided, will result in serious

injury, including death, or equipment and property damage.

PE

+

-

On

Tank

Set Temp

Tank Heater

Off

Heated Hose

Standby Temp

Alarm

Ground

Applicator

Overtemp

Actual Temp

Protective Earth

Pump Motor

Adhesive Flow

Source Power

Valve Group Manual Task Input Output

WARNING: Indicates a hazard, which, if not avoided, can result in

serious injury, or equipment and property damage.

CAUTION: Indicates a hazard, which, if not avoided, can result in

minor in

j

ur

y,

or e

q

ui

p

ment and

p

ro

p

ert

y

dama

g

e.

DANGER: High Voltage. Can cause serious injury, including

death. Disconnect electrical power at external source before

servicing.

WARNING: Hot Surface. Can cause serious injury and burns.

Wear heat resistant clothing, gloves and safety goggles.

WARNING: Disconnect electrical power at external source.

Failure to do so can cause electrical shock.

WARNING: High Pressure. System contents under pressure. Can

cause serious injury and burns or equipment and property

damage. Relieve pressure before servicing.

!

!

!

2SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

1.6 Safety Symbols and Signal Words

The following safety symbols and signal words are used throughout the

manual and on the product to alert the reader and operator to personal

safety hazards or to identify conditions that may result in equipment or

property damage.

General Safety Symbols

Specific Symbols and Signal Words

Other Product Symbols

The manufacturer reserves the right to make design changes for product

improvement. This manual may not reflect all details of these

improvements.

DANGER: Indicates a hazard, which, if not avoided, will result in serious

injury, including death, or equipment and property damage.

PE

+

-

On

Tank

Set Temp

Tank Heater

Off

Heated Hose

Standby Temp

Alarm

Ground

Applicator

Overtemp

Actual Temp

Protective Earth

Pump Motor

Adhesive Flow

Source Power

Valve Group Manual Task Input Output

WARNING: Indicates a hazard, which, if not avoided, can result in

serious injury, or equipment and property damage.

CAUTION: Indicates a hazard, which, if not avoided, can result in

minor in

j

ur

y,

or e

q

ui

p

ment and

p

ro

p

ert

y

dama

g

e.

DANGER: High Voltage. Can cause serious injury, including

death. Disconnect electrical power at external source before

servicing.

WARNING: Hot Surface. Can cause serious injury and burns.

Wear heat resistant clothing, gloves and safety goggles.

WARNING: Disconnect electrical power at external source.

Failure to do so can cause electrical shock.

WARNING: High Pressure. System contents under pressure. Can

cause serious injury and burns or equipment and property

damage. Relieve pressure before servicing.

!

!

!

2SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

1.6 Safety Symbols and Signal Words

The following safety symbols and signal words are used throughout the

manual and on the product to alert the reader and operator to personal

safety hazards or to identify conditions that may result in equipment or

property damage.

General Safety Symbols

Specific Symbols and Signal Words

Other Product Symbols

The manufacturer reserves the right to make design changes for product

improvement. This manual may not reflect all details of these

improvements.

DANGER: Indicates a hazard, which, if not avoided, will result in serious

injury, including death, or equipment and property damage.

PE

+

-

On

Tank

Set Temp

Tank Heater

Off

Heated Hose

Standby Temp

Alarm

Ground

Applicator

Overtemp

Actual Temp

Protective Earth

Pump Motor

Adhesive Flow

Source Power

Valve Group Manual Task Input Output

WARNING: Indicates a hazard, which, if not avoided, can result in

serious injury, or equipment and property damage.

CAUTION: Indicates a hazard, which, if not avoided, can result in

minor in

j

ur

y,

or e

q

ui

p

ment and

p

ro

p

ert

y

dama

g

e.

DANGER: High Voltage. Can cause serious injury, including

death. Disconnect electrical power at external source before

servicing.

WARNING: Hot Surface. Can cause serious injury and burns.

Wear heat resistant clothing, gloves and safety goggles.

WARNING: Disconnect electrical power at external source.

Failure to do so can cause electrical shock.

WARNING: High Pressure. System contents under pressure. Can

cause serious injury and burns or equipment and property

damage. Relieve pressure before servicing.

!

!

!

2SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

1.6 Safety Symbols and Signal Words

The following safety symbols and signal words are used throughout the

manual and on the product to alert the reader and operator to personal

safety hazards or to identify conditions that may result in equipment or

property damage.

General Safety Symbols

Specific Symbols and Signal Words

Other Product Symbols

The manufacturer reserves the right to make design changes for product

improvement. This manual may not reflect all details of these

improvements.

DANGER: Indicates a hazard, which, if not avoided, will result in serious

injury, including death, or equipment and property damage.

PE

+

-

On

Tank

Set Temp

Tank Heater

Off

Heated Hose

Standby Temp

Alarm

Ground

Applicator

Overtemp

Actual Temp

Protective Earth

Pump Motor

Adhesive Flow

Source Power

Valve Group Manual Task Input Output

WARNING: Indicates a hazard, which, if not avoided, can result in

serious injury, or equipment and property damage.

CAUTION: Indicates a hazard, which, if not avoided, can result in

minor in

j

ur

y,

or e

q

ui

p

ment and

p

ro

p

ert

y

dama

g

e.

DANGER: High Voltage. Can cause serious injury, including

death. Disconnect electrical power at external source before

servicing.

WARNING: Hot Surface. Can cause serious injury and burns.

Wear heat resistant clothing, gloves and safety goggles.

WARNING: Disconnect electrical power at external source.

Failure to do so can cause electrical shock.

WARNING: High Pressure. System contents under pressure. Can

cause serious injury and burns or equipment and property

damage. Relieve pressure before servicing.

!

!

!

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 6 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 7

2 INTRODUCTION

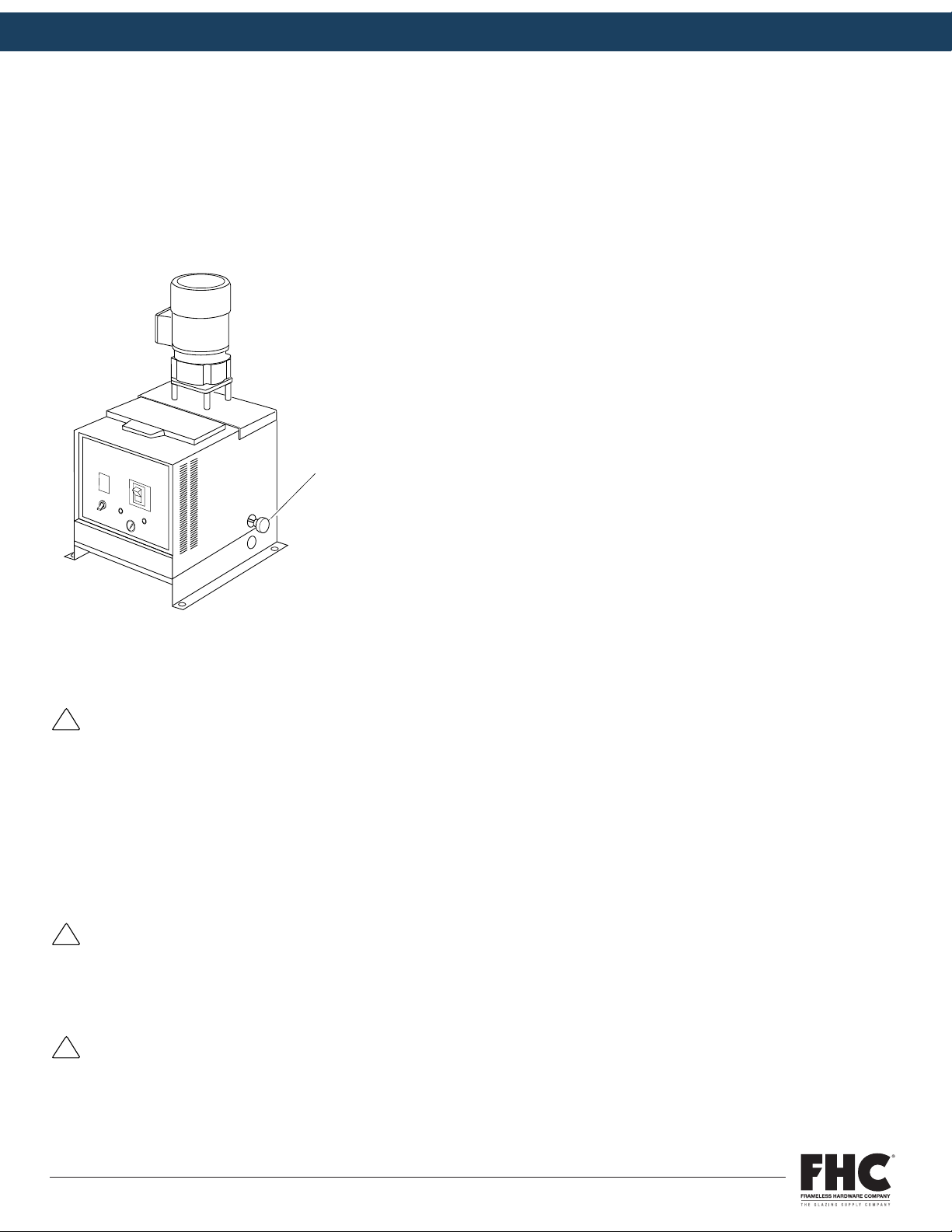

2.1 Description

The 96 Hot Melt Unit is a hot melt applicator system developed to melt and pump high viscosity butyl rubber-based

sealant. The melt unit features a 10 lb (4.5 kg) capacity tank. The cylindrical design accepts briquette form butyl sealants,

which are converted to fluid state and pumped by an electric motor-driven gear pump through an L2 Handgun/hose as-

sembly.

A rotating chain and scraper assembly in the tank propels the molten butyl sealant to the pump inlet port. A 38/31 rpm

60/50 Hz 1/6 hp motor and flow control valve provide output control. Tank temperature is regulated by an adjustable bime-

tallic controller mounted directly on the melt unit base. Hose temperature is controlled by an adjustable thermostat with

capillary bulb sensor.

The 96 Hot Melt Unit features the proven all-electric heating and pumping system. The melt unit is housed in an indus-

trial grade sheet metal enclosure and comes with a standard 8 ft (2.44 m) handgun/hose assembly; a 12 ft (3.66 m) hose

assembly is optional.

2.2 Features

ɸ All-electric systems available for 115 VAC power

ɸ Pumps high viscosity materials up to 500,000 centipoise

ɸ No compressed air

ɸ Positive-displacement V1-675 gear pump

ɸ A pump warm-up thermostat protects the pump drive mechanism by preventing operation below a safe temperature level

ɸ Tank and hose/handgun temperatures independently controlled

ɸ Over temperature protection if tank thermostat fails

ɸ Pump output adjusts by turning external flow control knob

ɸ Switched handgun assembly decreases pump wear and increases motor service life

SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00 3

2 Introduction

2.1 Description The SS96 Hot Melt Unit is a hot melt applicator system developed

to melt and pump high viscosity butyl rubber-based sealant. The

melt unit features a 10 lb (4.5 kg) capacity tank. The cylindrical

design accepts briquette form butyl sealants, which are converted

to fluid state and pumped by an electric motor-driven gear pump

through an L2 Handgun/hose assembly.

A rotating chain and scraper assembly in the tank propels the

molten butyl sealant to the pump inlet port. A 38/31 rpm 60/50 Hz

1/6 hp motor and flow control valve provide output control.

Tank temperature is regulated by an adjustable bimetallic

controller mounted directly on the melt unit base. Hose

temperature is controlled by an adjustable thermostat with

capillary bulb sensor.

The SS96 Hot Melt Unit features the proven all-electric heating

and pumping system. The melt unit is housed in an industrial-

grade sheet metal enclosure and comes with a standard 8 ft

(2.44 m) handgun/hose assembly; a 12 ft (3.66 m) hose assembly

is optional.

2000354

FHC96

FHC96

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 7 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 8

3 SPECIFICATIONS

3.1 Electrical

Input voltage .............................................................................. 115 VAC single phase

Power requirement ................................................................. Melt unit 900 W

............................................................................................................ Hose, 8 ft 262 W

............................................................................................................ Hose, 12 ft 390 W

............................................................................................................ Handgun 120 W

Breaker rating............................................................................. 15 A

3.2 Physical

Tank capacity ............................................................................. 4.5 kg (10 lb)

Hose capacity ............................................................................ 1 no. 8 hose

Shipping weight ........................................................................ 29.1 kg (64 lb)

3.3 Performance

Warm up time ............................................................................. 45–60 minutes

Melt rate ........................................................................................ 3.6 kg/hr (8 lb/hr)

Viscosity ........................................................................................ Maximum 500,000 cps

Temperature range:

Melt tank ................................................................................ 37–232 °C (100–450 °F)

Hose ........................................................................................ 175–232 °C (350–450 °F)

Maximum pump flow rate:

Motor rpm ............................................................................ 38/31 rpm @ 60/50 Hz

Pump size ............................................................................. V1-675

Output .................................................................................... 18.1 kg/hr (40 lb/hr)

3.4 Environmental

Storage temperature ............................................................. 0–60 °C (32–140 °F)

Ambient air temperature ..................................................... 5–45 °C (41–113 °F)

Humidity ....................................................................................... 30–95 R.H. (%)

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 8 OF 31

EXPERIENCE AND INNOVATION

P. 9

3 SPECIFICATIONS (CONT.)

3.5 Dimension

4 INSTALLATION

4.1 Setup

1. Remove all packaging material around melt unit.

2. Carefully lift melt unit out of box.

3. Unpack binder containing manuals and warranty information. Retain for future reference.

4. Unscrew four screws from plywood board base.

5. Carefully uncoil hose from around melt unit and remove bubble wrap from handgun.

6. Position melt unit for convenient servicing and easy access to control panel.

7. Use level mounting surface to prevent warping of melt unit and misalignment of pump and motor shaft.

8. Using the base mounting holes, bolt melt unit to a durable mounting surface in accordance with illustration on

opposite page to prevent accidental upset and possible injury.

9. Assure all screws are tight before startup. If melt unit experiences excessive vibration, re-tighten screws.

4.2 Component Installation

1. Manual systems are generally shipped with all standard components installed. No user installation is required.

2. In the event a melt unit is received without an attached handgun/hose assembly, refer to Section 8.1, Hose Replacement.

6SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

3.5 Dimensions

269.875mm

10.625 in.

355.60mm

14.0 in.

558.80mm

22.0 in.

285.75mm

11.25 in.

292.10mm

11.50 in.

342.90mm

13.50 in.

2000355

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 9 OF 31

EXPERIENCE AND INNOVATION

P. 10

GLASS DRILL INSTRUCTION MANUAL

GLASS DRILL INSTRUCTION MANUAL

4 INSTALLATION (CONT.)

4.3 Electrical Circuits and Wiring

96 Melt Units use single phase 115 VAC power sources with earth ground for safety. See illustration below for terminal

block location. An identification plate is attached to each melt unit on the outside rear door of the tank housing. This plate

specifies the exact melt unit voltage and pump motor frequency. Pump motor voltage, frequency and current are specified

on the motor data plate. For safe and proper installation, refer to the identification plate before applying electrical power to

melt unit.

4.3.1 Power Cord

Prewired 115 VAC ų6 Melt Units are equipped with a power cord and a standard 3-prong grounding power plug. The

system becomes fully operable by plugging the power cord into a grounded outlet.

4.3.2 Switched Handgun Pump Motor Circuit

The switched pump motor circuit allows the pump motor to be switched ON and OFF using the handgun trigger. This feature

increases pump motor life and turns ON the pump motor at the time of application. This remote switch is located on switched

handguns and is wired into the melt unit between terminal block locations TA-9 and TA-9a.

8SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

CAUTION: To avoid possible system damage,

always check wiring configuration in terminal

blocks to verify the jumpers are in their correct

locations.

4.3 Electrical Circuits and Wiring

SS96 Melt Units use single phase 115 VAC power sources with

earth ground for safety. See illustration below for terminal block

location. An identification plate is attached to each melt unit on the

outside rear door of the tank housing. This plate specifies the

exact melt unit voltage and pump motor frequency. Pump motor

voltage, frequency and current are specified on the motor data

plate. For safe and proper installation, refer to the identification

plate before applying electrical power to melt unit.

Block Diagram 115 VAC Single Phase:

4.3.1 Power Cord

Prewired 115 VAC SS96 Melt Units are equipped with a power

cord and a standard 3-prong grounding power plug. The system

becomes fully operable by plugging the power cord into a

grounded outlet.

4.3.2 Switched Handgun Pump Motor Circuit

The switched pump motor circuit allows the pump motor to be

switched ON and OFF using the handgun trigger. This feature

increases pump motor life and turns ON the pump motor at the

time of application. This remote switch is located on switched

handguns and is wired into the melt unit between terminal block

locations TA-9 and TA-9a.

!

L2G

NL1

2000356

115

115

GroundNeutralL1

2000357

FHC96

FHC96

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 10 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 11

5 OPERATION

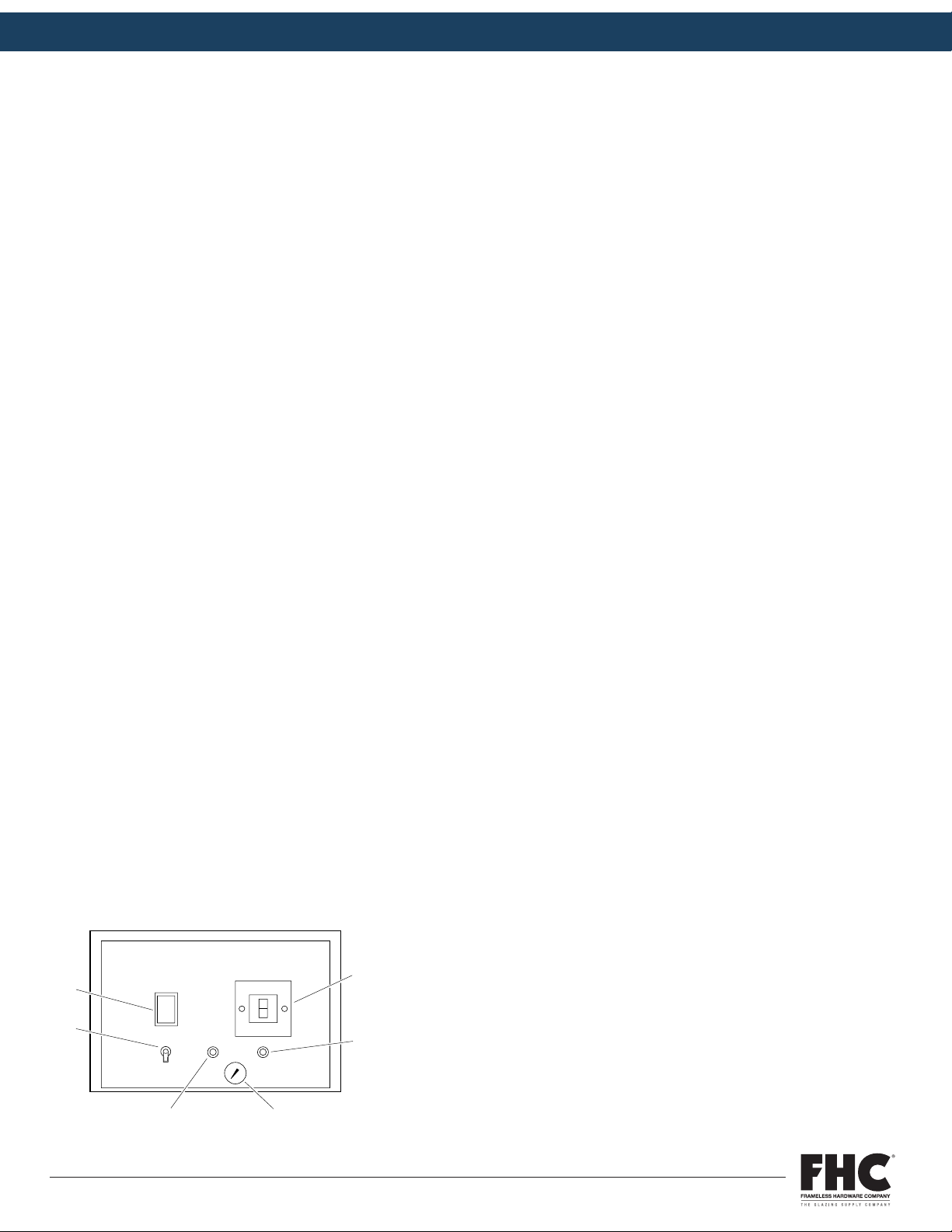

5.1 Controls and Indicators

Read this section carefully before attempting to operate this machine. See illustration on opposite page.

[1] System Power Switch/Circuit Breaker and Indicator

A magnetic type breaker opens the circuit at currents exceeding 15 A. The power switch illuminates when in the ON position.

[2] Pump On/Off Breaker Switch

Allows user to switch OFF pump motor during system warm up or maintenance. It is a magnetic type circuit breaker that

protects the motor during overload conditions.

[3] Tank Thermometer

Indicates temperature of the material in the melt tank.

[4] Tank Heating Indicator

Illuminates amber when tank heaters are powered and assists the user when making temperature adjustments to the tank

temperature controller.

[5] Tank Over temperature Indicator

Indicates tank temperatures exceeding approximately 232 °C (450 °F). In the event of a tank thermostat failure, power to

the tank heaters is controlled by a back-up thermostat and light illuminates red indicating an over temperature condition.

Should an over temperature condition occur, turn tank temperature control down or replace if failed. Refer to Section 7,

Troubleshooting.

[6] Applicator

Not applicable to this unit.

[7] Flow Control Valve (not shown)

Controls the amount of adhesive available at the applicator by a pump pressure bypass valve, or flow control valve attached

to the gear pump. Adjust on the right side of the melt unit. Refer to Adhesive Flow Adjustment Section 5.3.3.

[8] Tank Temperature Controller (not shown)

A full-range adjustable thermostat sets and controls tank temperature. Located on the front of the melt tank base, it is

accessible at the small access panel inside the electrical enclosure. Adjustment requires a flat blade screwdriver. Refer to

Tank Temperature Controller, Section 5.3.1.

[9] Hose Temperature Controller (not shown)

An adjustable thermostat controller sets and controls hose temperature. Located on the thermal panel inside the electrical

enclosure, the controller is attached to a capillary bulb sensor located in the hose. Refer to Hose Temperature Controller,

Section 5.3.2.

SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00 11

[8] Tank Temperature Controller (not shown)

A full-range adjustable thermostat sets and controls tank

temperature. Located on the front of the melt tank base, it is

accessible at the small access panel inside the electrical

enclosure. Adjustment requires a flat blade screwdriver. Refer to

Tank Temperature Controller, Section 5.3.1.

[9] Hose Temperature Controller (not shown)

An adjustable thermostat controller sets and controls hose

temperature. Located on the thermal panel inside the electrical

enclosure, the controller is attached to a capillary bulb sensor

located in the hose. Refer to Hose Temperature Controller,

Section 5.3.2.

ON

OFF

PUMP

HEATING OVERTEMP

POWER

APPLICATOR

TEMPERATURE

TANK

ON

OFF

1

5

34

2

6

2000345

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 11 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 12

5 OPERATION (CONT.)

5.2 Startup Instructions

DANGER: To avoid personal injury, follow all safety labels. Failure to properly operate and maintain equipment can lead

to serious injury.

Ŀ Wear protective clothing, safety goggles and safety gloves. Hot melt materials can cause severe burns resulting in dis-

figurement or blindness.

Ŀ Use only manufacturer recommended materials in this system. Fire, explosion, personal injury, property and equipment

damage can result if improper or unsafe materials are used.

Ŀ Disconnect electrical power from external source to melt unit before undertaking maintenance or troubleshooting.

Failure to disconnect power can result in fatal electrical shock.

Ŀ Depressurize system before performing any maintenance to pump, pump filter, flow control valve or hose. Turn pump

switch off and depress trigger on handgun until there is no flow. Air trapped in the system or in a component can form a

pressure pocket. Loosen fittings cautiously. Adhesive under pressure can cause severe burns and blindness.

Ŀ Always read the manufacturer’s recommended use of the material.

1. Become familiar with Section 5.1, Controls and Indicators.

2. Install melt unit as specified in Section 4, Installation.

3. Fill tank with hot melt material.

4. Turn melt unit on and allow sufficient warm up time for hot melt material to thoroughly melt.

5. Align motor on receipt of a new unit or after transportation.

a. Loosen four screws holding motor pan to side of melt unit.

b. Heat melt unit and run motor. This centers the motor.

c. With motor running, tighten four screws in a crisscross pattern.

6. Set hose and tank temperatures to desired settings. Lower settings increase pot life of the material. Materials degrade

over time due to oxidation.

7. To prevent motor stalling, adjust flow control valve to the minimum flow requirement.

5.3 Adjustments

5.3.1 Tank Temperature Controller

1. To prevent hot melt degradation, set melt tank temperature to the minimum temperature specified by hot melt manu-

facturer.

2. Open front control panel.

3. To raise melt tank temperature, turn tank temperature controller adjustment shaft [1] clockwise with screwdriver. See

illustration below.

4. To lower melt tank temperature, turn adjustment shaft [1] counter-clockwise with screwdriver. The melt tank

temperature controller range is 260 °C (500 °F) for one 320° rotation of the adjustment shaft.

5. Allow melt tank temperature to stabilize 30 minutes before adjusting further.

6. Verify temperature on tank thermometer.

12 SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

DANGER: To avoid personal injury, follow all

safety labels. Failure to properly operate and

maintain equipment can lead to serious injury.

•Wear protective clothing, safety goggles and

safety gloves. Hot melt materials can cause

severe burns resulting in disfigurement or

blindness.

•Use only manufacturer recommended materials

in this system. Fire, explosion, personal injury,

property and equipment damage can result if

improper or unsafe materials are used.

•Disconnect electrical power from external

source to melt unit before undertaking

maintenance or troubleshooting. Failure to

disconnect power can result in fatal electrical

shock.

•Depressurize system before performing any

maintenance to pump, pump filter, flow control

valve or hose. Turn pump switch off and

depress trigger on handgun until there is no

flow. Air trapped in the system or in a

component can form a pressure pocket.

Loosen fittings cautiously. Adhesive under

pressure can cause severe burns and

blindness.

•Always read the manufacturer’s recommended

use of the material.

5.2 Startup Instructions

1. Become familiar with Section 5.1, Controls and Indicators.

2. Install melt unit as specified in Section 4, Installation.

3. Fill tank with hot melt material.

4. Turn melt unit on and allow sufficient warmup time for hot

melt material to thoroughly melt.

5. Align motor on receipt of a new unit or after transportation.

a. Loosen four screws holding motor pan to side of melt

unit.

b. Heat melt unit and run motor. This centers the motor.

c. With motor running, tighten four screws in a crisscross

pattern.

6. Set hose and tank temperatures to desired settings. Lower

settings increase pot life of the material. Materials degrade

over time due to oxidation.

7. To prevent motor stalling, adjust flow control valve to the

minimum flow requirement.

!

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 12 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 13

5 OPERATION (CONT.)

5.3.2 Hose Temperature Controller

Temperature graduations on hose controller reflect approximate hose temperature.

1. Measure inside hose temperature with a pyrometer and bead probe. Hose temperature should be the minimum

temperature required for application to prevent degradation of material in the hose and maximize hose life.

2. Open front control panel.

3. To raise hose temperature, turn adjustment shaft [2] clockwise with screwdriver to desired temperature on dial.

See illustration below.

4. To lower hose temperature, turn adjustment shaft [2] counterclockwise with screwdriver to desired temperature on dial.

5. Refer to Temperature Check in Maintenance section of the handgun manual.

5.3.3 Adhesive Flow Adjustment

CAUTION: For maximum performance and motor life, do not allow pump motor to stall. A prolonged stall condition

will cause motor to go into thermal overload.

Flow Control Valve

An adjustable pressure regulating device is mounted on the pump under the melt unit chassis.

1. Adjust adhesive flow with flow control knob [1] on right side of melt unit.

2. To increase pressure and adhesive flow, turn knob [1] clockwise.

3. To decrease pressure and adhesive flow, turn knob [1] counterclockwise.

4. To achieve minimum pressure and lowest flow rate suitable for application, turn knob fully counterclockwise. Gradually

turn clockwise until desired pressure and flow rate is reached.

SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00 13

5.3 Adjustments

5.3.1 Tank Temperature Controller

1. To prevent hot melt degradation, set melt tank temperature to

the minimum temperature specified by hot melt manufacturer.

2. Open front control panel.

3. To raise melt tank temperature, turn tank temperature

controller adjustment shaft [1] clockwise with screwdriver. See

illustration below.

4. To lower melt tank temperature, turn adjustment shaft [1]

counter-clockwise with screwdriver. The melt tank

temperature controller range is 260 °C (500 °F) for one 320°

rotation of the adjustment shaft.

5. Allow melt tank temperature to stabilize 30 minutes before

adjusting further.

6. Verify temperature on tank thermometer.

5.3.2 Hose Temperature Controller

Temperature graduations on hose controller reflect approximate

hose temperature.

1. Measure inside hose temperature with a pyrometer and bead

probe. Hose temperature should be the minimum temperature

required for application to prevent degradation of material in

the hose and maximize hose life.

2. Open front control panel.

3. To raise hose temperature, turn adjustment shaft [2]

clockwise with screwdriver to desired temperature on dial.

See illustration below.

4. To lower hose temperature, turn adjustment shaft [2]

counterclockwise with screwdriver to desired temperature on

dial.

5. Refer to Temperature Check in Maintenance section of the

handgun manual.

12000008a

2

12 SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

DANGER: To avoid personal injury, follow all

safety labels. Failure to properly operate and

maintain equipment can lead to serious injury.

•Wear protective clothing, safety goggles and

safety gloves. Hot melt materials can cause

severe burns resulting in disfigurement or

blindness.

•Use only manufacturer recommended materials

in this system. Fire, explosion, personal injury,

property and equipment damage can result if

improper or unsafe materials are used.

•Disconnect electrical power from external

source to melt unit before undertaking

maintenance or troubleshooting. Failure to

disconnect power can result in fatal electrical

shock.

•Depressurize system before performing any

maintenance to pump, pump filter, flow control

valve or hose. Turn pump switch off and

depress trigger on handgun until there is no

flow. Air trapped in the system or in a

component can form a pressure pocket.

Loosen fittings cautiously. Adhesive under

pressure can cause severe burns and

blindness.

•Always read the manufacturer’s recommended

use of the material.

5.2 Startup Instructions

1. Become familiar with Section 5.1, Controls and Indicators.

2. Install melt unit as specified in Section 4, Installation.

3. Fill tank with hot melt material.

4. Turn melt unit on and allow sufficient warmup time for hot

melt material to thoroughly melt.

5. Align motor on receipt of a new unit or after transportation.

a. Loosen four screws holding motor pan to side of melt

unit.

b. Heat melt unit and run motor. This centers the motor.

c. With motor running, tighten four screws in a crisscross

pattern.

6. Set hose and tank temperatures to desired settings. Lower

settings increase pot life of the material. Materials degrade

over time due to oxidation.

7. To prevent motor stalling, adjust flow control valve to the

minimum flow requirement.

!

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 13 OF 31

EXPERIENCE AND INNOVATION

P. 14

5 OPERATION (CONT.)

Flow Control Valve (Image)

6 MAINTENANCE

WARNING: Hot Melt materials can cause severe burns resulting in disfigurement or blindness. Follow these

precautions before beginning any maintenance:

Ŀ Wear protective clothing, safety goggles, and safety gloves.

Ŀ Turn pump motor switch to off position. De-pressurize applicator(s) by triggering.

Ŀ Unless stated otherwise, always allow melt unit to cool before beginning any maintenance.

Ŀ Disconnect hose electrical connector when hose fittings are disconnected and power is off.

CAUTION: To prevent damage to components (hose fittings, etc.), heat part(s) being serviced to approximately 121 °C

(250°F) prior to dismantling, assembling, or adjusting. Heat parts by applying power to the unit using a hand held hot

air gun or placing parts on a hot plate. Failure to do this will result in stripped threads and ruining both parts and tools.

CAUTION: To avoid arcing of electrical contacts and possible failure of components, do not connect electrical

connectors when the hose power switch is on.

14 SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

CAUTION: For maximum performance and motor

life, do not allow pump motor to stall. A prolonged

stall condition will cause motor to go into thermal

overload.

5.3.3 Adhesive Flow Adjustment

Flow Control Valve

An adjustable pressure regulating device is mounted on the pump

under the melt unit chassis.

1. Adjust adhesive flow with flow control knob [1] on right side of

melt unit.

2. To increase pressure and adhesive flow, turn knob [1]

clockwise.

3. To decrease pressure and adhesive flow, turn knob [1]

counterclockwise.

4. To achieve minimum pressure and lowest flow rate suitable

for application, turn knob fully counterclockwise. Gradually

turn clockwise until desired pressure and flow rate is reached.

!

1

2000359

12 SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

DANGER: To avoid personal injury, follow all

safety labels. Failure to properly operate and

maintain equipment can lead to serious injury.

•Wear protective clothing, safety goggles and

safety gloves. Hot melt materials can cause

severe burns resulting in disfigurement or

blindness.

•Use only manufacturer recommended materials

in this system. Fire, explosion, personal injury,

property and equipment damage can result if

improper or unsafe materials are used.

•Disconnect electrical power from external

source to melt unit before undertaking

maintenance or troubleshooting. Failure to

disconnect power can result in fatal electrical

shock.

•Depressurize system before performing any

maintenance to pump, pump filter, flow control

valve or hose. Turn pump switch off and

depress trigger on handgun until there is no

flow. Air trapped in the system or in a

component can form a pressure pocket.

Loosen fittings cautiously. Adhesive under

pressure can cause severe burns and

blindness.

•Always read the manufacturer’s recommended

use of the material.

5.2 Startup Instructions

1. Become familiar with Section 5.1, Controls and Indicators.

2. Install melt unit as specified in Section 4, Installation.

3. Fill tank with hot melt material.

4. Turn melt unit on and allow sufficient warmup time for hot

melt material to thoroughly melt.

5. Align motor on receipt of a new unit or after transportation.

a. Loosen four screws holding motor pan to side of melt

unit.

b. Heat melt unit and run motor. This centers the motor.

c. With motor running, tighten four screws in a crisscross

pattern.

6. Set hose and tank temperatures to desired settings. Lower

settings increase pot life of the material. Materials degrade

over time due to oxidation.

7. To prevent motor stalling, adjust flow control valve to the

minimum flow requirement.

!

12 SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

DANGER: To avoid personal injury, follow all

safety labels. Failure to properly operate and

maintain equipment can lead to serious injury.

•Wear protective clothing, safety goggles and

safety gloves. Hot melt materials can cause

severe burns resulting in disfigurement or

blindness.

•Use only manufacturer recommended materials

in this system. Fire, explosion, personal injury,

property and equipment damage can result if

improper or unsafe materials are used.

•Disconnect electrical power from external

source to melt unit before undertaking

maintenance or troubleshooting. Failure to

disconnect power can result in fatal electrical

shock.

•Depressurize system before performing any

maintenance to pump, pump filter, flow control

valve or hose. Turn pump switch off and

depress trigger on handgun until there is no

flow. Air trapped in the system or in a

component can form a pressure pocket.

Loosen fittings cautiously. Adhesive under

pressure can cause severe burns and

blindness.

•Always read the manufacturer’s recommended

use of the material.

5.2 Startup Instructions

1. Become familiar with Section 5.1, Controls and Indicators.

2. Install melt unit as specified in Section 4, Installation.

3. Fill tank with hot melt material.

4. Turn melt unit on and allow sufficient warmup time for hot

melt material to thoroughly melt.

5. Align motor on receipt of a new unit or after transportation.

a. Loosen four screws holding motor pan to side of melt

unit.

b. Heat melt unit and run motor. This centers the motor.

c. With motor running, tighten four screws in a crisscross

pattern.

6. Set hose and tank temperatures to desired settings. Lower

settings increase pot life of the material. Materials degrade

over time due to oxidation.

7. To prevent motor stalling, adjust flow control valve to the

minimum flow requirement.

!

12 SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

DANGER: To avoid personal injury, follow all

safety labels. Failure to properly operate and

maintain equipment can lead to serious injury.

•Wear protective clothing, safety goggles and

safety gloves. Hot melt materials can cause

severe burns resulting in disfigurement or

blindness.

•Use only manufacturer recommended materials

in this system. Fire, explosion, personal injury,

property and equipment damage can result if

improper or unsafe materials are used.

•Disconnect electrical power from external

source to melt unit before undertaking

maintenance or troubleshooting. Failure to

disconnect power can result in fatal electrical

shock.

•Depressurize system before performing any

maintenance to pump, pump filter, flow control

valve or hose. Turn pump switch off and

depress trigger on handgun until there is no

flow. Air trapped in the system or in a

component can form a pressure pocket.

Loosen fittings cautiously. Adhesive under

pressure can cause severe burns and

blindness.

•Always read the manufacturer’s recommended

use of the material.

5.2 Startup Instructions

1. Become familiar with Section 5.1, Controls and Indicators.

2. Install melt unit as specified in Section 4, Installation.

3. Fill tank with hot melt material.

4. Turn melt unit on and allow sufficient warmup time for hot

melt material to thoroughly melt.

5. Align motor on receipt of a new unit or after transportation.

a. Loosen four screws holding motor pan to side of melt

unit.

b. Heat melt unit and run motor. This centers the motor.

c. With motor running, tighten four screws in a crisscross

pattern.

6. Set hose and tank temperatures to desired settings. Lower

settings increase pot life of the material. Materials degrade

over time due to oxidation.

7. To prevent motor stalling, adjust flow control valve to the

minimum flow requirement.

!

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 14 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 15

6 MAINTENANCE (CONT.)

6.1 Preventive Maintenance

6.1.1 Monthly Inspection Procedure

1. Verify hose is properly supported so it is not over stressed during use. Minimum bend radius is 20.32 cm (8 in.)

when hot.

2. Check tank and hose temperatures and adjust as explained in Sections 5.3.1 and 5.3.2.

* Extra maintenance required for continuous duty machines.

7 TROUBLESHOOTING

Procedure Daily Monthly As Required*

Check for foreign material in tank. X

Wipe off excess sealant from cover. X X X

Purge tank and hoses. X X

Clean applicator nozzle. X X

Check for leaks. X

Problem Solutions

Tank does not heat

1. Turn on main power breaker switch. If switch light fails to illuminate, replace switch.

2. Inspect power-in connections for proper fit.

3. Check for faulty wires.

4. Inspect power wires or power plug at main power source.

5. Check supply voltage to melt unit with voltmeter.

6. Check incoming control voltage to terminal blocks.

7. Check tank controller for proper operation.

8. Compare wire connections to electrical schematic to ensure melt unit is properly wired.

9. If problem persists, check tank heaters as specified under Section 8.6, Tank Heater Replacement.

10. Check incoming power to ensure voltage matches rating of melt unit.

Tank heats slowly

1. Check status of components with a voltmeter (system powered) or ohmmeter

(system un-powered, wires disconnected).

2. Adjust tank temperature controller.

3. If problem persists, check tank heaters as specified under Section 8.6, Tank Heater Replacement.

Tank over

temperature

indicator light on.

1. Check tank temperature when over-temp indicator is lit. If too high, turn tank controller coun-

terclockwise to reduce temperature. If light is on at an acceptable or low tank temperature,

thermostat is faulty or rated at a low temperature. Replace over temperature thermostat.

Handgun and

hose heat slowly.

1. Adjust hose and handgun temperature controllers.

2. Check voltage to hose controller.

3. Verify hose electrical connector is properly connected. If problem persists, refer to Section

8.2, Hose Controller Replacement.

4. Verify proper temperature range of hose controller.

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 15 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 16

7 TROUBLESHOOTING (CONT.)

If troubleshooting attempts fail, contact your factory representative.

Problem Solutions

Handgun and hose

fail to heat.

1. Verify incoming hose power connector is properly installed. Connector wire pins may be

misaligned or loose.

2. If no change, disconnect incoming hose power connector and check hose heater resistance

with ohmmeter. If hose heater has failed, replace hose. Refer to Heated Hose Manual.

3. Determine if applicator is heating by using a pyrometer or temperature sensing device. Do

not touch applicator by hand to determine temperature. Refer to handgun manual.

Adhesive output

too high

1. Decrease system fluid pressure with flow control valve. If no change, remove nozzle and

replace with a smaller orifice nozzle.

2. Decrease hose temperature by 4–10 °C (25–50 °F). If no change, consult your hot melt

material vendor regarding application.

3. Decrease tank temperature by 4 °C (25 °F).

Adhesive output

too low

1. Increase system fluid pressure without stalling motor by adjusting flow control valve.

If no change, remove nozzle and replace with a larger orifice nozzle.

2. Clean applicator nozzle.

3. Purge system.

4. Hot melt formulations tend to be a factor in previously listed problems. Refer to

Section 5.2, Startup Instructions, for cautions.

5. Increase hose temperature by 4–10 °C (25–50 °F). If no change, consult your hot melt

material vendor regarding application.

FHC PRODUCT MANUAL Item No. FHC96

FRAMELESS HARDWARE COMPANYLLC| 4361 Firestone Blvd. Los Angeles, CA 90033| Toll Free: (888) 295-4531Fax: (323) 336-8307| fhc-usa.com

LIT0251 12.01.22

PAGE 16 OF 31

EXPERIENCE AND INNOVATION

GLASS DRILL INSTRUCTION MANUAL

P. 17

8 REPAIR AND REPLACEMENT

Refer to Parts List, in Section 9, for all replacement parts listed in this section.

8.1 Hose Replacement

8.1.1 REMOVAL OF EXISTING HOSE

1. Turn off system power and allow hot melt in tank to completely solidify.

2. Turn system back on for 5 minutes to allow fittings to warm up or heat fitting with a hand-held hot air gun.

3. Turn off system power and disconnect melt unit electrical power.

4. Disconnect hose electrical connector [1].

5. Remove screws [2] from hose mounting block [3]. See illustration below.

6. Tilt unit backward.

7. Loosen hose JIC fitting [4] and remove hose from fitting [5] on flow control block [6].

8. Carefully remove capillary bulb [7] from hose.

CAUTION:

For safe and proper hose replacement, verify all material in the melt tank has completely solidified.

12 SS96 Hot Melt Unit 19600-135 Rev. B 10/26/00

DANGER: To avoid personal injury, follow all

safety labels. Failure to properly operate and

maintain equipment can lead to serious injury.

•Wear protective clothing, safety goggles and

safety gloves. Hot melt materials can cause

severe burns resulting in disfigurement or

blindness.