Filamos SSB 02.1 Series User manual

Concrete Spraying Machine - SSB 02.1 Series

PRODUCER: FILAMOS, s. r. o.

Hate 546, 261 01 Pribram, Czech Republic

Tel: + 420 318 637 763, Fax: + 420 318 624 181

www.filamos.com

User Manual

Concrete Spraying Machine

SSB 02.1

Concrete Spraying Machine –SSB 02.1

2

CONTENT PAGE

I. Preface..........................................................................................3

II. Use................................................................................................3

III. Machine Operating........................................................................3

IV. Description....................................................................................5

V. Technical Data..............................................................................7

VI. Accessories...................................................................................9

VII. Material .........................................................................................9

VIII. Executions.....................................................................................9

IX. Markings .....................................................................................10

X. Testing ........................................................................................10

XI. Delivery.......................................................................................10

XII. Warranty .....................................................................................11

XIII. Packaging ...................................................................................11

XIV. Transport.....................................................................................11

XV. Storing.........................................................................................11

XVI. Servicing .....................................................................................11

XVII. List of Standards.........................................................................12

XVIII. Supplements...............................................................................12

Concrete Spraying Machine –SSB 02.1

3

I. Preface

This user manual is necessary to get basic information about safety use of

concrete spraying machine SSB 02.1 (further only machine), made by producer

FILAMOS, s.r.o., Hate 546, 261 01 Pribram, Czech Republic. Other information,

recommendations and technical parameters are mentioned in the Operating and

maintenance instructions made by producer. The user manual is obligatory for all

users that use this machine.

II. Use

Shotcreting machine SSB 02.1 is designed for the processing of dry or wet

mixtures. It is appropriate to execute works of medium and large scope. It is used,

in particular, to reinforce surfaces of engineering structures and the construction

of water works, to reinforce the vaulting of tunnels and collectors in underground

engineering and to maintain concrete constructions.

The machine is designed for the operation in the places free of a danger from the

methane explosion (SNM-0) and other inflammable gasses as stated in CSN EN

1127-2.

The machine may be used in media with temperatures ranging from +5 to +40 °C.

III. Machine Operating

Start operating –opening and adjusting compressed air, then turning on the

electric motor.

Presence of the machine operator is not necessary unless during refilling of the

mixture and its application.

Finish operating –it is necessary to empty the feeding hopper and blow

compressed air distribution system by air. To switch off the electric motor

thereafter and close the compressed air cock.

Workmen have to be introduced with:

-User manual

-Operating and maintenance instructions

-Operating rules applied to the construction place

Workmen are obliged to use personal protective equipment stated in Operating

and maintenance instructions (crash helmet, ocular protection and respirator

against cement dust, convenient work clothes and shoes, work gloves). Workmen

are obliged to do daily notes into the operating diary.

Concrete Spraying Machine –SSB 02.1

4

Safety instruction concerning:

-Assembly and the installation –Assembly of the machine is carried out at the

producer and the transport to the client is performed in already assembled form

of the machine. The check of the machine integrity, complexity of the

equipment of the machine is performed in the place of operation. Machine is

switch to the electrical supply and to the compressed air supply after setting to

the place of application.

-Setting to the operation –Machine and its accessories must be appropriately

assembled before setting to the operation. All necessary assembly and

following checking operation steps must be carried out according to the

Operation and Maintenance Manual provided by the producer.

-Operation of the machine –Machine must be used only in accordance with the

Operation and the Maintenance Manual provided by the machine producer.

Machine is operated by one operator who is responsible for the faultless

conditions of the machine at the same time.

-Manipulation –machine can be transported by the suitable transport means

defined by the site manager. Total weight of the machine is 950 kg (± 5 %).

Each machine is equipped with catching loops for the connection to lifting

machine. Manipulation must be careful without any dynamic crashes.

-Assembly and disassembly –Disassembly of the hoses is done in case of each

transfer to the other operation place Transfer of the machine in assembled

mode is done by mechanical transport means (crane truck, truck). It is

necessary so that there is no pressure of the compressed air in the machine as

well as the switch off the electric supply is done before any disassembly of the

machine.

-Adjustment –It means setting up according to the Operation and the

Maintenance Manual. Simple steps without any influence to the safety of the

equipment must be done by the operators according to the local conditions.

Other procedures must be left to the specialised service according to the

Operation and the Maintenance Manual.

-Maintenance –small and operational steps are done by the operators according

to the time order in the Operational Manual. Procedures requiring higher

specific knowledge are done by the authorised service agencies for those

machines.

-Disposal –Disposal of the machine is comprised of decomposition of the

parts to:

- Steel material polluted by the dangerous substances

- Colour metals

- Plastics, rubber and the parts polluted by the dangerous substances

must be disposed off in accordance to the Act about the liquidation of

the dangerous substances

Concrete Spraying Machine –SSB 02.1

5

Training Instructions

There are only mentally and physical competent workmen older than 18 years

with theoretical and practical skills qualified to operate the machine.

Other Ways of Use

The Machine cannot be used for any other purpose than transport of dry and wet

concrete mixes, fire-resistant mixes and similar materials. If used for any other

purpose, the manufacturer does not assume any liability for damages caused by or

to the Machine. It is not presumed that the equipment should be operated by any

unqualified operating staff and, therefore, the Operating and Maintenance

Instructions are compiled in a manner and to an extent inevitably necessary for a

safe operation of the Machine by a trained member of the staff.

IV. Description

The Machine comprises the following main parts:

-the Machine drive (electromotor, gearbox, speed variator, if any)

-basic frame

-dosing drum (rotor) with wearing plates

-the Machine head with upper sealing plate, lower sealing plate and exhauster,

-feeder and vibrator,

-rippling equipment,

-tightening bolts,

-exhauster with a filtration bag,

-air distribution and manometers,

-electrical installations,

-central lubricating system,

-bantam wheels (rail undercarriage, frame),

-accessories (hoses, quick couplers, nozzle, sealing plates, etc.)

The Machine drive is executed by the slipping gear (speed variator, if any) and

electrical motor.

The bearing part of the dosing, the Machine drive and air distribution are situated

on the frame. The bantam wheels are screwed on the basic frame sides.

The dozing drum is fixed on the top part of the bearing part shaft by a square(end)

and tightening nut.

The Machine head is installed on the hinged frame. The sealing plate is mounted

on its bottom side and its bottom side rests on the dozing drum. The air intake is

installed on the Machine head upper side as well as the feeder and exhaust with

the filtration bag.

Concrete Spraying Machine –SSB 02.1

6

The bottom sealing plate is fixed on the frame on which the dozing drum is rested

as well as the exhauster and bottom exhaust.

The Machine feeder is complimented by vibrator for acceleration of filling of the

transported mix, and a sifter.

The Machine head is mounted on by four tightening bolts serving to control

(adjust) thrust of the sealing plates to the dozing drum.

The exhausts with filtration bags serve to capture air remains and dusty particles

from the dozing drum cylinders.

The air distribution comprises the main intake and four controlling cocks. The

main intake is provided with a controlling cock and quick coupler for connection

of the pressured air DN 50 hose. The controlling cocks serve to intake air to the

Machine head (primary (upper) air), to the exhauster (secondary (bottom) air), to

clean the Machine and control the pneumatic vibrator. The controlling cocks for

the air intake to the head (primary (upper) air) and to the exhauster (secondary

(bottom) air) are equipped with manometers.

The central lubrication system comprises the lubricating equipment and tank,

controlling automatic system, outputs and pipe. The lubrication system transports

the lubricant (grease) or oil between the areas of sealing and wearing plates and so

avoids their excessive friction.

The control of the Machine is concentrated on the electric motor cover side. The

compressed air intake is situated on the cover side.

The whole Machine is alternatively placed on a solid frame, rail undercarriage or

bantam wheels.

Working Principle

The shotcreting machine SSB 02 works on the principle of pneumatic transport.

Dry-gunning

The dry mixture for spraying or transportation is poured in the machine and

smoothly fills the cylinders of the rotor below the hopper. To fill a mixture into

the rotor more easily, a vibrator and a rippling are fitted in the hopper.

The rotating movement of the rotor moves the mixture along by 180 degrees in

the clockwise direction. The mixture is thus blown out from individual cylinders

of the rotor into transport hoses. As the mix passes through the blower into the

transport hoses, lower pressure air is added to enhance the continuous flow of the

material in hoses. The hoses are equipped with the spraying nozzles at the end,

into which the mixing water is fed at the same time to wet the transported mixture.

The required wetting of the mixture is controlled with the supply cock.

Concrete Spraying Machine –SSB 02.1

7

Wet-gunning

When the concrete mixture is applied in so-called wet method, the hopper is filled

in with the prepared wet mix. In principle, the mix passes through the machine in

the same way as when spraying the dry mixture. A hose for addition of chemical

additives (e. g. accelerating admixture) is taken from the external dosing pump to

the spraying nozzle instead of mixing water.

Drive and Output Control

The Machine is propelled by electric motor.

I. Two-speed Electric Motor (DUO)

The machine is propelled by two-speed electric motor. The motor is fitted with a

stepped pulley and connected by one V-belt with the slide-on gearbox, which is keyed

by a hollow output shaft to the shaft of the bearing part of the dosing drum.

The machine output (rotor speed) is controlled by two-position switch. The motor runs

on 4 or 6 poles.

II. Electric Motor with a Speed Variator (COM-V)

The electric motor is fitted with speed variator gearbox. It is connected to the slipping

gearbox by V-belt, and the gearbox is keyed to the bearing part of the dozing drum

with an output hollow shaft. The output is changes by means of the speed variator.

V. Technical Data

SSB 02.1 DUO : 4/6 poles electric motor 4,5/6,5 kW.

Rotor revolutions: 12/8 rpms/min.

Performance parameter

Type of rotor

small rotor

big rotor

Rotor volume [dm3]

13,5

21,9

Rotor rpm [min-1]

8

12

8

12

Theoretical output [m3x h-1]

6,5

9,8

10,4

15,6

Concrete Spraying Machine –SSB 02.1

8

SSB 02.1 COM-V: 4 poles electric motor 7,5 kW.

Rotor revolutions in the range: 2,4 –12,5 rpms/min.

Performance parameter

Type of rotor

small rotor

big rotor

Rotor volume [dm3]

13,5

21,9

Rotor rpm [min-1]

2,4

12,5

2,4

12,5

Theoretical output [m3x h-1]

1,9

9,8

3,0

15,6

Note: The drum should be selected with a view to the performance required.

The actual output of the machine depends on the kind and composition of the

mixture to be transported, its moisture content, transport distance, transport hoses

inner diameter, the compressed air pressure and quantity and the way of filling the

machine hopper.

Technical parameters

The transporting distance and height are directly affected by:

-The composition and water content of the conveyed mixture (with mixtures

consisting mostly of fine fractions should be tested individually,

-Sufficient amount of compressed air,

-Transport hoses or piping (for larger distances these must be straight with no

bends).

The compressed air must be always dry!

Parameter

Small rotor

Big rotor

Air consumption [m

3

/min]

(transport distance of 40 m)

6÷8

8÷14

Air pressure [MPa]

0,5 - 0,6

Motor output [kW]

4,5/6,5; 7,5

Mains connection

3 x PEN 400 V

Transport hoses inside diameter [mm]

DN 50, DN 60

DN 60, DN 65

Granularity of transported material [mm]

max. 16

max. 20

Max moisture of material [%]

(dry gunning)

6

Horizontal transport distance [m]

(dry/wet gunning)

250/40

Vertical transport distance [m]

(dry/wet gunning)

100/15

Water hose inside diameter [mm]

DN 20

Minimum water pressure at nozzle [MPa]

0,3

Max. deviation of voltage system

± 10 %

Coverage

IP 55

Concrete Spraying Machine –SSB 02.1

9

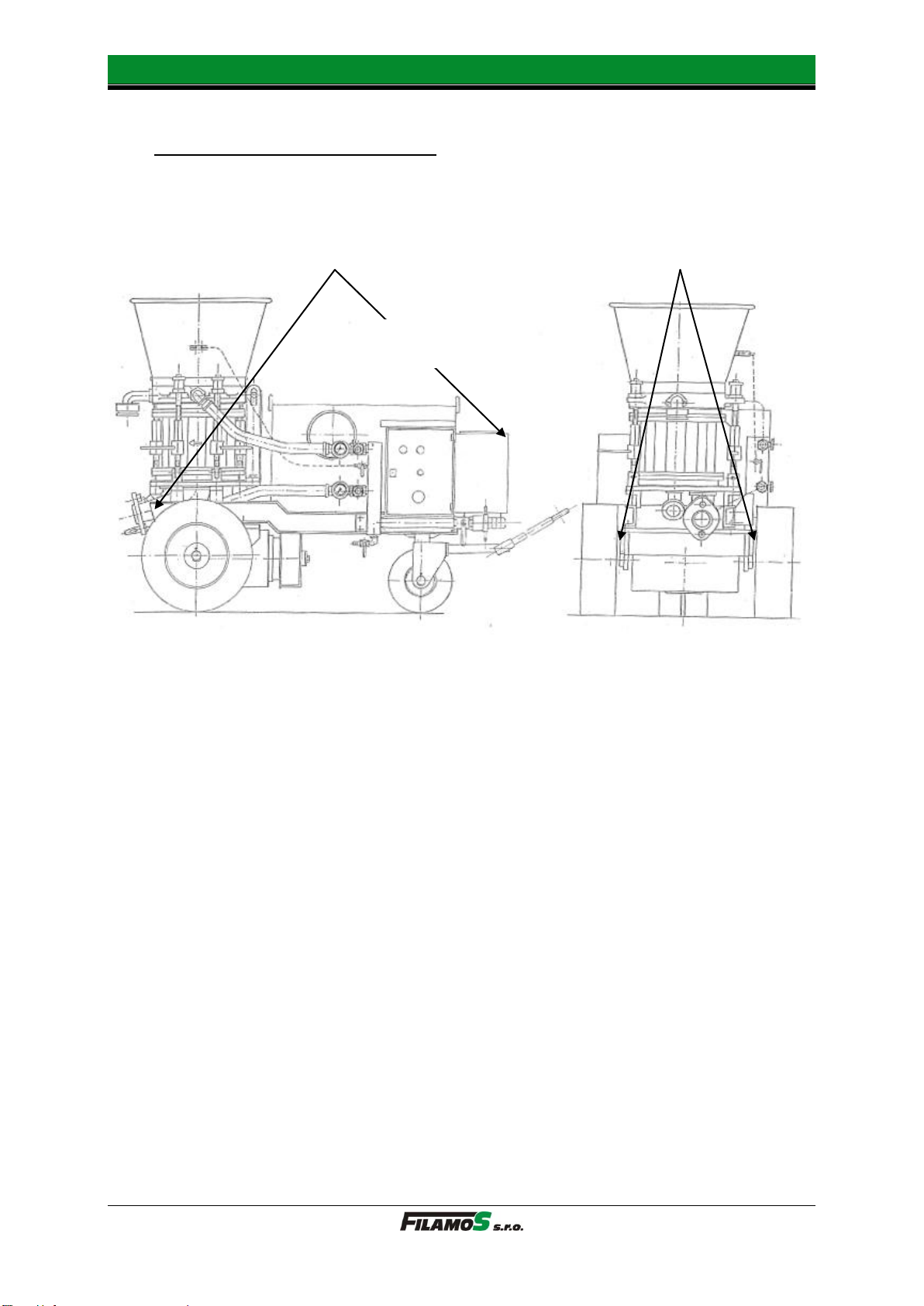

Principal dimensions

Parameter

Length [mm]

1820

Width [mm]

990

Height [mm]

1480

Weight (with no accessories) [kg]

950

VI. Accessories

Standard set of accessories consists of:

- Delivery hose –20 m

- End hose with the nozzle –20 m

- Water hose –20 m

- Upper sealing plate –3 pcs

- Lower sealing plate –3 pcs

- Nozzle ending –2 pcs

The standard set of accessories can be adjusted according to the customer’s

requirements (length of hoses, number of sealing plates etc.).

VII. Material

The material used in manufacturing the machine conforms to the valid

manufacturing documentation as regards chemical composition and mechanical

properties.

Aggregate properties for sprayed concrete conform to standards ČSN EN 12620 a

ČSN EN 13055-1.

VIII. Executions

All parts have been manufactured according to production blue-prints. Intolerance

dimensions conform to standards CSN ISO 2768-1.

The electric wiring conforms to standards CSN EN 60204-1. Protection against

the dangerous touch voltage is secured by an automatic switch off the source.

Metal-coating of parts performed in accordance with manufacturing

documentation and standards CSN EN 12 329. Before assembly, the coreless parts

were treated with primer on contact surfaces.

Welds were performed in accordance with blue-prints and standards CSN EN ISO

9692-1.

Concrete Spraying Machine –SSB 02.1

10

The product has the surface treatment of 3rd degree of rust aggressive

surroundings protection and the paint complies with CSN ISO 3864.

IX. Markings

The machine has a rating plate with the following data:

-Name and residence of manufacturer,

-CE mark –declaration of conformity,

-manufacturer’s number and year of production,

-rated air pressure,

-rated water pressure,

-input,

-rated voltage,

-weight of machine.

Electric motor and gearbox have their own rating plates.

X. Testing

The properties of the machine are checked in the manufacturing plant by means of

a functional test: running empty and under pressure of 0,3 MPa with sealing in

operation mode. Each machine has been tested.

The test consists of the following checks:

-functionality and tightness of the dosing drum and sealing plates (with

exhaust sealed, tightened clamping bolts and machine at the rest),

-loading of the electric motor at idle run with tightened clamping bolts,

-direction of dosing drum rotation (the direction of clock hands). The

direction is marked by the arrow-head on the machine head,

-functionality and tightness of the air distribution system,

-functionality of the vibrator and the rippling.

The execution of the tests is recorded in the „CERTIFICATE OF QUALITY

AND COMPLETENNES“.

XI. Delivery

Each product is delivered assembled with the following documentation:

-User manual

-Operating and maintenance instructions

-Report of initial control of electric equipment

-Certificate of quality and completeness –Warranty certificate

-Spare parts catalogue

Concrete Spraying Machine –SSB 02.1

11

XII. Warranty

The warranty period is 12 months from the date of the machine delivery.

Otherwise according to conditions in purchase contract.

The manufacturer provides no warranty:

-If the product is used for purposes or in a manner other than specified in

the User manual and Operating and Maintenance Instructions,

-If the product is not being given proper care (poor storage, assembly,

incorrect operating),

-If the product has been changed, modified or repaired without the

manufacturer’s previous consent,

-If the machine has been damaged by incorrect electrical connection,

-If the product has been damaged by a third person or vis major,

-If warranty is being claimed without Warranty Certificate,

-On the sealing plates, wearing plates, dosing drum, blower, transport

hoses and the nozzle since theirs lifetime depends on the abrasiveness of

the transported material.

XIII. Packaging

The machine is supplied on standard pallets, covered with plastic foil. If different

packaging is requested, this must be included in the purchase contract. The

standard accessories are placed on the pallet with the machine, or placed in the

machine loading hopper. All casings are disposable and charged to the customer.

XIV. Transport

The machine is transported by usual transportation means. When being

transported, the machine should be fixed to avoid spontaneous movement and

damage. For additional information –binding plan, Appendix No. 1.

XV. Storing

The machine and accessories must be stored in spaces protected against the

elements, excessive dampness, acid vapours, oils and fungi.

XVI. Servicing

Servicing is carried out in accordance with the servicing conditions given in the

Operating and Maintenance Instructions.

Concrete Spraying Machine –SSB 02.1

12

XVII. List of Standards

At the Machine design and conformity review the following Standards have been

used: Directive of the European Community No. 98/37/ES –Mechanical

Equipment, Basic Requirements according to Appendix No. 1 to NV 24/2003 Sb.,

Czech National Standards (ČSN) EN ISO 12100–2, ČSN EN 294, ČSN EN 418,

ČSN EN 811, ČSN EN 953, ČSN EN 983, ČSN EN 1037, NV 178/2001 Coll.,

NV 502/2000 Coll., ČSN EN 1127-2, ČSN EN 12620, ČSN EN 13055-1,

ČSN ISO 2768-1, ČSN EN 60204-1, ČSN EN 12329, ČSN EN ISO 9692-1 and

ČSN ISO 3864.

XVIII. Supplements

Appendix No. 1: Binding plan

Appendix No. 2: Machine Assembly

The End

Pribram –November 2008

Prepared by: Ing. Jiri Labuda

Company: FILAMOS, s.r.o., Hate 546, 261 01 Pribram, Czech Republic

Concrete Spraying Machine –SSB 02.1

13

Appendix No. 1: Binding plan

Remove the rear

cover first.

Concrete Spraying Machine –SSB 02.1

14

Appendix No. 2: Machine Assembly

Air vibrator

Speed

Variator

Upper

pressure

gauge

Upper air

cock

Stop button

Start button

Lubrication

indicator

Lower

pressure

gauge

Lower air

cock

Main air cock

Emergency stop

Power

connector

Tightening

bolts

Central

lubrication

Hopper

Blower

Air outlet

Air connecter

Table of contents

Other Filamos Paint Sprayer manuals