Fieldbus Specialists Profibus User manual

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 1 USER MANUAL

PROFIBUS Gateway

for MCD 3000 Series Soft Starters

P/N FS-1135

User Manual

Ver. 1.9

10 October 2003

© Copyright 2002 Fieldbus Specialists

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 2 USER MANUAL

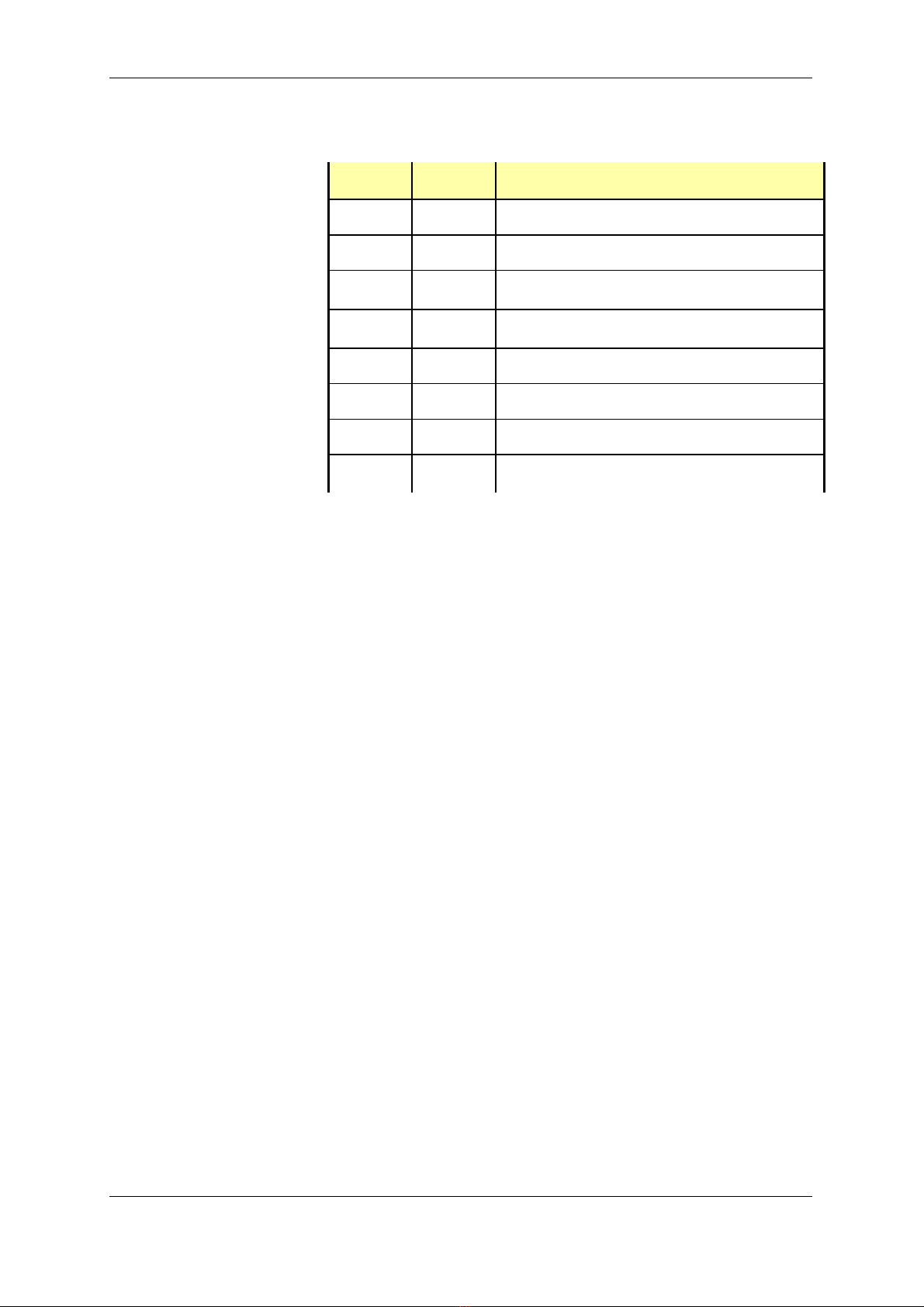

REVISION NOTES

Index

Date

Chapte

r

Author

Rev.

Revision note

1

04-Feb-2002

All

AMcN

1.0

Created

2

11-Feb-2002

All

AJ

1.1

Various corrections

3

10-Mar-2002

All

AJ

1.2

Extended indications for invalid PROFIBUS

address

4

14-Mar-2002

2.6.2, 7

AJ

1.3

Local/Remote setting recommendations,

corrections to Specifications

5

4-April-2002

2.6.1

AKJ

1.4

Wiring diagrams added, mapping of read

memory corrected

6

5-MAY-2002

All

AmcN,

AJ

1.5

Unified format, added functions to handle

comm. breakdown

7

25-OCT-2002

AJ

1.6

Added comments related to Siemens S7

PLC

8

1-OCT-2003

JP

1.7

Added comments re. firmware version 2.02

and code compliance with Danfoss

manual AMB00000 Rev. G

9

9-OCT-2003

JP/AJ

1.8

Modified to reflect compliance with

AMB00000 Rev. G

10

10-OCT-2003

JP

1.9

Note re.byte sequencing in 2.10

TECHNICAL SUPPORT

In case of any questions or problems, please contact Fieldbus Specialists on

We will endeavour to reply immediately.

PREFACE

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 3 USER MANUAL

The data and illustrations in this manual are not binding.

Fieldbus Specialists reserve the right to modify our products in

line with our policy of continuous product development. The

information in this manual is subject to change without notice

and should not be considered as a commitment by Fieldbus

Specialists.

Fieldbus Specialists assume no responsibility for any errors that

may appear in this document.

Although this product has been developed with great care

and extensively tested, Fieldbus Specialists cannot guarantee

the suitability of this product for any purpose. Warranty claims

shall be limited to the right to require rectification of faults.

Liability for any damages, which may have arisen from the use

of this product or its documentation, shall be limited to cases of

intent.

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 4 USER MANUAL

CONTENTS

1 INTRODUCTION ............................................................................................................................. 6

1.1 IMPORTANT USER INFORMATION............................................................................................................... 6

1.2 GENERAL.................................................................................................................................................. 6

2 INSTALING THE GATEWAY ..........................................................................................................8

2.1 GATEWAY CONNECTION DIAGRAM............................................................................................................ 8

2.2 FRONT PANEL ........................................................................................................................................... 9

2.3 INSTALLATION SEQUENCE....................................................................................................................... 11

2.4 POWER CONNECTION .............................................................................................................................. 11

2.5 PROFIBUS CONNECTION....................................................................................................................... 12

2.5.1 Cabling..........................................................................................................................................12

2.5.2 GATEWAY CONFIGURATION ................................................................................................................... 13

2.6 MCD3000 CONNECTION......................................................................................................................... 14

2.6.1 Cabling..........................................................................................................................................14

2.6.2 MCD3000 configuration .............................................................................................................16

3 PROGRAMMING THE MASTER CONTROLLER ........................................................................ 18

3.1 GSD FILE................................................................................................................................................ 18

3.2 DECLARING MODULES ............................................................................................................................ 18

3.3 SETTING PROFIBUS PARAMETERS........................................................................................................ 19

3.4 MASTER-SLAVE DATA EXCHANGE .......................................................................................................... 21

3.5 DATA WRITE AREA.................................................................................................................................. 21

3.6 DATA READ AREA................................................................................................................................... 22

3.7 ISSUING COMMANDS .............................................................................................................................. 24

4 OPERATION OF THE GATEWAY ................................................................................................ 29

4.1 SCANNING SLAVES.................................................................................................................................. 29

4.2 SCANNING TIMES .................................................................................................................................... 29

4.3 OFFLINE SLAVES..................................................................................................................................... 31

5 SPECIFICATIONS......................................................................................................................... 32

6 TROUBLESHOOTING .................................................................................................................. 33

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 5 USER MANUAL

Table List

Table 1 – LED Indication.......................................................................................................................................10

Table 2 – PROFIBUS socket pin assignment .......................................................................................................12

Table 3 – RS-485 pin assignment.........................................................................................................................14

Table 4 – MCD 3000 Local/Remote modes ..........................................................................................................17

Table 5 – MCD 3000, RS-485 baud rate values....................................................................................................17

Table 6 – MCD 3000 node address on RS-485 network.......................................................................................17

Table 7 – Gateway parameter, RS-485 link baud rate..........................................................................................19

Table 8 – Gateway parameter, gateway operation on communication loss..........................................................20

Table 9 – PROFIBUS Write / Out Memory in control module................................................................................22

Table 10 – Command result codes .......................................................................................................................22

Table 11 – PROFIBUS Read / In memory.............................................................................................................24

Table 12 – Valid commands..................................................................................................................................25

Table 13 – New Command / Command Acknowledge handshaking ....................................................................27

Table 14 – Result Ready / Result Acknowledge handshaking..............................................................................27

Table 15 – Scanning cycle length for different baud rates and the number of MCD 3000 devices present..........30

Table 16 – Maximum time to detect return of an offline device.............................................................................30

Table 17 – Gateway specifications........................................................................................................................32

Table 18 – Troubleshooting guide.........................................................................................................................33

Figure List

Figure 1. Typical diagram of a PROFIBUS network, a gateway and an RS-485 sub-network...............................8

Figure 2. Gateway front panel................................................................................................................................9

Figure 3. Entering address via dip switches, an example....................................................................................13

Figure 4. Recommended wiring diagram for one MCD3000 device.....................................................................15

Figure 5. Wiring diagram for a number of MCD3000 devices connected to a single gateway.............................15

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 6 USER MANUAL

1INTRODUCTION

1.1 Important user information

This manual describes operation and programming of a

PROFIBUS gateway for MCD3000 series soft starters, gateway

firmware revision 2.11.

Gateway with firmware version 2.11 complies with MCD3000

protocol as described in Danfoss manual AMB00000 Rev. G

and is likely to be incompatible with earlier versions of the soft

starter. Remote programming of parameters is not supported

at the moment. Contact Fieldbus Specialists if you require a

firmware version that supports earlier models.

Observe all the necessary safety precautions when controlling

any MCD 3000 series device over the serial communications

link, including alerting personnel that the machinery may start

without warning.

1.2 General

The MCD 3000 series of solid state soft starters incorporate a

serial communications facility that allows for the remote

control and interrogation of the MCD 3000 from an intelligent

host (master) via a multi-drop RS-485 communications network

using a proprietary protocol, specific to MCD 3000 devices.

The RS-485 link may be used to interface a MCD 3000 device to

a PROFIBUS network using the PROFIBUS to MCD 3000 gateway.

The PROFIBUS Master can then control any connected MCD

3000 device – start it, stop, reset trip conditions and read

operational status, motor conditions or trip status.

The PROFIBUS to MCD 3000 Gateway is a certified PROFIBUS

slave device. A number of gateways and other PROFIBUS

slave devices can be connected to the same network, subject

only to standard PROFIBUS limitations.

The gateway is a master on the RS-485 multi-drop MCD 3000

communications network. Up to 30 MCD 3000 devices may be

connected to a single Gateway. In this way up to 30 MCD

3000 devices will share one PROFIBUS address on the PROFIBUS

communications network.

This manual describes how the PROFIBUS to MCD 3000

gateway operates, how to connect MCD 3000 series soft

starters to the gateway and how to connect and operate the

gateway on a PROFIBUS network.

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 7 USER MANUAL

When reading this manual, it may help to refer to the MCD

3000 Operating Instructions, Danfoss document no. AMB00000.

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 8 USER MANUAL

2INSTALING THE GATEWAY

2.1 Gateway connection diagram

The diagram below shows how the gateway is connected to

the PROFIBUS network and to the RS-485 sub-network.

PROFIBUS DP

Master

DP Slave DP Slave

MCD 3000

Gateway

MCD 3000

device MCD 3000

device

MCD 3000

device

MCD 3000

device

PROFIBUS network

RS-485 sub-network

Figure 1. Typical diagram of a PROFIBUS network, a gateway

and an RS-485 sub-network.

A gateway can coexist with a number of other PROFIBUS

nodes, including other gateways. Each gateway constitutes a

single PROFIBUS node, even if it connects to a number of MCD

3000 devices.

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 9 USER MANUAL

2.2 Front panel

Figure 2. Gateway front panel

Fig. 2 shows the front panel of the gateway. Located on the

front panel are:

1. RS-485 sub-network connector for connecting up to 30

MCD 3000 devices, DB9, male,

2. PROFIBUS network connector, DB9, female,

3. Power connector, 2 pin removable terminal block,

4. Bi-colour PROFIBUS status LED,

5. Bi-colour RS-485 status LED,

6. Dip switches for PROFIBUS address selection.

The following table indicates the status of the PROFIBUS

connection.

RS485

STATUS 1

ON

2345678

ADDRESS

LSB

24V DC

_

+

MCD 3000 - PROFIBUS Gateway

FS-1135

PROFIBUS

PROFIBUS

STATUS

1

5

6

3

4

2

RS485

POWER

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 10 USER MANUAL

PROFIBUS

LED

RS-485

LED

Gateway status

Gateway starting (max. 6 sec) or no power

ANY

Invalid PROFIBUS address

ANY

PROFIBUS link down – no PROFIBUS Master,

incorrect address or no connection,

ANY

PROFIBUS link error – wrong configuration or

parameter in Master

ANY

PROFIBUS link up and problem-free

ANY

No communication on the RS-485 link

ANY

Occasional errors on the RS-485 link

Both PROFIBUS and RS-485 links operational

and error-free

Legend:

- LED off

- LED steady green

- LED flashing red/off

-LED flashing green/red

-LED flashing green/red/off

ANY – applies irrespective of LED status

Table 1 – LED Indication

These simple rules may be worth remembering:

-Flashing indicates errors on the relevant link,

-Flashing red means that the gateway attempts to

communicate but fails every time,

-Flashing red/green means that the gateway can

communicate, but errors occur.

R/B

B

B

B

G

G

G

G

G/R

G/R

G/R/B

R/B

R/B

R/B

G/R/B

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 11 USER MANUAL

2.3 Installation sequence

When installing the gateway, we recommend the following

sequence:

!Connect power, see section 2.4 for details. If there are no

indications of power, check voltage and polarity.

!Set the PROFIBUS address on dip switches, configure and

activate PROFIBUS master, see section 2.5 for instructions.

Configure the PROFIBUS master for one MCD device only.

On success the PROFIBUS status LED will go green, on error

it will blink red. If the LED stays red, check the cable,

address on the gateway and address setting in the

master. If the LED flashes green/red, verify the

configuration of modules in the PROFIBUS master. Do not

proceed further until you get the PROFIBUS LED steady

green.

!Configure and connect the first MCD 3000 device, set it to

address 1, see section 2.6 for details. On success, the RS-

485 status LED should go green. We recommend initially

to configure PROFIBUS master for only one MCD device

connected to the gateway and to get this configuration

working successfully. Later on you can increase the

number of MCDs. If the RS-485 status LED stays solid red,

check the RS-485 cable, the MCD 3000 device

configuration (set to Local), wiring to MCD 3000 and the

value of the PROFIBUS parameter in the gateway

configuration data in PROFIBUS master – RS-485 sub-

network baud rate setting.

!Configure and connect the remaining MCD 3000 devices,

make also the relevant changes to the configuration of

PROFIBUS master. On success the RS-485 LED should go

solid green. If it flashes green/red, one or more MCD 3000

does not communicate with the gateway.

2.4 Power connection

The gateway requires 24V DC power, approx. 130mA. The

voltage can be unregulated – the gateway will operate

correctly for power voltage in the range 12-32V. The current

drawn changes with voltage – it is ~240mA for 12V and ~90mA

for 32V. The power connector is a removable terminal block,

2-pin. The device is reverse polarity protected – in the case of

reversed connection it will not get damaged but it will not

operate either.

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 12 USER MANUAL

Presence of correct power can be verified by looking at the

LEDs on the front panel – at least one LED should be illuminated

at all times, whether green or red.

2.5 PROFIBUS connection

The PROFIBUS socket of the PROFIBUS to MCD 3000 Gateway

must be connected to a PROFIBUS network in accordance

with PROFIBUS Technical Guideline “Installation Guideline for

PROFIBUS DP/FMS”, PROFIBUS International Order No. 2.112.

2.5.1 Cabling

The PROFIBUS to MCD 3000 Gateway connection requires a

PROFIBUS cable with DB9, male connector. Pin assignment in

the PROFIBUS socket is as follows:

DB9 socket Pin

Purpose

1

Shield/functional ground

2

Not connected

3

RXD/TXD-P (Data Line)

4

Not connected

5

Data ground (reference potential for VP)

6

VP – supply voltage, +5V

7

Not connected

8

RXD/TXD-N (Data Line, Inverted)

9

Not connected

Table 2 – PROFIBUS socket pin assignment

Pins 3 (RXD/TXD-P) and 8 (RXD/TXD-N) must be connected. The

other pins can be used, if needed.

The gateway does not provide termination on the PROFIBUS

cable. If the gateway is located at either end of the cable,

the termination resistors should be provided externally, usually

in a PROFIBUS plug with the termination option. The gateway

provides termination power on pins 5 and 6.

The shield on the PROFIBUS socket is galvanically connected to

the metal top lid on the enclosure. An earthing lug is provided

for earthing the top lid. When the PROFIBUS cable plug is in the

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 13 USER MANUAL

socket, the shield on the PROFIBUS cable is connected with the

socket shield, the top lid and the earthing lug.

2.5.2 Gateway configuration

The gateway automatically detects the baud rate for the

PROFIBUS network. All standard baud rates are supported as

per PROFIBUS Specification, up to 12 Mbits/s.

The PROFIBUS node address of the PROFIBUS to MCD 3000

Gateway is configured with an 8-way DIP switch that is located

on the front panel of the gateway. The address must be set to

a value that is not in use by any other device on the PROFIBUS

network. Valid address range – 0 to 125.

The procedure for setting the node address of the gateway is

as follows:

!Ensure that the device is not powered up by unplugging

the power connector.

!Set the DIP switches to the desired value (see figure

below).

!Reinsert the power connector

Fig. 1 shows the location of the DIP switches on the front panel.

These switches are used to enter the address, with the most

significant bit on the left and the least significant bit on the

right. The address is entered in binary, with the switch in up

position for ‘0’ and in the switch in the down position for ‘1’.

For example, to set the address “3”, binary 0000 0011, the

switches need to be positioned as follows.

1

ON

2345678

ADDRESS

LSB

Figure 3. Entering address via dip switches, an example

In addition to setting the address, it is necessary to define the

gateway’s configuration in the PROFIBUS Master. For detailed

description of this important stage, refer to section 3.

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 14 USER MANUAL

2.6 MCD3000 connection

2.6.1 Cabling

The MCD 3000 devices should be connected to the RS-485

serial sub-network as per the MCD 3000 Operating Instructions.

The gateway is connected to the RS-485 sub-network using a 9

pin male DB connector, located to the left side of the

enclosure. Pin assignment is as the following table indicates.

Pins not listed there are unused or reserved and MUST NOT be

connected.

Pin Number

Purpose

1

+ Signal

5

Shield/Ground

9

- Signal

Table 3 – RS-485 pin assignment

We recommend using a shielded twisted pair cable. When the

gateway is located away form the soft starter, the

communications cable should be shielded and should not be

run in the vicinity of high current power cabling. It is advisable

to fit termination resistors at each end of the cable to match its

characteristic impedance, typically in the range of 100-120

ohm.

The recommended connection diagram is shown in fig. 4

below. We recommend connecting cable shield on the

gateway side only and we recommend that the connection

point 61 on the MCD3000 device be left unconnected.

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 15 USER MANUAL

69

61

68

SERIAL COMM.

PORT RS485

to pin 5

to pin 9

to pin 1

cable shield

RS485

+

GND

_

MCD3000 device Gateway

Figure 4. Recommended wiring diagram for one MCD3000

device.

to pin 5

to pin 9

to pin 1

69

_

61

68

+

GND

MCD3000

69

_

61

68

+

GND

MCD3000

69

_

61

68

+

GND

MCD3000

FS-1135

gateway

Figure 5. Wiring diagram for a number of MCD3000 devices

connected to a single gateway

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 16 USER MANUAL

If a number of MCD3000 devices are connected to a single

gateway, we recommend wiring them in series, see fig. 5. The

cable should constitute a single line, without side branches.

Note that we recommend connecting GND points (61) on all

MCD 3000 devices to guarantee that they share the same

ground potential. If the devices are connected to the

common ground in some other way (ex. via a metallic

mounting), it may not be necessary to connect points 61.

RS-485 interface on MCD3000 is not galvanically isolated.

Failure to equalize ground potential on MCD 3000 devices

connected via RS-485 link may result in their damage.

2.6.2 MCD3000 configuration

The gateway can communicate at any of the baud rates that

MCD 3000 devices can support. All MCD 3000 devices

connected to the same sub-network must be configured for

the same baud rate.

Each MCD 3000 device must be configured with a node

address. Each must have a different address and each

address must be in the range 1 to the number of MCD 3000

devices connected to the gateway, inclusive. Example: if four

devices are connected to a gateway, they must have

addresses 1, 2, 3 and 4.

Each MCD 3000 Local/Remote Mode parameter (Parameter

20) must be set to 0, 1 or 2. Setting this parameter to 3 disables

the RS-485 communications port. For more detailed

explanation refer to the MCD 3000 Operating Instructions.

MCD 3000 devices must be set for “Local” operation using the

Local/Remote pushbutton on the front panel. When this is

done, the LED labeled “REMOTE” on the front panel is off.

NOTE: When the MCD3000 device is set for “Remote”, it does

not execute commands received over the RS-485 link.

However, it still acknowledges these commands.

Consequently, the gateway and the PROFIBUS master cannot

detect this condition. For working with a gateway, we

recommend to set Local/Remote Mode parameter (Parameter

20) to 2 – “Local control only”. This will eliminate the possibility

of the MCD3000 device being set for “Remote” accidentally or

by mistake.

The MCD 3000 devices must be configured using the keypad/

LCD display on its front panel. The method of setting

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 17 USER MANUAL

parameters is described in details in the MCD 3000 Series Soft

Starter Operating Instructions.

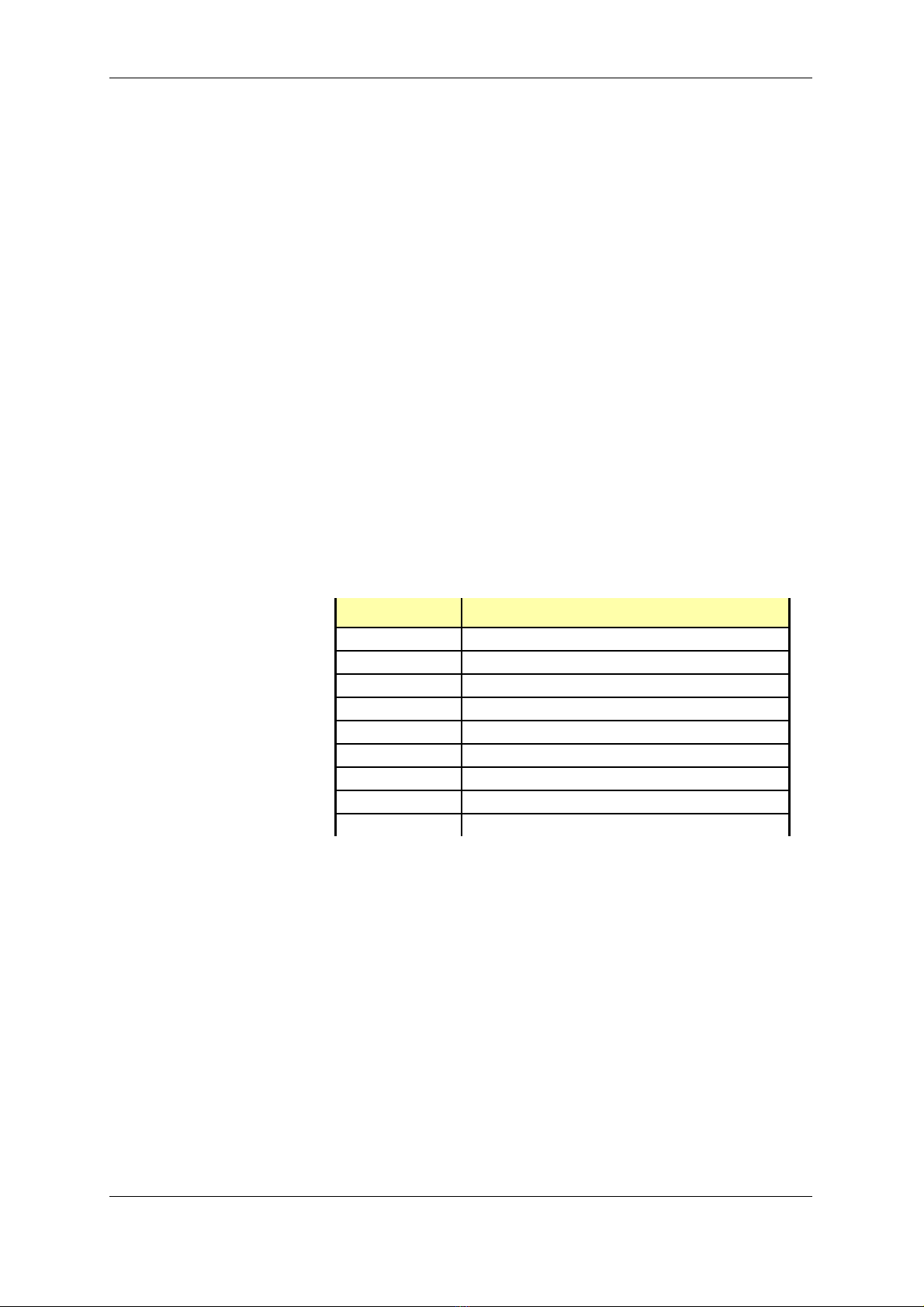

The following tables show the required configuration for the

MCD 3000 soft starter parameters relevant to the operation of

the gateway.

Parameter 20 Local/Remote Mode

Configuration Options

0

Local/Remote enabled

1

Local/Remote enabled

only when motor stopped

2

Local control only

3

Remote control only

Default Setting

0

Local/Remote enabled

Table 4 – MCD 3000 Local/Remote modes

Parameter 22

Serial communication baud rate

Configuration Options

1

1200 baud

2

2400 baud

3

4800 baud

4

9600 baud

5

19200 baud

Default Setting

4

9600 baud

Table 5 – MCD 3000, RS-485 baud rate values

Parameter 23

MCD 3000 address for RS-485 serial

communications

Configuration Options

1 – 99

Required Setting

A number between 1 and the total

number of MCD 3000 devices on the

network

Table 6 – MCD 3000 node address on RS-485 network

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 18 USER MANUAL

3PROGRAMMING THE MASTER CONTROLLER

3.1 GSD file

Information on the technical characteristics of the gateway is

loaded into PROFIBUS master software by means of a GSD file.

A floppy disk with the GSD file is supplied with the gateway. The

GSD file name is “FS1135.GSD”. Follow the instructions in the

PROFIBUS configuration/management software manual for

loading the GSD file and adding the new slave, the gateway,

to the network.

If you need a copy of the GSD file, please contact us at

sales@fieldbus.com.au.

For the PROFIBUS Master to communicate with the gateway, it

must be provided with information about the way that the

gateway works. You can do it by following these steps:

!load the GSD file, for details refer to the manual for

master configuration software,

!declare the required modules within the gateway,

!set PROFIBUS parameters of the gateway.

3.2 Declaring modules

The gateway is a modular PROFIBUS slave, consisting of several

modules as defined in the GSD file. The gateway must be

configured with the control module declared first, and then

with one slave module declared for each soft starter

connected to it.

The control module has 10 bytes of input data and 3 bytes of

output data, no consistency. This module is declared in the

GSD file with the “Preset” keyword and many configuration

applications will automatically declare it as required and in the

correct position – as the first module in the configuration.

Check that the software you are using supports the “Preset”

keyword and if not, declare this module manually as the first

one in the configuration data of the gateway.

In addition to the control module, you must declare a slave

module (5 Bytes In, module consistency) for each MCD 3000

device connected to the gateway. The gateway assumes

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 19 USER MANUAL

that the addresses of the MCD 3000 devices start at 1 and are

consecutive, up to the number of expected devices.

The first motor starter module relates to the MCD 3000 with

address 1, the second one to 2 and so on. Address values are

not related to physical positioning of MCD 3000 devices on the

RS-485 sub-network.

NOTE for users of SIMATIC S7:

Motor starter modules are defined as so called “modules with

data consistency”. This is necessary to guarantee accuracy of

current reading. The consequence of it in S7 is that module

data cannot be read directly – direct reading always returns 0.

Instead, you should use SFC14 to cyclically copy module data

to PLC internal memory and then retrieve the required values.

In case of problems consult an S7 expert re. the memory

addresses to be used for motor starter modules and the correct

way of retrieving module data.

3.3 Setting PROFIBUS parameters

The gateway requires three parameters, associated with the

control module in the gateway configuration. The first

parameter defines the desired baud rate on the RS-485

network. The gateway supports all the baud rates that the

MCD 3000 devices support:

First Parameter

Value

Baud Rate

1

1,200 bps

2

2,400 bps

3

4,800 bps

4

9,600 bps (Default)

5

19,200 bps

Table 7 – Gateway parameter, RS-485 link baud rate

MCD 3000 – PROFIBUS GATEWAY

MCD 3000 SERIES 20 USER MANUAL

The second parameter defines gateway operation if

communication with the master stops:

Second

parameter

Action on communication

breakdown

1

Stop polling MCD3000

devices

2

STOP command sent to all

MCD3000 devices

3

COAST TO STOP sent to all

devices

Table 8 – Gateway parameter, gateway operation on

communication loss

The selected action will be executed when the gateway had

established initial communication with the master and

subsequently this communication stops.

If the second parameter is set to 1, the gateway will stop

poling MCD3000 devices on communications breakdown. This

may cause MCD3000 devices to trip, if they are so

programmed (Parameter 24). For other values of this

parameter, the gateway will keep on polling and will prevent

MCD3000 tripping.

The third parameter defines the timeout, in seconds, for

communication with the master.

If the gateway stays off-line on PROFIBUS for the time period as

set in the third parameter, the gateway will take action as

defined by the second parameter. Allowed range is 0 to 255.

Default value is 5, setting the timeout at 5 sec. If the third

parameter is set to 0, no timeout supervision will be carried out

and once communication with master commences, the

gateway will keep on polling MCD3000 devices irrespective of

the status of gateway-master link.

On receiving an invalid parameter value or invalid

configuration data from the PROFIBUS master, the gateway

goes offline and flashes the PROFIBUS status LED green, red and

then turns it off. After a few seconds the PROFIBUS master will

try again to set the gateway to ONLINE state and the cycle

repeats until the error is corrected.

Table of contents

Popular Gateway manuals by other brands

Philio Technology Corporation

Philio Technology Corporation PSC03 user manual

Dell

Dell Dell Edge Gateway 3002 Specifications

Genexis

Genexis DRG 7000-Series installation guide

TRI02SYS

TRI02SYS EnOcean 02LINE Installation and operating manual

Juniper

Juniper SRX1500 How to set up

XiNCOM

XiNCOM Twin WAN XC-DPG503 user guide