Filtec FT-50 Installation manual

Document 40378-0502

Dud Inspection Operation Manual

Can and Bottle Inspection

for the FT-50 and FT-70

Industrial Dynamics Company, Ltd.

Document 40378-0502 Copyright. All rights reserved.

No part of this publication may be reproduced or used in any form or by any means (graphic,

electronic, or mechanical including photocopying, recording, taping, or information storage

and retrieval system) without written permission of Industrial Dynamics Company, Ltd.

Filtecand Industrial Dynamicsare registered trademarks of Industrial Dynamics Company,

Ltd. All other trademarks are the property of their respective owners.

Contact Information

Corporate Headquarters: 3100 Fujita Street,

Torrance, California

90505-4007

U.S.A.

Telephone:(310) 325-5633

FAX: (310) 530-1000

Internet: www.filtec.com

Mailing Address: P.O. Box 2945,

Torrance, California

90509-2945

U.S.A.

Shipping Address: 3100 Fujita Street,

Torrance, California

90505-4007

U.S.A.

Customer Service: (800) 733-5173

1

Document 40378-0502

Dud Inspection Overview

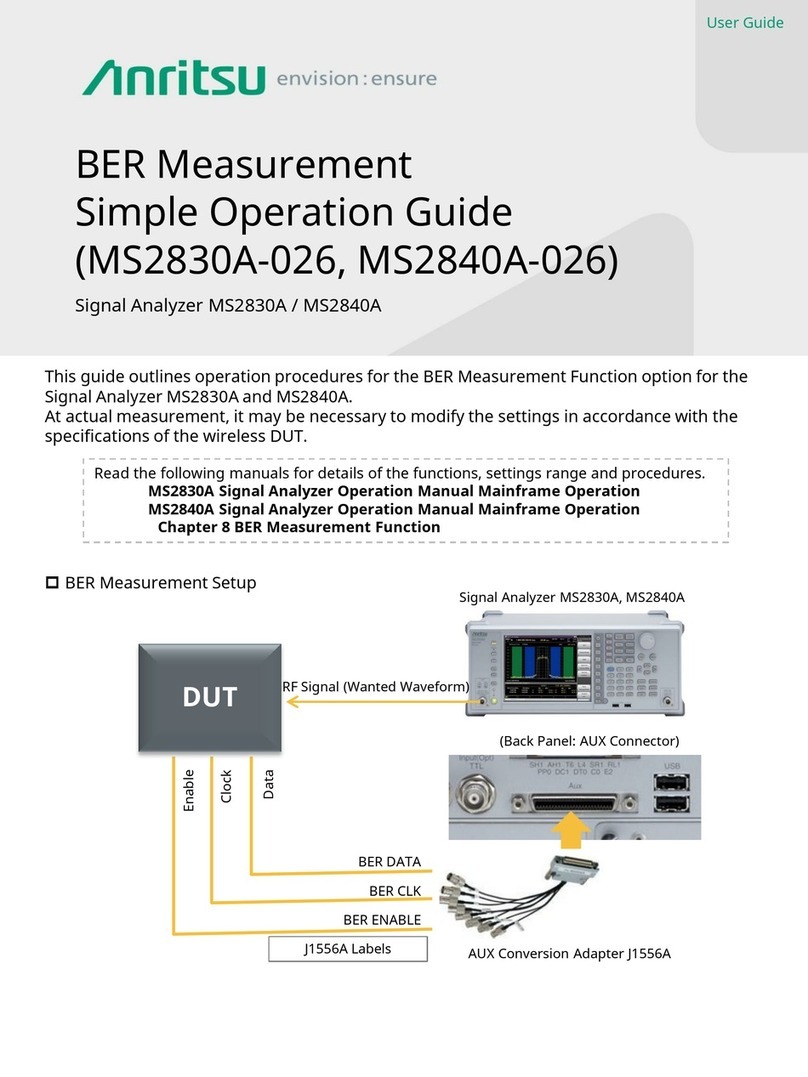

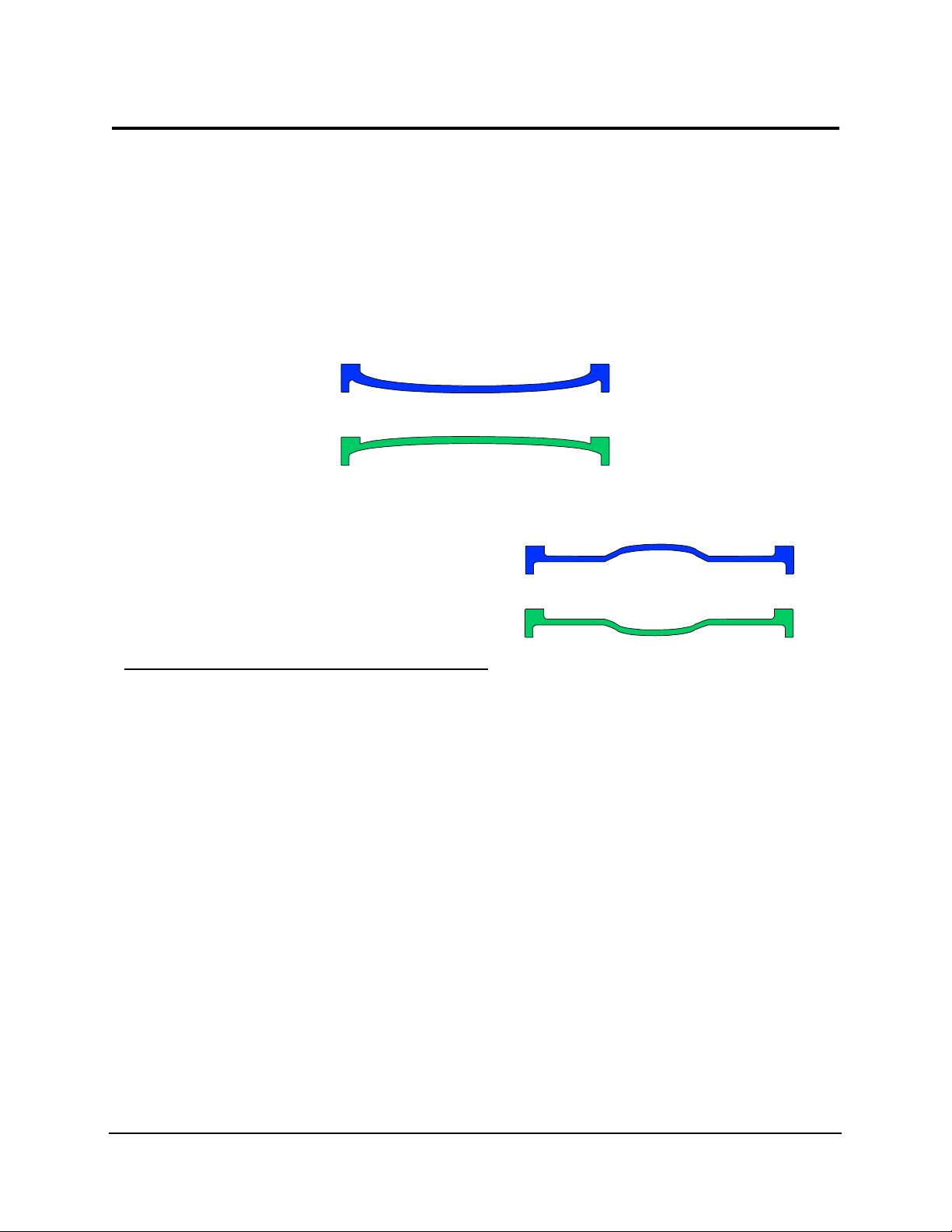

Dud inspection detects improperly sealed vacuum or pressure

sealed containers. If the container is not sealed properly, the

container shape is distorted and the dimensions at the inspection

reference point will deviate from a correctly sealed container.

When inspecting cans the reference point is the lid and when

inspecting bottles the reference point is the cap seal button.

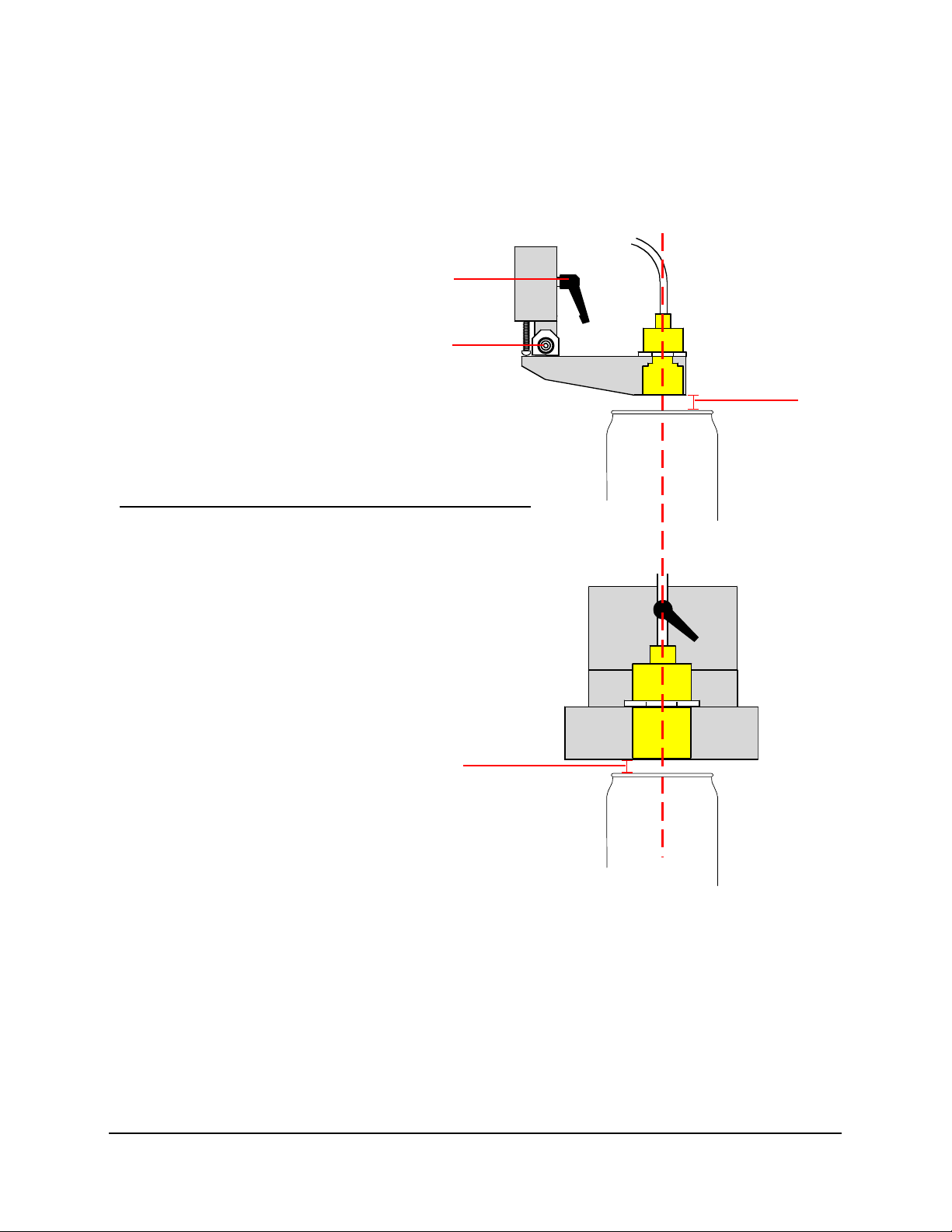

Figure 1. Lid and cap characteristics of vacuum and pressure

sealed containers.

If a container is pressurized properly and the seal is intact, the

pressure will distort the lid or cap by raising it (pressurized) or

indenting it (vacuumed). If the container is not pressurized

properly, or the seal is not intact, the cap is not raised or

indented as there is low pressure or indented as there is over

pressure.

1

2

3

4

No. Description

1 Vacuum seal good as lid is indented.

Pressure seal bad as lid is indented (dud).

2 Vacuum seal bad as lid is raised (dud).

Pressure seal good as lid is raised.

3 Vacuum seal bad as cap button is raised (dud).

Pressure seal good as cap button is raised.

4 Vacuum seal good as cap button is indented.

Pressure seal bad as cap button is indented (dud).

2Dud Inspection Operation Manual

Document 40378-0502

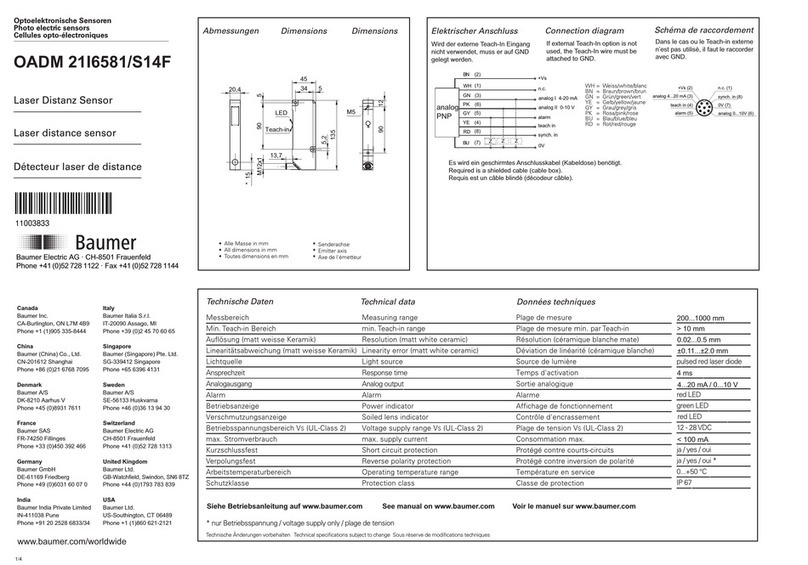

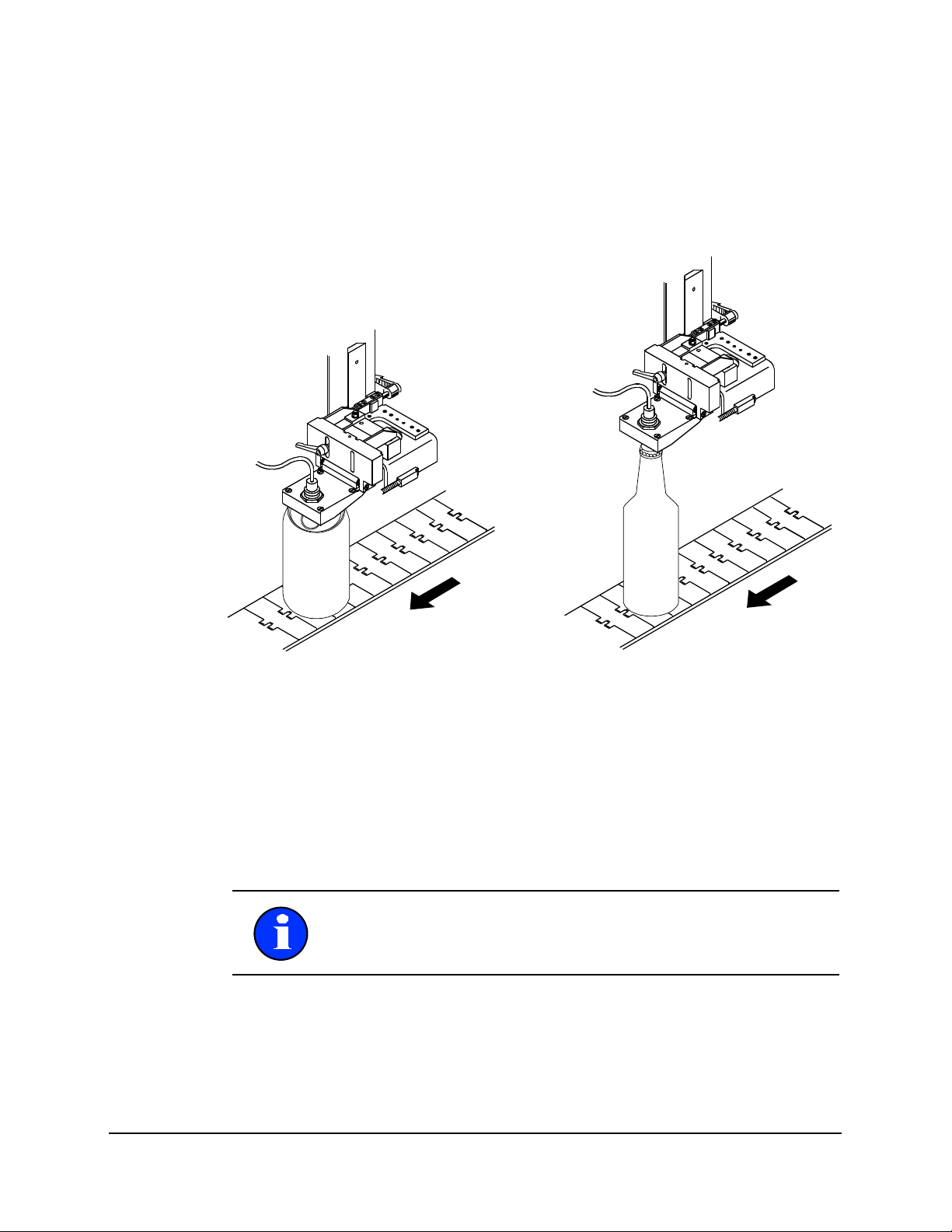

As the container passes under the proximity sensor the sensor

determines if the seal is intact based on the distance between

the sensor and the top surface of the lid or cap. If the lid or cap is

too far from the sensor, the pressure seal is not intact because

the cap is not raised high enough by the container pressure.

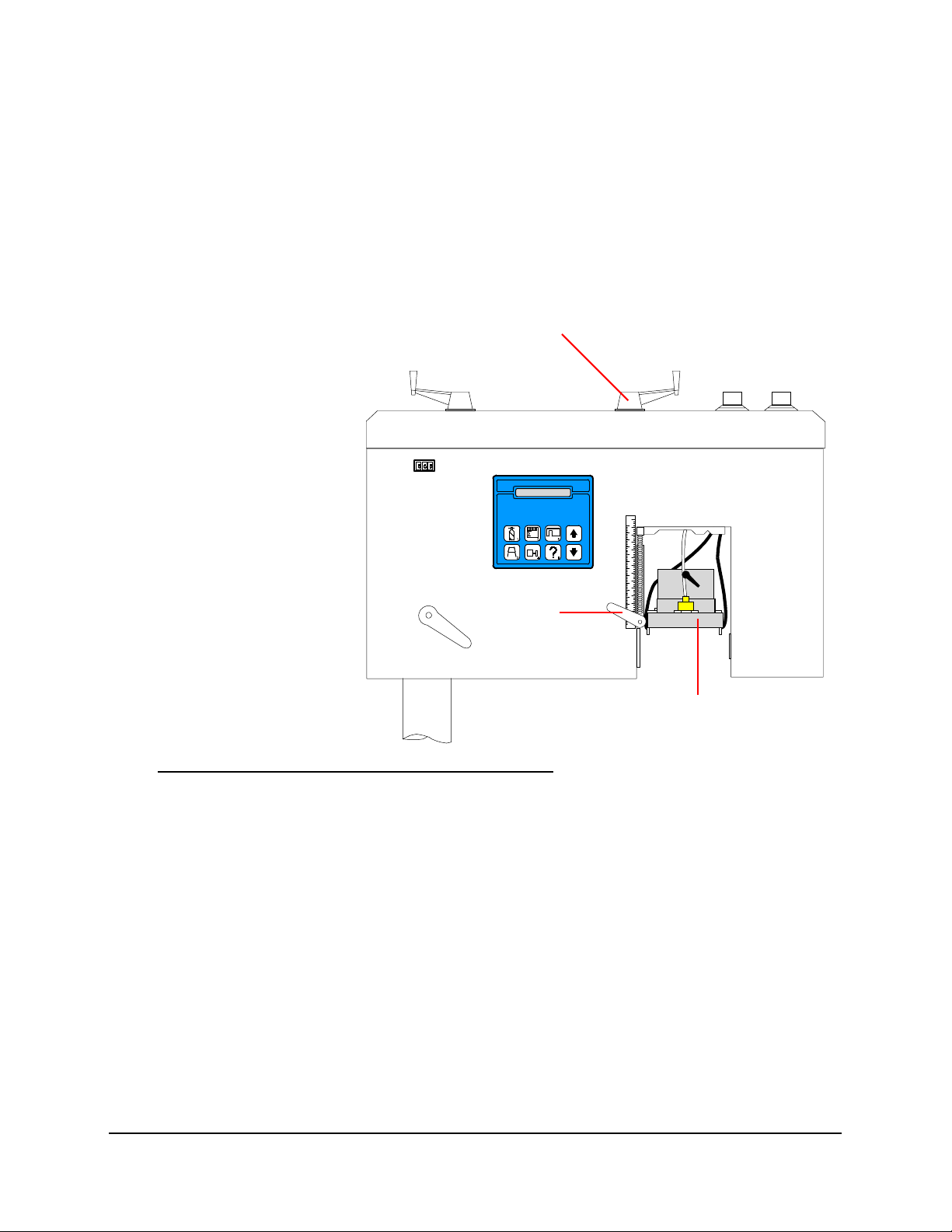

Figure 2. Containers passing under the dud inspection sensor.

When configuring dud inspection you must pass both good and

bad containers through the inspection tunnel to perform the

automatic calibration procedure. This determines the threshold

settings for good and bad containers. During inspection each

container is compared to these thresholds and non-conforming

containers are rejected.

For proper inspection, the overall variation in can height should

be no more than 1/16 inch (1.5 mm). The containers must flow

smoothly under the exact center of the dud sensor as they travel

on the conveyor.

Note: Low threshold defines the low pressure or over vacuum

and high threshold defines the over pressure or low vacuum.

3

Document 40378-0502

Container Changeover

When changing to a container type that does not require dud

inspection:

1. Press Key 5 until Dud Status appears and press the Arrow Key

to turn dud inspection off.

2. Perform the container fill level changeover as explained in

the inspection unit Operation Guide.

3. Verify the dud sensor is raised out of the way, so that it is not

will not be struck by the containers.

When changing to a container type that requires dud Inspection:

1. Perform the container fill level changeover as explained in

the inspection unit Operation Guide. This places the

proximity sensor at the correct height above the can.

2. Repeat the dud sensor alignment procedure. For more infor-

mation see Dud Inspection Sensor Alignment on page 4.

4Dud Inspection Operation Manual

Document 40378-0502

Dud Inspection Sensor Alignment

Before you align the dud sensor you must configure the inspection

head and inspection trigger to the proper height for fill level

inspection and calibrate the fill level inspection. Align the dud

sensor immediately after all fill level inspection adjustments are

complete. For more information refer to the service manual

provided with you inspection unit.

Also, verify the following:

• The containers are centered on the conveyor so they pass

directly under the center of the dud sensor.

• The dud sensor face is parallel with the top of the

containers.

1. Locate several good production containers. These should be

containers that pass all inspections. If the height of the

containers varies slightly, select the container that is the

shortest.

2. With the conveyor moving slowly and no production

containers present, place the good container on the conveyor

upstream of the inspection head.

3. Watch the container as it passes under the dud sensor and

verify the container is centered directly under the dud sensor

as it passes under the sensor.

4. Stop the conveyor and place the center the good container

directly underneath the dud sensor.

Note: Aligning the dud sensor can change the height of the

inspection trigger. After you align the dud sensor, verify the

inspection trigger height has not changed.

5

Document 40378-0502

5. Unlock the dud sensor height adjustment mechanism and

adjust the height of the sensor so the sensor’s face is 3/32

±1/32 inch [3 ±1 mm] above the container.

Figure 3. Centering a container under the sensor and adjusting

the height of the sensor.

1

2

3

3

No. Description

1 Height Adjustment Locking Lever

2 Bracket Pivot Hinge allows deflection if hit by container.

3 3/32 inch [3mm] space between can rim or bottle cap.

6Dud Inspection Operation Manual

Document 40378-0502

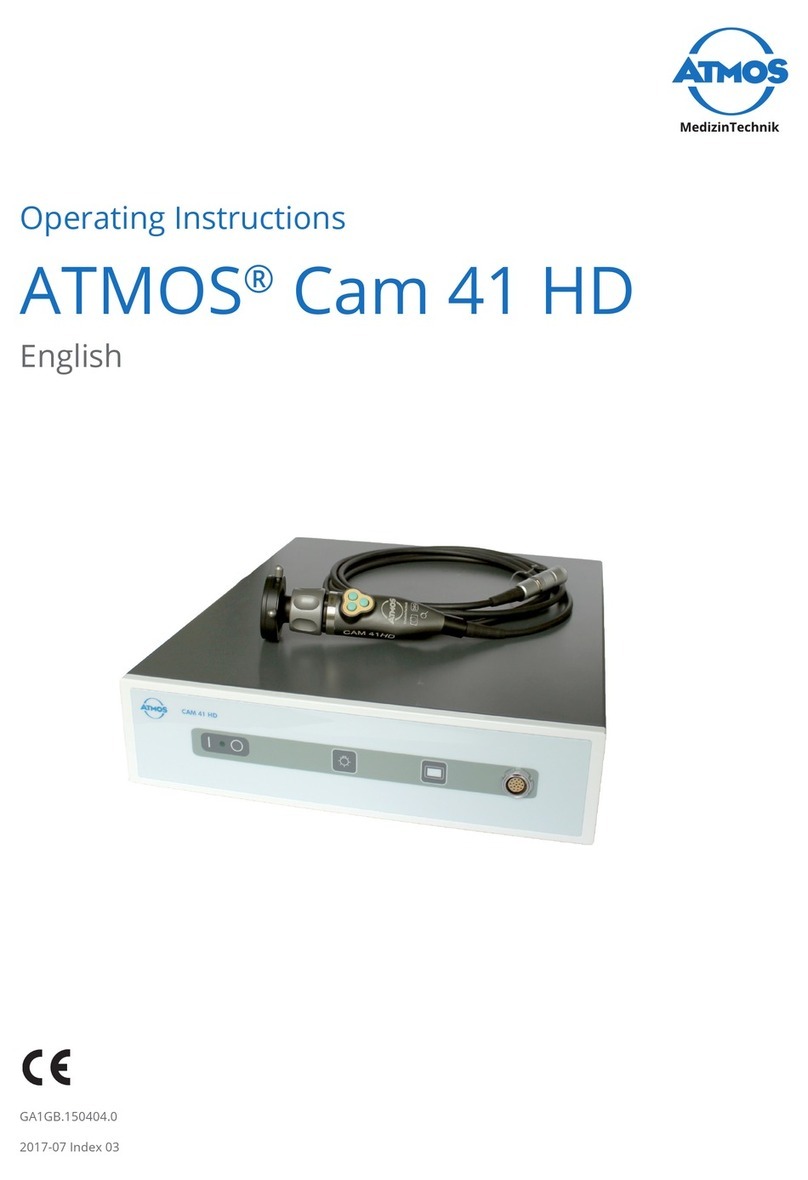

6. Verify the dud sensor face is parallel to the top of the can. If

necessary, use the adjusting screw to change the angle. When

complete, tighten the adjusting screw and its locknut

securely.

Figure 4. Level the sensor bracket parallel to the container top.

7. Press Key 5 until System Display appears.

8. Press the Arrow Key until Calibrate appears in the bottom line

of the display, and if prompted, enter the password to access

the Calibrate Mode.

9. Press Key 2 until Dud Status appears and verify the status is

turned on. If not, press the Arrow Key until ON appears. Dud

inspection is now activated.

10.Press Key 2 until Dud Readings appears. Four (4) readings are

listed on the bottom line. The reading marked C= is the

current dud sensor reading.

1

2

3

4

No. Description

1BracketPivotHinge

2 Bracket Leveling Adjustment Screw

3 Bracket is parallel with lid or cap

4 Direction of container flow

7

Document 40378-0502

11.Unlock the inspection (centerline) trigger adjustment

mechanism and raise or lower the sensor very slightly until

the C= reading is between:

• 120-140 for cans

• 70-90 for bottles

Record the position of the trigger on the trigger height scale

for ease of future container changeovers.

Figure 5. Fine tuning the sensor position.

12.Lock the inspection (centerline) trigger adjustment

mechanism.

13.Press the Key 5 until Container Width At Trigger appears and

verify the width of the container at the point where it inter-

sects the trigger is correct. For more information refer to the

Service Manual provided with your inspection system

1

2

3

No. Description

1 Centerline Bracket Height Locking Lever

2 Centerline Bracket Positioning Lever

3 Dud Sensor Bracket attached to Centerline Bracket

8Dud Inspection Operation Manual

Document 40378-0502

Dud Inspection Software Setup

1. Align the dud sensor. For more information see Dud Inspection

Sensor Alignment on page 4.

2. Prepare five good containers and four bad containers to use

during the calibration procedure.

• The good containers should be containers you are certain

will pass dud inspection and any other inspection enabled

on the inspection unit.

• The bad containers should be containers that you are

certain will fail only dud inspection, but pass all other

enabled inspection processes. For more information see

How to Create a Dud Container on page 12.

3. Press the Key 2 until Reject Undefined appears and press the

Arrow Key to turn the function On. The Reject Undefined

function enables rejection of any containers that give faulty

dud readings. These readings can be caused by:

• off-centered containers.

• containers with bulged, missing, deformed or abnormal

lids.

• bulged lid containers which struck the dud sensor bracket

and passed under the sensor before the bracket returned

to position.

• the sensor being too close to or too far away from the

container.

A low priority diagnostic will be generated for each undefined

reject to explain the cause of the reject.

Note: Turning the Beacon Status is on while setting up the dud

inspection enables low priority diagnostic messages, that can

help provide feedback about errors that can occur during the

setup procedure.

9

Document 40378-0502

4. Depending on the type of container you are inspecting,

proceed as follows:

• If you are inspecting bottles, proceed to step 5 on page 9

to determine the dud reference points for cap inspection.

When finished proceed to step 9 on page 10.

• If you are inspecting cans, proceed to step 5 on page 9 to

determine the dud reference points for cap inspection.

When finished proceed to step 9 on page 10.

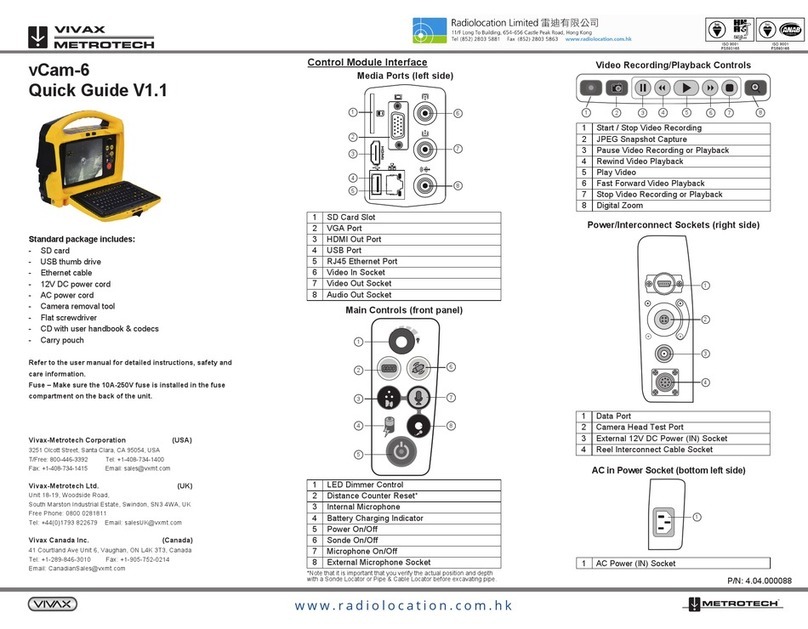

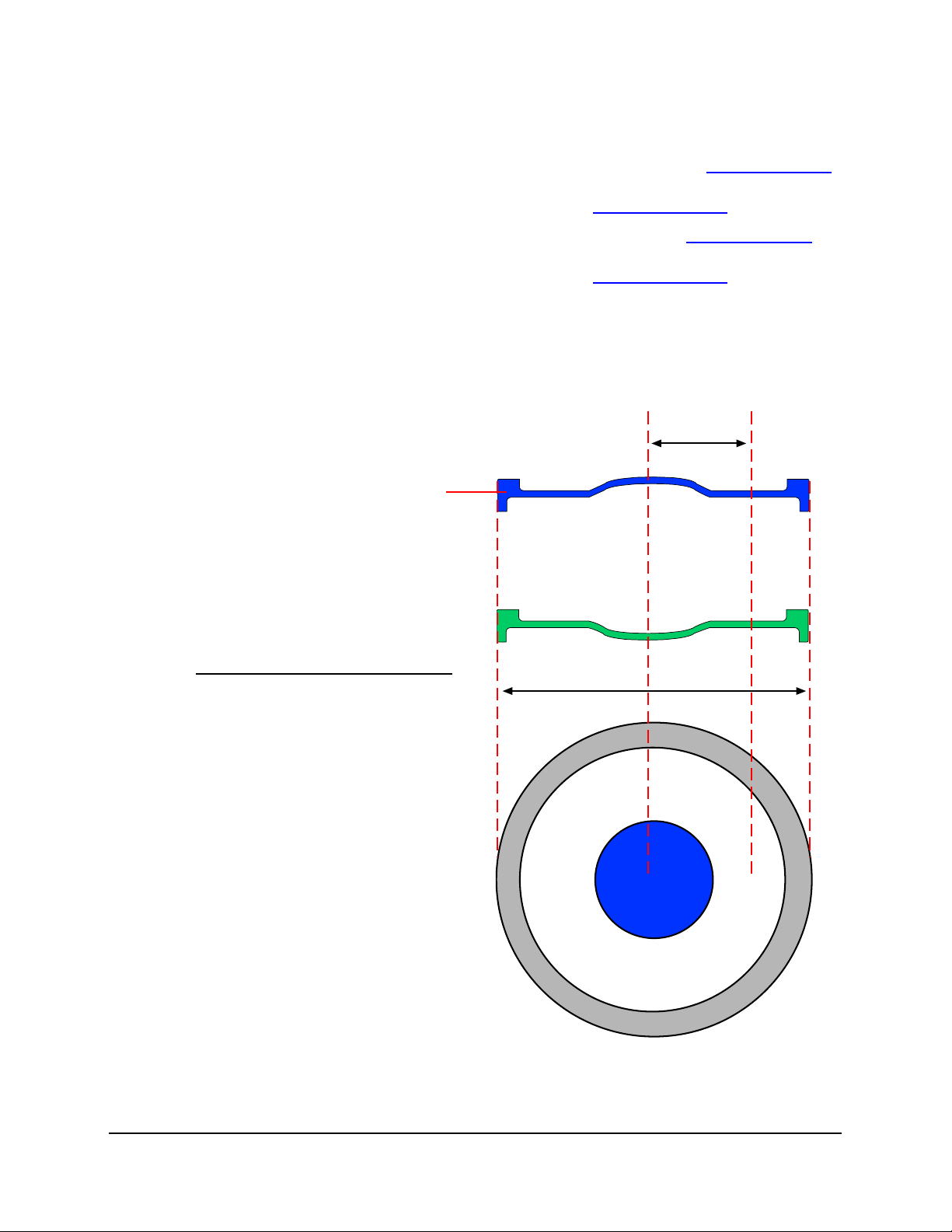

5. Determine the Dud Reference Points by measuring (in milli-

meters) from the center of the dud button outward to the

middle of the flat portion of the cap.

Figure 6. Measure the dud reference points.

12

3

4

No. Description

1 Center of Cap or Dud Button

2 Center of outer flat area.

3 Distance between 1 and 2.

4 Diameter of cap or lid.

5 Lip or Rim of Cap.

5

10 Dud Inspection Operation Manual

Document 40378-0502

6. Multiply the measurement from step 5 on page 9 by two (2) to

calculate the Diameter of Dud Reference Points.

7. Press Key 2 until Diameter of Dud Reference Points appears

and use the Arrow Key to enter the value you calculate in step

6 on page 10. When complete, proceed to step 9 on page 10.

8. Press Key 2 until Dud Insp. Method appears and use the Arrow

Key to select a can inspection method from the list below.

When you have selected an inspection method proceed to

step 9 on page 10.

9. Press Key 2 until Calibrate Dud appears and a flashing execute

message also appears.

10.Press the Arrow Key and a message instructing you to Run 5

Good Containers appears.

Method Description

Necked-in 3p Necked-in centering and 3-point inspection

point calculation. Default method used for

standard aluminum cans.

Necked-in Abs Necked-in centering an absolute inspection

point calculation. Can be used for standard

aluminum cans.

Chines 3p Chines centering and 3-point inspection point

calculation. Preferred method for standard steel

3-piece cans.

Chines Abs Chines centering and absolute inspection point

calculation. Can be used for standard steel 3-

piece cans.

Distance Abs Distance or encoder based centering and

absolute inspection point calculation.

Distance 3p Distance or encoder based centering and 3-point

inspection point calculation.

Necked-In Weighted Similar to Necked-in Abs and Necked-in 3P with

added logic to improve inspection margins.

Consult IDC Technical Support before using this a

method.

Measurement (mm) x 2 = Diameter of Dud Ref. Points

11

Document 40378-0502

11.With the conveyor running, place a good container on the

conveyor upstream of the inspection head. As the container

passes under the dud sensor, verify the beacon does not light.

• If there are no errors, pass 4 more good containers

through the inspection head. The display will count down

until the run is complete.

• If the beacon lights or the message Aborted appears, press

Key 6 to determine the cause of the fault. Correct the

error before proceeding.

12.You are now prompted to Run 4 Bad Containers through the

inspection head. When the data from the last can is

processed, Completed appears. Verify that the Beacon does

not light, indicating problems.

If the beacon lights or the message Aborted appears, press

Key 6 to determine the cause of the fault. Correct the error

before proceeding.

13.Repeat step 11 on page 11 and step 12 on page 11 to verify

14.Press Key 5 until Alarm Low or High Dud appears. Use the

Arrow Key to enter the number of consecutive rejects which

you want to cause a consecutive rejects alarm. When this

number of consecutive rejects occurs, a high priority

diagnostic message is activated and the beacon will flash.

15.Press the Key 5 until Alarm Undefined (Dud) appears. Use the

Arrow Key to enter the number of consecutive rejects which

you want to cause a consecutive rejects alarm.

12 Dud Inspection Operation Manual

Document 40378-0502

How to Create a Dud Container

The calibration and testing procedures used to setup dud

inspection require you to create or acquire at least four (4) bad

containers. Depending upon the type of container you are

inspection you will need to create dud cans or dud bottles.

Creating a Dud Can

To create a dud can puncture the can just below the lid seam and

allow the pressure to dissipate. Create as small a puncture hole

as possible and be careful not to disfigure the can. Alternatively,

you can fill cans with non-carbonated water and then pass them

through the seamer.

Figure 7. Creating a dud can.

Creating a Dud Bottle

To create a dud bottle, loosen the cap until the seal indiction

button pops and then tighten the cap.

1

No. Description

1 Puncture or drill a hole directly under the lip. Be

careful not to dent or alter the shape of the can.

13

Document 40378-0502

Dud Software Advanced Functions

The FT-50/70 includes special advanced functions that enable you

to configure the dud inspection parameters. These functions are

accessed through the following control panel keys:

Key 2: Can Finish

Dud Status

Enables or disables dud inspection. When disabled all dud

inspection functions deactivated and will not appear in the

software menus.

Reject Undefined

Enables rejection of any containers that give faulty dud readings

caused by:

•bulgedcan

• raised lid/high cap

• deformed lid/crooked cap

• container not centered under sensor

• sensor too far away from lid

• sensor too close to lid

Errors for undefined Rejects (in order of priority) are:

•DiagnosticError94

• Diagnostic Error 108

• Diagnostic Error 109

• Diagnostic Error 113

• Diagnostic Error 114

• Diagnostic Error 116

•DiagnosticError93

• Diagnostic Error 100

•DiagnosticError95

For more information see Diagnostic Errors on page 18.

14 Dud Inspection Operation Manual

Document 40378-0502

This function may also reject the container following a bulged

can or high cap that strikes the sensor bracket and the container r

passes under the sensor before bracket returns to position.

If your system contains a bulged can, raised can, or high cap

inspection, the dud inspection software will not increment the

undefined (dud) reject counter.

Dud Low Threshold

If the current dud value falls below the Low Threshold a low dud

reject is generated. A low threshold reject can be a low pressure

container or an over vacuum container depending on the appli-

cation.(range 255, default: 0).

Two values are stored under this setting; one for absolute

inspection and one for three point inspection. Only one is

displayed and adjusted depending on the method selected.

Dud High Threshold

If the current dud value falls above the High Threshold a over

pressure reject is generated. A high threshold reject can be a

high pressure container or an under vacuum container depending

on the application.(range 255, default: 0).

Two values are stored under this setting; one for absolute

inspection and one for three point inspection. Only one is

displayed and adjusted depending on the method selected.

Diameter of Dud Reference Points

This diameter is used to help find the center of the container for

both the necked-in and chines inspection methods. It is automati-

cally calculated in during the calibrate dud procedure. It should

only need manual adjustment in special applications.(Range: 1

mm - 90% of Can Width At Trigger, default: 35 mm)

Diameter of Dud Inspection Points

The diameter in millimeters used in the 3 point inspection

methods. Used as a flowing reference for inspection. It is

automatically calculated in during the calibrate dud procedure.

This should only need manual adjustments in special applica-

tions.(Range: 1-255 mm)

15

Document 40378-0502

Calibrate Dud

Automatically calibrates the dud inspection and calculates the

reference and inspection diameters, Container Threshold and the

Container Inspection Window Threshold.

You need 1 good container and 1 bad container to execute the

routine properly. A good container must be run 5 times and the

bad container run 4 times. It automatically detects the difference

between the good and the bad containers and updates the appro-

priate threshold (low or high). The process needs to be repeated

to setup both the high and low thresholds.

A bad sample of both a high and low reject will be needed.

Calibration will abort if differences between good and bad is too

small or if more than one container is between the trigger and

rejector.

Dud Readings

Displays the dud sensor readings for the current lid. These

readings are primarily used for troubleshooting. Pressing either

arrow key will toggle the following display modes.(Range: 0 - 255)

1=XXX, M=XXX, 2=XXX, C=XXX (Continuous display mode)

R1=XXX, M-XXX, 2=XXX, C=XXX (Reject Only mode)

It displays the inspection points used to create the current dud

value.

• 1 is the reading at inspection point 1,

• M is the reading in the middle of the container,

• 2 is the reading at inspection point 2,

• C is the current reading from the sensor.

Dud Values (Low Vac and Pressure)

The measurement of the dud position for the current can and the

measurement of the last rejected can. (Range: 0-255)

CUR=XXX, LAST REJ=XXX displays the last dud inspection reading

for current inspection method. It also displays the last reject

reading.

16 Dud Inspection Operation Manual

Document 40378-0502

Dud Data Length and Values

The inspection buffer length, the inspection points and their

positions or offsets in the buffer. This display is used to help

determine if the automatic centering methods of necked-in or

chines are working. All values range from 0 to 255. This system is

set up properly if the average of the positions of reference 1 and

2 are in the middle of the buffer length. Pressing either arrow key

will toggle display modes.

XXX 1=XXX, XXX 2=XXX, XXX (continuous display mode)

RXXX 1=XXX,XXX 2=XXX,XXX (reject only mode)

Dud Data Position

The centering offset value, inspection buffer length, and

reference diameter calculated. This display is used to help

determine if the automatic centering methods of necked-in or

chines are working. The offset value should normally be in the

single digits (+ or -) or less than 10-15% of the buffer length. The

dia value (the difference between the reference positions and 1

and 2)should not vary by more than 10-15%.

Dud Inspection Method

This function allows you to select one of the six dud inspection

method. This function applies to can inspection only. For more

information see step 8 on page 10

Dud Skew Threshold

This setting is hidden under S1-5 and is used to generate an

undefined reject and diagnostic 95.

Key 3: Counters

Total Dud Low Threshold Vac

The total number of containers that were rejected as duds since

the last time the counter was reset. This includes the total of all

cans that were detected below the dud low threshold. (Range: 0

to 99,999,999)

17

Document 40378-0502

Total Dud High Threshold

The total number of containers that were rejected as duds since

the last time the counter was reset. This includes the total of all

cans that were detected above the Dud High Threshold. (Range: 0

To 99,999,999)

Total Undefined (Dud)

The total number of containers that were rejected by dud

inspection for undefined faults that interfered with dud

inspection since the last time the Counter was reset. This

includes missing lids/caps, bulged cans/high caps, sliding

containers, down containers. (Range: 0 to 99,999,999)

Reset Dud Low Vac

Resets the Total Dud Low Vac counter. If the previous count value

is to be saved, it must be recorded externally as there is no

storage for the number in the counter once it is reset.

Reset Dud High

Resets the Total Dud High Vac counter. If the previous count value

is to be saved, it must be recorded externally as there is no

storage for the number in the counter once it is reset.

Reset Total Undefined

Resets the Total Undefined (Dud) counter. If the previous count

value is to be saved, it must be recorded externally as there is no

storage for the number in the counter once it is reset.

Last Reject Detect

The classification of the last dud reject; low dud, high dud, or

undefined reject

Note: Lowfilled containers are not included in the dud totals. A

container is not counted unless it is properly filled. If it is not

properly filled it is counted in the fill level counters.

18 Dud Inspection Operation Manual

Document 40378-0502

Key 5: System

Alarm Dud Low or High

Defines the number of consecutive dud rejects that will trigger an

alarm condition. Rejects must be consecutive. Each good bottle,

for this condition, that passes through the FT-50/70 will reset the

counter to zero. (Range: OFF, 1-250, Default: OFF)

Alarm Undefined (Dud)

Dud Undefined status turns off rejection of undefined dud

inspection and deactivates all undefined dud software functions.

Last Reject Detected

Displays the cause for the last reject which falls into one of the

following categories: fill level, missing cap, high cap, dud.

Diagnostic Errors

The amber warning beacon on top of the inspection head signals

an alarm or error condition by blinking rapidly. The error

condition number can be obtained from the FT-50/70 by pressing

the Key 6. Below The diagnostic errors specifically related to the

dud inspection are listed below. For other errors, refer to the

inspection system Service Manual.

Error Number 92

Too many containers in dud queue.

Error Number 93

Possible sliding container, missing cap, high lid, or dud sensor is

positioned too far away from cap. Verify sensor position.

Error Number 94

Container diameter entered is smaller than Dud ref. Diameter

setting. Verify Dud ref. Diameter and verify trigger width of

container.

Other manuals for FT-50

3

This manual suits for next models

1

Table of contents

Popular Analytical Instrument manuals by other brands

Kummert

Kummert K-28 HD instruction manual

Eddyfi Technologies

Eddyfi Technologies INUKTUN MINIMAG user manual

Bacharach

Bacharach Oxor III operation & maintenance

KROHNE

KROHNE OPTISENS TSS 7000 Supplementary instructions

Ames Instruments

Ames Instruments 64001 Owner's manual & safety instructions

Coffee Laboratory

Coffee Laboratory Color Track GENESIS User reference guide