18 4222V101-UK

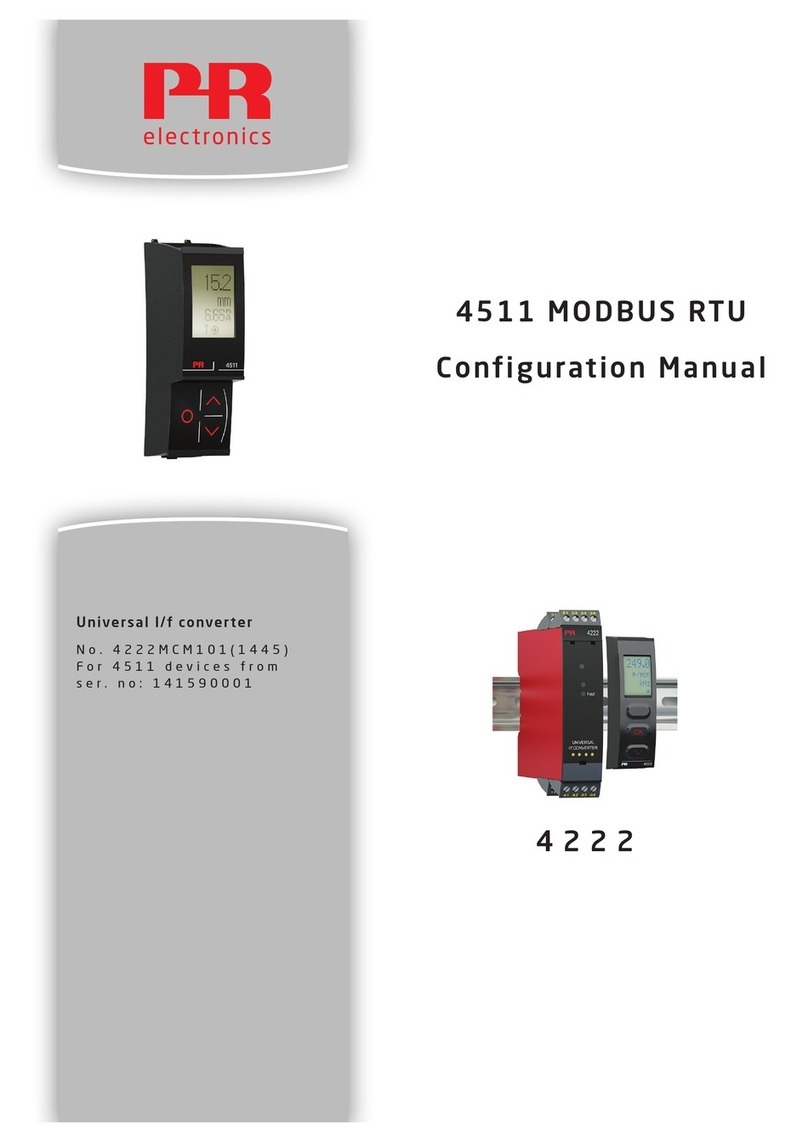

Configuration / operating the function keys

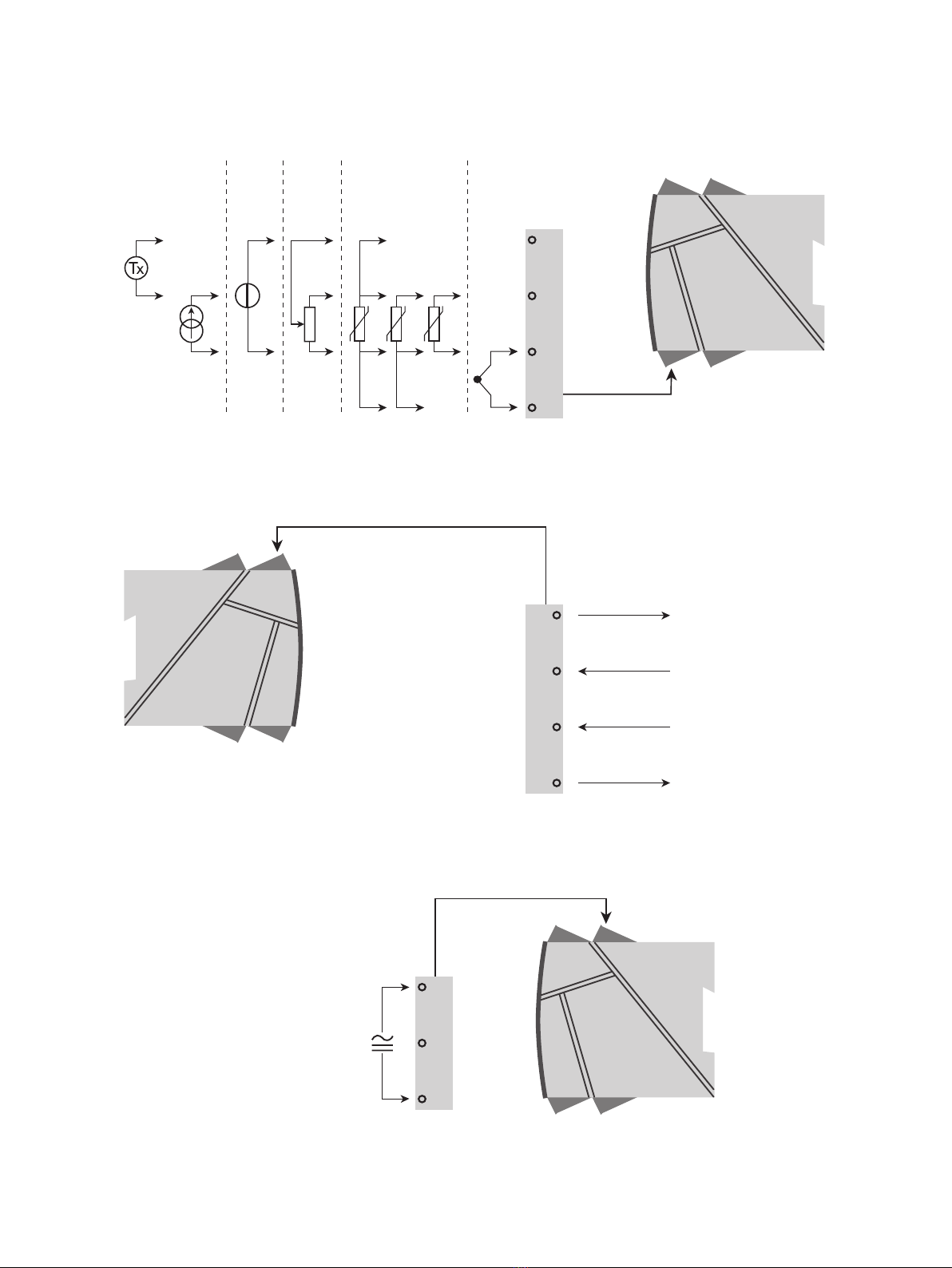

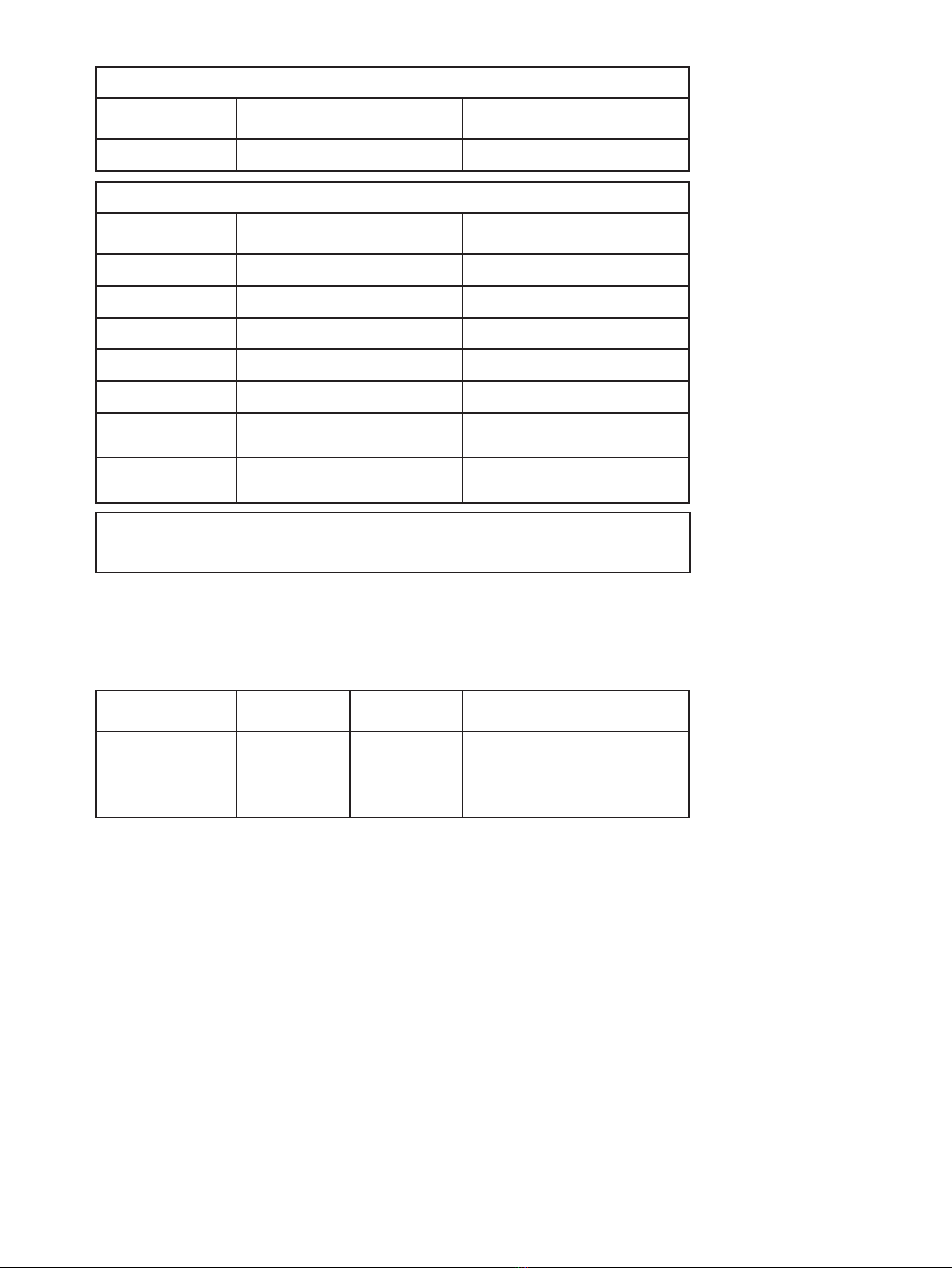

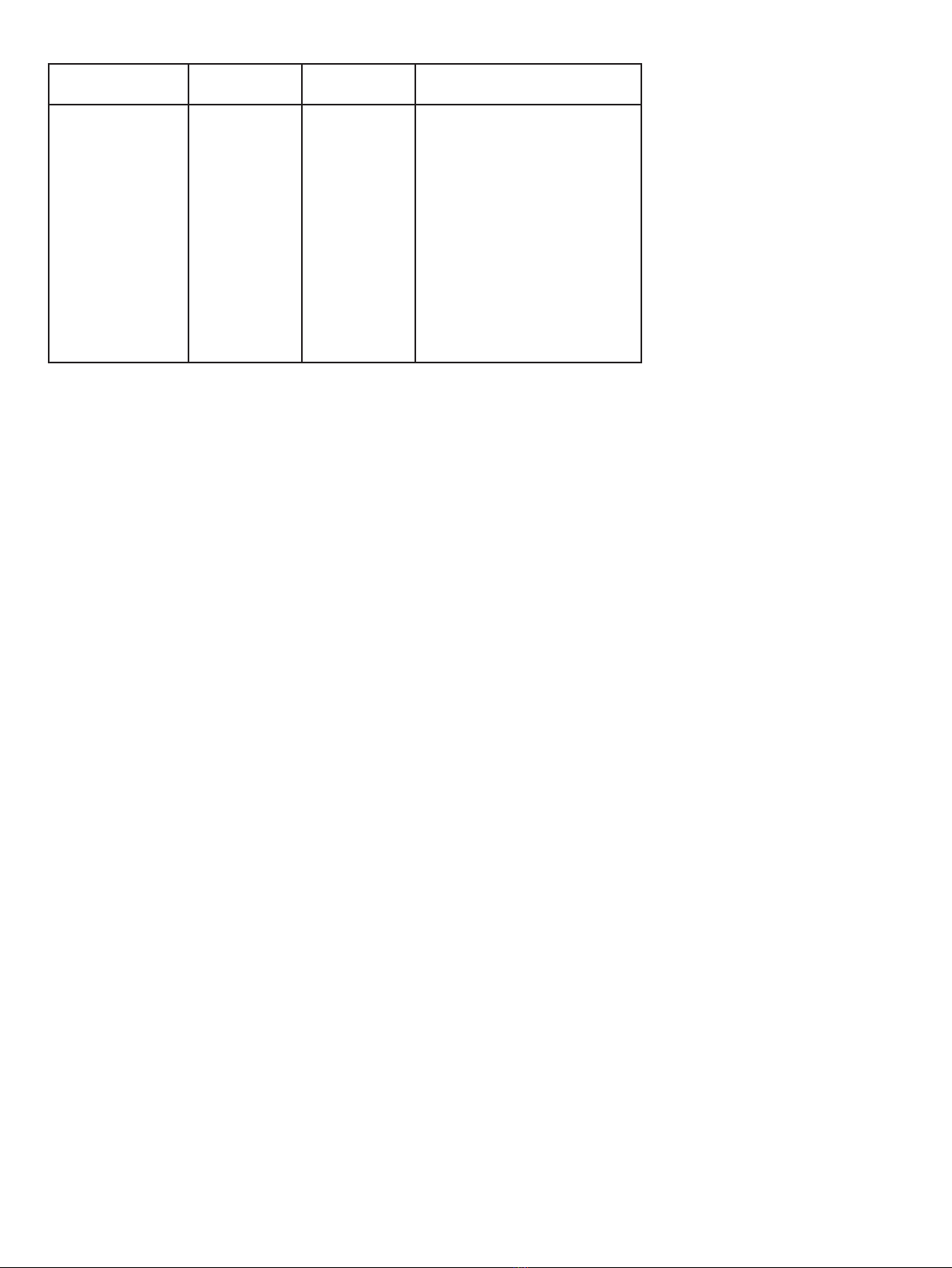

Documentation for routing diagram.

In general

When configuring the 4222, you will be guided through all parameters and you can choose the settings which fit the

application. For each menu there is a scrolling help text which is automatically shown in line 3 on the display.

Configuration is carried out by use of the 3 function keys:

1will increase the numerical value or choose the next parameter

2will decrease the numerical value or choose the previous parameter

3will save the chosen value and proceed to the next menu

When configuration is completed, the display will return to the default state 1.0. Pressing and holding 3will return to the

previous menu or return to the default state (1.0) without saving the changed values or parameters.

If no key is activated for 1 minute, the display will return to the default state (1.0) without saving the changed values or

parameters.

Further explanations

Password protection: Programming access can be blocked by assigning a password. The password is saved in the device in

order to ensure a high degree of protection against unauthorized modifications to the configuration.

If the configured password is not known, please contact PR electronics support - www.prelectronics.com/contact.

Signal and sensor error info via display front PR 4500

Sensor error (see limits in the table) is displayed as SE.BR (sensor break) or SE.SH (sensor short). Signals outside the selected

range (not sensor error, see table for limits) are displayed as IN.LO indicating low input signal or IN.HI indicating high input

signal. The error indication is displayed in line 3 as text and at the same time the backlight flashes. Line 4 of the display is a

status line which displays COM (flashing bullet) indicating correct functioning of PR 4500 and arrow up/down which indicates

tendency readout of the input signal.

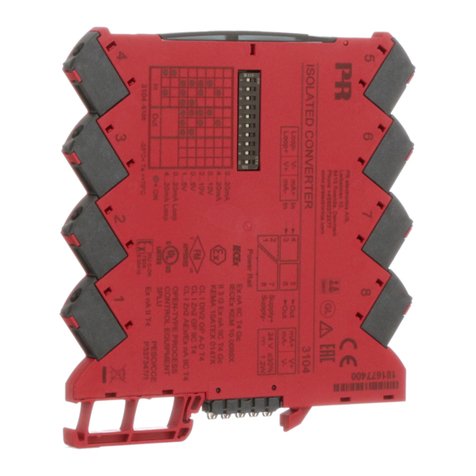

Signal and sensor error indication without display front

Status of the unit can also be read from the red / green LED in the front of the device.

Green flashing LED 13 Hz indicates normal operation.

Green flashing LED 1 Hz indicates sensor error.

Steady green LED indicates internal error.

Advanced functions

The unit gives access to a number of advanced functions which can be reached by answering “Yes” to the point “ADV.SET”.

Memory (MEM): In the memory menu you can save the configuration of the device in the PR 4500, and then move the PR

4500 onto another device of the same type and download the configuration in the new device.

Display setup (DISP): Here you can adjust the brightness contrast and the backlight. Setup of TAG numbers with 6

alphanumerics. Selection of functional readout in line 3 of the display. This line can either show the digital output or the TAG

number.

Two-point process calibration (CAL): The device can be process-calibrated in 2 points to fit a given input signal . A low input

signal (not necessarily 0%) is applied and the actual value is entered via PR 4500. Then a high signal (not necessarily 100%) is

applied and the actual value is entered via PR 4500. If you accept to use the calibration, the device will work according to this

new adjustment. If you later reject this menu point or choose another type of input signal the device will return to factory

calibration.

Process simulation function (SIM): In the menu point “EN.SIM” it is possible to simulate an input signal by means of the arrow

keys and thus control the output signal up or down. You must exit the menu by pressing 3(no time-out).

The simulation function exits automatically, if the PR 4500 is detached.

Password (PASS): Here you can choose a password between 0000 and 9999 in order to protect the unit against

unauthorized modifications to the configuration. The unit is delivered default without password.