FILTRINOV GS14 User manual

EN

Installation and operating instructions.

Read carefully and retain for future reference.

INTEGRATED FILTERING WALL

GS14 RANGE GS14 MIRROR RANGE

20

CONTENTS

Recommendations

Technical description of the filtering wall

Technical description of the mirror filter wall

Installation

POOL-EARTH

Electrical connections

Starting the filter wall

Filtration: Operating principle

Setting the timer

LED light

Vacuum point for manual suction cleaner or

hydraulic robot

Optional BY PASS

Optional Salt chlorinator

Optional Ph controller

Customisation

Pump disassembly and winterisation

Trouble shooting

1

2

3

4

5

6

7

8

9

10

........................................................................ P.3

.......................... P.4

................... P.5

........................................................................................ P.6

.................................................................................... P.8

................................................................. P.8

................................................................... P.9

................................................... P.9

........................................................................... P.10

......................................................................................... P.10

................................................................................ P.11

......................................................................... P.11

........................................................... P.11

................................................................ P.12

............................................................................... P.12

............................... P.13

.......................................................................... P.14

11

12

13

14

16

15

17

EN

21

- These installation instructions are an integral part of the product and must be given to the

user. This booklet should be retained for reference.

- Check the condition of the contents after unpacking the filtering wall.

- Before wiring up the unit, make sure the manufacturer’s data is compatible with the

planned system and does not exceed the maximum permitted limits of the particular item.

- Always cut the electrical power from the main consumer unit before carrying out any

maintenance, handling or repair work.

- Any repair work must be carried out by an authorised technical support service using

only OEM spare parts. Failure to comply with the above requirements may lead to unsafe

operation of the filtering wall and will void the manufacturer’s warranty.

- A high-sensitivity, 30 mA cut-off device must be fitted at the head end.

TERMS AND CONDITIONS OF DELIVERY :

All items, including when sold postage and packing paid, are transported at the

consignee’s risk. The consignee must record any reservations regarding damage in

transit in writing on the CARRIER’S delivery note and provide confirmation thereof

within 48 hours by registered letter sent to the CARRIER.

VOLTAGE: before operating, check that the appliance voltage indicated on the data

plate is the same as the mains voltage (usually 230 Volts AC).

FOREWORD :

Thank you for purchasing this GS14 filtering wall.

You can rest assured that every effort has been, and will continue to be made to bring

you complete satisfaction.

This product has been carefully designed with your safety in mind. Your new filtration

unit comes with the same features as a traditional filtration system.

REMINDER : a residual current device (maximum 30 mA) must be fitted upstream,

and manually tested, as a safety measure to cut the low-voltage power to pool

appliances.

TO PREVENT WATER INGRESS INTO THE NON-WATERTIGHT GS14 TANK

WE ADVISE YOU TO INSTALL A DRAIN ALL AROUND THE POOL THAT RUNS

INTO A RELIEF WELL CONTAINING A BASEMENT

SUMP PUMP.

CLEAN THE CARTRIDGE AND EMPTY THE BASKET AT REGULAR INTERVALS

ALWAYS LOCK THE LID SHUT AFTER CARRYING OUT MAINTENANCE WORK

IN THE TANK

DO NOT USE FLOCCULANTS OR «MULTIFUNCTIONAL» CHLORINE

RECOMMENDATIONS

1

22

TECHNICAL DESCRIPTION OF THE FILTERING WALL

2

3

2

5

1

4

Wide-mouth skimmer

2 Multi-directional nozzles

Colour LED light + Remote control

Removable lid with mechanical lock

In-ground section containing the filter ele-

ments and optional items

Overflow

3

4

2

1

56

6

EN

23

TECHNICAL DESCRIPTION OF THE MIRROR FILTERING WALL

3

3

2

5

1

4

Skimmer miroir pour aspiration

2 Multi-directional nozzles

Colour LED light + Remote control

Removable lid with mechanical lock

In-ground section containing the filter ele-

ments and optional items

Overflow

Low-level suction

3

4

2

1

56

7

6

7

FILTRINOV

GS 14 / M

052584

E3

24

Place the filter wall on the

concrete slab or directly on top of

one or more rows of polystyrene

blocks. Support the weight of the

filter wall beneath its tank.

Fit and secure the formwork

on the front and back of the filter

wall to keep the concrete in place

during casting.

(washers and bolts at front;

washers and nuts behind)

Build up the wall of polystyrene blocks

on both sides of the through-wall filter.

2

3

4

Product is designed for a film

liner or reinforced PVC liner seal

1

INSTALLING THE FILTER WALL

4

TECHNICAL DESCRIPTION OF THE FILTER WALL (cont.)

3

3

4

2

1

IN-GROUND SECTION

Filter pump: 14m

3

/h - 3/4cv - 0.5kw

Cartridge filter + basket: 4.5m² - 25µ

Control panel incl. transformer and timer

Overflow

2

4

3

1

EN

25

Fit the sealing gasket,

skimmer, nozzles and light

in the usual way for fitting a

film liner or reinforced PVC

liner(Manufacturer’s guide

supplied).

Pour the concrete in one

go. The filter wall integrates

perfectly with the pool

structure.

Lay the felt directly

onto the filter wall

using the usual

adhesive.

5

6

7

It is advisable to

place foam or fit

formwork around the

mouth to prevent

concrete getting into

the tank while it is

being poured.

The overflow is to be hooked

up to a drain outlet or other

water drainage point (Ø 50).

If the water level in the pool

rises too high, the water is

quickly carried away via the

overflow to prevent it flooding

over the top.

8

26

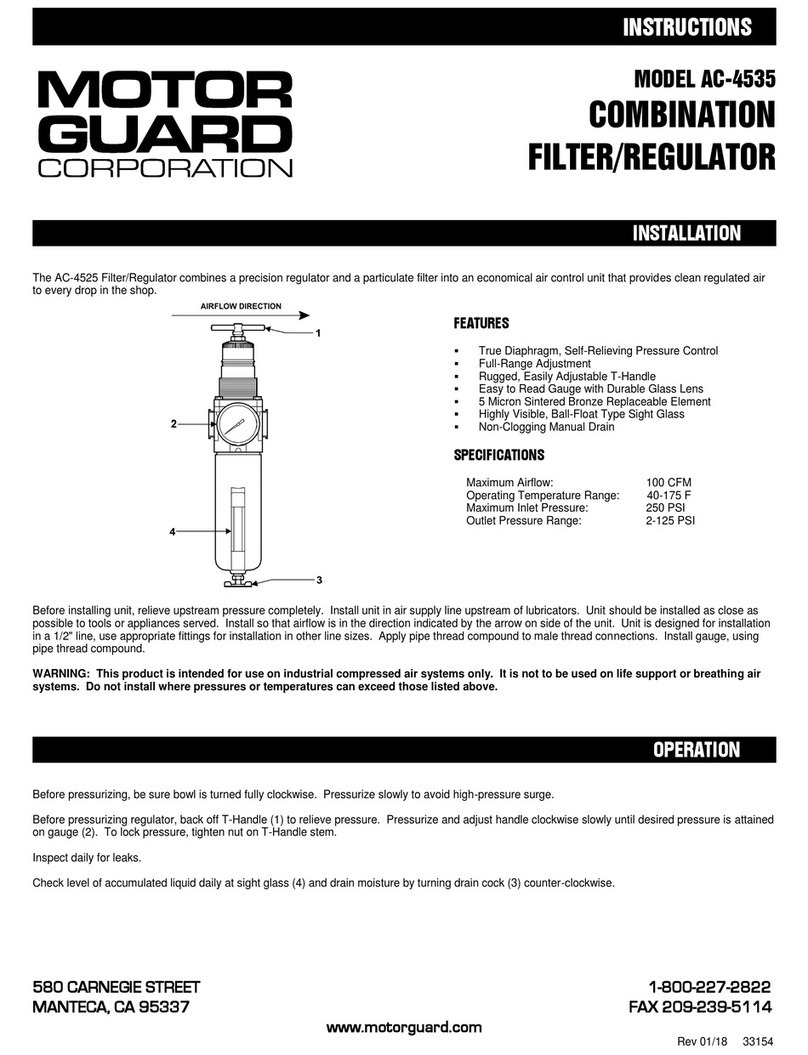

The filtering wall should be connected to an insulated electricity supply

running directly from the main consumer unit with a 16A fuse or circuit-

breaker and a 30mA RCD. Use a 3-wire cord, earth-live-neutral, with a 1.5

or 2.5 mm² section for lengths of less than 30 linear metres.

> Electrical box wiring

diagram included

6ELECTRICAL CONNECTIONS

POOLEARTH

5

The pool must be earthed without fail in

order to remove stray currents from the

water.

Stray currents are not dangerous to

people, but they do electrolyse the metal

components in the pool, which increases

corrosion. They can also disrupt the

treatment probes, resulting in incorrect amounts of

product being injected.

This is why FILTRINOV has included a pool earth

with these products. Screw it into the threaded

attachment point provided and connect it to the

earth rod with a Ø 6 mm copper braid earth strap

(parts not included).

A hole will have to be drilled in the tank to route the braid through the

packing gland provided.

With this cable gland, the

electrical cable can be run

from the house to the filter

box in the equipment housing.

Pump

protection

Protection

treatment

Filtration

pump

230V Power supply

(Ph + N + E)

Light 220V

Treatment

220V

Non servo

External connections

EN

27

Check all the couplings for leaks and retighten if necessary.

- Open the 3 valves upstream and downstream of the pump.

- Fill the pool.

- Switch on the pump.

- Bleed the air via a PVC plug if necessary.

STARTING THE FILTER WALL

7

FILTRATION: OPERATING PRINCIPLE

8

Water from the surface of the pool is drawn in by the skimmers and sent

through the filter cartridges, where it is cleaned. It then travels on to the

pump, which discharges it through the return nozzle back into the pool.

The filter cartridges must be washed every few complete filtration cycles.

The cartridge should be cleaned at least once a week and whenever

the suction cleaner has been used. To clean the cartridge, remove the

basket, lift out the cartridge and gently hose it down. Refit the cartridge

once it is clean.

Your GS includes a cartridge housing at the bottom of the filter holder

to fit the cartridge. Turn the cartridge a quarter turn downwards to slot

it into place in the filter holder. Remember to fit the basket and its pre-

filter.

All FILTRINOV filtration units are checked and tested with the utmost

care and subject to FILTRINOV’S stringent quality controls.

The use of non FILTRINOV-approved parts and consumable items shall

render the pump and hydraulic system warranty void.

EASYFILTER bags and cartridges are not approved by FILTRINOV.

Persistent clogging and risk of permanent damage to the pump.

The filtration time should be increased as the water temperature rises :

12° to 16° = 6 hours

16° to 24° = 8 hours

24° to 27° = 10 hours

27° to 30° = 12 to 14 hours or more

Sequencing principle: Minimum 1 h of downtime after 4h of

operation.

28

SETTING THE TIMER

9

• Continuous mode (24-hour filtration)

Move the filter switch on the outside of the electrical panel to «Manual».

• Auto mode (timed filter operation)

a) Move the filter switch on the outside of the electrical panel to «Automatic».

b)Turn the clock hands to set the exact time relative to the pointer (triangle)

on the right of the clock (in the example below, the time is midday).

c) Select your hours by pushing the clock pins outwards.

LED LIGHT

10

Your integrated filtering wall comes

with a COLOUR LED light as standard

in 11 non-animated colours incl. white

and 5 sequence programmes (remote

control included)

(Manufacturer’s guide included)

*Data are provided as a guideline and may vary with the

operating conditions. A flat projector is considered to have a

lifetime of 20 years when lit 4 hours a night for 6 months

a year.

Supply voltage 12V AC / 50-60Hz

Wattage 18 W +/- 10%

Luminous flux 510 lumens +/- 10%

Number of LED 270

Colour 11 colours

Programmes 5 sequences

Control On/Off + remote control included

LED lifetime* > 30,000 h

Service life* 15,000 h

Plug & Play system Yes

Sequencing principle:

Minimum 1 h of downtime after 4 h of operation.

> See the instructions attached to the panel

EN

29

VACUUM POINT FOR MANUAL SUCTION CLEANER

OR HYDRAULIC ROBOT

OPTIONAL BY-PASS

OPTIONAL SALT CHLORINATOR

11

12

13

• Connect one end of the hose to the suction cleaner

• Hold the suction cleaner by the handle and insert it into the pool

• Gradually insert the hose into the water until the water pushes out the

air (tip : you can fill the hose with water by placing its tip in front of the

filtration unit nozzle with the filtration unit running)

• Feed the other end of the hose through the skimmer mouth and

attach it to the skim vac plate that seals off the basket

The by-pass consists of a 3-way valve

and a branch Tee.

Your heat pump is connected to the

filtration unit by a Ø 50 PVC pipe.

The cartridges should be cleaned at least once a week and whenever the

suction cleaner has been used. To clean the cartridges, remove the basket, lift

out the cartridge and gently hose it down. Refit the clean cartridge and the

basket.

Consists of a cell and a chlorinator

controller.

Read the accompanying settings, operating

and maintenance guide.

TO POOL

RETURN

TO HEAT

PUMP

30

pH CONTROLLER

14

• The pH controller consists of a peristaltic pump, a probe sensor,

and an injector.

Read the accompanying settings, operating and maintenance guide.

It is strictly forbidden to store pH containers inside the tank.

CUSTOMISATION

15

A // We also have a range of colour lids available for your filter wall

in grey, charcoal grey, and beige.

B // We also have a skimmer, nozzle and spotlight bezel kit for

your filter wall.

> Colours: grey, charcoal grey, and beige.

External container PH EPH

EN

31

PUMP DISASSEMBLY AND WINTERISING

16

An actively winterised pool continues to operate at a slower than normal

rate throughout wintertime.

This is the recommended winterising procedure in less cold regions. If you

live in a harsher winter climate, you should choose to passively winterise

your pool instead.

• First clean the pool structure, the water line, basket and cartridge.

• Next, shock the pool with chlorine.

• Run the filtration system non-stop for at least 12 hours.

• Then reset your timer to run the filtration system for 30 minutes

every 3 hours (do not be afraid to increase the running time if the

temperature is significantly below zero).

• Your pool will not require any more product treatments for

the whole winter. Just monitor the water’s pH level and adjust if

necessary.

• Check and clean the basket and cartridge at regular intervals.

• We also recommend that you use winter floats in your pool.

• You can also cover your pool with a winter cover or tarp.

Passive winterising involves stopping filtration entirely.

• First clean the whole of the pool and its equipment (floor and walls, water

line, basket, cartridge, etc).

• Check the water’s pH level and adjust if necessary.

• Shock the pool with a chlorine treatment.

• Run the filtration system non-stop for at least 12 hours.

• Use a drainage pump to lower the water level to below the skimmer.

• Bump-start in manual filtration mode 3 or 4 times, for 3 seconds each

time.

• Close the 3 valves (1 suction and 2 delivery valves).

• Unscrew the pump inlet and outlet unions.

• Let the water flow into the tank.

• Disconnect the 3 pump wires from the electrical panel.

• Take the pump out of the tank and store it in a dry place.

• We also recommend that you use winter floats in your pool.

• You can also cover your pool with a winter cover or tarp.

• Active Winterising :

• Passive winterising and pump disassembly:

32

FAQ / TROUBLE SHOOTING

17

CAUSE SOLUTION

Cartridges

• SITUATION 1: The cartridges are dirty but not clogged. Clean the cartridges at more regular intervals (once every fortnight)

•SITUATION 2: Renew the cartridges if they are clogged

•SITUATION 3: If you are using a flocculent or anti-algae treatment, lower the water level by 20 cm and renew the cartridges

Leaf baskets Clean the debris from the baskets at regular intervals and clean or renew the Netskims (skimmer socks/nets)

Pump Clean the pump housing to remove any foreign matter and unblock the turbine

Water level Check the water height, making sure it is ¾ of the way up to the skimmer niches

Priming

•Check that the pump has been primed properly

•If it hasn’t, remove the delivery system at the pump outlet, fill the pump with water and jolt-start the unit again on and off in

quick spurts (5 seconds on, 1 to 2 seconds off); 3 or 4 times should be enough

Position of the unit

•The 4 contact points on the rear of the side that is submerged in the pool should be hard against the pool wall

•This is only possible if you ensure that the tank section is perfectly horizontal and supported sufficiently high up to avoid strain that

would pull the contact points away from the pool (see the installation guide)

CAUSE SOLUTION

Power supply

•Check the wiring from the pump to the unit’s electrical enclosure

•Check the wiring from the electrical enclosure to the mains power supply

•Check the 30 mA circuit breaker at the line end

Pump switch •Check the wiring to the pump switch

•eplace the switch if it is not working

Front-mounted 3-position

switch (Auto/0/Manual) on

the electrical enclosure

•Put the switch in Manual mode

•If the pump still does not work, check the connections at the wire terminals behind the switch inside the enclosure

•If the problem is still not resolved, contact your retailer to have the switch replaced

Timer

•Check the timer wiring inside the electrical enclosure

•Check that the 3-position switch (Auto/0/Manual) is turned to Auto mode

•Also turn the switch in the bottom left corner of the timer dial face to Auto

•Use the timer segments to set the filtration to start and stop at different periods

•If the filtration does not start, the timer is faulty and will have to be replaced

CAUSE SOLUTION

Turbine Use a large flat-blade screwdriver at the rear and in the centre of the pump to try and release the turbine and get it turning

Condenser Replace the condenser

PROBLEM : Low pressure flow and/or air bubbles in the pumped

water flow

PROBLEM: The pump does not start

• If there is no noise:

• If the power unit is making a noise:

FILTERS/PUMPS

EN

33

FAQ / TROUBLE SHOOTING

17

CAUSE

(carry out the checks in the

order shown) SOLUTION

Lighting circuit breaker •Check whether the circuit breaker has been tripped and is still open

•If the circuit breaker has not stayed open, it is not working and will have to be replaced

Front-mounted 2-position (I/0)

switch on the enclosure

•Check that the switch is turned to I

•Check the connections at the terminals behind the switch inside the enclosure.

Transformerr (220V/12V) •Check the transformer’s output voltage (12V)

•If the transformer’s output voltage is zero, it is not working and will have to be replaced.

Remote control system unit

(blue enclosure with a black

antenna, inside the tank)

•Open the housing

•Press the small black button inside the housing; a small red LED next to it should come on

•If nothing happens, the remote control system unit is not working and will have to be replaced

•If the red LED comes on, configure the remote control (see paragraph 6 of the remote control unit instructions)

Remote control

•Open the remote control battery compartment and check for oxidation, etc, the condition of the battery and that it is fitted the

correct way round.

•Configure the remote control (see paragraph 6 of the remote control unit instructions).

•Look at the top of the remote to see whether it comes on when you press the button on the left.

•If nothing comes on, the remote control is not working and will have to be replaced.

Light •If none of the above items are found to be at fault, it is the light that does not work.

•It will have to be replaced using a niche (feed-through) system.

CAUSE SOLUTION

Crystal tube

The crystal tube along the inside the tank has come loose from its pneumatic switch after the side-mounted pneumatic button was

used to start the CCS.

Re-attach the tube.

Timer

• Make sure that not all the timer segments are pushed out, causing the filtration system to run non-stop. If they are, push some

back in to set OFF periods and then try to turn the dial forward in time by hand to an off period in order to stop the filter running.

•If the above step fails to switch the pump off, turn the front-mounted 3-position switch (Auto/0/Man) on the enclosure to 0. The

pump will stop, but the timer is not working and will have to be replaced.

Front-mounted 3-position

switch (Auto/0/Man)

on the electrical enclosure

•Turn the switch to 0

•If the pump is still running, check the connections at the wire terminals behind the switch inside the enclosure.

•If this still fails to switch the pump off, contact your retailer to have the switch replaced, and cut the mains electrical power to the

filter unit.

CAUSE SOLUTION

Overheating power unit

• To prevent the pump and its thermal circuit breaker from overheating, we advise you to programme your filter system to run for no

more than 3 or 4 hours at a time with a 1-hour break between operating periods.

Example : Water temperature: 24°C; required filtration time: 12 hours. We recommend that you programme the filtration unit to work

in stages from 7 am to 10 am then 11 am to 2 pm, 3 pm to 6 pm, and finally from 7 pm to 10 pm.

•We also recommend that you clean the cartridges.

Excessively dirty cartridges significantly reduce the flow of water into the pump, causing it to overwork and overheat.

PROBLEM: The pool light does not come on.

PROBLEM: The pump does not switch off

PROBLEM: The pump cuts out and starts up again later

LIGHTING

34

FAQ / TROUBLE SHOOTING

17

CAUSE SOLUTION

Light The light is reaching the end of its service life or is not/no longer watertight. Replace the light using a niche (feed-through) system.

PROBLEM: The light is blinking.

LIGHTING

CAUSE SOLUTION

Electrolyser circuit breaker in

the filtration electrical enclosure

•Check whether the circuit breaker has been tripped and is still open

•If the circuit breaker has not stayed open, it is not working and will have to be replaced

Electrolyser unit

If the circuit breaker is working properly but the unit does not switch on, the electrolyser unit is out of order and will have to be replaced.

CAUSE SOLUTION

Electrolyser circuit breaker in

the filtration electrical enclosure

•Check whether the circuit breaker has been tripped and is still open

•If the circuit breaker has not stayed open, it is not working and will have to be replaced

Nano PH pump

If the circuit breaker is working properly but the unit does not switch on, the electrolyser unit is out of order and will have to be replaced.

CAUSE SOLUTION

Electrolyser unit

•Set the treatment system to maximum operating capacity (10 for 100%) for 5 minutes

•Take a voltage reading from the electrolysis cell terminals

•If the voltage reading is between 0V and 2V, there is a problem with the electronics in the electrolyser unit (power board, etc)

Electrolysis cell

•Set the treatment system to maximum operating capacity (10 for 100%) for 5 minutes.

•Take a voltage reading from the electrolysis cell terminals.

•If the voltage reading is higher than 10V, the electrolysis cell is nearing the end of its service life (max. 15 days) or is not working

(above 12V), and will have to be replaced.

Cartridges Excessively dirty cartridges will quickly consume the chlorine that is generated to clean the pool, resulting in an incorrect chlorine

production reading.

PH Level The PH level should be between 7.0 and 7.2 to keep the chlorine at peak effectiveness

CAUSE SOLUTION

Container The pH regulator container may be empty and need replacing.

Suction strainer Check that the suction strainer (plunger in the container) is properly inserted in the container. Often, the container only needs to be

displaced slightly for the plunger to no longer be inserted properly and stop the reducer being injected.

Hose

•The hose from the dosing pump to the container may have drawn in something that is preventing the pH reducer from reaching the pool.

•The hose may also have a hole, possibly caused by the acidity level of the reducer. If so, it will have to be replaced.

•We recommend that you replace the hose at least every two years as the acidity level of the pH reducer will gradually cause it to

become porous.

PROBLEM: The electrolyser unit does not switch on..

PROBLEM: The Nano pH pump does not switch on.

PROBLEM: The electrolyser is producing little or no chlorine.

PROBLEM: The dosing pump is not injecting pH reducer.

AUTOMATIC WATER TREATMENT

EN

35

FAQ / TROUBLE SHOOTING

17

CAUSE SOLUTION

No «pool earth» fitted

•A stray current is probably interfering with your probe reading. Use a glass water to check if this is the case:

1. Dip the probe into a glass of tap water (pH level between 7.5 and 8.0) and see if the reading is consistent.

2. Next, dip the probe into a 7.0 reference solution. The reading should be around 7.0. If not, the probe needs to be recalibrated.

3. Next, dip the probe into a glass filled with water from the pool. Since the probe was calibrated properly in the previous step, the pH

level shown will be correct.

4. To finish, put the probe back in its proper place (retaining clamp on the suction line).

• If the reading matches the reading from the glass filled with water from the pool, there is no stray current in the pipes; the probe

was not calibrated properly.

•If the reading does not match the reading from the glass, you will need to install a «pool earth» to the system.

A pool earth is a metal rod placed in slightly damp ground and connected to the terminal provided on the filtration unit line by a

minimum 6 mm² braided connector.

The “Pool Earth” acts as a stray current earthing device.

•We always recommend connecting your system to a “pool earth”.

pH probe

Carry out the glass of water test mentioned above using a 7.0 reference solution. Calibrate the probe using the 7.0 solution and then

dip it into a 10.0 reference solution. If the reading is not 10.0 or thereabouts, the probe is not working properly and will have to be

replaced.

PROBLEM: The pH probe is giving incorrect readings.

This manual suits for next models

1

Table of contents

Other FILTRINOV Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Just Water Solutions

Just Water Solutions Grey Power Gator Maxi 100 Installation and operating instructions

Parker

Parker TGE 308 operating instructions

Essilor

Essilor Neptune user manual

WaterLogic

WaterLogic WL500 - Sparkling manual

Katadyn

Katadyn VARIO Tips and tricks

First Water

First Water FW-300-M Operation manual