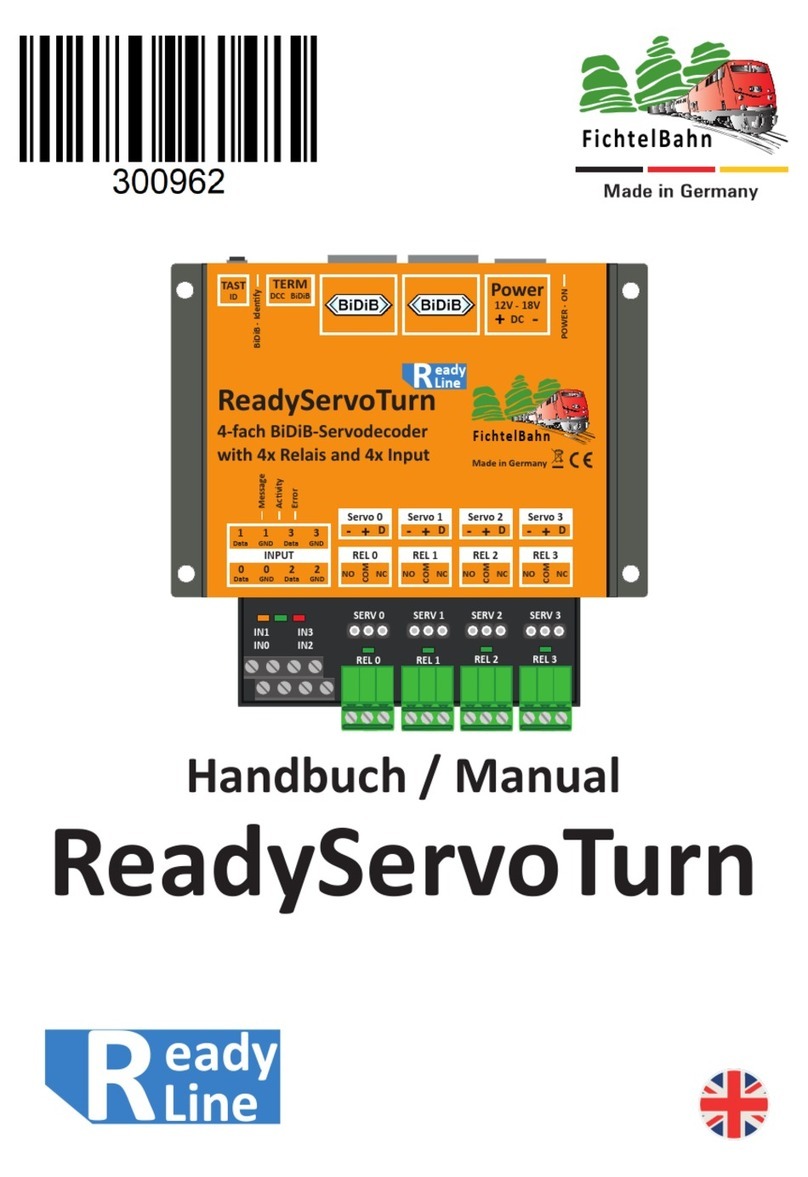

Fichtelbahn OpenDCC BiDiB LightControl V1.3 User manual

LightControl V1.3

„Manual for SMD pre fitted kit”

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 1

Table of contents

Introduction......................................................................................................... 3

1. LightControl: .................................................................................................... 7

2. Construction description of the SMD equipped board:..................................... 9

Step 1: the power supply............................................................................................................................ 9

step 2: „function test bootloader“ ........................................................................................................... 10

Step 3: BiDiB-interface ............................................................................................................................. 10

step 4: 16 Power outputs and 8 inputs ..................................................................................................... 11

step 5: 32x LED-outputs: ........................................................................................................................... 11

step 6: 4x servo-outputs:........................................................................................................................... 12

3. The firmware update...................................................................................... 13

3.1 Approach with the firmware update............................................................................................. 13

4. Status announcements................................................................................... 15

5. References ..................................................................................................... 17

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 2

Introduction

These instructions refer to the BiDiB / DCC decoder "LightControl " from OpenDCC and Fichtelbahn.

The decoder gets on not as a commercial ready product, but is a development aid or kit for technically interested

railroad modeler for the own construction.

Here once again a clear tip:

The decoder and these instructions were checked carefully and provided after the best knowledge. For the

information presented here no claim to completeness, actuality, quality and correctness is raised. No responsibility for

the damages which originate from the trust in the contents of these instructions, to the decoder or their use can be

taken over.

The software of the decoder can be downloaded on our Internet site , may be extended by everybody uses, and be

improved.

A commercial use of the software or parts from it are not permitted!

Warranty

The use of this manual is permitted only for the reproduction and the personal use of the described stone. An other use

needs the written approval of the author.

For the reproduction and its functions of the described stone the author assumes no liability.

The operator is responsible for the observance of existing regulations and the regular use of the product alone.

Reference:

RailCom® and RailComPlus® are regisrtered trademarks

of Lenz Elektronik GmbH and

ESU electronic Solutions Ulm GmbH & Co. KG.

for the rise of the legibility of the text have we refuses to refer by every use of the concept to it.

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 3

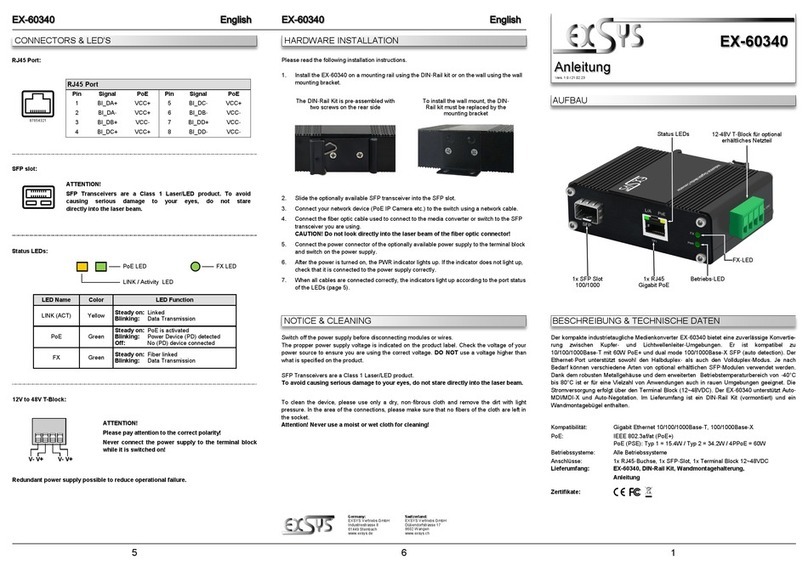

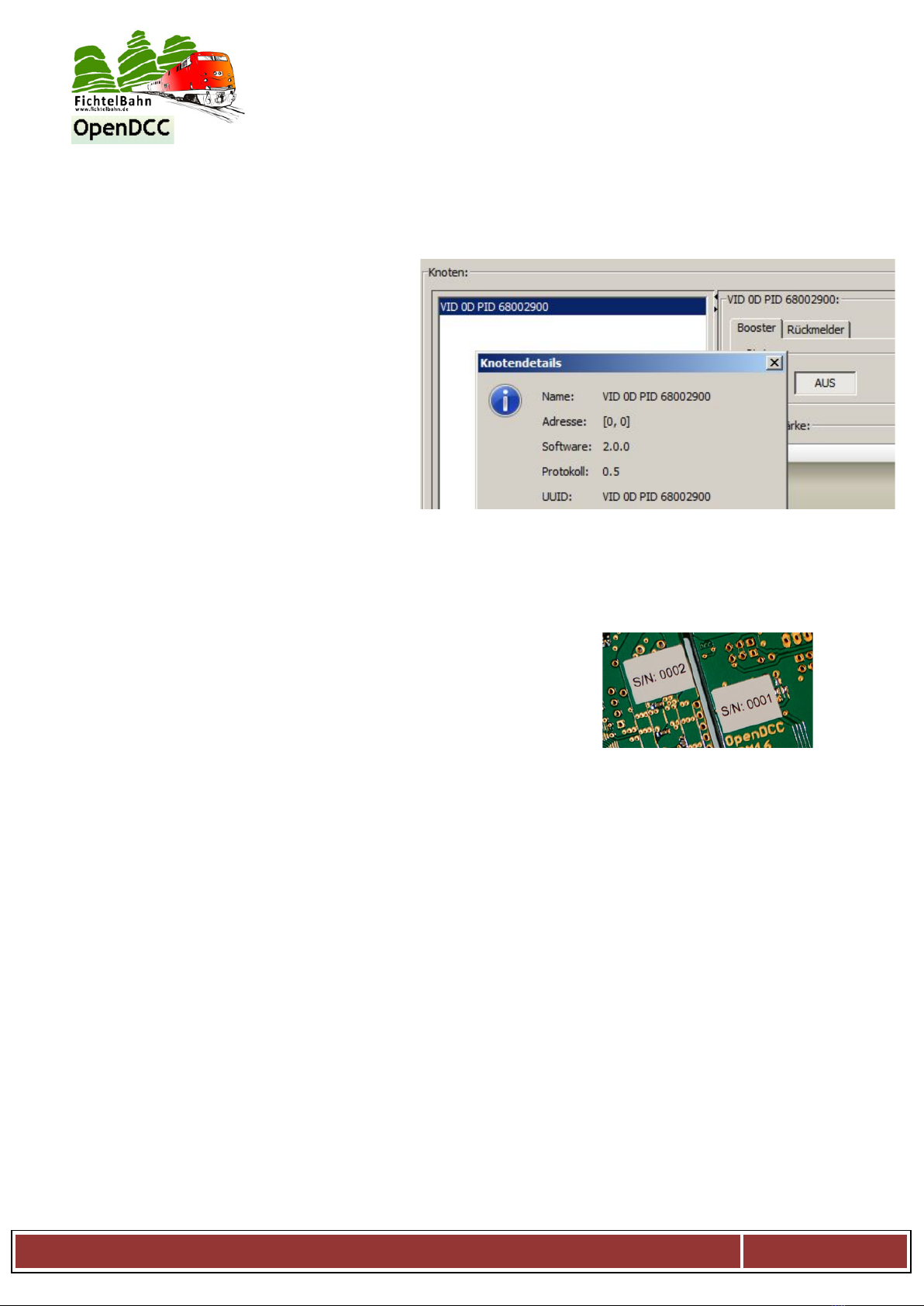

Interesting facts to the BiDiB-Seriennummer / Unique-ID

The picture shows a Unique-ID on a BiDiBus

Device.

All SMD equipped BiDiB assemblies bought from the

Fichtelbahn shop and are on the BiDiBus will be

delivered with an installed BiDiB-serialnumber. This

srialnumber is part of the unique-ID and therefore the

complete unique ID is printed at the back side of the

cuircuit.

What is the Unique-ID?

The from the manufacturer in the kit hard programmed, unequivocal ID, consisting of 16 Bit vendor ID and

32 Bit vendor specific number (e.t. produktindex and serialnumber).

V= VID (Vendor ID)

OD = Do it your self projects

P= PID (product ID)

6800 = GBMboost Master

6700 = GBMboost Node

6B00 = LightControl

0029 becomes to 2900 = serialnumber

The data of the Unique-ID are in HEX.

For what serves the Unique ID?

The Unique-ID is an absolutely unique number, with this number an assembly is found regardless of its

installation place and its place in the bus.

That means: The BiDiB system leads a sort of 'phone book', under which connection which assembly can

be reached. Then the hostprogram awards names for the single connections. The Unique-ID is here the

connector between the name in the PC and the assembly.

Example:

A LightControl is omounted under the railway station and has the Unique-ID 0D 6B001234. In the

Hostprogramm it is called central station west. The BiDiB system announces to the Hostprogramm:

0D6B001234 you find under connection 3. If one moves something now in central station west, the

Hostprogramm looks in the phone book: ah, I should call 3.

You have normally nothing more to do with addresses and dip switches.

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 4

Why should I stick on this number?

For what could I use this information?

All tools, however, also the actual PC-

hostprogramms communicate and

administer the assemblies with this

number. Now there is no more "address

DCC XX", but the cmmand is sent into the

knots *Unique-ID X* and his port.

The reverse is that for the configuration of

a new action at the output of a decoder

(e.g., LightControl) or the allocation of a

dispatch rider in the rail picture (e.g.,

GBM), the program must be informed

about the suitable Unique-ID of the BiDiB

assembly.

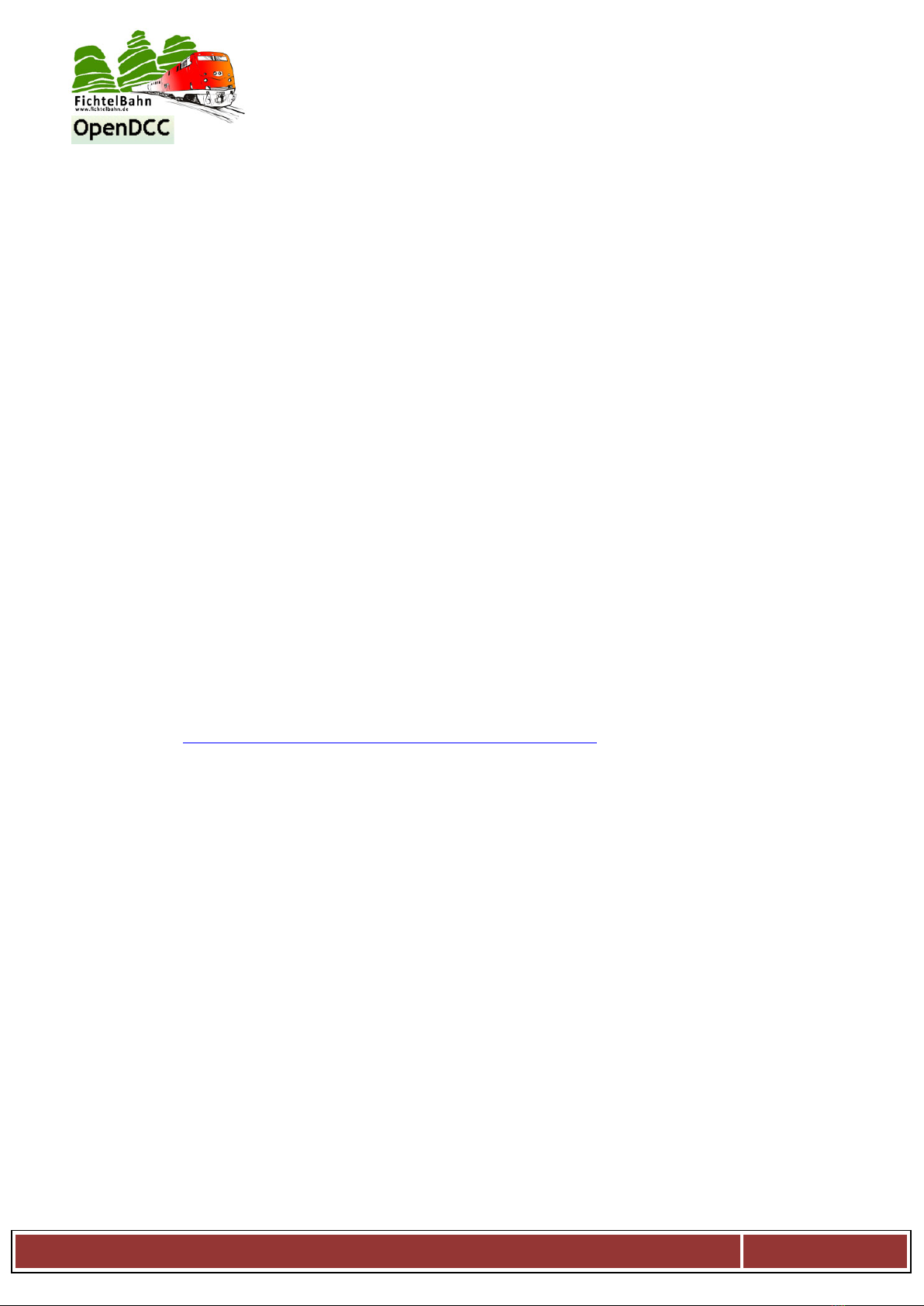

Hardware-serialnumber:

The stuck serialnumber with S/N at the back of the assembly is a hardware-

serialnumber and nothing deals with the Unique-ID serialnumber for the

BiDiB assemblies. With this number your assembly is registered with us.

Where is the Unique-ID stored on the assembly?

Here the procedure is bipartite a little bit. In the Flash/EEPROM-firmware file the VID and PID are already

integrated and are transmitted to the sassembly, however, no serialnumber is included. Hence, the

firmware files can be loaded easily in the processor or can be also updated. Besides, an already available

serialnumber will not be overwritten. If the sassembly still recognises no loaded serialnumber while

starting, a error code flashes and the use of the assembly is blocked.

Without serialnumber the firmware does not run!

(Exception with the master GBMboost: here a Notfall-S/N is generated with the sign: 0100. These S/N can

be overwritten any time with the upload of the valid S/N)

The serialnumber is always postpushed as the third act of the introduction and lands as first in the

EEPROM of the assembly.

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 5

By every new start the appliance explains the following examination:

He looks in the user signature area whether already a serialnumber exists.

If no serialnumber is available here the serialnumber from the EEPROM is filed and the assembly begins

starts to work. If there is in the USERS signature area already a serialnumber available the new-struck up

serialnumber is rejected by the EEPROM and the already deposited serialnumber from the user signature

area is used.

The deposited serialnumber in the USER signature area is also preserved with a CHIP ERASE and can be

deleted only with a USER signature ERASE.

If you must change the serialnumber on a BiDiBus suited Device, it works only with a previous USER

signature ERASE.

However, this also entails that available calibration values get lost because these are also stored in this area.

This should not be done without a special reason.

I have deleted the printed serialnumber by mistake.

How can this be uploaded again?

1. You load a new serialnumber with the generator and upload this after deleting the USER signature area

to the BiDiBus Device.

Importantly: Now do not forget to replace the existing sticker by the new Unique-ID. Link to to the

generator: http://www.opendcc.de/elektronik/bidib/opendcc_bidib.html

2. You want to use the available (printed) Unique-ID again because it was already deposited in the rail

trackplans of my PC programms.

In this case contact Fichtelbahn-Support with the information of the printed Unique-ID number and

the accompanying hardware-serialnumber.

This works only with preequipped SMD kits! With independently loaded serialnumbers you must look in

the history of your loaded serialnumbers in the generator, for the suitable number.

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 6

1. LightControl:

a. electrical parameters / functions

- Switch regulator with 3A source management

- 16 freely programmable switch exits with 300 mA each

-32 LED exits with adjustable stream spring and brightness regulation about PWM

- 4 Servo outputs, electricity supply of the Servo switchable

-8 universally Inputs

- BiDiBus- interface

-Universal port for USB (FTDI)

- Board size: 80mm x 100mm

b. partlist

base version:

(power supply, processor and system parts):

1x L1 SLF12575 33µH SMD-coil

1x D9 SSA33L SMD-diode

2x C37, C38 15pF / 0603 SMD-capacitor

4x D60, D70,

D80, D90 1N4007 rectifier diode

4x LED5-LED8 LED-0603 yellow, red, green LED

1x RN8 BCN16 1,0kOhm SMD-Parallelwiderstand

14x C3,C6,C16,C17

C24,C25,C34

C35,C27-C32 100nF / 0603 SMD-capacitor

1x C4 470µF/ 25V Panasonic_G electrolytic capacitor

1x C8 220µF/ 10V Panasonic_D electrolytic capacitor

1x C5 220µF/ 10V Panasonic_D electrolytic capacitor

1x C33 220µF/ 10V Panasonic_D electrolytic capacitor

1x IC1 LM2596DSADJR4G switching regulator 3A

1x IC4 LP2951CMX-3.3 voltage regulator 3,3V

1x IC7 ATXMEGA128A1Umicrocontroller

1x Q1 HC49-SMD 8MHz quartz

1x F1 1812L PTC Sicherung PTC fuse

1x S1 Taster 9314 SMD -button

1x Jumper 2,54 SW Jumper

1x SL 1x36G 2,54 pin row

1x X2 AKL055-03 terminal strip 3pole

1x R37 1,1kOhm 0805 SMD-resistor

1x R38 3,3kOhm 0805 SMD-resistor

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 7

upgrade servo:

1x R24 10kOhm 0603 SMD-resistor

1x RN5 BCN16 1,0kOhm SMD-parallel resistor

1x RN3 BCN16 100Ohm SMD-parallel resistor

1x R5 1Ohm 1206 resistor

1x C19 220µF/ 10V Panasonic_D electrolytic capacitor

4x C1, C2, C7, C9 47µF / 6 1206 capacitor

1x C14 100nF / 0603 SMD-capacitor

1x IC8 74VHCT 541D buffer

4x Q2, Q4, Q5, Q6 IRLML 5203 MosFet-transistor

1x JP9 Jumper jumper

1x SL 1x20G 2,54 pin row

upgrade power-output:

2x IC2, IC6 ULN2803 driver

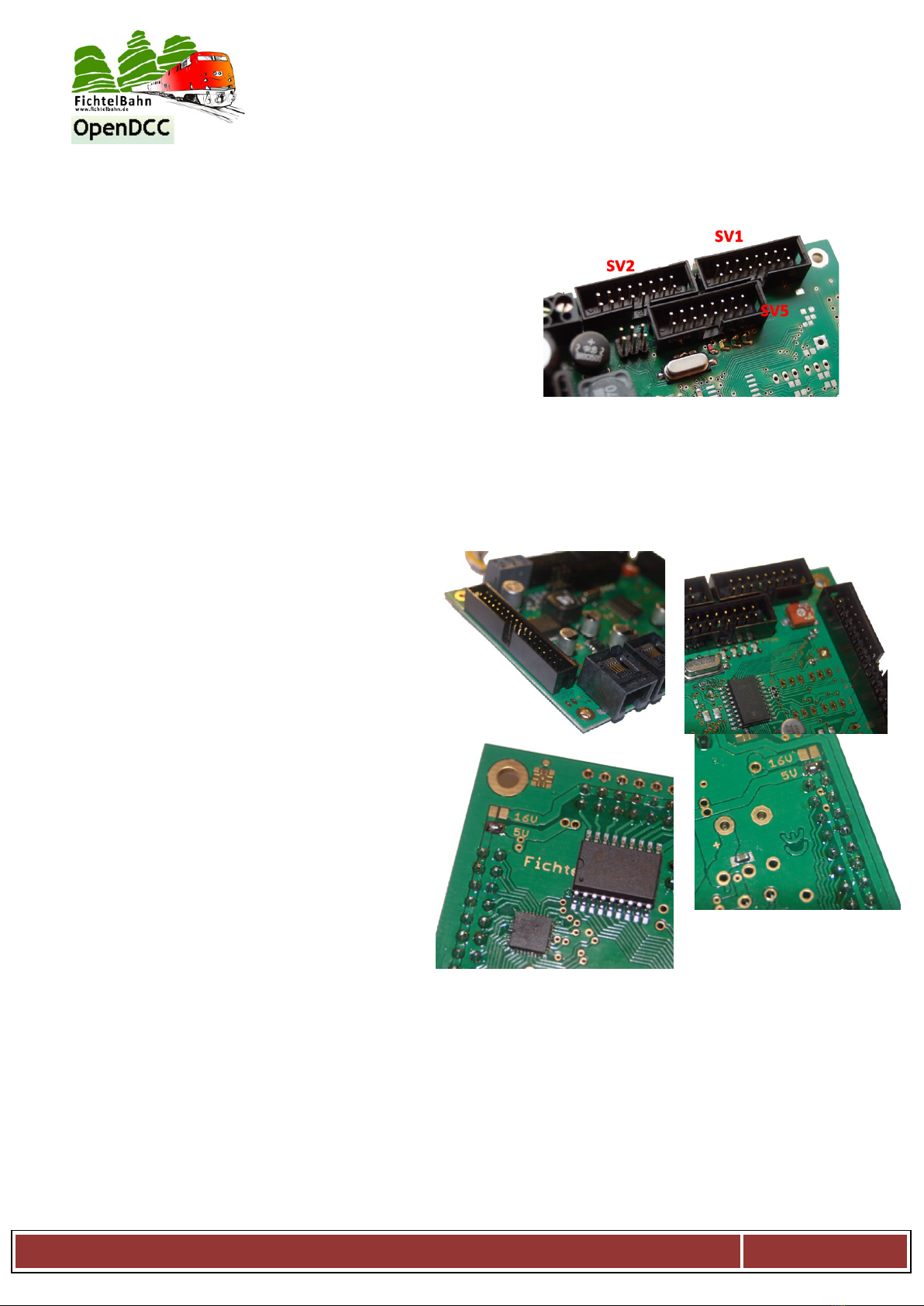

2x SV1, SV2 WSL16G Wannenstecker 16pol

upgrade LED-output:

2x R34, R36 10k Poti SMD SMD-Poti

2x U$1, U$2 TLC5941 LED-driver

2x R33, R35 1kOhm 0603 SMD-resistor

2x C22, C23 100nF 0603 SMD-capacitor

2x SV3, SV4 WSL 34G Wannenstecker 32pol

upgrade input:

1x SV5 WSL16G Wannenstecker 16polig

2x RN1, RN2 BCN16 1,0kOhm SMD-parallel resistor

upgrade BiDiB-interface:

2x X8, X9 MEBP 8-8G RJ45 socket

1x IC5 ISL83075EIBZA Transceiver

2x R7 10kOhm 0805 SMD-resistor

1x C10 100nF 0805 SMD-capacitor

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 8

2. Construction description of the SMD equipped board:

For the construction of the SMD of equipped board is not necessary much.

A soldering iron, with fine soldering tip, tin-solder and an ohm metre.

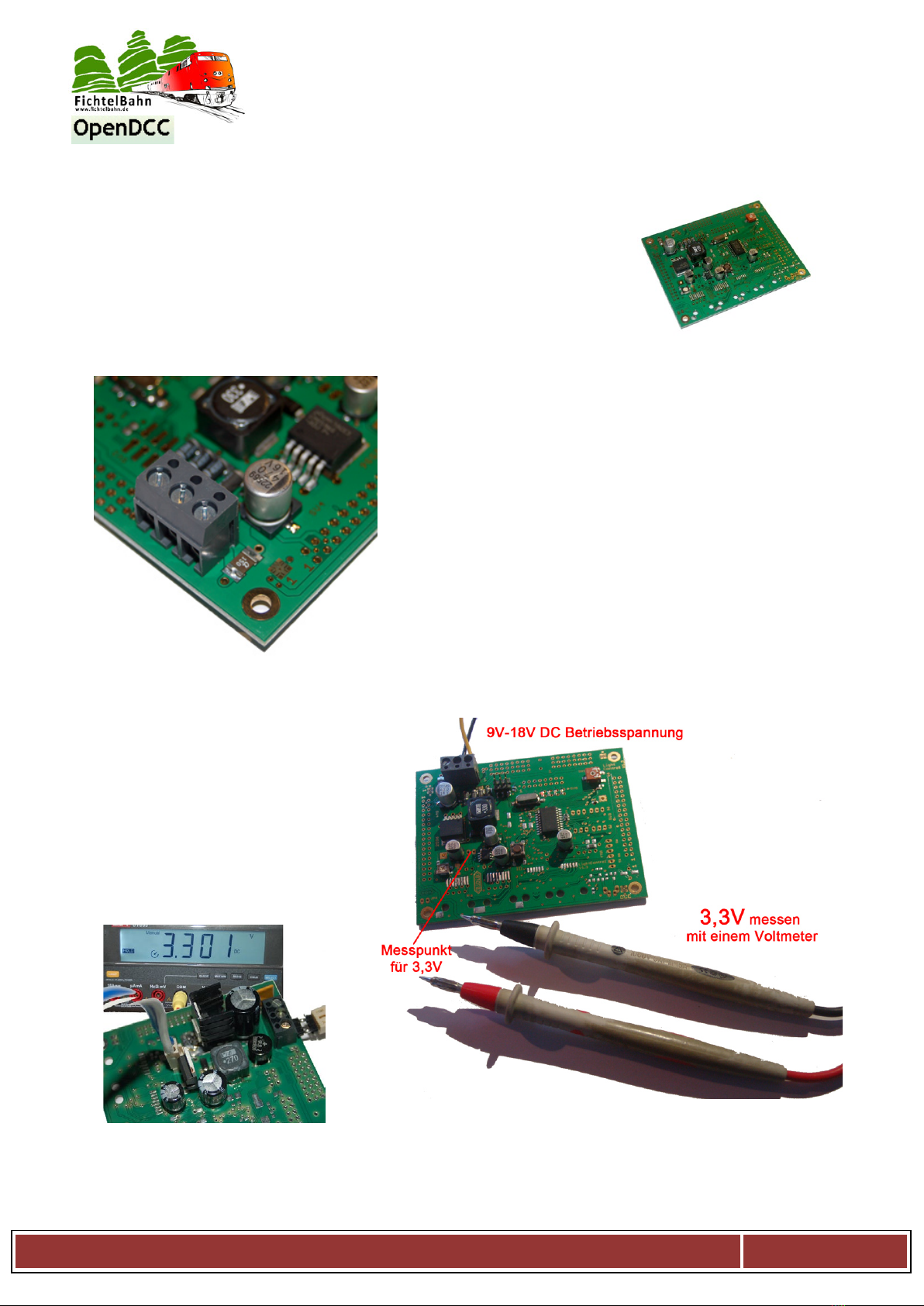

Step 1: the power supply

As the first we equip on the top of the board the 3-pole

connection clip X2.

With supply of the LightControl about an external source

(recommended) both solder jumpers SJ6 and SJ7 stay open. If the LC

about the tension DCC the both solder jumpers must be closed and X2

not equipped..

The LightControl can be supplied with DC voltage and AC voltage with

the help of the rectifier the suitable polarity always lies with the switch

regulator. Even if you supply the module with a DC voltage the rectifier

equipped remain, therefore receive a polarity protection.

important:Pay attention with this variation to the right polarity in the

clip X2 (X2-2 und X2-3).

The power supply for the light control is ready.

Check:

To test, the 3,3V a pin row can be

soldered at position J11. Now

3.3 V should be measurable here!

Follow the next section only

with successful tension

measurement!!

This picture has an insertion divergence, however, shows the measuring result!

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 9

step 2: „function test bootloader“

Switch on the LightControl (apply voltage) and afterwards you

press the button. Now the first red light-emitting diode must

shine!!

With this the micro controller unit is operational!

In the following steps the single functional exits are equipped:

comunication interfaces:

•BIDIB

functions:

•Inputs for internal functions and position indicators

•16x Power outputs for effects and magnetic

components

•4x servo-outputs

•32x LED-outputs

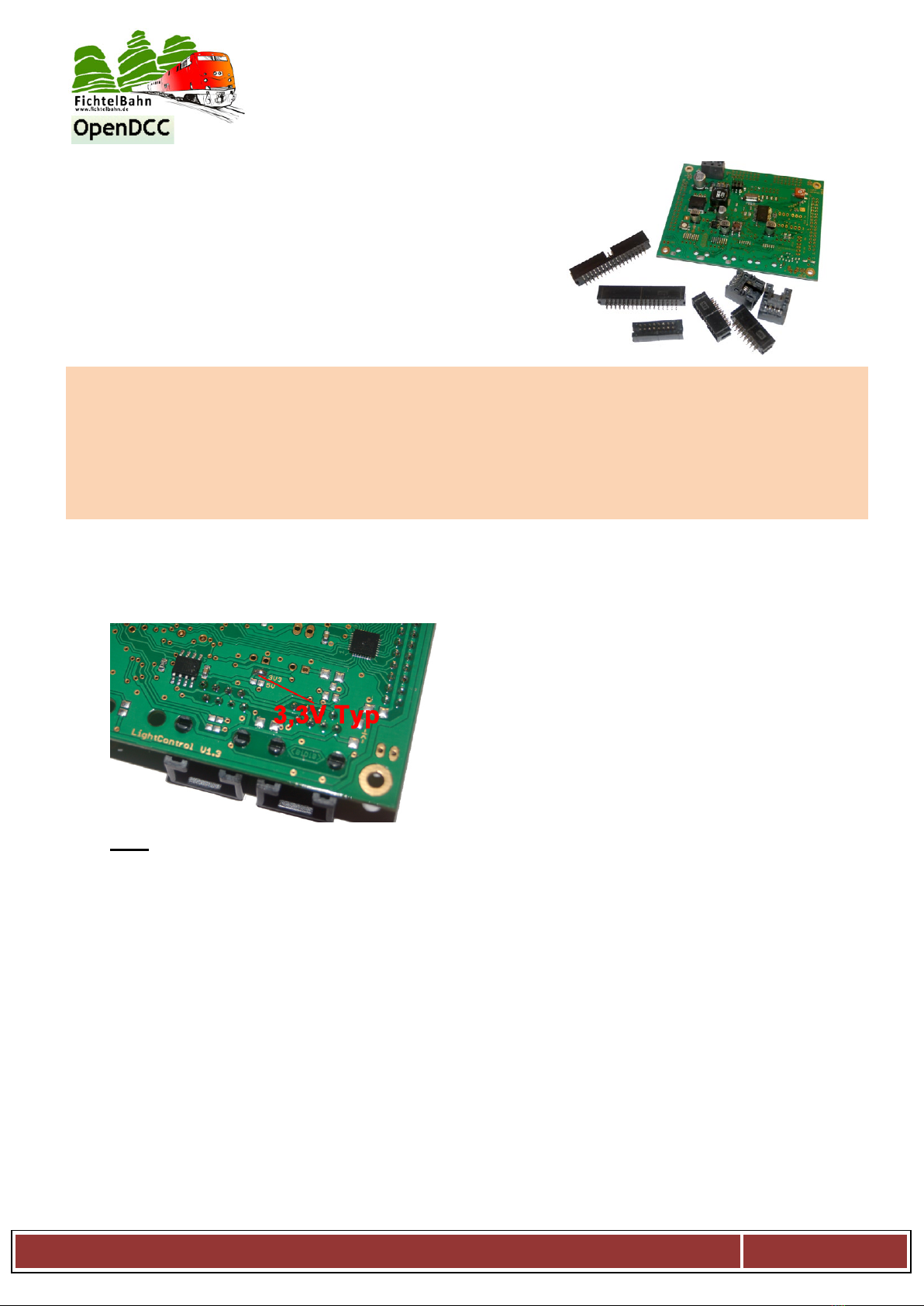

Step 3: BiDiB-interface

The BiDiB interface for adressless communication

consists of an RS-485 Transceiver.

important:

According to built-in RS-485 Transceiver both solder jumpers

must be closed differently.

In the SMD equipped version 3.3 V type is used!!

3,3V:

R10 (3,3V labeled) closed and R11 (5V labeled) open a ISL83075EIBZA is used

Both RJ45 sockets X8 and X9 are on the top the board. The board is prepared for a SMD or for a DIL

version. These both RJ45 sockets must be still equipped.

advice:

With a Hotplug function or an extensive BiDiBus wiring (e.g., gymnasium) we recommend one more

protective diode SM712 with to equip (not inevitably by small arrangements).

(available at the Fichtelbahn-Shop)

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 10

step 4: 16 Power outputs and 8 inputs

These 16 exits are suited for lighting effects with light bulbs,

also switch from bigger load max. to 300 mA per output or

for magnet articles.

For this the tub plugs SV2 and SV1 must be soldered for the

power outputs and SV5 for 8 inputs.

Please, follow the right installation direction

(see photo). With the tub plugs SV2 and SV1 the outer bore

row remains free!

step 5: 32x LED-outputs:

These 32 LED-outputs can be used for signal signs also for lighning effects.

With both Potis R34 and R36 you can change

the basic brightness of the respective driver

(power source).

The light-emitting diodes are connected in the

tub plugs SV3 and SV4. These must be still

soldered, besides, follow the right installation

direction (see photo)

Beside the tub plugs (bottom side) there are

still the solder jumpers SJ10, SJ11, SJ12

and SJ13, with it you can determine the

supply voltage for the LED.

We recommend for a supply without

dropping resistor 5 V of potential.

With several light-emitting diodes in row

per exit one needs 16 V variation.

Here the LEDs should be used with

dropping resistor.

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 11

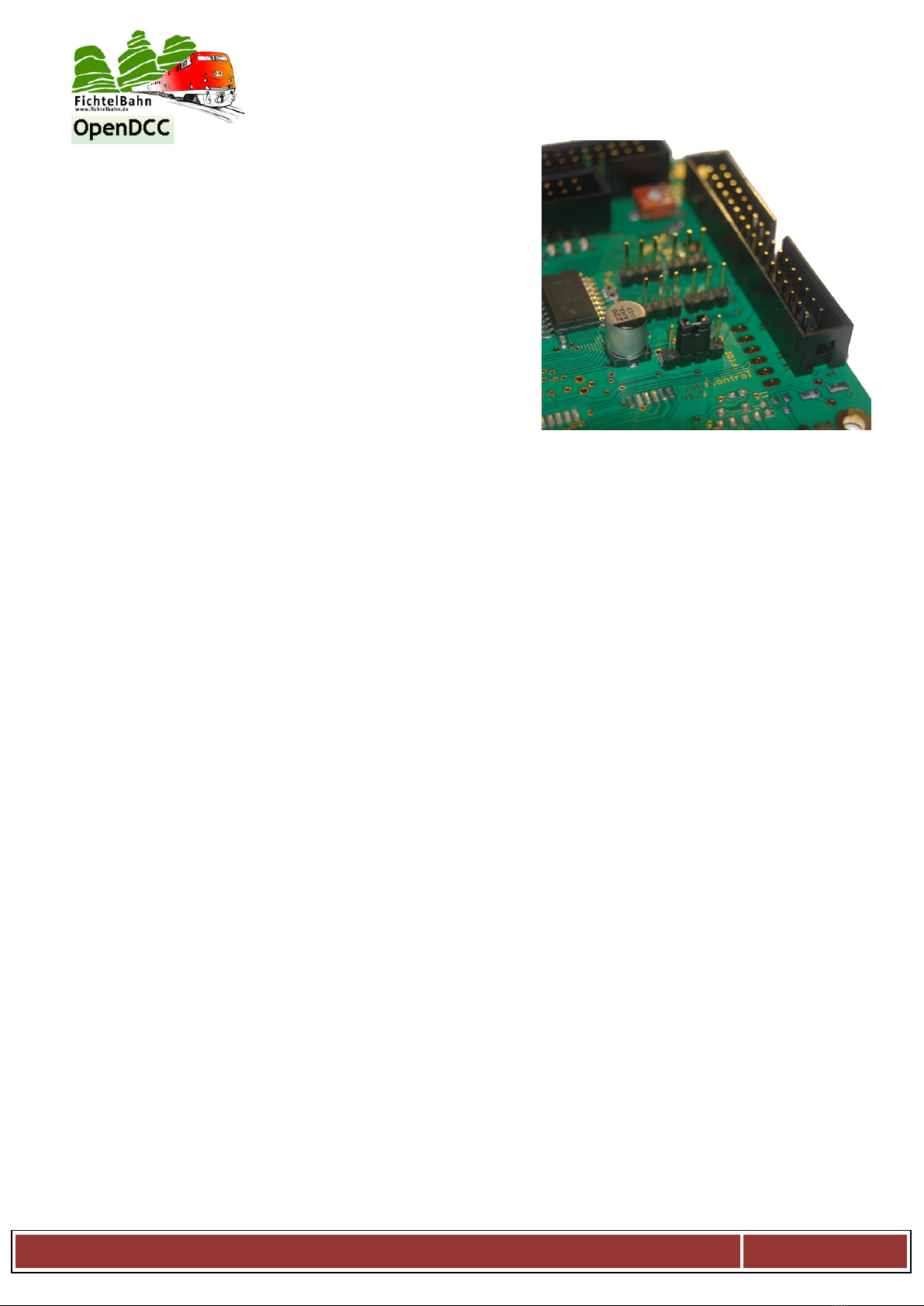

step 6: 4x servo-outputs:

The 4 servo ports can be used for raiload effects also for

servo railroad switches.

To the usage of this function still five pin headers JP3, JP4,

JP5, JP6 and JP9 / J12 must be equipped on the top.

CAUTION: Short circuit danger:

With JP9 / JP12 5 V of Servo care can be impaled

externally or 5 V of supply be measured. For internal 5 V of

Servo supply the Pins 2 and 3 must be connected by a

jumper.

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 12

3. The firmware update

With the SMD equipped LightControl we have this already done for you! The LightControl is

completely ready for use with the actual Bootloader, the actual firmware and the printed

serialnumber.

The chapter „firmware update“ describes only the steps for the case of an update if a new firmware

is available for the LightControl!

In other cases (first introduction if still no firmware was uploaded)please read the programming

steps in the construction instructions of the soldering kit.

3.1 Approach with the firmware update

The LightControl can become beside the

Programmer also directly flashed with the BiDiB-

Wizard tool. This function should be also used at

a firmware update.

The advantage is:

The LightControl can be updated in the built-in

state with the tool, you also speaks of a distant

servicing.

In the knot list of the BiDiB-Wizard tool you find

your LightControl and all other BiDiB

components, for configuration or for a firmware

update.

Download the actual firmware for the

LightControl from our web page and ectract the

ZIP file on your PC.

Tip:

Use with an update only the file with the name:

lightcontrol_update…000.hex

With this all macro and settings remain you

have configured on the LightControl preserved

and are not overwritten by Default values

.

You must transfer only this file to the LightControl with the BiDiB-Wizard tool.

Both other files are the firmware files for the first introduction. By use your stored settings with the Default

values are overwritten (default settings).

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 13

Step 1:

The LightControl is connected to the care tension and is

also connected to the BiDiBus.

Step 2:

Open the BiDiB-Wizard tool and in the knot list the

serialnumber of the interface (master GBMboost) and

the LightControl should be visible.

Step 3:

With the right mouse key click on the serialnumber of

the LightControl and select in the pop-up menu the

action”Firmware Update”.

Step 4:

In the last step the folder must be selected in which the firmware file lightcontrol_update_xxxxxx.000.hex

is stored and this must be transferredWith close of the window the LightControl is updated to the new

firmware and is ready for operation.

Tip:

With an update of the LightControl only the special marked update ….001.hex file shoul be used,

otherwise all macro and port settings on the LightControl get lost. (default settings)

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 14

Bootloader

button S1 pressed?

yes

Demo-Jumper inserted?

no

Application forward

yes

FTDI Bootloader

no

BiDiB Bootloader

4. Status announcements

Demo-jumper:

The LightControl has a TEST SELF or DEMO with its activation all ports a run

light spend. With this function all ports of the LightControl can be tested.

Preparation:

Close the 2pole pin row JP2 with a Jumper.

Approach:

Connect the Lightcontrol to yout power

supply and connect the LED and Power

outputs to a luminous-medium. When closing

the DEMO Jumper. With close of the jumper

"DEMO jumper " a run light is given

regardless of the stored macros to the power

and LED exits.

So you can detect defect ports..

also EXTRA:

If you close one of the 8 inputs one of the power exits shines independent of the run light permanently up

to again open of the input. so you can also test the functionally of the inputs.

Important:

Don´t forget to open the „DEMO Jumper“ after the test, before you transfer a macro to the Lightcontrol.

Otherwise the DEMO mode macro will be deleted.

Key combination for Bootloader:

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 15

Errorcodes and statusleds:

red LED shines

LC is in Bootloader Mode

all LED´s flashing

LC has no EEPROM-File loaded

Yellow and green

LED flashing

LC has no serialnumber loaded

first green LED

shimmers

LC is ready

First green LED

shimmers, second

green LED shined

LC is ready and connected to BiDiB

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 16

5. References

The continuing instructions "introduction and use" deal with the following main

topics:

- Introduction

- Functionality of the macros

- Configutariontool "BiDiB-Wizard Tool"

- Debuginterface

- Application in connection with railroad software

- Firmware update

I am very grateful for improvement suggestions and tips to mistakes.

On the construction manual or any software there is no liability for any damages or functional guarantee.

I do not guarantee for damages which cause the user or third parties by the use of the software or hardware

or suffer. In no case I guarantee for escaped turnover or profit or other property damages by the use or by

the use of these programmes or instructions can originate.

With further inquiries our Support forum is available to you with pleasure!

(www.opendcc.de/forum)

contact:

fichtelbahn.de

Christoph Schörner

Ahornstraße 7

D-91245 Simmelsdorf

support@fichtelbahn.de

© 2014 Fichtelbahn

All rights, in particular the right of her

Duplication and spreading as well as

of the translation reserve.

Duplications and reproductions

in any form need her

written approval by Fichtelbahn.

Technical changes reserve.

Manual to build the SMD pre fitted Hardware manual-Version V1.4-en

page 17

Table of contents

Other Fichtelbahn Media Converter manuals