TransTank WeedMasta User manual

“HELPING TO DEVELOP AND PROTECT THE LAND”

Operator’s Product HandBook

Backpack / Trolley Sprayer

WeedMasta™

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

2

Contents

Safety 4

General Safety Instructions 5

General Information 6

Specifications 6

Description 7

Machine Limitations 8

Recommended Pesticides and Spray Nozzles 8

WeedMasta Operating Instructions 9

Before first use 9

Filling the WeedMasta Tank 11

Operating Instructions 12

Clean-up and Decontamination 13

Maintenance 14

Periodic Checks 14

Maintenance Schedule 14

Trouble Shooting 17

Pump 17

Risk Assessment 18

Warranty 19

Warranty Policy 19

What this Warranty Does Not Cover? 19

How to Obtain Service Under this Warranty? 19

Warranty Limitations 19

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

3

Disclaimer

All information, illustrations, and specifications contained in this manual are based on the latest

product information available at the time of this publication’s printing. TransTank International

(TTi) reserves the right to alter and substitute specifications and methods at any time, in line

with our commitment to continuous improvement.

No patent liability is assumed with respect to the use of information contained within this

manual. While every precaution has been taken in the preparation of this manual, TTi assumes

no responsibility for errors or omissions.

Thank you for purchasing a TTi WeedMasta™ Rechargeable Knapsack Sprayer

with Trolley (WeedMasta), which will provide many years of reliable service

when operated and maintained in accordance with this manual.

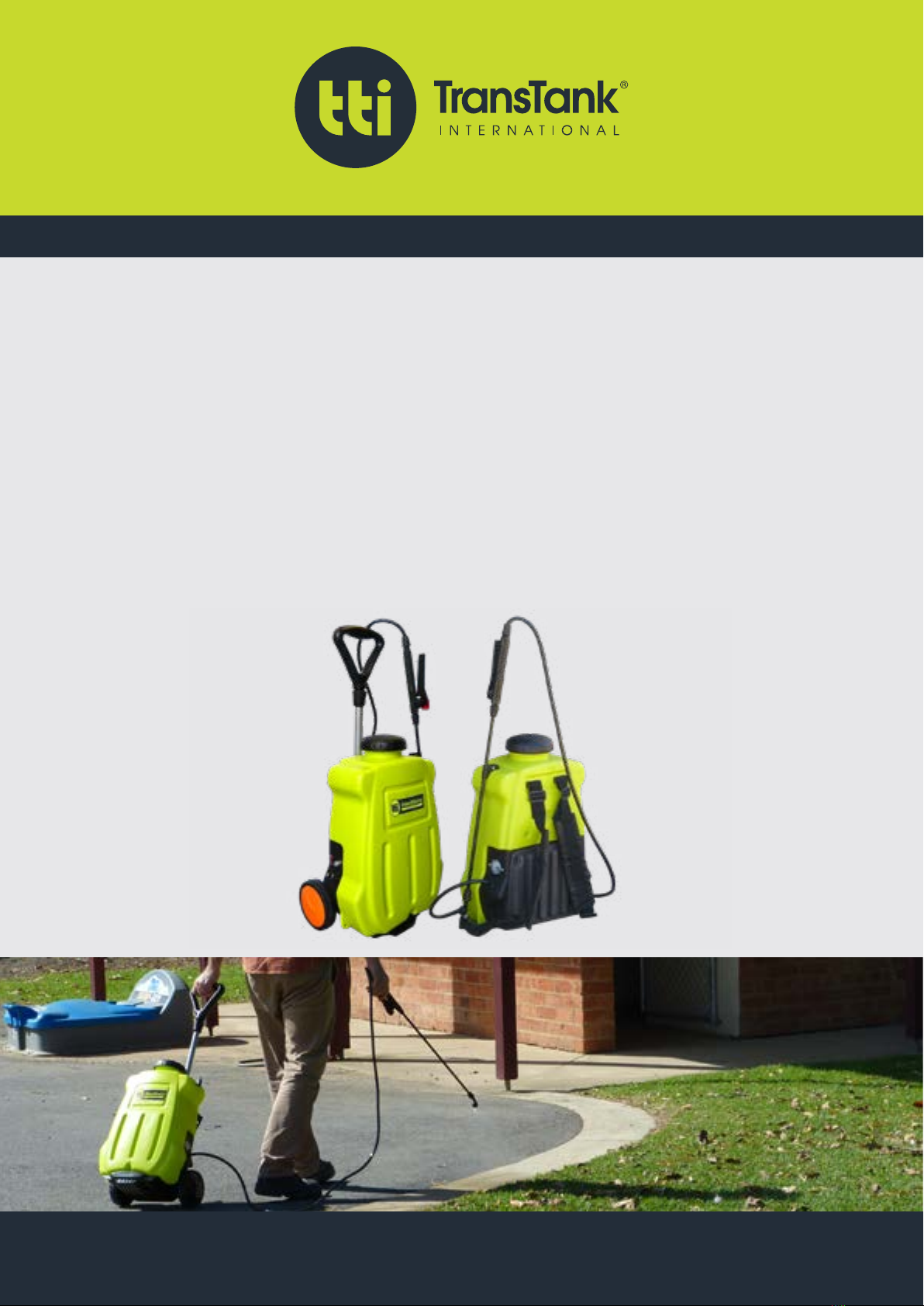

The TTi WeedMasta unit has a capacity of 16 litres and includes a sturdy trolley as standard. With the

trolley easily removed, the WeedMasta is equipped with padded shoulder straps and backrest for maximum

comfort when using as a knapsack in more difficult terrain.

Supplied with a 12-volt variable speed electric pump and built-in sealed lead acid battery, the WeedMasta

provides over two hours of continuous spraying from a single charge. The WeedMasta is fitted with a kink-

free hose and trigger operated lance. This manual describes the operation and maintenance procedures

applicable to the WeedMasta.

All TTi WeedMasta tanks are rotationally moulded from quality polyethylene, purpose designed and

manufactured to high standards. The WeedMasta is specifically designed to be towed by hand using the

trolley, or worn as a knapsack, to spray everything from herbicides to pesticides at a constant pressure.

With the variable speed pump, pressure can be adjusted to suit your requirements.

The WeedMasta unit is supplied complete, tested and ready for use. TTi warrants that the WeedMasta has

been designed and built for its intended purpose as a pesticide/herbicide spray unit.

The owner is responsible to ensure that the equipment is operated in accordance with this manual, with

Australian WorkSafe requirements, and local council regulations. TTi is not liable for any loss, injury or death

resulting from the failure to observe all safe working regulations as required by law.

Included with your WeedMasta unit is the Operator’s Handbook (this manual, which includes the Warranty

Registration Card)

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

4

Safety

This manual is intended for use by personnel experienced in the use of this and similar equipment. Read and

understand this manual before attempting to operate or perform routine maintenance on this equipment.

Your safety is of prime priority.

A WARNING highlights an essential operating or maintenance procedure,

practice, condition or statement, which, if not strictly observed, could result in

injury or death of personnel, or long-term health hazards.

A CAUTION highlights an essential operating or maintenance procedure,

practice, condition or statement, which, if not observed, could result in damage

or destruction of equipment.

A NOTE highlights or clarifies an essential systems description, operating or

maintenance procedure, condition or statement.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

5

General Safety Instructions

1. This unit is designed and manufactured solely for the purpose of carrying and spraying herbicides and

pesticides. Under no circumstances should it be used for any other purpose.

2. Only authorised and trained personnel are to operate this equipment. Operators must have read and

fully understood this manual before operating the WeedMasta unit.

3. Do not operate the WeedMasta anywhere near bystanders, livestock, watercourses or any non-targeted

vegetation that may be in danger from spray drift contamination.

4. Wind direction and speed must be taken into account, as windy conditions may endanger the operator

or damage to adjacent non-target vegetation. Avoid spraying on hot and sunny days or when wind speed

exceeds 6.5km/h.

5. Do not operate this equipment while under the influence of alcohol or any drugs that could impair your

capabilities in any way.

6. PPE appropriate to the chemicals being used must be worn at all times when operating the WeedMasta.

As a minimum, the PPE should include coveralls, gloves and boots. A face shield and PVC apron are

recommended depending on the task. It is recommended that the following documents should be read

and understood by the operator:

• Australian Standard for Chemical protective clothing AS3765

• Australian Standard for Respiratory protection devices AS1715

7. Care should be taken when lifting the WeedMasta, particularly when used as a knapsack, to avoid back

injury. As a guide, one litre of water weights one kilogram (kg), therefore a full 16 litre WeedMasta will

weigh in excess of 20kg.

8. In knapsack mode, ensure the WeedMasta is securely and comfortably worn, with the padded shoulder

straps adjusted correctly to reduce shoulder and back strain.

9. Care should be taken at all times, particularly when operating on rough or steep terrain.

10. The WeedMasta must never be left unattended while being filled with fluids.

11. Do not operate the pump when there is no fluid in the tank.

12. Do not disconnect any hoses, nozzles or filters while the equipment is operating. Disconnecting any

components while under pressure may result in uncontrolled fluid discharge which may be hazardous.

13. Ensure any electrical connections are properly configured, to prevent damage such as shorting or

reverse polarity.

14. At completion of operation, switch the pump off and relieve any residual pressure by squeezing the spray

gun trigger.

15. At completion of the operation, decontaminate the WeedMasta tank and spray lines. Drain any residue

chemicals and store in a sealed container. Dispose of any unwanted chemicals and tank rinse residue in

accordance with current environmental and workplace health and safety regulations.

16. The WeedMasta has safety labels affixed to various locations on the unit. These labels should be kept

clean and legible, and replaced if damaged.

17. Any unauthorised modifications to this equipment may affect its function and create a serious safety

risk. Any unauthorised modifications will void any warranty on the unit.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

6

General Information

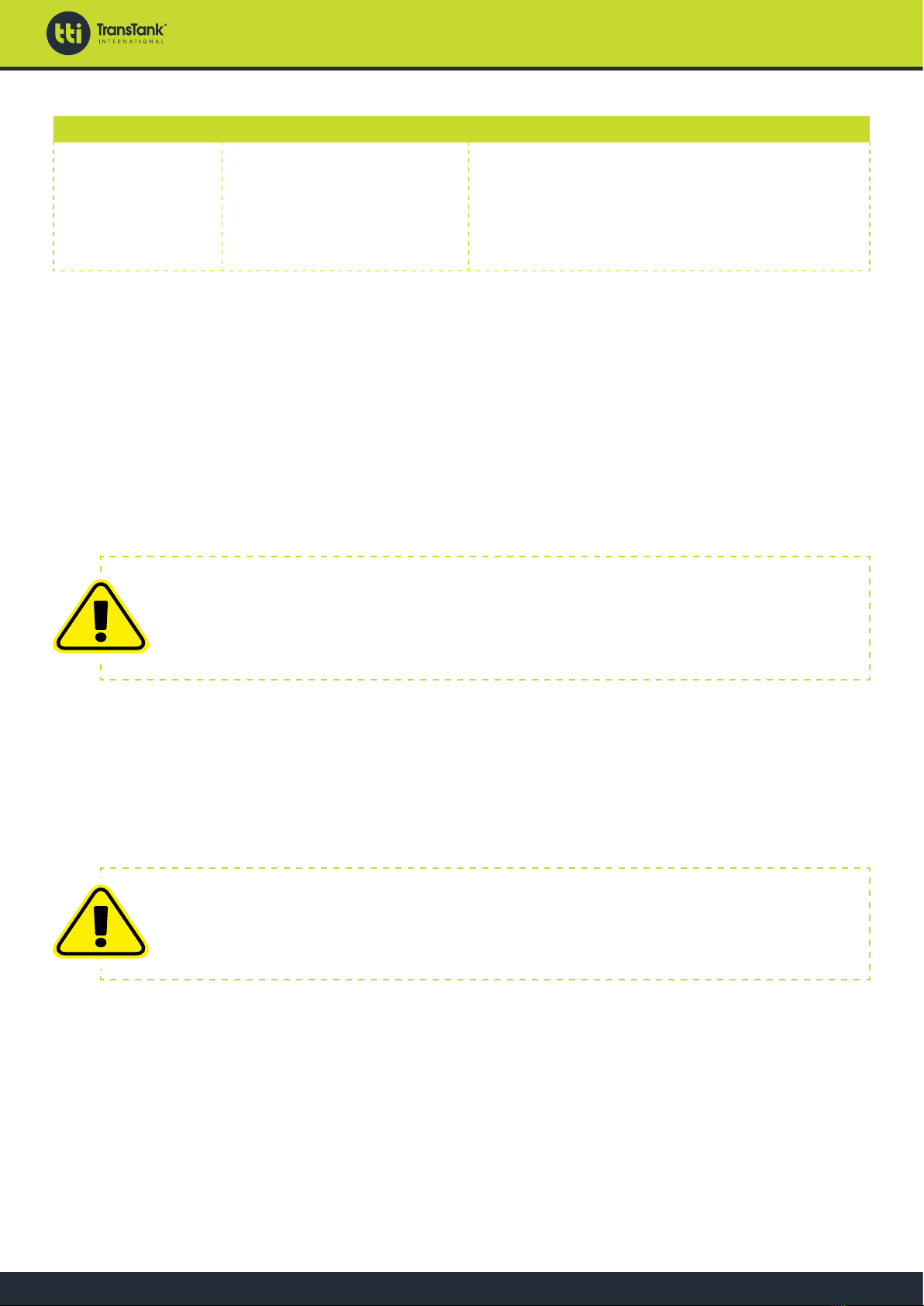

Specifications

Tank UV resistant polyethylene tank complete with large diameter lid and basket

filter – 16 litres capactity

Trolley Composite material and steel with height adjustable handle

Standard

Equipment

12V electric variable speed pump, 2.4L/min 70psi with ON-OFF switch and

fuse

Built-in rechargeable sealed lead acid battery

Kink resistant hose with spray gun and lance, c/w various nozzles:

• Cone spray nozzle – 3.0 – 4.5 Bar, 0.7 – 0.9 L/min

• Double spray nozzle – 2.5 – 4.0 Bar, 1.3 -1.6 L/min

• Fan spray nozzle – 0.2 – 0.4 Bar, 0.6 – 1.1 L/min

• Four-hole adjustable nozzle – 0.2 – 0.4 Bar, , 0.6 – 1.1 L/min

Three-stage Battery charger

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

7

Description

The TTi WeedMasta Rechargeable Sprayer is designed to carry and distribute herbicides or pesticides

using a self-contained pump and spray gun. The WeedMasta has the features shown in Figure 1

Figure 1 – Component Identification

Pump

The WeedMasta is fitted with a 2.4 L/min 70psi 12V variable speed electric pump, enabling adjustable

spray pressure. The pump pressure is controlled via rotary potentiometer next to the ON-OFF switch,

which varies the speed of the pump’s motor. If the spray gun is not in operation when the pump is running,

the fluid bypasses back into the tank.

Battery

The built-in sealed lead acid 12 volt rechargeable battery is connected directly to the supplied battery

charger via the socket adjacent to the power switch on the side of the WeedMasta. With the battery fully

charged, it will deliver more than two hours of continuous spraying.

Hose and Spray Gun

A manually coiled 10mm diameter kink resistant hose is connected to a trigger actuated spray gun

with a variety of nozzles supplied, depending on required use. When the trigger is squeezed, the

fluid is discharged; when the trigger is released, the fluid bypasses back into the tank. The spray gun

incorporates a sliding catch to lock the trigger open for broad coverage spraying. The spray gun has a

built-in filter and is stowed by means of a clip on the side of the WeedMasta tank.

Trolley

The WeedMasta trolley is constructed from robust composite materials, featuring large wheels and handle

for maximum ergonomic operation. The handle shaft incorporates three holes at lower end, enabling the

securing screw to be fitted for the most convenient height.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

8

Tank

All TTi tanks are constructed from UV resistant, virgin material polyethylene. The tank is fully drainable

and has an internal basket strainer under the large filling cap. A small filter is located in the tank,

accessible through the tank filler opening.

Filters

The WeedMasta has a double filter system, in addition to the basket filter in the tank lid. The suction filter

is located inside the bottom of the tank, and is easily removed and installed. The secondary filter is inside

the spray gun’s handle unit.

Machine Limitations

The WeedMasta units are subject to operating limitations. It is the operator’s responsibility to ensure that

this equipment is being operated safely and within these limitations.

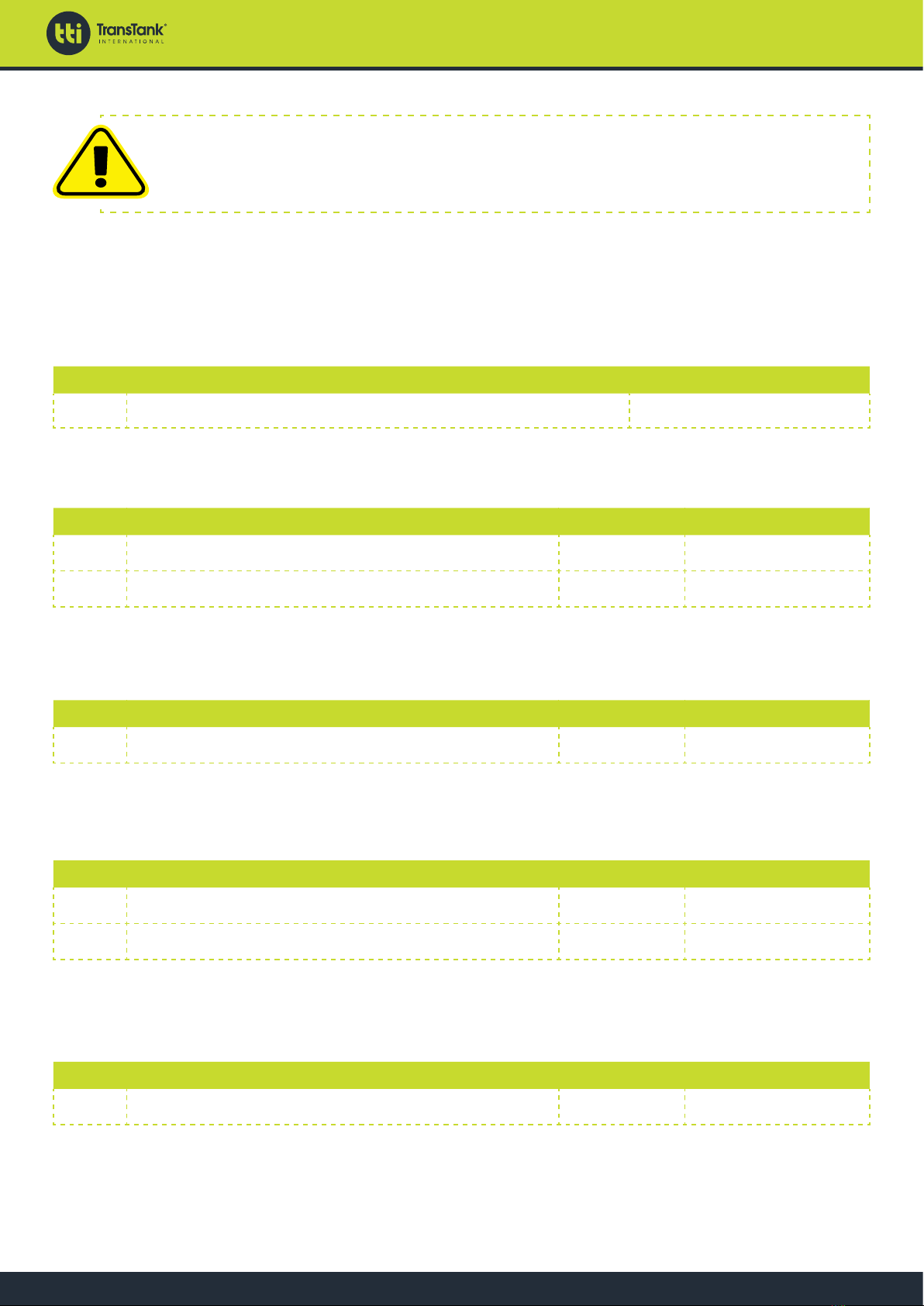

Recommended Pesticides and Spray Nozzles

PPE appropriate to the chemicals being used must be worn at all times when calibrating and filling the

WeedMasta. As a minimum, the PPE should include coveralls, gloves and boots. A face shield and PVC

apron are recommended. The following pesticides and nozzle combinations are as follows:

Pesticide Use Directions for use

Isoprocarb (MIPC) For control of planthopper,

leafhopper on rice fields.

Mix 150-200mL MIPC with 75-100kg water. Use the cone

nozzle to spray evenly with the wind on one side and crossly

spray in multi rows.

Capable of killing common thrips and leeches. Safe to

spiders and natural predators of planthopper.

Toxic to fish and bee, and can be harmful to tuber crops.

Unfit for application on tuber crops.

Chlorothalonil For prevention of stalk rot

on wheat

• Mix 11g 75% wettable powder with 6kg water for every

100 square metres.

For Prevention of leaf

mold and spot blight on

vegetables

• Mix 135 - 150g wettable powder with 60-80kg water. Use

the cone nozzle to spray evenly with the wind, on one side

and crossly spray in multi-row.

For prevention of downy

mildew on fruit trees

• Mix 75-100g 75% wettable powder with 30 - 40kg water.

Use the adjustable spray nozzle with the four apertures

to spray evenly with the wind, accompanied by significant

loss of chemical. Being toxic to fish, operate far away

from fish ponds.

Fluazifop-butyl Applicable for annual

graminaceae weeds with

strong inhibition function to

budlets of weed.

Safe to broad-leaf crops. Of no force for dicotyledonous

weeds. Toxic to fish, use the fan spray nozzle to spray evenly

with the wind, on one side while moving forward in a parallel

manner. Be sure to avoid hurting other unintended crops by

the chemical fog.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

9

Crops To control Dilute rate

Wheat, Barley, Bean,

Cole, Peanut, Beet,

Potato, etc.

Cockspur grass, Hairy

crabgrass, Oat grass, Dentes

foxtail, Green foxtail, Chinese

sprangletop, and other annual

graminaceae weeds

Mix 40-50g active ingredient with 60kg water to spray

in one mu (approx. 0.16 acre)

WeedMasta Operating Instructions

Before first use

Your WeedMasta Sprayer is delivered partially assembled and ready for final assembly. Before use, it needs

to be set up using the following instructions:

1. Complete the warranty registration online at www.tti.com.au/warranty-registration, or use the Warranty

Registration Card at the back of this handbook.

2. Store this handbook in a safe and easily accessible place for future reference.

WARNING: The operator must fully understand all aspects of this handbook. Do not

operate the WeedMasta unit if you are unfamiliar with its operation until you have

read this handbook.

3. Read and thoroughly understand this handbook, paying particular attention to all safety requirements,

before using the WeedMasta for the first time.

4. Check that all fittings, hoses and electrical leads are secure following transit, and are not damaged in

any way.

5. Inspect the tank for any damage or abrasions that may occur during transit.

6. Tighten the two hand-nuts securing the WeedMasta to the trolley.

NOTE: If the WeedMasta is to be used as a knapsack, TTI recommends adjusting the

padded shoulder straps and trying it on while empty.

7. If the unit is to be used as a knapsack, loosen the two hand-nuts and lift the WeedMasta out of the trolley.

Unfold the straps and adjust to suit by lengthening or shortening as required.

8. Assemble the trolley handle unit as follows, refer to Figure 2:

a. Insert the handle onto the end of the shaft with the single hole, aligning the shaft hole with the

corresponding hole on the handle.

b. Using a screwdriver, insert the supplied screw to lock the handle onto the shaft.

c. Slide the cover nut along the shaft and tighten it onto the handle.

d. Insert the handle assembly into the top of the trolley, aligning one of the three shaft holes with the

corresponding hole in the trolley body.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

10

e. Using a screwdriver, insert the supplied screw to lock the handle shaft into the trolley body.

f. Slide the cover nut along the shaft and tighten it onto the trolley body.

9. Unpack the spray gun and lance, then assemble, selecting the required nozzle as determined by the

spray requirements.

10. Connect the spray gun’s hose to the WeedMasta outlet.

NOTE: The WeedMasta’s battery is fully charged at the factory, however, some

discharge may occur during storage and transit.

11. Fully uncoil the battery charger leads and plug the connector into the WeedMasta’s charger socket.

Plug the 240V cable into a power point and turn ON.

12. At the WeedMasta, check that the pump speed potentiometer is turned fully anti-clockwise, then turn

the power switch to ON, to enable the built-in battery condition voltmeter. The state of the battery is

determined as follows:

a. GREEN indicates a fully charged battery

b. YELLOW indicates a partially depleted battery but has some residual power available

c. RED indicates extremely low battery power that requires immediate charging.

13. If charged, turn the power switch to OFF and unplug the charging cable. Your WeedMasta is now ready

for use.

Figure 2 – Trolley Handle Assembly

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

11

Filling the WeedMasta Tank

WARNING: Ensure the filling area is in an open, well-ventilated space if filling with

chemicals. Follow the instructions provided with the chemicals or the applicable

Safety Data Sheet.

Mixing and filling the WeedMasta unit should be undertaken at a carefully chosen site, away from any risk

of spillages draining into water courses or into environmentally sensitive areas. Children and animals must

always be kept away from mixing and filling operations.

The WeedMasta’s tank is filled as follows:

1. Open the tank filler by twisting and lifting the cap.

2. Withdraw the internal basket strainer and inspect it for any debris. Clean it if required and reinstall it into

the top of the tank.

3. Follow the chemical manufacturer’s instructions and safety precautions carefully, taking note of the

order in which the products are added to the tank.

4. Measure the correct quantities of chemicals using clean measuring containers specifically for this

purpose only, then add the chemicals to the tank.

5. Rinse out the measuring containers and any empty containers and pour all rinsing liquid into the

WeedMasta tank.

CAUTION: Do not overfill the tank. This may result in chemical spillage.

CAUTION: The WeedMasta must never be left unattended while being filled with

fluid.

6. Top up the tank with water to the required level, ensuring it is not overfilled.

7. Thoroughly mix the contents by stirring with a suitable paddle.

8. Upon completion of filling the WeedMasta tank, replace the filler cap and twist to tighten.

9. Wash off any spillage from outside the tank.

10. Close the chemical supply containers and store appropriately. Any empty containers must be thoroughly

rinsed and set aside for collection and disposal in compliance with environmental and work safety

requirements.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

12

Operating Instructions

The WeedMasta is started and operated as follows:

WARNING: Suitable PPE must be worn by the operator when conducting manual

hose spraying operations.

CAUTION: Do not spray in windy conditions, where spray drift contamination may

occur.

1. Confirm the tank contains the required chemical or water quantity.

2. Check that the battery has sufficient charge (refer to Before first use section).

CAUTION: Ensure the potentiometer is set to the minimum position.

3. At the pump, check that the adjustable potentiometer is set to the minimum position by turning the knob

anti-clockwise, refer to Figure 3.

Figure 3 – WeedMasta Controls

4. Start the pump by turning the power switch to ON.

5. With the pump running, turn the potentiometer knob clockwise to the required pressure. As a guide,

refer to the nozzle details and delivery rates in the Specifications table.

6. Unclip the spray gun from its holder on the side of the tank.

7. Aim the spray gun in the required direction and squeeze the trigger.

8. Use a constant speed when spraying and release the trigger at the end of each swath or change of

direction, to prevent overdosing. Work in parallel lines when spraying large areas, rather than swinging

from side to side.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

13

9. At the end of the task, release the spray gun trigger and switch the pump to OFF.

10. With the pump now turned OFF, aim the spray gun in the required direction and squeeze the trigger. This

will release the residual pressure in the hose, which will result in a small amount of fluid discharging.

11. With the hose pressure released, the hose is ready to stow back on the WeedMasta.

Clean-up and Decontamination

After use, the WeedMasta unit must be thoroughly decontaminated inside and outside – including the

pump, hoses, boom and spray gun – to avoid damage to crops from any harmful pesticide spray residues.

Decontamination also prevents sprayer corrosion and abrasion.

Cleaning the WeedMasta should be undertaken at a carefully chosen site, away from any risk of spillages

draining into watercourses or into environmentally sensitive areas.

The recommended decontamination procedure is as follows:

WARNING: Suitable PPE must be worn by the operator when cleaning and

decontaminating the WeedMasta unit. Follow the instructions provided with the

chemicals or the applicable Safety Data Sheet.

WARNING: Ensure the cleaning area is in an open, well-ventilated space, and any

flushingwateriscapturedtopreventrunoffintowatercoursesor intoenvironmentally

sensitive areas.

1. After spraying operations are complete, drain any residual fluid from the tank. Capture and dispose or

store any fluid in accordance with environmental and work safety requirements.

2. Rinse out the tank with several changes of water, plus a recommended cleaning fluid. Where it can be

reached internally, use a brush to scrub the inside of the tank.

3. Operate the WeedMasta unit with clean water, using the spray gun, to ensure no chemical residue

remains.

4. Reaching inside the tank, pull the small suction filter off its mount near the bottom of the tank – the filter

is shown in Figure 4. Soak the filter screen in clean water, brushing carefully with a nozzle brush. Refit

the filter by pressing it back into its mount.

5. Ensure that the tank’s basket strainer is free from chemical residue or debris.

6. Unscrew the rear section of the spray gun trigger unit and withdraw the filter, refer to Figure 4. Clean

and reassemble.

7. Nozzles, nozzle filters, nozzle caps and gaskets should be cleaned by soaking in water, brushing with

a nozzle brush and allowed to dry. Do not blow through the nozzles or use wire or pins to clear any

blockages.

8. Dispose of all rinsing water in compliance with environmental and work safety requirements.

If the WeedMasta unit is to be stored for an extended period, thoroughly clean and decontaminate the unit

as described above. Ensure it is allowed to dry, the tank and all lines empty and not pressurised then store

it in a well ventilated area.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

14

Figure 4 – WeedMasta Filters

Maintenance

Your WeedMasta Spray Trailer requires minimal maintenance but regular cleaning and checks will ensure

safe and reliable service over its lifetime. Periodic checks and inspections will identify any potential issues,

enabling timely rectification and minimising downtime.

Periodic Checks

CAUTION: In dusty, dirty or smoky environments, cleaning, inspection and servicing

of the unit on a regular basis is essential. The cleaning, inspection and servicing must

be undertaken more frequently in harsh conditions to avoid damage or destruction

of equipment.

The following checks and cleaning operations should be undertaken on a regular basis (at least annually).

The frequency of these activities will depend on the nature of the operating environment and the operational

hours of the WeedMasta unit. Refer to the maintenance schedule tables below for details of maintenance

intervals.

1. Clean the unit and inspect it for any signs of damage or wear. Replace any safety labels if they are

damaged or illegible.

2. Check all fittings are firmly secured, tighten if necessary.

3. Unwind the hose fully to check that hose is in good order. Pressurise the line and check operation of

spray gun nozzle.

4. If the WeedMasta is to be stored for an extended period, thoroughly clean and decontaminate the unit as

described above. Ensure it is allowed to dry, the tank and all lines empty and not pressurised then store

it in a well ventilated area.

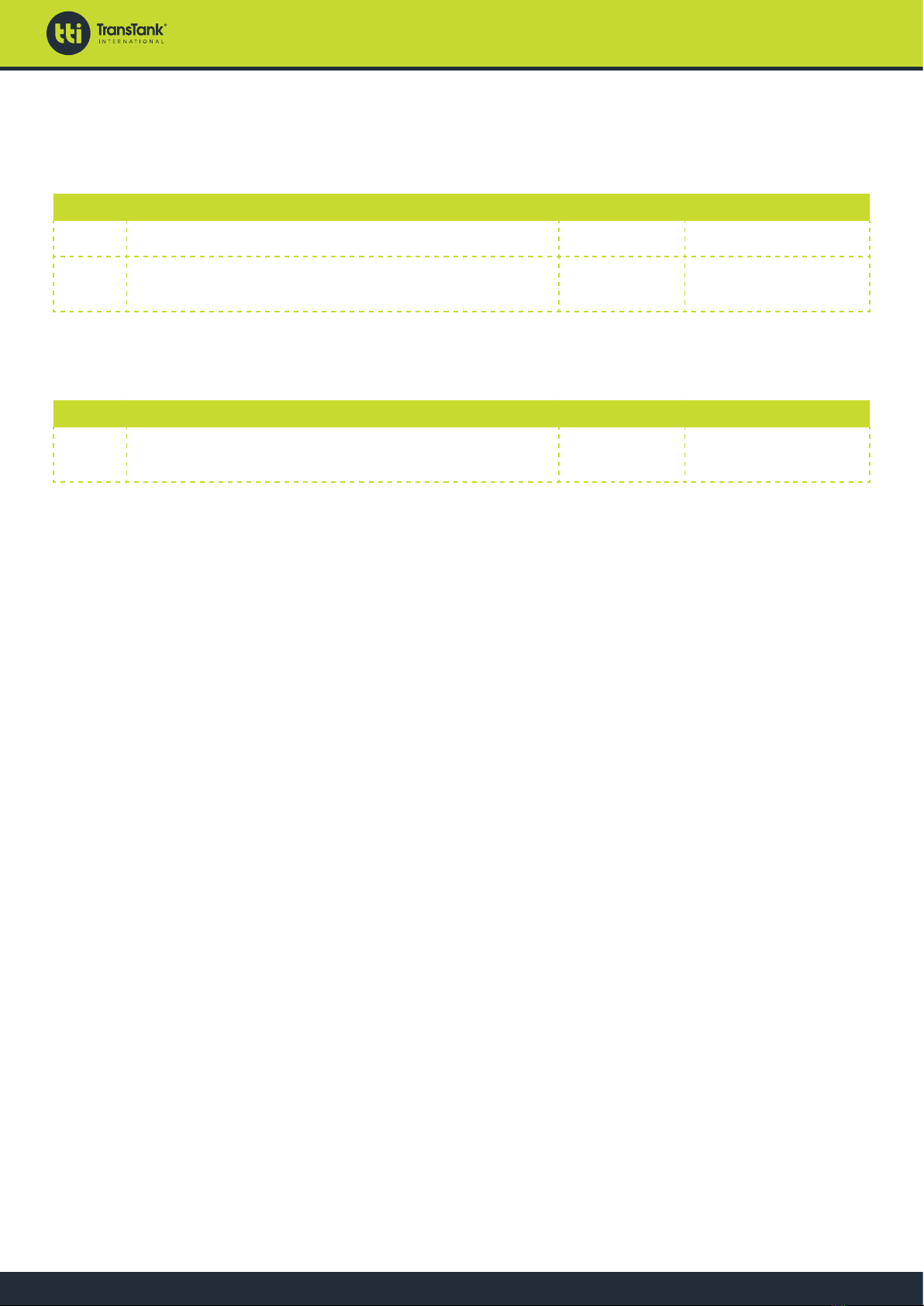

Maintenance Schedule

The following tasks are be conducted in accordance with each of the schedules. All scheduled tasks are to

be undertaken concurrently. For example, at the three month maintenance interval, all task listed are to be

undertaken, in addition to the daily, weekly and monthly tasks.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

15

NOTE: Maintenance is important. Keep a record of all maintenance tasks conducted

on the WeedMasta unit.

TTi recommends photocopying these schedules in order to keep a detailed log of all maintenance tasks. A

copy of these schedules will be required to support any warranty claim.

Daily tasks

The following tasks are to be undertaken daily, or prior to each use, of the WeedMasta unit.

No. Task Notes

1Inspect the WeedMasta unit for any signs of damage or wear Clean, repair or replace

Weekly Tasks

The following tasks are to be undertaken each week or 10 operating hours, whichever occurs first.

No. Task Date Signed

1All Daily tasks

2Check battery, charge if necessary

Monthly tasks

The following tasks are to be undertaken each month or 20 operating hours, whichever occurs first.

No. Task Date Signed

1All Daily and Weekly tasks

Three Monthly tasks

The following tasks are to be undertaken every three months or 50 operating hours, whichever occurs first.

No. Task Date Signed

1All Daily, Weekly and Monthly tasks

2Check all hoses, fasteners, nozzles and fittings

Six Monthly tasks

The following tasks are to be undertaken every six months or 100 operating hours, whichever occurs first.

No. Task Date Signed

1All Daily, Weekly, Monthly and 3-Monthly tasks

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

16

Twelve Monthly tasks

The following tasks are to be undertaken every twelve months or 200 operating hours, whichever occurs

first.

No. Task Date Signed

1All Daily, Weekly, Monthly, 3-Monthly & 6-Monthly tasks

2Check internal tank and spray gun filters, replace if

required

Two-Yearly tasks

The following tasks are to be undertaken every 24 months or 500 operating hours, whichever occurs first.

No. Task Date Signed

1All Daily, Weekly, Monthly, 3-Monthly, 6-Monthly and

12-Monthly tasks

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

17

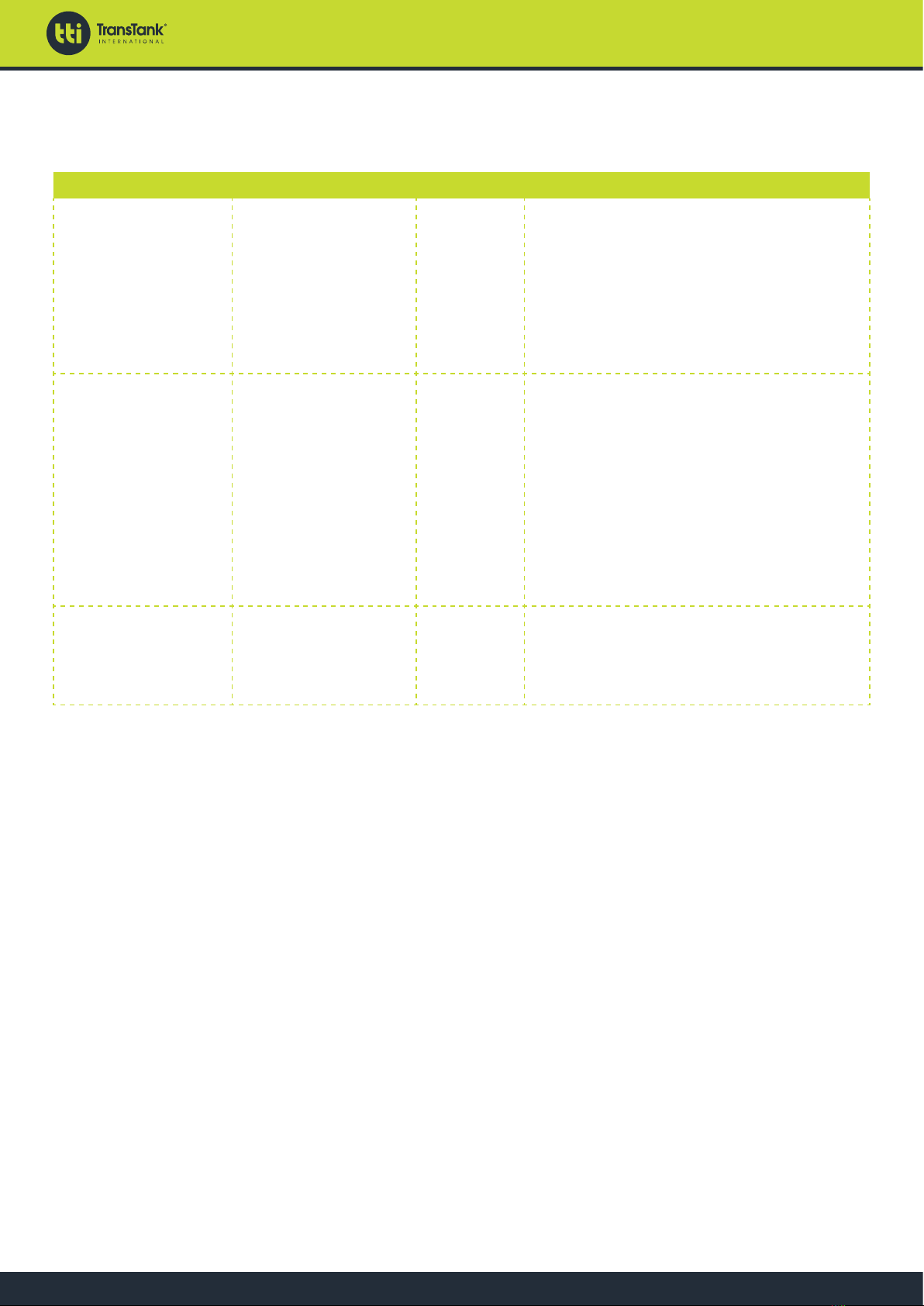

Trouble Shooting

If a fault develops with your WeedMasta unit, the following trouble shooting tables provides guidance to

identify and rectify the problem.

Pump Problem Possible cause Remedy

The motor fails to run after

being turned ON.

• The pump pressure has been set

at the min. value.

• Fuse burn-out

• Battery out of power

• Power switch has been damaged

• Power wires broken/

disconnected

• Motor damaged

• Potentiometer has been damaged

• Turn the knob clockwise to increase

the pressure

• Replace

• Recharge

• Replace the switch

• Disassemble the base to reconnect

the wires

• Replace the Motor

• Replace the Potentiometer

Abnormal sounds while the

motor rotates

The pump fastening screws are loose Tighten the screws

Leakage occurs to the

underside of the base

The pump inlet and outlet hoses loose

or broken

Disassemble the base to tighten the hose

clamp or repair it.

Poor atomization results • Extra-low pump pressure

• Sprinkler sheet holes are blocked

• Spray hole and split sheet are worn

out

• Spraying sheet has been inversely

assembled

• Pipe joints may be loose

• Battery short of power

• One inlet valve or outlet valve of

the pump has been jammed to

reduce the pressure by 50%

• Turn the knob clockwise to increase

the pressure

• Remove the debris

• Replace the sheets

• Disassemble and correct it

• Tighten the joint

• Recharge the battery

• Remove the base, pump clean water

while knocking at the pump head

gently; disassemble the pump housing

to repair

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

18

Risk Assessment

Task Hazard Risk Control Measure/Mitigation

Check weather

conditions

Manual handling; slips,

trips or falls

Low • Wear PPE as per chemical requirements

SDS – coveralls, gloves, safety footwear,

glasses & respirator

• Follow safe manual handling techniques:

don’t lift on your own if >20kg, bend knees

& keep back straight.

Mix chemicals (if

applicable) and fill

spray tank

As above, spray drift,

chemical spillage,

emission of vapours or

flammability: weather,

untrained visitors

Medium • As above

• User trained in relevant chemical mixing &

administration course, e.g, Chem Cert;

• Follow relevant Environmental Protection

Authority requirements;

• Fire extinguisher nearby;

• Keep visitors away from job location

unless wearing full PPE.

Clean up, maintenance

& storage

As above Low • As above;

• Continue to wear PPE for clean up;

• Store unit in a dry, well ventilated area.

www.tti.com.au

WeedMasta™

PRODUCT HANDBOOK

Freecall: 1800 816 277

19

Warranty

Warranty Policy

TTI will, at its option, repair or replace without charge any part covered by this warranty which is found

to be defective in material and/or workmanship within one (1) year after date of sale to the original retail

purchaser. If the product is used for rental purposes, this warranty is limited to ninety (90) days.

Upon request, the customer will make the defective part available for inspection and/or return the defective

part to TTi, transportation charges prepaid. All parts and components are covered by this warranty except

the following, which are warranted separately by their respective manufacturers:

⦁ engines

⦁ gearboxes

⦁ pumps

⦁ regulators.

TTi does not assume any warranty obligation, liability or modification for these items, which are covered

exclusively by the stated warranty of the respective manufacturers.

What this Warranty Does Not Cover?

This warranty does not cover:

1. Defects caused by depreciation or damage caused by incorrect mounting, normal wear, accidents,

improper maintenance, improper use or abuse of the product, alterations or failure to follow the

instructions and warnings provided.

2. Any charges for making service calls, clean up time and transport charges.

3. The use of non-genuine parts on equipment supplied by TTi. This will automatically negate any warranty.

How to Obtain Service Under this Warranty?

Warranty service can be arranged by contacting your dealer, or by contacting TTi directly on 1800 816 277.

Proof of warranty registration and date of purchase may be required to verify warranty coverage. Any

defective parts returned to TTI must be accompanied by a Return Goods Note. This form can be obtained

by contacting Product Support on 1800 816 277 or emailing ProductSupport@tti.com.au.

Warranty Limitations

Warranty limitations are as follows:

1. There is no other express warranty. Any warranty that may be implied from this purchase including

merchantability and fitness for purpose is hereby limited to the duration of this warranty and to the

extent permitted by law. Any and all implied warranties are excluded.

2. TTI will not be liable for any incidental, consequential or special damages and/or expenses in connection

with the purchase or use of this equipment, to the extent permitted by law.

3. Only the warranty expressed in this limited warranty shall apply and no dealer, distributor or individual

is authorised to amend, modify, or extend this warranty in any way. Accordingly, additional statements,

whether oral or written, do not constitute warranties by TTi, and should not be relied upon.

1800 816 277

PO Box 137, Nathalia, VIC, 3638

Murray Valley Hwy, Nathalia, VIC 3638

Proudly Built By:

Signature Date Signature Date

Quality Checked By:

www.tti.com.au

Table of contents

Other TransTank Paint Sprayer manuals