Page 3

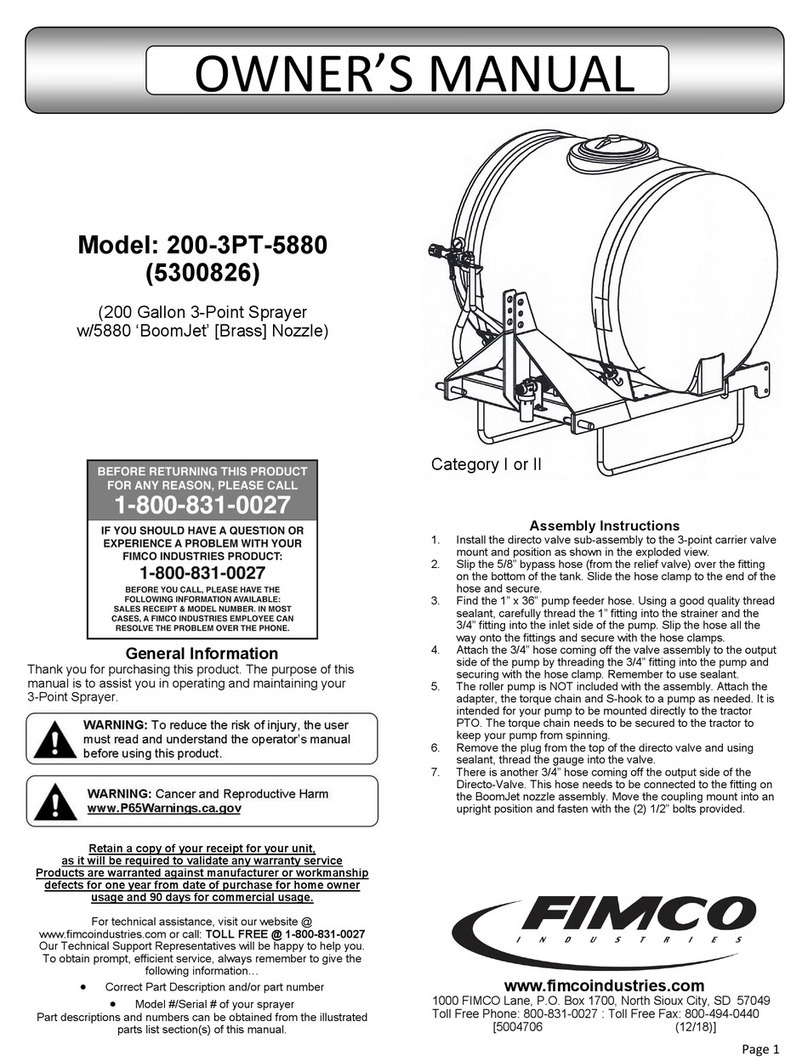

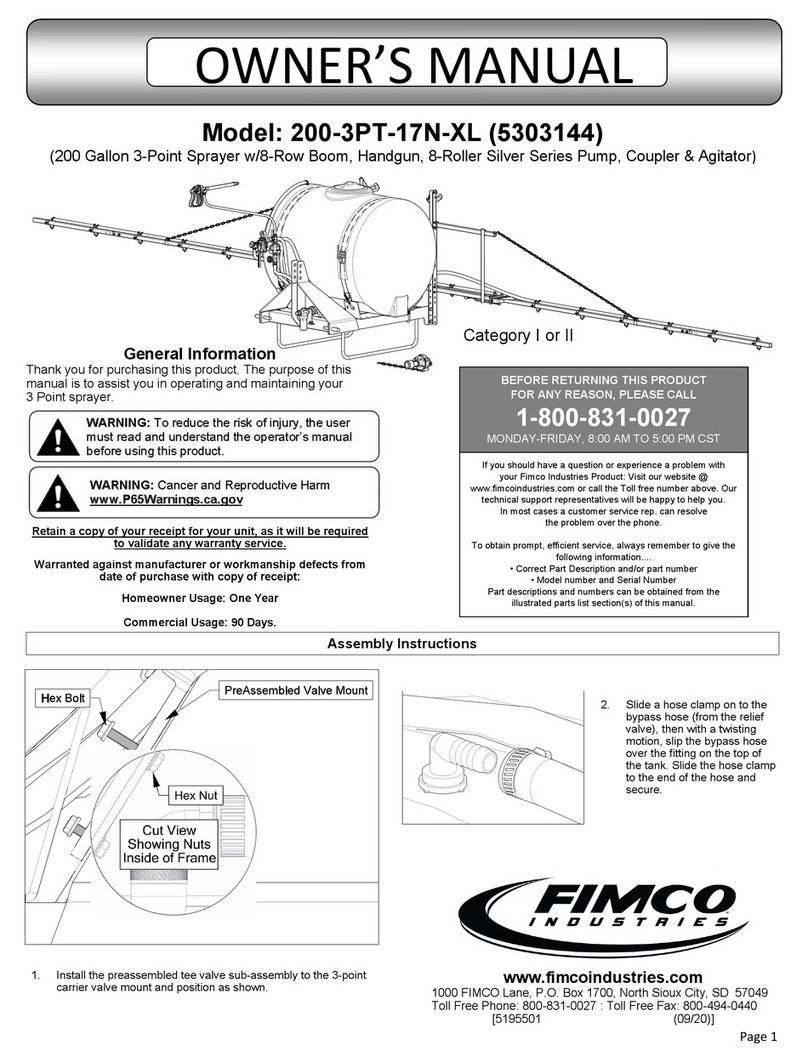

A torque chain, ‘S’ hook, nut and bolt are included in this assembly to

secure your pump during operation.

1. Attach one end of the torque chain over the threaded stem of the

bolt

2. Thread the whiz nut onto the bolt. Hand-tighten

3. Thread the bolt, chain and nut ‘pre-assembly’ into the threaded

hole on the underside of the pump. Tighten sufficiently

4. Affix the ‘S’ Hook to your frame (or hitch). Wrap the chain around

the frame or hitch and ‘S-Hook’ it in place. Make sure this con-

nection is very secure! Not having a good, tight connection may

result in the pump spinning on your PTO shaft and damaging

some components of your sprayer

*** Insure that this connection point will not allow the roller pump to

spin on the PTO shaft ***

Torque Chain Attachment to a Roller Pump

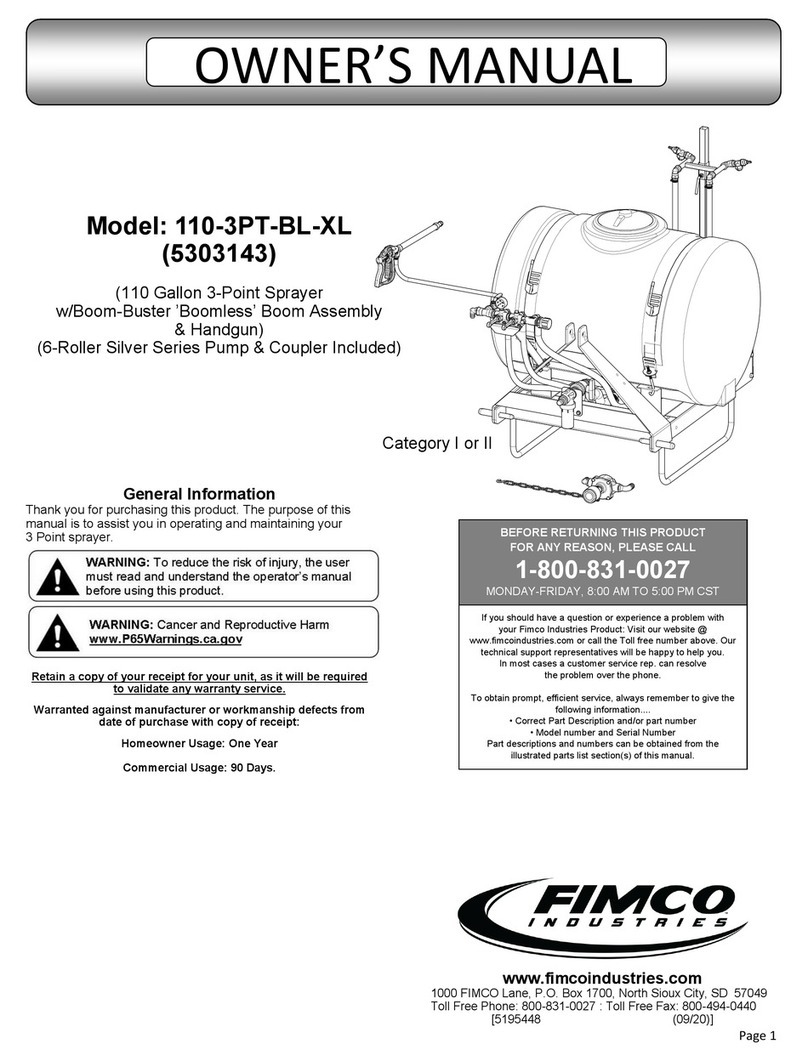

Strap/Buckle Detail

Strap Attachment

to a “Bent” Buckle

The nylon straps are to be inserted in and out of the slots in the

buckle, as shown. Be sure the straps are snug before tightening the

hook bolts. In most cases, it will be necessary to re-tighten the straps

after filling the tank with liquid.

Testing the Sprayer

Attach the sprayer to the tractor 3 point hitch. Mount the pump to the

PTO and affix the torque chain.

NOTE: It is important for to test your sprayer with plain water before

actual spraying is attempted. This will enable you to familiarize your-

self and check for leaks without the possibility of losing any expen-

sive chemicals.

Fill the tank about 1/2 full with plain water.

Before starting, open the suction line valve (located underneath the

carrier frame), turn the relief valve handle out to lower the line pres-

sure. This will help prime the pump.

CAUTION: Always be sure that the water (or solution) has reached

the pump before starting your sprayer. If the pump is allowed to run

dry, serious damage to the pump will result.

Always have the pressure line open to the tips so that the air which

may be trapped in the line will be forced (or purged) out.

Start the tractor PTO. Check the entire system for leaks. Once the

pump is primed, the pressure may be increased by turning the han-

dle of the pressure relief valve in. Keep the pressure line open to the

tips when setting the pressure. Set the pressure and then lock the

relief valve handle in place. Shut off the directo-valve and check for

leaks again. Pressure will increase when the pressure line valve is

closed and then return to the preset pressure when the valve is

opened again.

During the testing period, be sure to observe the spray pattern given

by the spray nozzles. If there is any pattern distortion, it will be

necessary to remove and clean the affected tips.

Caution: Never use a metal object or other sharp item for cleaning a

nozzle tip. It is better to use a nozzle brush (NOT wire brush) or

compressed air for tip cleaning.

Conditions of weather and terrain must be considered when setting

the sprayer. Do not spray on windy days. Protective clothing must be

worn in some cases

Be sure to read the chemical label(s) before application!

Operation

The performance of any agricultural chemical depends upon the

proper application.

Always fill the tank with a desired amount of water first and then add

the chemical slowly, mixing as you pour the chemical into the tank.

You may use the handgun to spraying into the solution in order to

mix the chemical and water.

The tips supplied as standard with the sprayer can be used for a

wide variety of spraying applications. Other tip sizes are available for

different coverages. The speed and pressure charts shown indicate

the rates can be changed considerably by changing speed and

pressure. The pumping system draws solution from the tank through

the strainer/filter and to the pump. The pump forces the solution

under pressure to the boom nozzles.

Tank Care & Maintenance

Warning: Do not use the tank as a container for fuel oils, kerosene,

gasoline or any other petroleum distillate product. All polyolefins are

softened and permeated by such products. In an enclosed area the

vaporization of these materials from the outside surface of the tank

could create a dangerous condition.

The tank should not be used as a pressure vessel nor used with

chemicals or solutions having a weight of more than 12 pounds per

gallon.

Store the tank in a dry dark place when not in use. Storage out of

sunlight will prolong the life of the tank.

Do not drop, strike or kick the tank, especially at low temperatures.

Tanks become brittle and are subject to cracking at temperatures

below 20° Fahrenheit.

Maintenance During/After Spraying

Periodically close the suction line valve and check the strainer and

clean the screen.

Proper care and maintenance will prolong the life of your sprayer.

After use, fill the sprayer tank part way with water. Start the sprayer

and allow the clear water to be pumped through the plumbing system

and out through the spray nozzles. Refill the tank about half full with

plain water and use FIMCO Tank Neutralizer and Cleaner and repeat

cleaning instructions above (If no tank cleaner is available, you may

substitute dish soap for this step, about 1-2 oz. per gallon). Flush the

entire sprayer with the neutralizing/cleaning agent, then flush out one

more time with plain water. Follow the chemical manufacturer’s dis-

posal instructions of all wash or rinsing water. For the boom (if appli-

cable) remove the tips and screens from the nozzle assemblies.

Wash these items out thoroughly. Blow the orifice clean and dry. If

the orifice remains clogged, clean it with a fine bristle (NOT WIRE)

brush or with a toothpick. Do not damage the orifice. Water rinse and

dry the tips before storing.

WARNING: Some chemicals will damage the pump valves if

allowed to soak untreated for a length of time! ALWAYS flush the

pump as instructed after each use. DO NOT allow chemicals to sit in

the pump for extended times of idleness. Follow the chemical manu-

facturer’s instructions on disposal of all waste water from the sprayer.

Winter Storage

Drain all water out of your sprayer, paying special attention to the

pump, handgun and valve(s). These items are especially prone to

damage from chemicals and freezing weather.

The sprayer should be winterized before storage by pumping a solu-

tion of automotive antifreeze (containing a rust inhibitor) through the

entire plumbing system. This antifreeze solution should remain in the

plumbing system during the winter months. When spring time comes

and you are preparing your sprayer for the spray season, rinse the

entire plumbing system out, clearing the lines of the antifreeze solu-

tion. Proper care and maintenance will prolong the life of your

sprayer.