X20(c)SA4430

4 Data sheet V1.141 X20(c)SA4430 Translation of the original documentation

4 Technical data

Model number X20SA4430 X20cSA4430

Short description

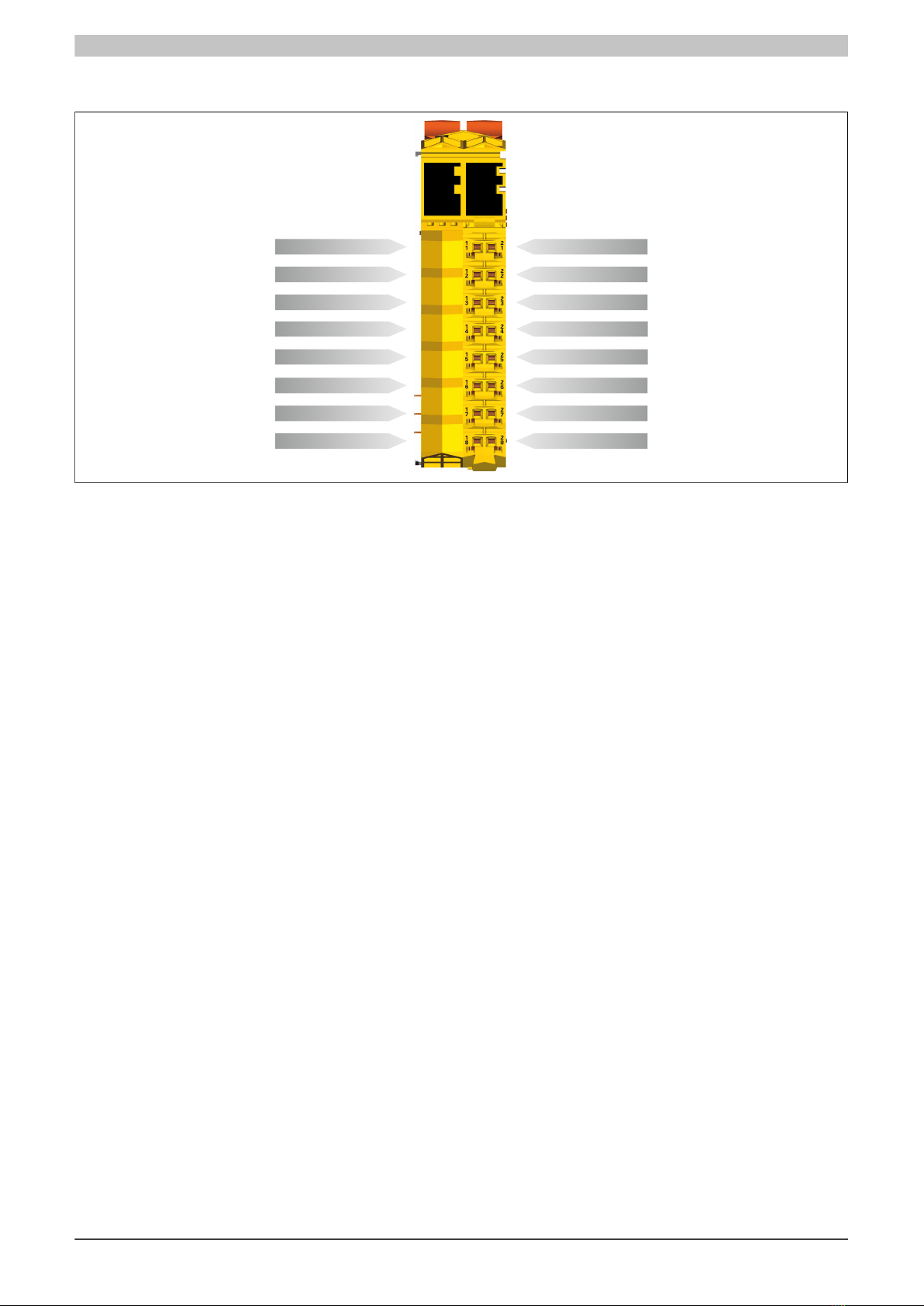

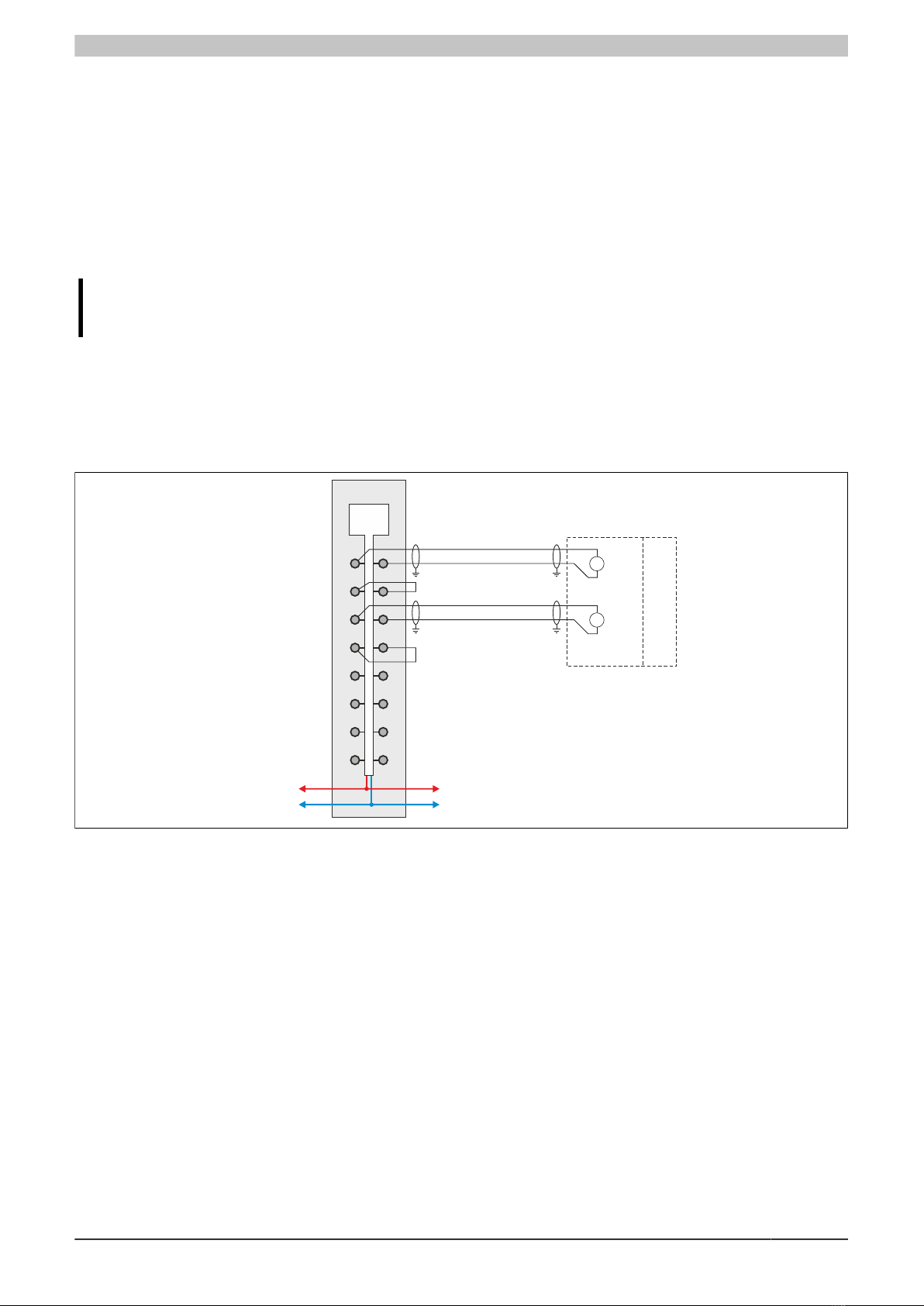

I/O module 2x 2 safe analog inputs, 4 to 20 mA, channels individually galvanically isolated

General information

B&R ID code 0xB8B5 0xDD9F

System requirements

Automation Studio 3.0.81.15 or later 4.0.16 or later

Automation Runtime 3.00 or later V3.08 or later

SafeDESIGNER 2.81 or later 3.1.0 or later

Safety Release 1.4 or later 1.7 or later

Status indicators I/O function per channel, operating state, module status

Diagnostics

Module run/error Yes, using status LED and software

Inputs Yes, using status LED and software

Blackout mode

Scope Module

Function Module function

Standalone mode No

Max. I/O cycle time 2 ms

Power consumption

Bus 0.25 W

Internal I/O 1.7 W

Electrical isolation

Channel - Bus Yes

Channel - Channel Yes

Channel pair - Channel pair Yes

Certifications

CE Yes

KC Yes -

EAC Yes -

UL cULus E115267

Industrial control equipment

HazLoc cCSAus 244665

Process control equipment

for hazardous locations

Class I, Division 2, Groups ABCD, T5

ATEX Zone 2, II 3G Ex nA nC IIA T5 Gc

IP20, Ta (see X20 user's manual)

FTZÚ 09 ATEX 0083X

DNV GL Temperature: A (0 - 45°C)

Humidity: B (up to 100%)

Vibration: A (0.7 g)

EMC: B (bridge and open deck)

Functional safety cULus FSPC E361559

Energy and industrial systems

Certified for functional safety

ANSI UL 1998:2013

Functional safety IEC 61508:2010, SIL 3

EN 62061:2013, SIL 3

EN ISO 13849-1:2015, Cat. 4 / PL e

IEC 61511:2004, SIL 3

Functional safety EN 50156-1:2004

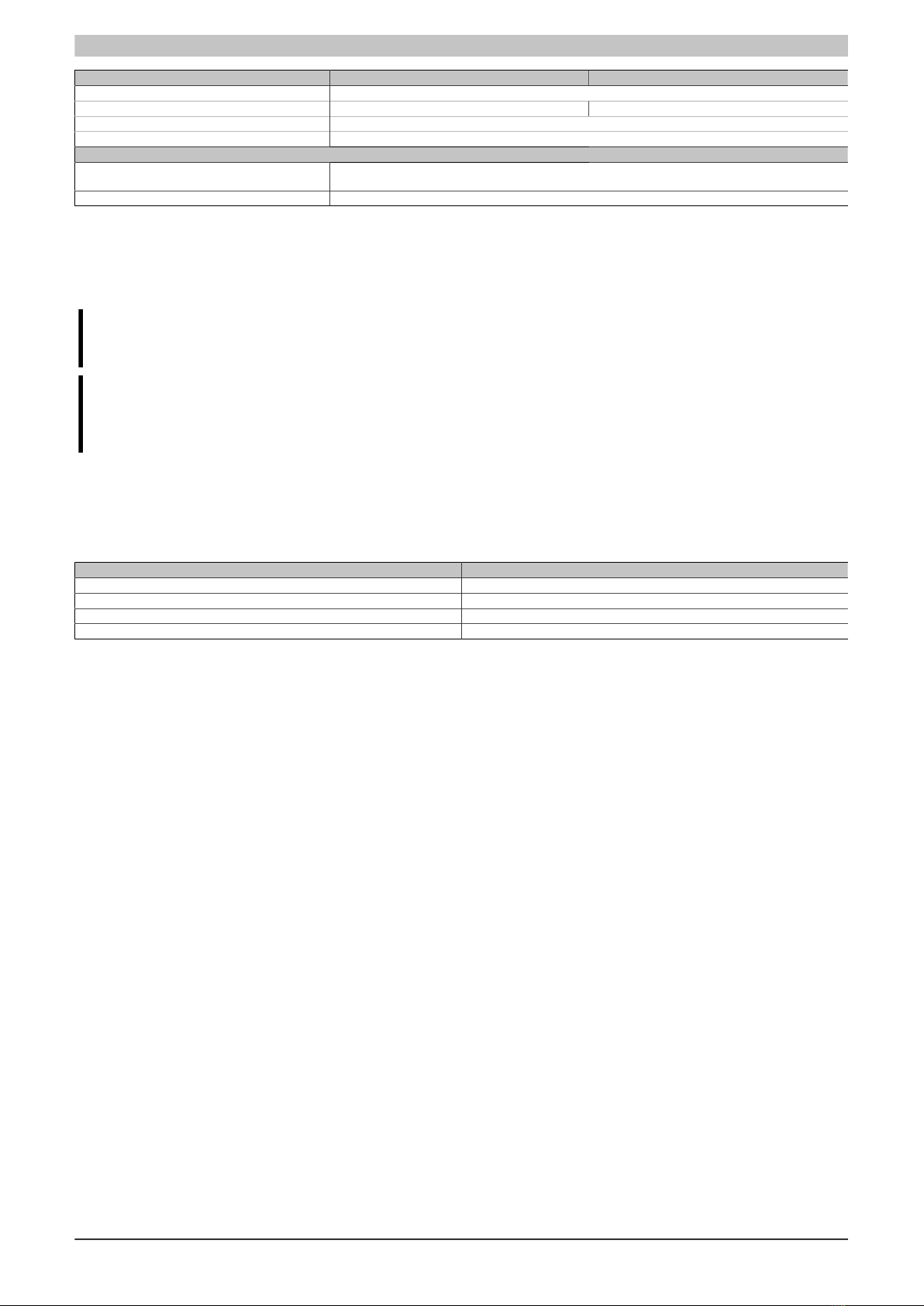

Safety characteristics

Note The following characteristic values apply only to the use of input channel pairs.

Assessing the channels from a safety point of view when they are used individually is not possible. 1)

EN ISO 13849-1:2015

Category Cat. 4 (SHUNTTEST enabled), Cat. 3 (SHUNTTEST disabled)

PL PL e (SHUNTTEST enabled), PL d (SHUNTTEST disabled)

DC >94% (regardless of whether SHUNTTEST is enabled or disabled)

MTTFD 2200 years (regardless of whether SHUNTTEST is enabled or disabled)

Mission time Max. 20 years

IEC 61508:2010,

IEC 61511:2004,

EN 62061:2013

SIL CL SIL 3 (regardless of whether SHUNTTEST is enabled or disabled)

SFF >90% (regardless of whether SHUNTTEST is enabled or disabled)

PFH / PFHd

Module <1*10-9 (regardless of whether SHUNTTEST is enabled or disabled)

openSAFETY wired Negligible

openSAFETY wireless <1*10-14 * Number of openSAFETY packets per hour

PFD <1*10-4 (regardless of whether SHUNTTEST is enabled or disabled)

Proof test interval (PT) 20 years

Table 5: X20SA4430, X20cSA4430 - Technical data