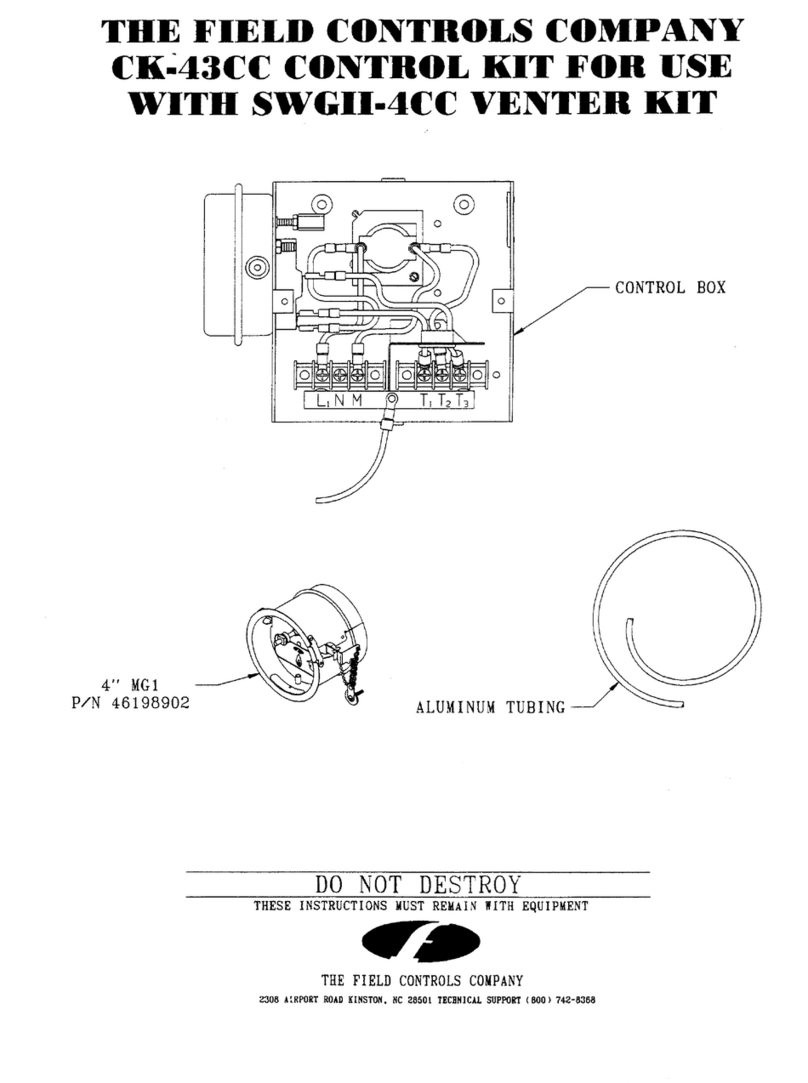

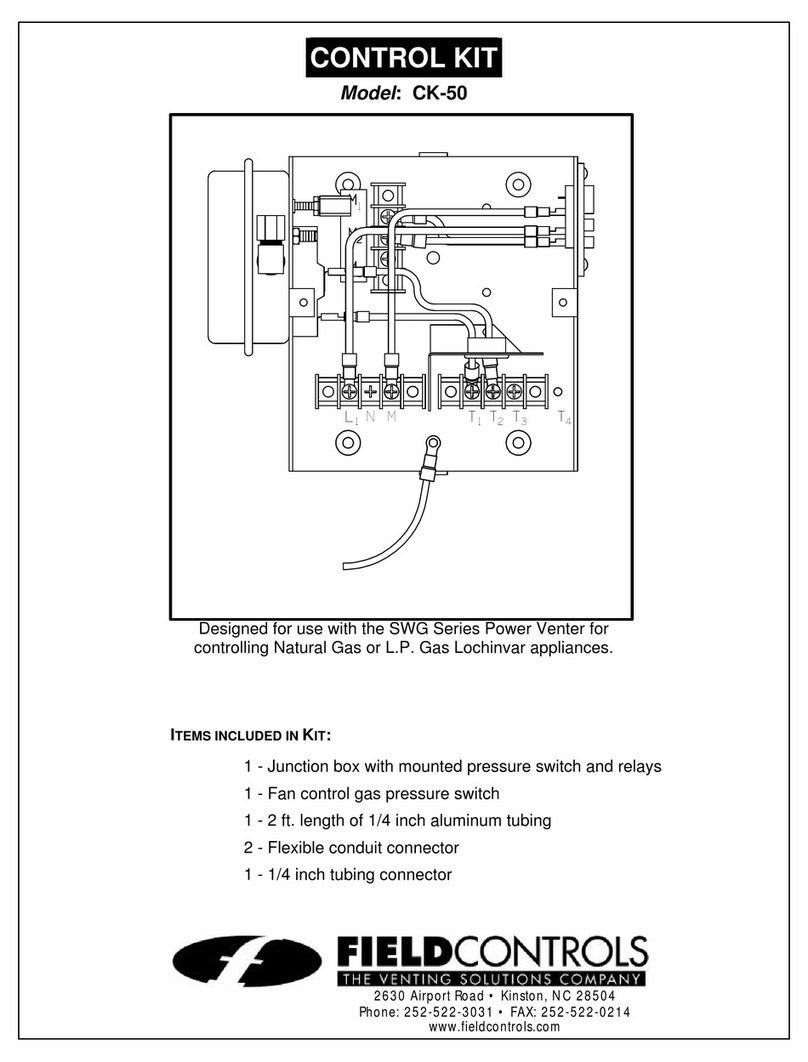

WIRING INSTRUCTIONS

CAUTION: DISCONNECT ELECTRICAL POWER WHEN WIRING POWER VENTER

Wire the venter motor and controls in accordance with the National Electrical Code, manufacturer's

recommendations and/or applicable local codes. UNITS MUST BE GROUNDED. Check ground

circuit to make certain that the unit has been properly grounded. The wiring should be protected by an

overcurrent circuit device rated at 15 amperes. CAUTION must be taken to ensure that the wiring

does not come into contact with any heat source. All line voltage and safety control circuits, between

the venter and the appliance, MUST be wired in accordance with the National Electrical Code for class

one wiring or equivalent methods. Route the venter motor and control wiring with an appropriate wiring

method. Refer to Wiring Diagrams A and B.

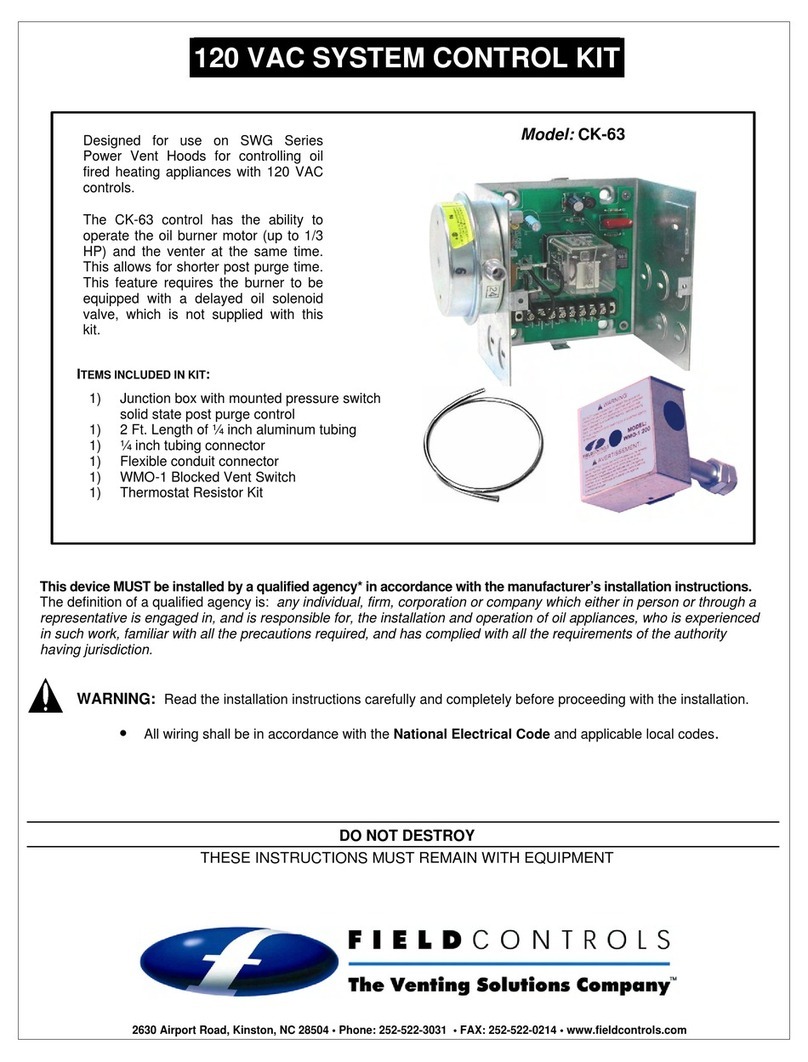

LOW VOLTAGE WIRING INSTRUCTIONS FOR BOILERS AND WARM AIR FURNACES:

1. With boilers, locate terminal on spark ignition module or gas valve (if standing pilot) which would

normally be 24 volts hot on a call for heat. With spark ignition systems, this terminal could be TH-

W, 24 V, THS or T1 depending on the spark ignition control.

With warm air furnaces, locate terminal W in furnace junction box.

2. Remove wire from this terminal and reroute to T1 on CK-40F.

3. With boilers, connect T3 on CK-40F to hot side of gas valve (if standing pilot) or to terminal TH-W,

24 V, THS or T1 if spark ignition.

NOTE: Remember, the correct terminal is the one that would normally be hot on a call for heat.

With warm air furnaces, connect T3 on CK-40F to terminal W in furnace junction box.

4. Connect T2 on CK-40F to a 24 volt neutral where convenient.

LINE VOLTAGE WIRING INSTRUCTIONS:

1. Connect 120 volts hot power source wire to terminal L1 on CK-40F.

2. Connect 120 volts neutral power source wire and white wire from venter motor to terminal N on

the CK-40F.

3. Connect black wire from venter motor to terminal M on the CK-40F.

REFER TO THE SWG VENTER INSTALLATION INSTRUCTIONS FOR SETTING SYSTEM AIR FLOW.

Page 4

SYSTEM CONTROL CHECK OUT PROCEDURES:

1. For furnaces or boilers, adjust the thermostat to call for heat and observe the power venting

system for proper operation sequence. (Repeat if necessary)

a. Thermostat calls for heat.

b. Relay is energized and venter motor starts.

c. Pressure switch closes and burner starts.

d. Thermostat is satisfied, the burner stops.

e. This starts the post purge cycle. Purge time 1 to 2 min.

2. While system is operating, disconnect power to the venter motor. This should open the pressure

switch contacts and stop burner operation.

TROUBLE SHOOTING HINTS

1. Venter does not activate when thermostat calls for heat.

a. Check wiring.

b. Check gas pressure switch for continuity across terminals when gas valve is pressurized.

c. Check gas pressure.

2. Flue gas odor:

a. Check system draft.

b. Check for negative pressure in building.

Page 5

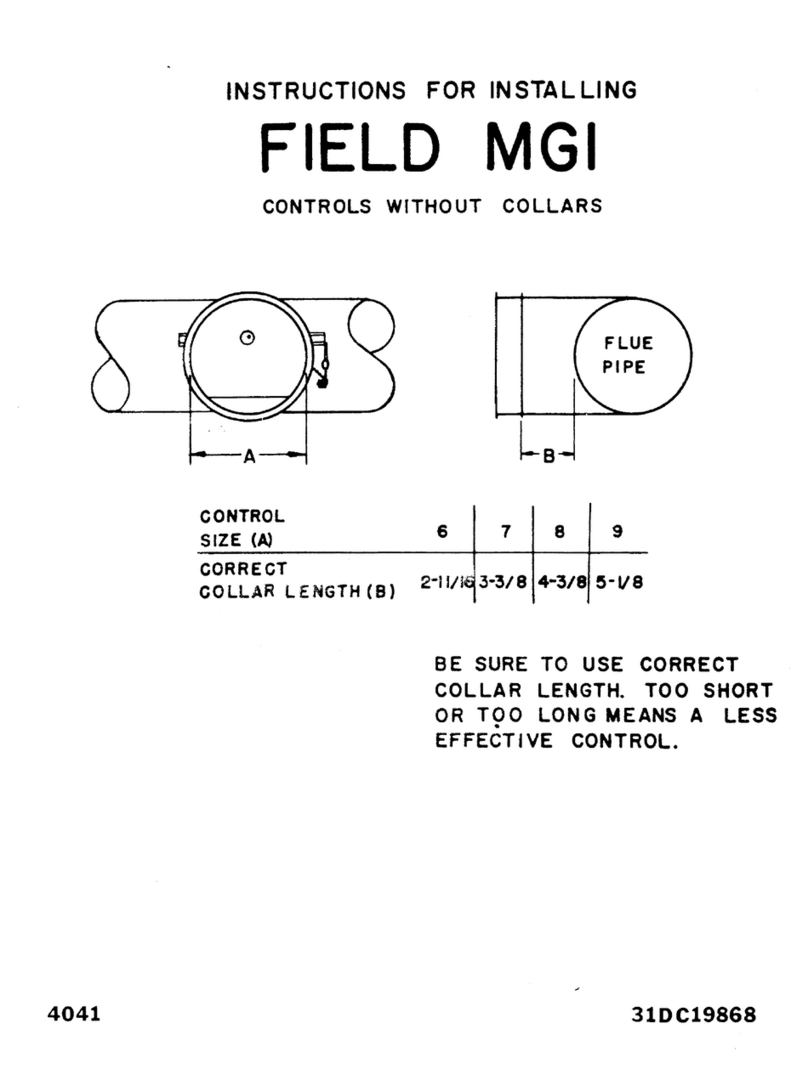

Diagram A