Filtration Group Pi 150 User manual

Other Filtration Group Water Filtration System manuals

Filtration Group

Filtration Group PiW 2175 User manual

Filtration Group

Filtration Group Pi 370 Setup guide

Filtration Group

Filtration Group AF 172 G2 User manual

Filtration Group

Filtration Group Pi 210 Series User manual

Filtration Group

Filtration Group R5-3 User manual

Filtration Group

Filtration Group EWH 16 User manual

Filtration Group

Filtration Group Facet HCS-222-1324 Owner's manual

Filtration Group

Filtration Group SFK-01 KG User manual

Filtration Group

Filtration Group EG3 User manual

Filtration Group

Filtration Group Pi 480 User manual

Popular Water Filtration System manuals by other brands

A.O. Smith

A.O. Smith X8 user guide

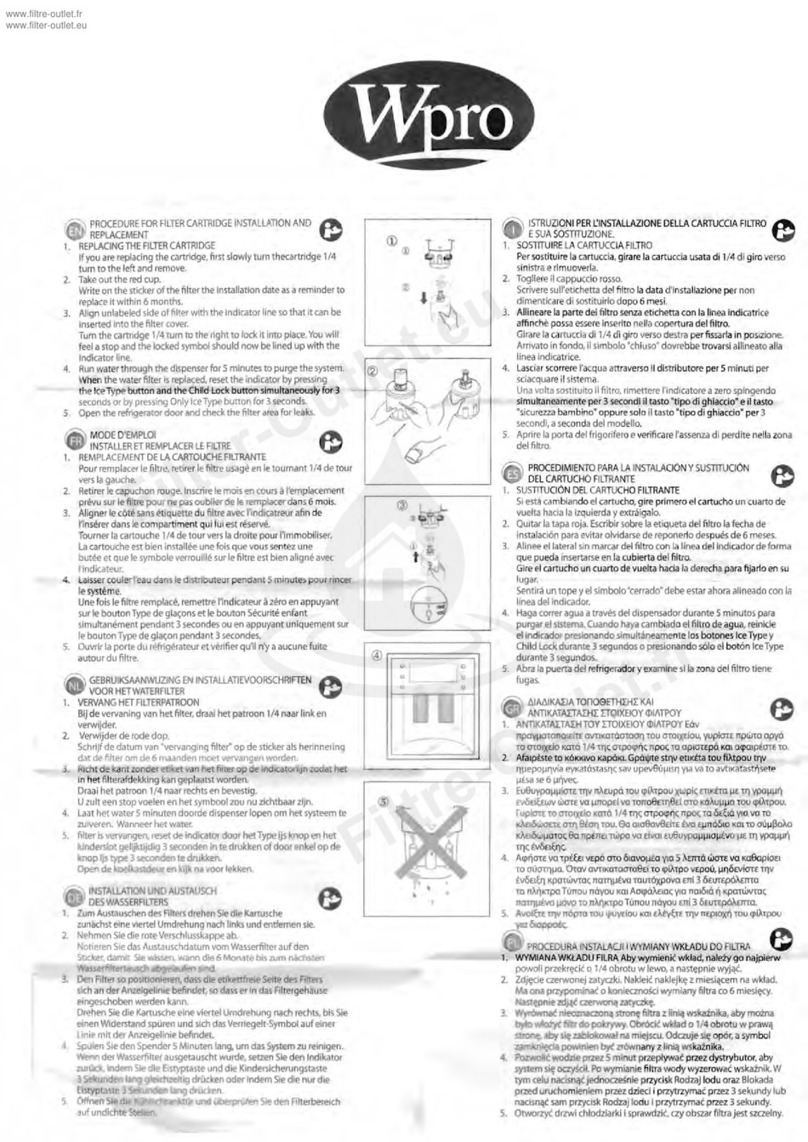

wpro

wpro APP100 Procedure for installation and replacement

Riello

Riello BAG3 MIX BASIC Instructions for the Installaer and for Technical Assistance

Steinbach

Steinbach Speedclean Comfort 50 ORIGINAL OWNER'S MANUAL

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS TCU Series Operating and maintenance instructions

Pentair

Pentair FLECK 2815 Service manual

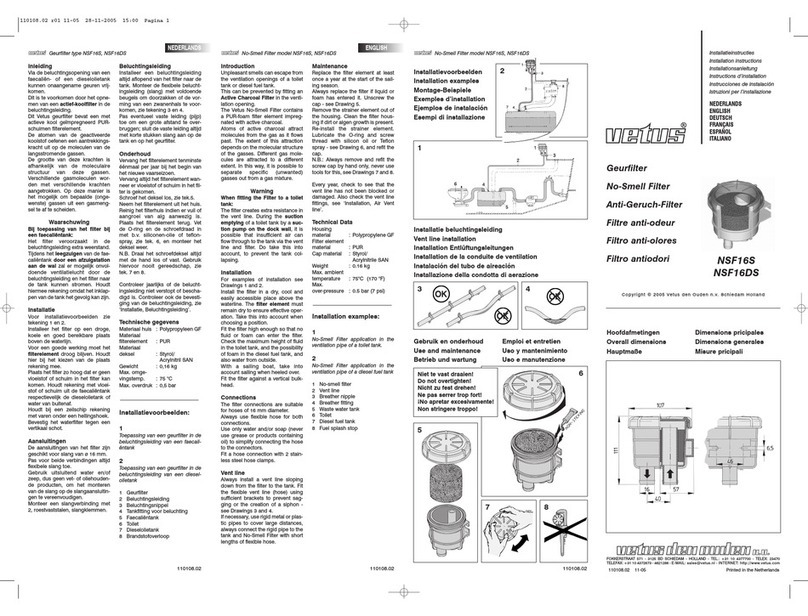

Vetus

Vetus NSF16S installation instructions

Hidrotermal

Hidrotermal Filtration Combo Series user manual

Axeon

Axeon Hydrogen user manual

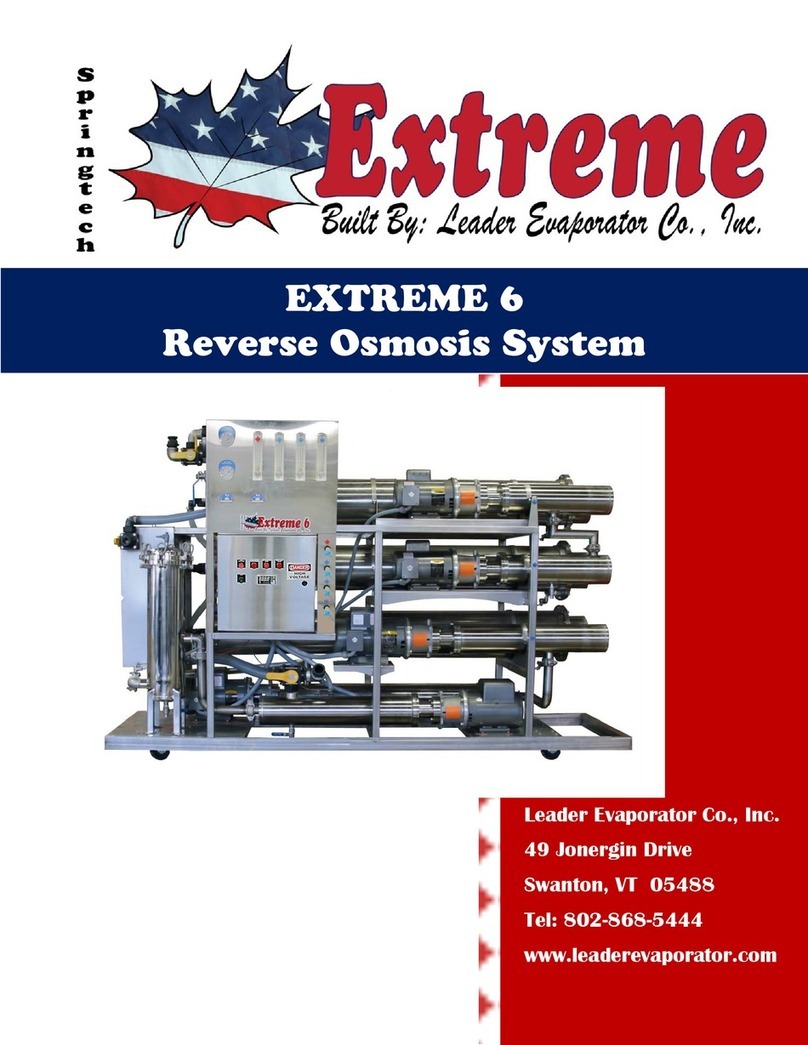

Leader Evaporator

Leader Evaporator Springtech EXTREME 6 manual

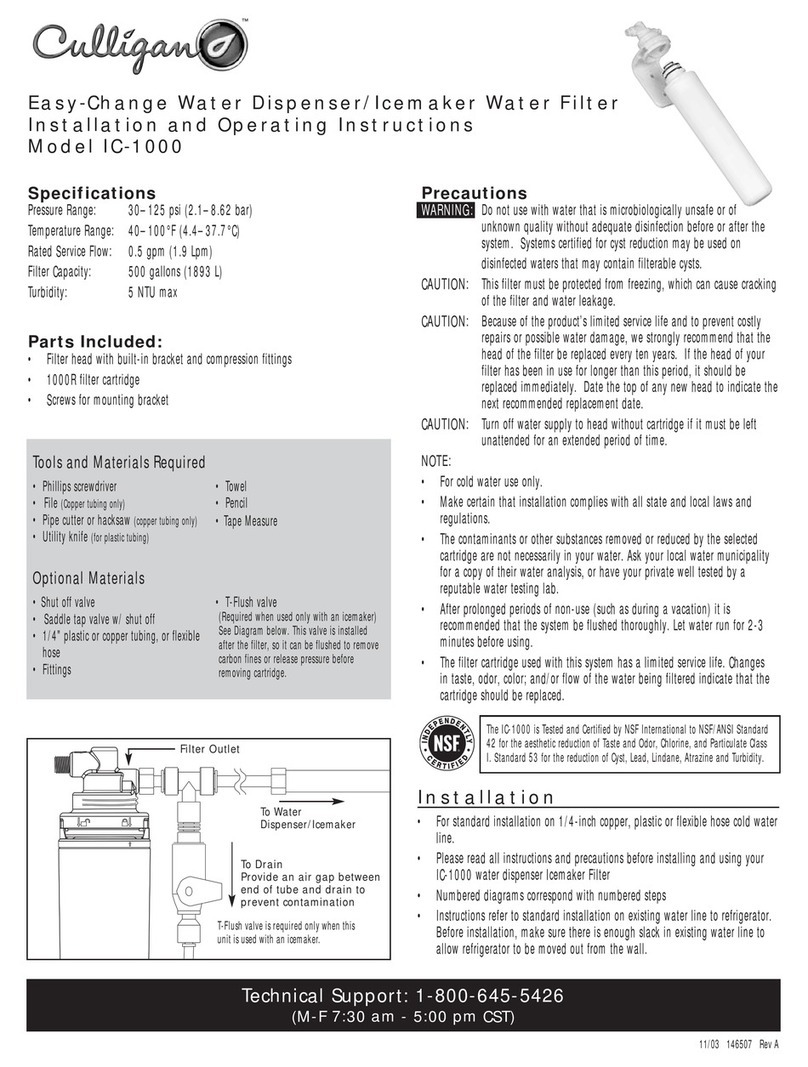

Culligan

Culligan IC-1000 Installation and operating instructions

Nature Pure

Nature Pure Ultrafine Faucet Series installation instructions