MODEL AC-4535

COMBINATION

FILTER/REGULATOR

580 CARNEGIE STREET 1-800-227-2822

MANTECA, CA 95337 FAX 209-239-5114

www.motorguard.com

Rev 01/18 33154

The AC-4525 Filter/Regulator combines a precision regulator and a particulate filter into an economical air control unit that provides clean regulated air

to every drop in the shop.

FEATURES

True Diaphragm, Self-Relieving Pressure Control

Full-Range Adjustment

Rugged, Easily Adjustable T-Handle

Easy to Read Gauge with Durable Glass Lens

5 Micron Sintered Bronze Replaceable Element

Highly Visible, Ball-Float Type Sight Glass

Non-Clogging Manual Drain

SPECIFICATIONS

Maximum Airflow: 100 CFM

Operating Temperature Range: 40-175 F

Maximum Inlet Pressure: 250 PSI

Outlet Pressure Range: 2-125 PSI

Before installing unit, relieve upstream pressure completely. Install unit in air supply line upstream of lubricators. Unit should be installed as close as

possible to tools or appliances served. Install so that airflow is in the direction indicated by the arrow on side of the unit. Unit is designed for installation

in a 1/2" line, use appropriate fittings for installation in other line sizes. Apply pipe thread compound to male thread connections. Install gauge, using

pipe thread compound.

WARNING: This product is intended for use on industrial compressed air systems only. It is not to be used on life support or breathing air

systems. Do not install where pressures or temperatures can exceed those listed above.

Before pressurizing, be sure bowl is turned fully clockwise. Pressurize slowly to avoid high-pressure surge.

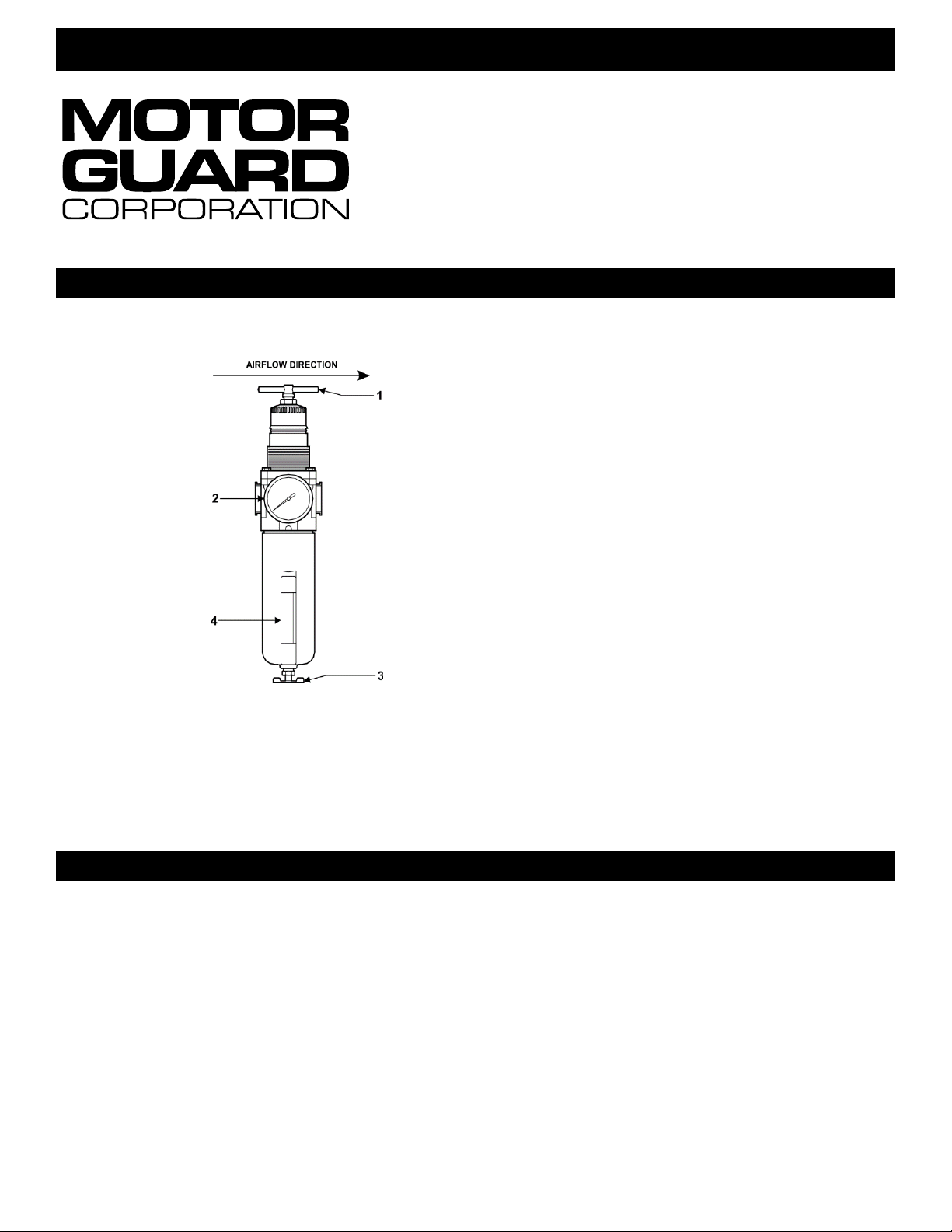

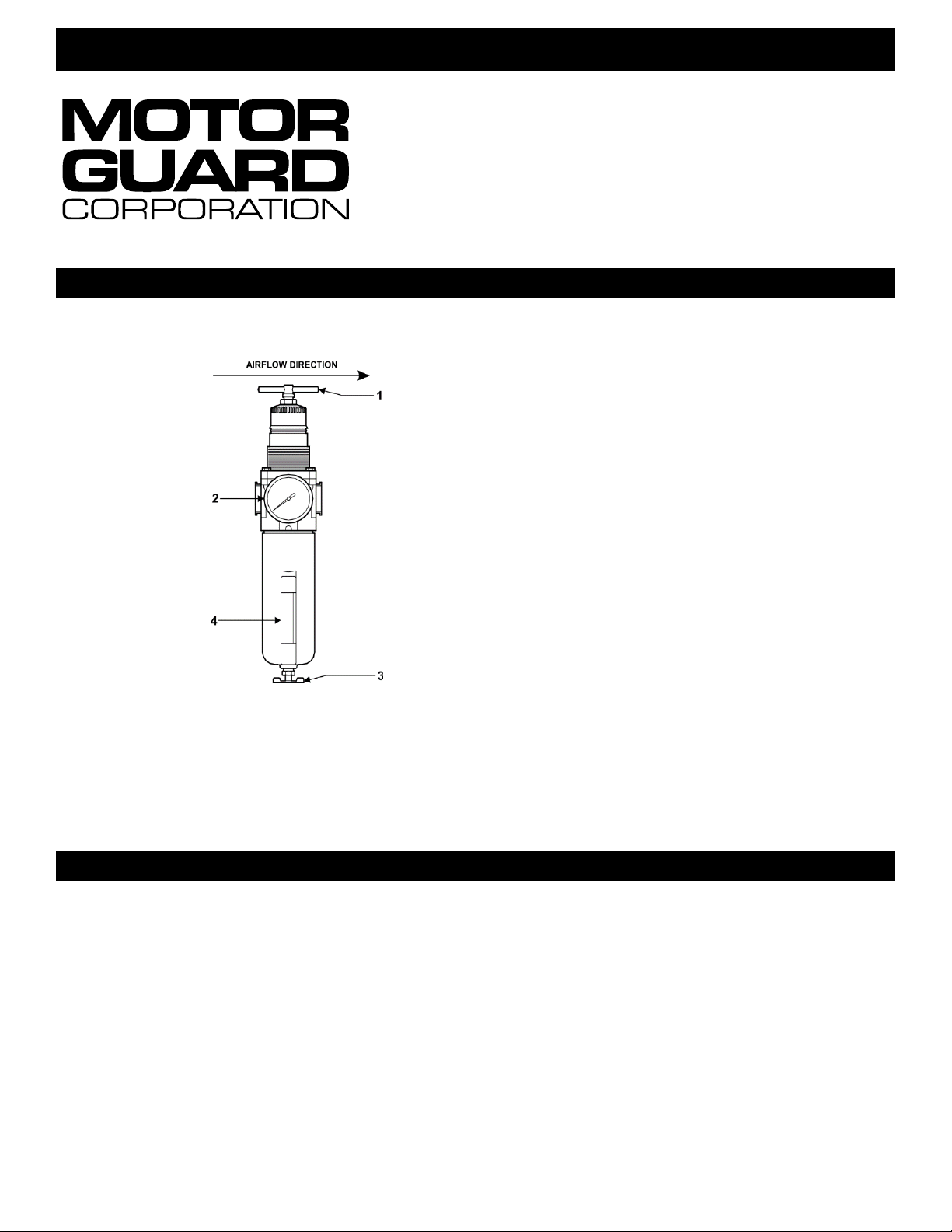

Before pressurizing regulator, back off T-Handle (1) to relieve pressure. Pressurize and adjust handle clockwise slowly until desired pressure is attained

on gauge (2). To lock pressure, tighten nut on T-Handle stem.

Inspect daily for leaks.

Check level of accumulated liquid daily at sight glass (4) and drain moisture by turning drain cock (3) counter-clockwise.