Parker TGE 308 User manual

Other Parker Water Filtration System manuals

Parker

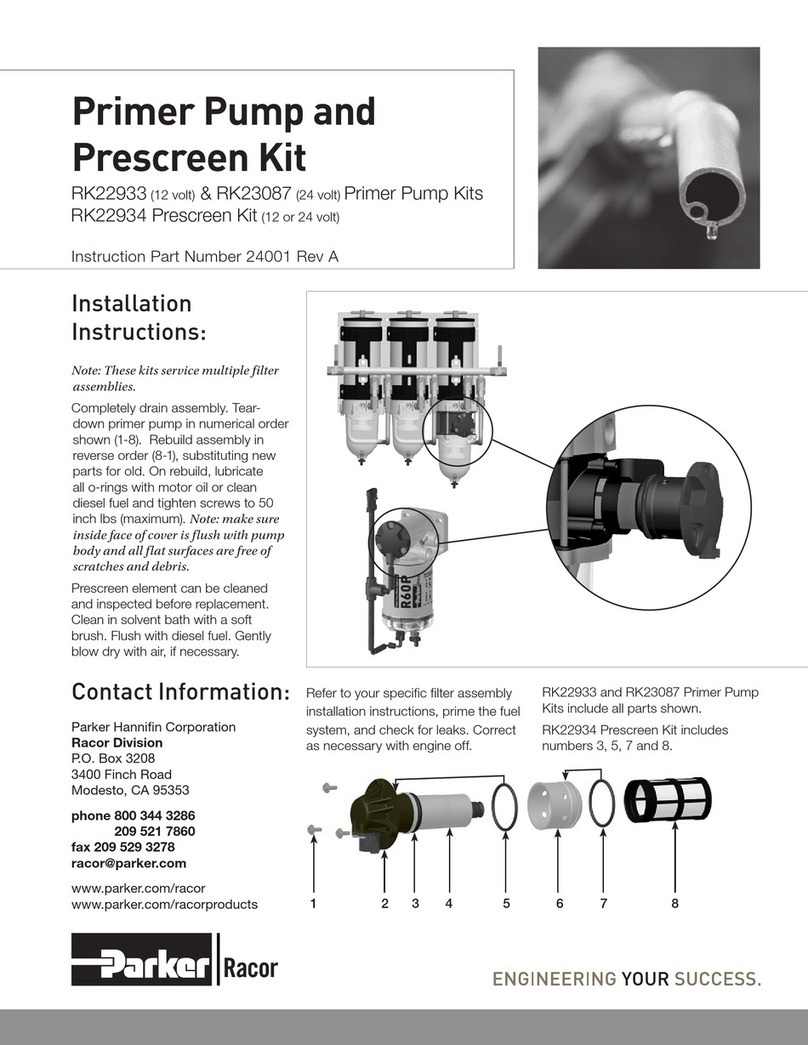

Parker Racor RK22933 User manual

Parker

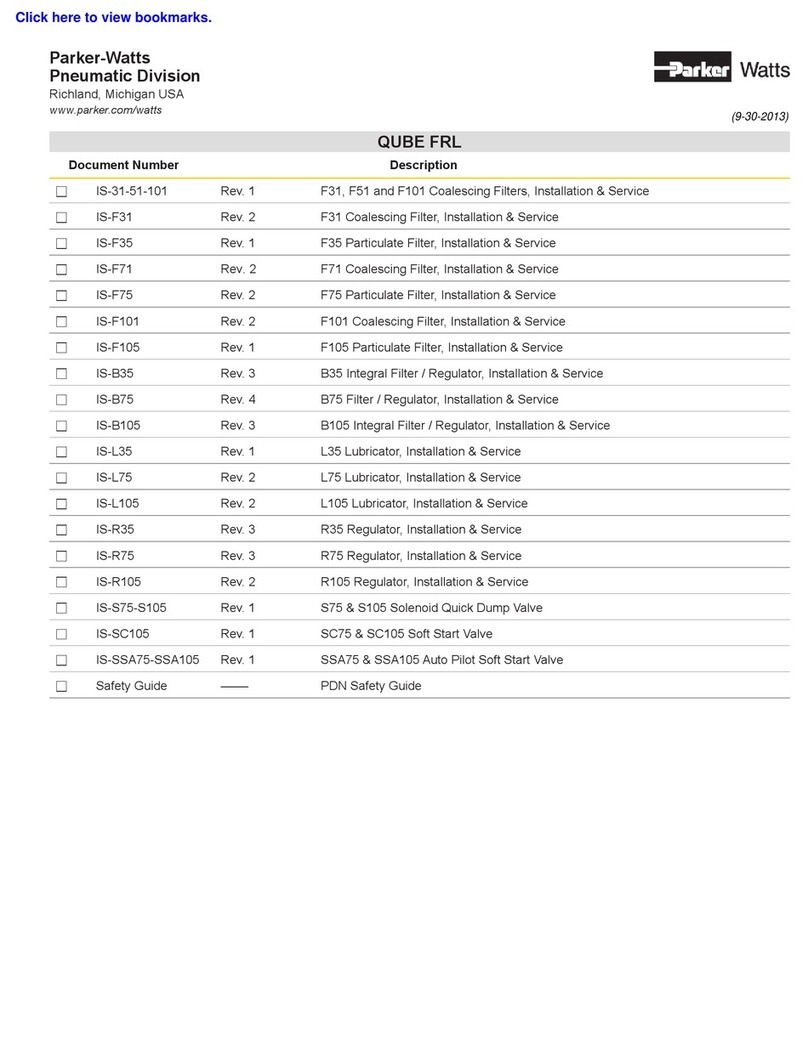

Parker F31 Installation and maintenance instructions

Parker

Parker Domnick Hunter WS Series User manual

Parker

Parker Racor 800D-5REC-D Quick guide

Parker

Parker BAF010 User manual

Parker

Parker Racor RK20025-01 User manual

Parker

Parker 320R-RAC Series User manual

Parker

Parker OIL-X PX010 User manual

Parker

Parker Zander FL17 Series User manual

Parker

Parker Hiross Hyperfilter HFN018 User manual

Parker

Parker 5MF User manual

Parker

Parker Sentinel User manual

Parker

Parker Racor CCV User manual

Parker

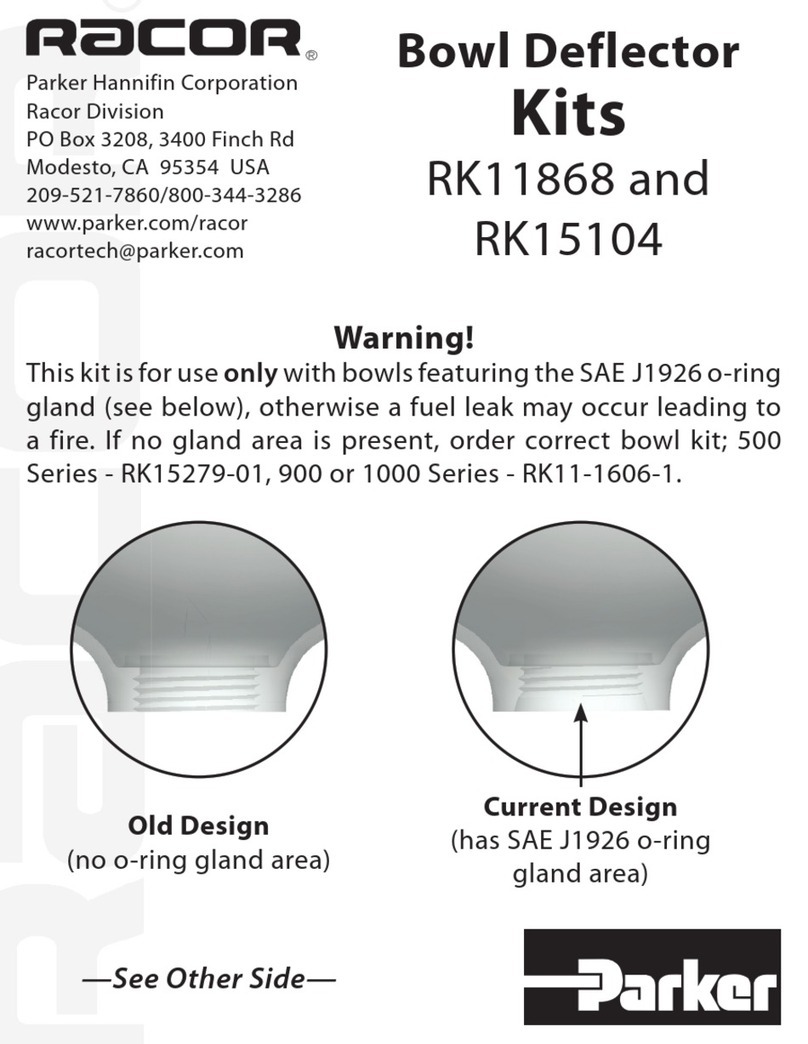

Parker Racor RK11868 User manual

Parker

Parker OVR300 User manual

Parker

Parker GL Series User manual

Parker

Parker Hiross Hyperfilter NFF520 User manual

Parker

Parker 140R Series User manual

Parker

Parker PHB Demi User manual

Parker

Parker TGA 102-118 User manual

Popular Water Filtration System manuals by other brands

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual