Español

ESP

TRADUCCIÓN INSTRUCCIONES ORIGINALES

10

mientos suaves. No pulverice en ángulo porque pro-

vocará que la pintura forme gotas sobre la supercie.

Cuando pulverice sobre grandes supercies siga un

esquema adecuado de trabajo (11). Realice los movi-

mientos para pintar con el brazo, no con la muñeca.

Controle la velocidad con la que mueve la pistola pin-

tar para lograr un movimiento uniforme. Un movimien-

to demasiado rápido conllevará que la capa de pintura

sea demasiado na. Un movimiento demasiado len-

to conllevará que la capa de pintura sea demasiado

gruesa. Aplique las manos de una en una, dejando

los tiempos de secado entre cada mano apropiados

según las recomendaciones del fabricante.

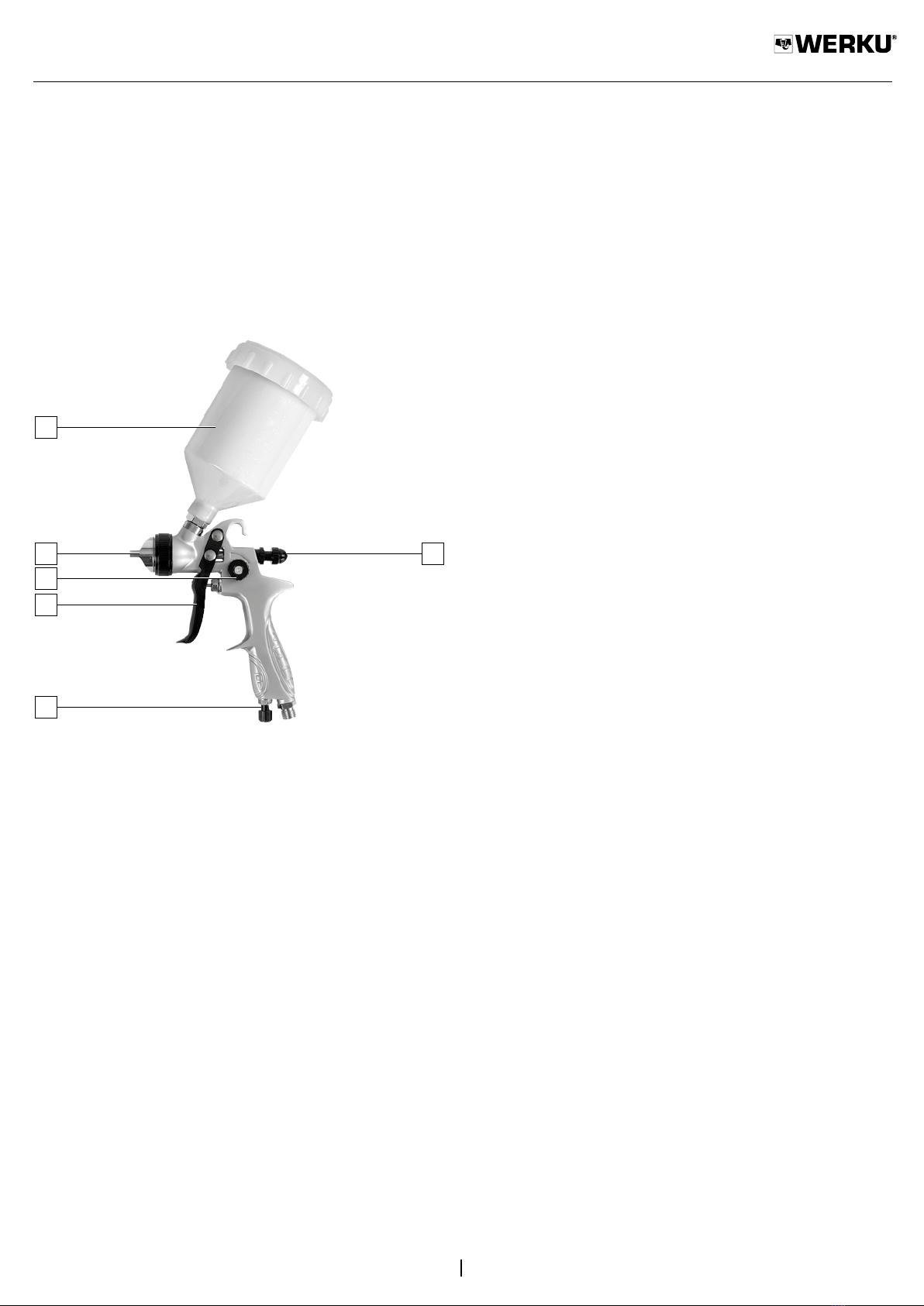

CAMBIO DE AGUJA, PICO Y REGULADOR

Desenrosque y retire el regulador de dirección de aba-

nico (A). Desenrosque y retire el regulador de paso

uido (E). Posteriormente, tire hacia atrás la aguja de

paso uido hasta haberla sacado en su totalidad. Con

la llave suministrada, desenrosque y retire del cabezal

el pico de paso de uido, posteriormente, enrosque

el nuevo pico de paso de uido. Introduzca la nueva

aguja de paso uido. Posteriormente enrosque el re-

gulador de paso uido (E). Enrosque el nuevo regula-

dor de dirección de abanico (A).

IMPORTANTE.

El uso de productos que contengan hidrocarburos ha-

logenados puede originar reacciones químicas en for-

ma de explosión. Al utilizar disolventes y detergentes

en base a hidrocarburos halogenados, como 1,1,1-tri-

cloroetano y cloruro de metileno, puede haber reaccio-

nes químicas en el vaso, la pistola y las piezas galva-

nizadas (el 1,1,1-tricloroetano en presencia de trazas

de agua produce ácido clorhídrico). Recomendamos el

uso de productos que no los contengan. Antes de la

puesta en servicio de la pistola de pintar y sus acce-

sorios deben limpiarse con disolvente de limpieza, con

el n de eliminar el tratamiento de protección aplicado

antes de su embalaje. En ningún caso utilizar ácidos,

sosa (álcalis, decapantes, etc.) para la limpieza.

MANTENIMIENTO.

Drene la condensación de los tanques compresores de

aire y las mangueras (12). Para ello, abra los grifos de

descompresión u otras válvulas de drenaje de los tan-

ques. La pistola de pintar ha sido diseñada para funcio-

nar durante mucho tiempo con un mínimo mantenimien-

to. El funcionamiento óptimo depende del buen cuidado

de la pistola de pintar y de una limpieza frecuente. La

pistola de pintar debe limpiarse de manera ecaz utili-

zando aire comprimido. Utilice siempre gafas protecto-

ras cuando trabaje con aire comprimido. Si no puede

utilizar aire comprimido, retire el polvo de la pistola de

pintar sirviéndose de un cepillo. Algunos productos de

limpieza y disolventes dañan los componentes de plás-

tico, entre los cuales se encuentran la gasolina, el te-

traclorometano, los disolventes de limpieza clorados, el

amoníaco y los productos de limpieza domésticos que

contienen amoníaco. No utilice ninguno de los produc-

tos mencionados para limpiar la pistola de pintar.

PROTECCIÓN DEL MEDIO AMBIENTE.

Los materiales y componentes que han sido uti-

lizados para fabricar este producto pueden ser

reutilizados y reciclados. Werku®está adherido a

un Sistema Integrado de Gestión que se encarga

de la correcta eliminación de los residuos de este

producto. No elimine este producto en la basura

doméstica. Werku®ofrece a sus clientes un servi-

cio gratuito de retirada de dichos residuos en cual-

quiera de sus puntos de venta, en los puntos de

recogida establecidos por el Sistema Integrado de

Gestión o en los puntos limpios de su localidad.

GARANTÍA Y SERVICIO TÉCNICO.

Werku®ofrece una garantía que cubre la reparación

de los defectos que se aprecian debido a fallos

en los materiales o en la fabricación. Para ello es

imprescindible que los defectos se produzcan dentro

del periodo de validez. El consumidor tiene derecho

a la reparación gratuita de los defectos (gastos de

envío, mano de obra y materiales incluidos), bien

mediante la reparación o mediante la sustitución (si

es necesario por un modelo posterior). En todo caso,

Werku®no aceptará sustituciones si estos suponen un

coste desproporcionado en comparación con el coste

de reparación. Esta garantía no afecta los derechos

del consumidor establecidos por leyes europeas o

nacionales. El periodo de validez de esta garantía es

de 3 años. El periodo de validez se inicia en la fecha

de compra por el primer consumidor. Esta fecha se

reeja en la factura o tique de compra. La reclamación

en virtud de esta garantía debe de presentarse al

distribuidor de Werku®o al Servicio de Asistencia

Técnica de Werku®. Para ello es imprescindible

presentar esta garantía debidamente cumplimentada

y sellada por el distribuidor, junto con la factura o tique

de compra. Para cualquier información referente a esta

garantía el comprador y/o el distribuidor puede ponerse

en contacto con el Servicio de Asistencia Técnica a

través del teléfono +34 981 648 119, o mediante correo