DC000154-000 Rev. 2

FR20V AND FRHP32V

Technical Data

• Output: 11 oz per stroke (33ml)

Fluid Compatibility (FR20V, FRHP32V & FRAP32V)

• Engine oils

• Diesel

• Antifreeze

• Paraffin

DEF Compatibility (FRHP32V & FRAP32V)

• AUS32 (Aqueous Urea Solution 32.5%) Diesel Exhaust Fluid

Wetted Materials (all pumps)

• Polypropylene (body and valves)

• Stainless Steel (inlet screen)

• Fluorocarbon (O-rings)

* Before using with acids or aggressive chemicals, check compatibility of wetted

materials with the chemical manufacturer.

Technical Information and Specifications

FRAP32V

Technical Data

• Ratio: 1:1

• Air Pressure Regulator: 100 PSI

• Air Inlet: 1/4" BSP

• Maximum Air Pressure: 100 PSI

• Minimum Air Pressure: 30 PSI

• Air Consumption: 30 gal/min

• Exhaust: Double Baffled

• Maximum Sound Level @ 1m (3'): 74 db

Output Data (approximately 8.5 oz/stroke when fully primed)

• Hydraulic Oils (ISO 32): 0 - 5 GPM

• Lubrication Oils (ISO 68): 0 - 4 GPM

• Gear Oils (ISO 220): 0 - 2.5 GPM

• Diesel Exhaust Fluid (AUS32): 0 - 6.5 GPM

Minimum Operating Temperature

It is recommended that the pump is not used below 36°F because ice

formation may cause the regulator to malfunction.

• Gear oils

• Hydraulic oils

• Mild acids*

• Degreasers

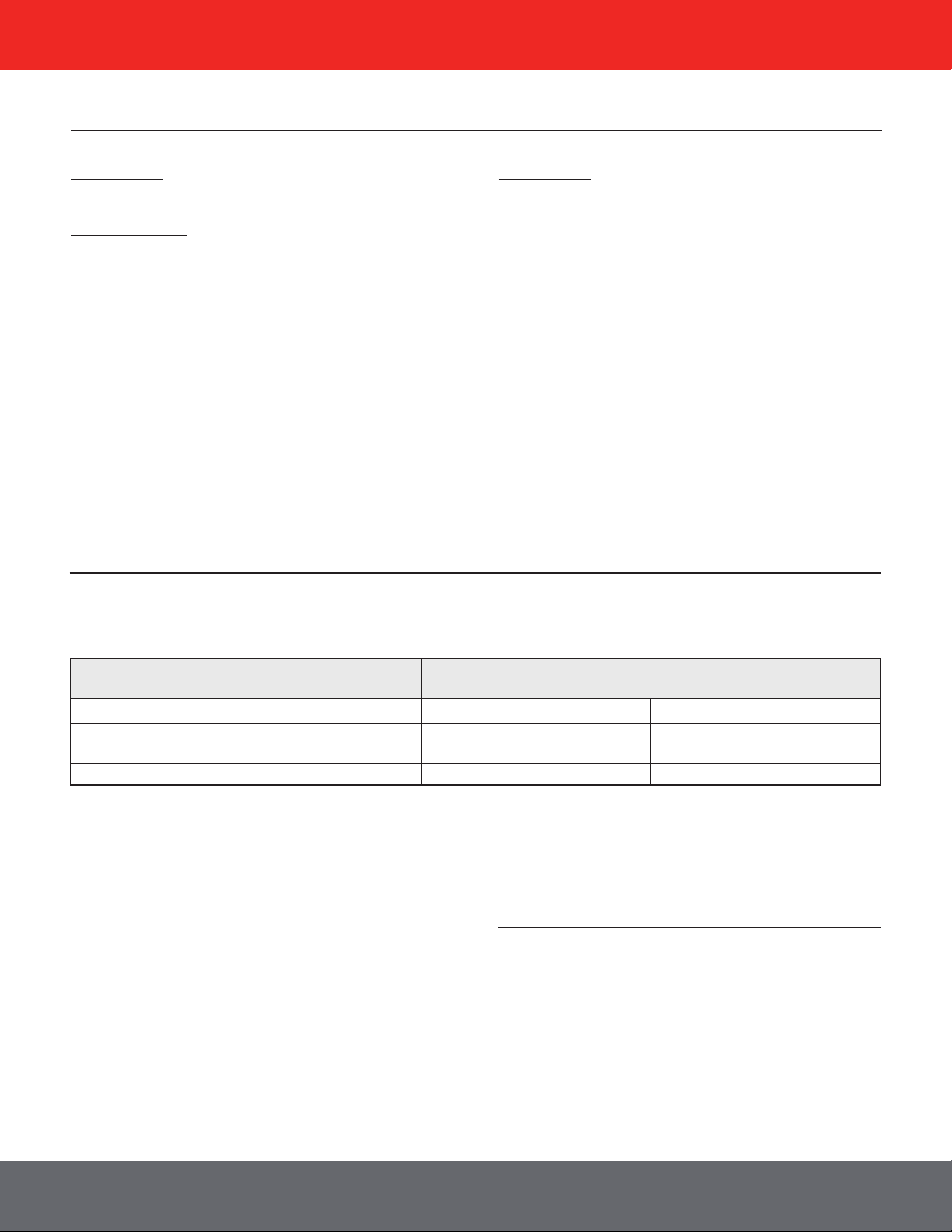

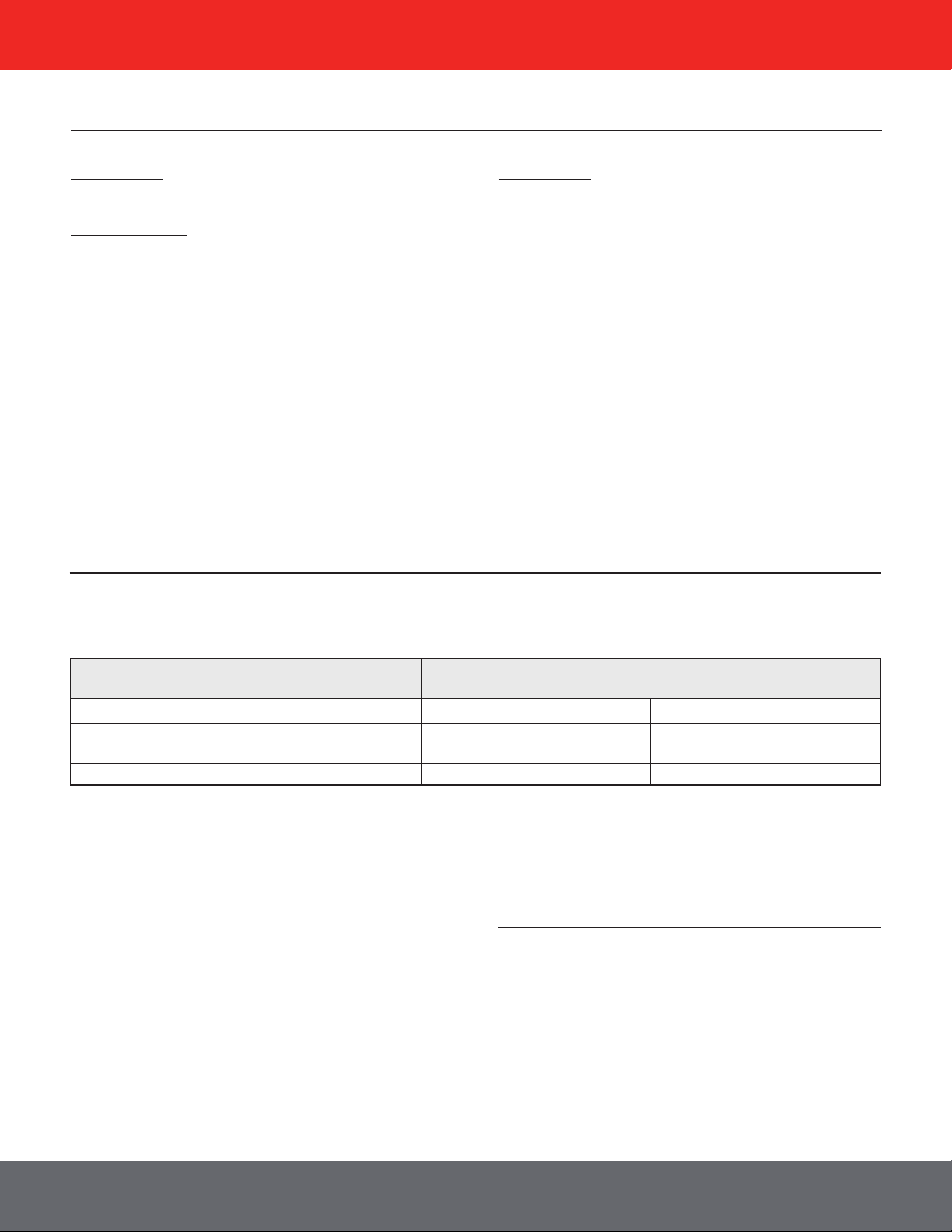

Fill-Rite Limited Product Warranty Policy

Revision Date: August 1, 2014, Fill-Rite and Sotera Products

Fill- Rite Company (“Manufacturer”) warrants each consumer buyer of its products (“Buyer”) from date of sale that goods of its manufacture (“Goods”) shall be free

from defects of materials and workmanship. The duration of the warranty is as follows:

From Date of Sale Not to Exceed the Following Period

from Date of Manufacture Product Series

Five Years 60 Months SP100 Series Pumps 400 Series Pumps

Two Years 27 Months Heavy Duty Pumps and Meters, 820, 825, 850

Meters

Cabinet Pumps, Cabinet Meters, TN Meters, TM

Meters, TS Meters

One Year 15 Months Standard Duty Pumps, 1600 Pumps Accessories, Parts

End users must contact the place where they purchased the product to

process a warranty. “Place of purchase” is defined as any authorized

Fill-Rite Distributor, including any and all retail stores, mail order houses,

catalogue houses, on-line stores, commercial distributors.

Manufacturer’s sole obligation under the foregoing warranties will be limited

to either – at Manufacturer’s option – replacing defective goods (subject

to limitations hereinafter provided) or refunding the purchase price for

such Goods theretofore paid by the buyer, and Buyers exclusive remedy

for breach of any such warranties will be enforcement of such obligations

of the Manufacturer. If the Manufacturer so requests the return of such

Goods, the Goods will be redelivered to the manufacturer in accordance with

Manufacturer’s instructions FOB Factory.

The remedies contained herein shall constitute the sole recourse of the Buyer

against the Manufacturer for breach of warranty. IN NO EVENT SHALL THE

MANUFACTURER’S LIABILITY FOR ANY CLAIM FOR DAMAGES ARISING OUT OF

THE MANUFACTURE, SALE, DELIVERY, OR USE OF THE GOODS EXCEED THE

PURCHASE PRICE.

The foregoing warranties will not extend to goods subject to misuse, neglect,

accident, improper installation or maintenance, or have been repaired by

anyone other than the Manufacturer or its authorized representative.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES OF MERCHANTABILITY, FITNESS FOR PURPOSE OF ANY OTHER

TYPE, WHETHER EXPRESSED OR IMPLIED. No person may vary the forgoing

warranties or remedies, except in writing signed by a duly authorized officer of

the Manufacturer. The Buyer’s acceptance of delivery of the Goods constitutes

acceptance of the foregoing warranties and remedies, and all conditions and

limitations thereof.

Fill-Rite Company

8825 Aviation Drive

Fort Wayne, Indiana 46809 USA

T 1 (800) 720-5192

1 (260) 747-7524

F1 (800) 866-4681

fillrite.com | sotera.com | gormanrupp.com