Page 7

IMPORTANT: Remove tank lid and be sure the tank is clean and free of any foreign material. Rinse tank out of any tank

residue before filling with water to test.

NOTE: It is important to test the sprayer with plain water

before actual spraying is attempted. This will enable you to

check the sprayer for leaks in the plumbing system

Testing the Sprayer

1. Fill the tank about 1/2 full with plain water.

Only fill the tank with what you’re going to spray in a day,

never leave chemicals sit in tank.

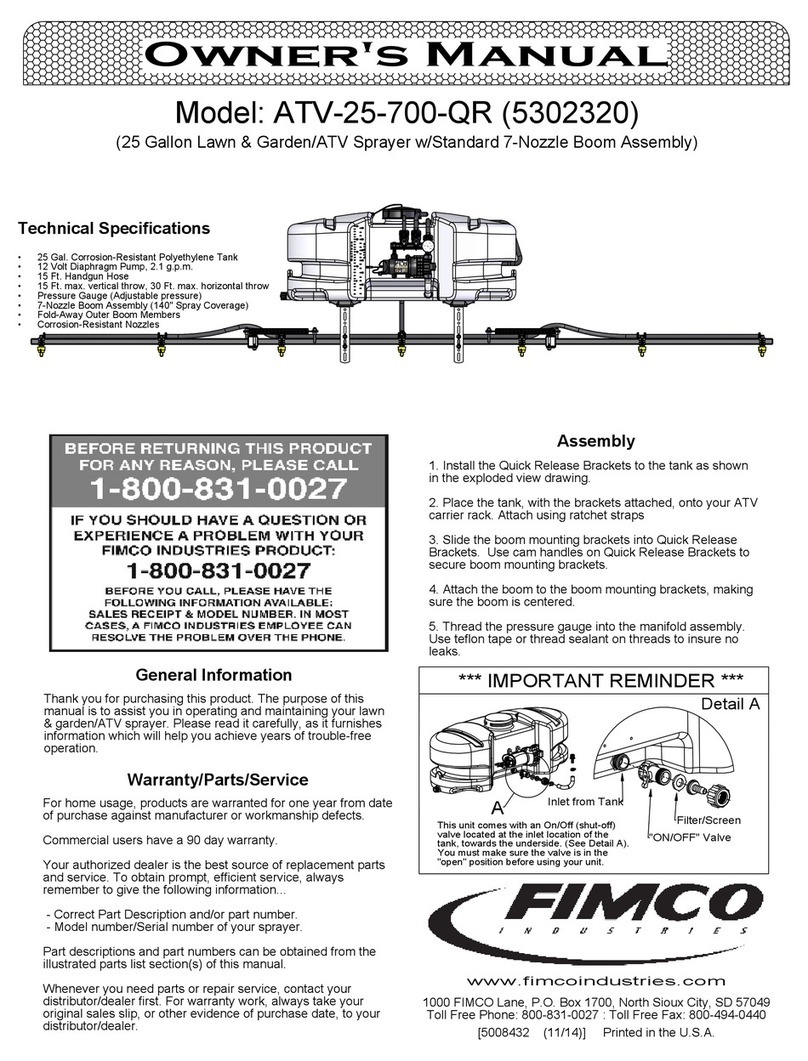

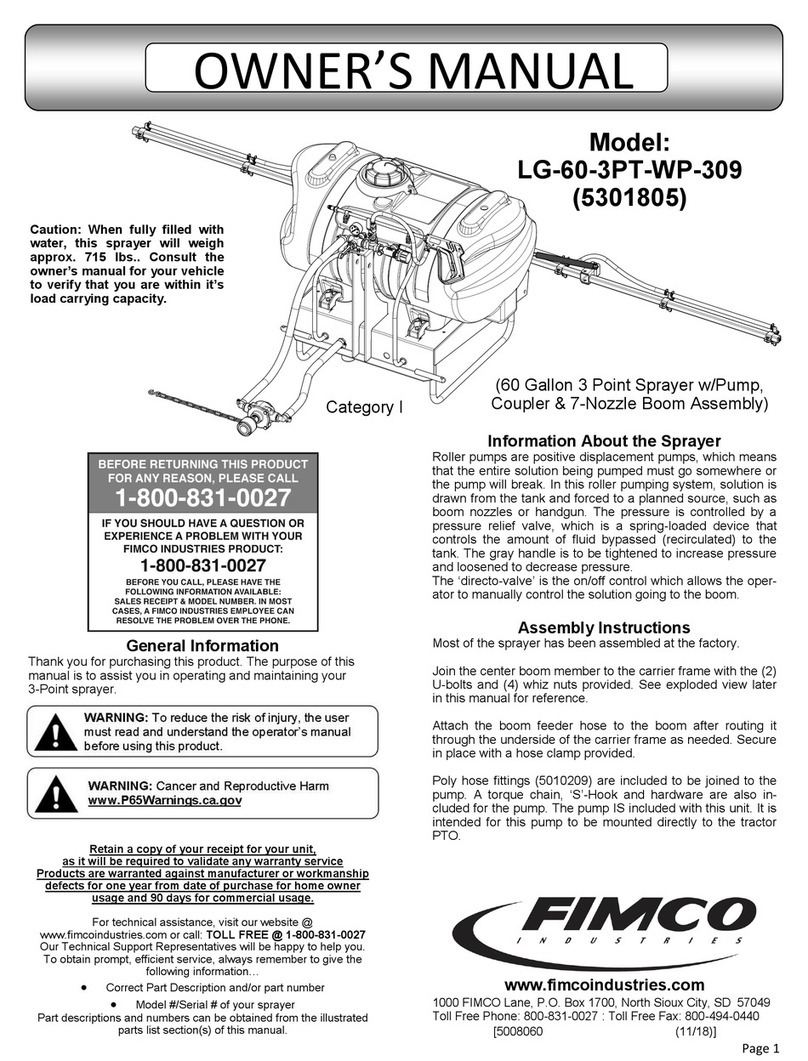

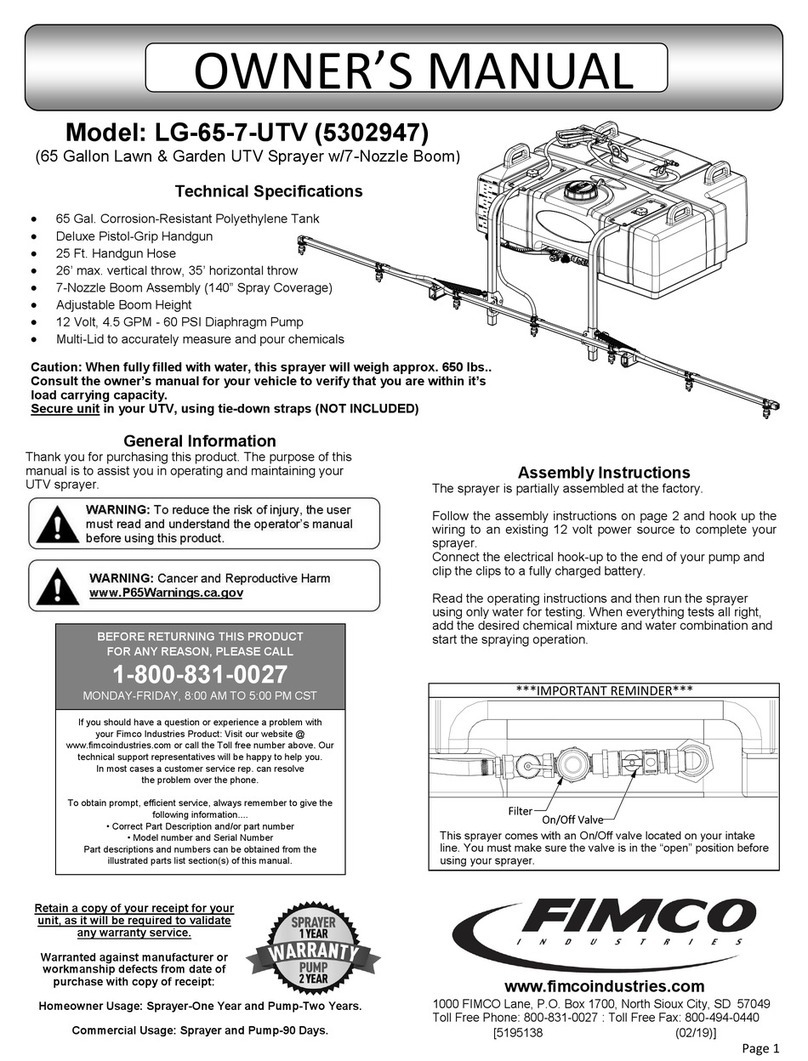

2. Open the brass valve in the suction line (See Detail A) and

allow water to flow to the pump. The valve is located at

this point to enable the strainer to be taken apart for

cleaning, while solution remains in the tank.

CAUTION: Always be sure that water (or solution) has

reached the roller pump before starting your sprayer. If the pump is run dry, serious damage to the pump will result. Do

not run your sprayer with the boom/handgun line closed AND the bypass line closed. Doing this will damage the pump.

3. It is always best to start the sprayer at little or no pressure. This sprayer is equipped with a spring loaded relief valve.

Turn the valve knob out to decrease pressure and in to increase pressure.

The bypass valve is the “pressure control” for the entire plumbing system. The more the valve is open, the lower your

line pressure. Almost fully closed provides maximum pressure to your boom and/or handgun. NEVER run your system

with this valve 100% closed.

NOTE: Engine is shipped with no oil. Add proper oil to the engine crankcase and gasoline to the gas tank. Refer to the engine

manual for the correct type and amount.

4. You may now start the engine following the engine manufacturers instructions. Let the sprayer run at low pressure

until water has reached the handgun and all air has been purged from the system.

The pressure should now be increased to 30-125 P.S.I. Operate the sprayer at this increased pressure for 3-5 minutes,

thoroughly testing the unit before adding chemicals.

Caution: Care must be taken, being sure the handgun is secured in the operators hand. If this is not done a recoiling

action may occur causing damage or personal injury.

Add water to the tank and drive to the starting place for spraying. When you are ready to spray, position booms out for

spraying and turn the boom valve to the “on” position. This will start solution spraying from the tips of the boom. The

pressure will decrease slightly when the boom is spraying. Adjust the pressure by twisting the gray twist knob on the

bypass (pressure relief) valve. Twist ‘clockwise’ to increase pressure , ‘counter-clockwise’ to decrease pressure.

Read the operating instructions and initially begin spraying by closing the ‘bypass’ valve and opening the boom line

valve. This will enable the air in the line to be eliminated (purged) through all the tips, while building pressure. When

everything tests all right (no leaks and good pressure), add the desired chemicals to the mixture and water combination

and start your spraying operation. Adjust the pressure and spray as you did in the testing procedure.

Conditions of weather and terrain must be considered when setting the sprayer. Do not spray on windy days. Protective

clothing must be worn in some cases

Be sure to read the chemical label(s) before application!

Information About the Sprayer

In this pumping system, solution is drawn from the tank and forced to a planned source, such as boom nozzles or

handgun. The pressure is controlled by opening/closing the valve which recirculates solution back into the tank.

Priming the pump

To help prime the pump, keep the inlet or suction line as short as possible with a minimum of bends, elbows and kinks.

Make sure all connections are tight and do not leak air. Make sure the line strainer is free of debris. If pump does not self

-prime, disconnect suction hose, fill with water and reconnect to liquid source. Often a squirt of oil into the ports of the

pump will seal clearances and help priming. Facing the pump, the suction port is on your left.

Tank Care & Maintenance

Warning: Do not use the tank as a container for fuel oils, kerosene, gasoline or any other petroleum distillate product.

All polyolefins are softened and permeated by such products. In an enclosed area the vaporization of these materials

from the outside surface of the tank could create a dangerous condition.

The tank should not be used as a pressure vessel nor used with chemicals or solutions having a weight of more than 12

pounds per gallon.

Store the tank in a dry dark place when not in use. Storage out of sunlight will prolong the life of the tank.

Do not drop, strike or kick the tank, especially at low temperatures. Tanks become brittle and are subject to cracking at

temperatures below 20° Fahrenheit.

Always flush the tank with water and a neutralizing agent at the end of each use, to prevent contamination of solutions.

Detail A

Valve Open

IMPORTANT:

Occasionally close valve and check the strainer screen to

ensure it is clean and clear of any debris. Strainer is locat-

ed next to the valve on the intake. Use protecve gear

when cleaning the strainer.