Fimer FLEXA AC Stand Alone User manual

FIMER FLEXA AC Wallbox

Installation Manual

Safety instructions

This manual contains important safety instructions that must be followed during installation and maintenance of the

equipment.

Keep this manual

Keep this document in a safe place for easy access at all times during installation and maintenance.

The installer must read this document in its entirety

before installing the equipment

Operators are required to read this manual and to comply strictly with the instructions it contains.

FIMER cannot be held responsible for damage caused to persons and/or property, or to the equipment, if the conditions

described below have not been complied with.

The purpose of this document is to support qualified technicians, who have received appropriate training and/or have

demonstrated adequate skills and knowledge in the construction, installation, operation and maintenance of electrical

equipment.

The warranty requirements are contained in the Terms and Conditions of Sale section included with the purchase order

for this product.

NOTE: Any modification not approved by FIMER will immediately invalidate the product warranty.

Warranty and delivery conditions

The warranty conditions are considered valid if the customer complies with the instructions contained in this manual;

any deviation from the warranty conditions with respect to what is described below must be expressly indicated in the

purchase order.

FIMER declares that the equipment complies with the legal provisions currently in force in the country of installation and

has issued the relative declaration of conformity.

FIMER assumes no responsibility for failure to comply with the instructions for proper installation and cannot be held

responsible for the systems upstream or downstream of the equipment supplied.

It is absolutely forbidden to modify the equipment. Any modification, manipulation or alteration of the hardware or soft-

ware not expressly agreed with the manufacturer will immediately void the warranty.

Due to the large number of possible combinations of system configurations and installation environments, it is essential

to check the following before installing the product: adequate space for housing the equipment, ambient noise produced

by the environment and possible flammable conditions.

FIMER cannot be held responsible for defects or malfunctions deriving from: improper use of the equipment; deteriora-

tion due to transport or particular environmental conditions; incorrect or insufficient maintenance; tampering or unsafe

repairs; use or installation by unqualified persons.

FIMER is not responsible for any disposal of the equipment, or part of it, that does not comply with the regulations and

laws in force in the country of installation.

Purpose and structure of the document

This user and maintenance manual is a guide to help you to work safely and carry out the necessary operations to keep

your equipment in good working order.

If the equipment is used in a manner not specified in this manual, the protection provided by the equipment may be

impaired.

This document was originally written in Italian. Therefore, in case of inconsistencies or doubts, ask FIMER for the orig-

inal document.

List of documents in the appendix

In addition to this user manual, product documentation can be consulted and downloaded by visiting www.fimer.com.

This document only contains the information deemed necessary for the use and routine maintenance of the equipment.

Skills and requirements of the operator and

maintenance personnel

Personnel involved in the use, maintenance and installation of the equipment must be qualified by FIMER (by means

of a letter certifying their qualification) for the activities described and must reliably demonstrate their ability to correctly

interpret what is described in the manual.

The installation must be carried out by FIMER-qualified installers and/or FIMER-authorised electricians in accordance

with the regulations in force in the country of installation and in compliance with all safety regulations for carrying out

electrical work.

It is forbidden to entrust the installation or maintenance of the product to unqualified persons or those in an altered

physical or mental state.

The customer bears civil responsibility for the qualification and mental or physical state of the personnel who handle

the equipment. Such personnel must always use the personal protective equipment (PPE) required by the laws of the

country of destination and by the instructions of their employer.

Table of Contents

1 General information........................................................................... 6

Fields of use.................................................................................................................................. 6

Support.......................................................................................................................................... 6

Symbols and definitions.............................................................................................................. 7

Product dimensions and features .............................................................................................. 8

Available models and versions ................................................................................................... 9

Inverter Net Additional features....................................................................................... 9

Future Net Additional features......................................................................................... 9

2 Safety and equipment ..................................................................... 13

Safety warnings..........................................................................................................................13

Proper use ...................................................................................................................................13

Product handling........................................................................................................................14

3 Installation....................................................................................... 15

Preparing for Installation...........................................................................................................15

Tools required .............................................................................................................................16

Package Contents ......................................................................................................................16

Space and positioning...............................................................................................................16

Unpacking ...................................................................................................................................17

Wall mounting plate installation ..............................................................................................18

Wallbox installation....................................................................................................................19

Connection of power and earth cables....................................................................................20

Residual-Current Device Management....................................................................................23

External protection..........................................................................................................23

National restrictions in Italy and the Netherlands.......................................................23

Installation example........................................................................................................24

Communication cables connection .........................................................................................25

Port Description..........................................................................................................................26

Opto-isolated digital outputs ........................................................................................27

Digital inputs....................................................................................................................27

AC Relay OUT....................................................................................................................28

TA Sensor..........................................................................................................................28

Gigabit Ethernet ..............................................................................................................29

RS-485 Smart Grid ..........................................................................................................30

RS-485 Mid Meter ...........................................................................................................31

USB ...................................................................................................................................32

Dynamic power management ...................................................................................................33

TA sensor installation......................................................................................................33

Closing operations and power supply ....................................................................................34

4 First start-up and configuration ..................................................... 35

Behaviour of the LED..................................................................................................................35

Behaviour of the LED when switching on the device...................................................35

Behaviour of the LED during operation .........................................................................35

5 Instructions for use ......................................................................... 36

Preliminary charging operations ..............................................................................................36

Charging operations ..................................................................................................................36

Plug&Charge charging ....................................................................................................37

Interrupting Plug&Charge charging ..............................................................................38

Charging with RFiD authentication................................................................................38

Interrupting charging with RFiD authentication ..........................................................40

Charging via RFiD and OCPP Service Centre (Future Net model only) .....................41

Remote charging via OCPP Service Centre (Future Net model only).........................42

RFiD TAG operations ..................................................................................................................43

Idle status indication (IDLE) ...........................................................................................43

TAG registration .............................................................................................................44

TAG verification................................................................................................................44

TAG deletion.....................................................................................................................44

MyFIMERWallbox App................................................................................................................45

Wallbox pairing................................................................................................................45

First page .........................................................................................................................46

Viewing, Adding and Deleting Wallboxes .....................................................................46

Wallbox configuration.....................................................................................................47

Active alarms ...................................................................................................................48

6 Trouble shooting .............................................................................. 49

Alarms and warnings .................................................................................................................49

Global Alarms...................................................................................................................50

Global Warnings ..............................................................................................................50

Socket Alarms ..................................................................................................................51

Socket Warnings..............................................................................................................51

7 Maintenance .................................................................................... 52

8 Decommissioning and disposal....................................................... 53

6

1

General information

FIMER FLEXA AC Wallbox is the AC charging solution for powering electric vehicles, ideal for public, semi-public and

residential applications: it is available in single-phase or three-phase configurations and can be equipped with a Type 2

SOCKET or a Type 2 CABLE or a Type 3A SOCKET (according to the IEC 62196-2 standard). Other types of connec-

tors are not supported.

Characterised by significant robustness and ease of use, this device allows you to charge an electric vehicle up to a

maximum of 22 kW (with Type T2 socket or cable) or up to 3.7 kW (with Type 3A socket).

Prepare and size the entire power supply system in compliance with the local and international standards in force

according to the product configuration and the power rating chosen.

This document describes how to install, configure, and maintain the product.

A description of the features of the equipment is provided to identify its major components and specify the technical

terminology used in the manual.

This chapter contains information on models, details on equipment, features and technical data, overall dimensions and

identification of the equipment.

In some cases, it may be necessary to document the software configuration features separately by consulting additional

documentation to this manual intended for specialised FIMER-trained technicians (e.g. sim data, etc.).

Fields of use

FIMER shall not be liable for damage of any kind resulting from incorrect or careless operations.

The equipment may not be used for any purpose other than that intended in the field of use. The equipment must not

be used by inexperienced personnel, or even by expert personnel if operations are carried out on the equipment that do

not comply with this manual and the accompanying documentation.

This equipment is a charging device for electric vehicles; the following classification (according to IEC 61851-1) identi-

fies its characteristics:

• Power supply: permanently connected to the AC power supply grid

• Output: alternating current

• Environmental conditions: outdoor use

• A device for places with free access

• Fixed installation on wall or dedicated FIMER FLEXA Stand

• Protection against electric shock: Class I

• Charging type: Mode 3 according to the IEC 61851-1 standard

• Optional function for ventilation not supported

In case of installation in TN-type earthing systems, there may be additional specific local regulations regarding system

safety and protection against faults that the installer must understand and implement.

The device can be used for the European and Australian markets, as up to date certifications have been issued.

Support

For any reports or requests for further support, FIMER is available through the dedicated section of the website www.

fimer.com or by writing to service.emobility@fimer.com.

7

It is strictly prohibited to:

• Install the equipment in environments subject to particular flammability conditions or in adverse or unpermitted envi-

ronmental conditions

• Use the equipment with defective or disabled safety devices

• Use the equipment or parts of the equipment by connecting it to other machines or equipment, unless expressly

provided for

• Modify operating parameters that are not accessible to the operator and/or parts of the equipment to alter its perfor-

mance or make changes to its insulation

• Clean the product with corrosive products that could damage parts of the equipment or generate electrostatic charges

• Use or install the equipment or any associated parts thereof without having read and properly understood the

contents of the operation and maintenance manual

Symbols and definitions

Symbol Description

GENERAL WARNING

IT IS MANDATORY TO CONSULT THE ORIGINAL MANUAL AND ADDITIONAL DOCUMENTATION

PROHIBITION OR RESTRICTIONS

IT IS COMPULSORY TO PERFORM THE DESCRIBED OPERATIONS USING THE CLOTHING AND/OR PROTECTIVE

EQUIPMENT PROVIDED BY THE EMPLOYER

ALTHOUGH THEY ARE NOT MADE OF MATERIALS THAT ARE HARMFUL TO HEALTH, THE PRODUCTS SHOULD

NOT BE DISPOSED OF ALONG WITH HOUSEHOLD WASTE BUT COLLECTED SEPARATELY BECAUSE THEY ARE

MADE OF MATERIALS THAT CAN BE RECYCLED

SIGN FOR ELECTRICAL VOLTAGE HAZARD

SIGN FOR OBLIGATION TO READ THE INSTRUCTIONS

ELECTRONIC DEVICE INSTALLATION CARRIED OUT BY QUALIFIED PERSONNEL ONLY

8

With respect to the symbols on the product’s nameplate, we shall identify the wording not shown above as follows:

44 x 130 mm

Product description

(model and version)

Product commercial code

EAN product code

Electrical characteristics

QR code for link to

FIMER website

Part and Serial Number

data

Week (first 2 digits) and year

(last 2 digits) of production

Product dimensions and features

Weight: 7 kg (versions with socket) and 8.5 kg (versions with cables) Dimensions: 275mm x 480mm x 140mm

140

(5,5)

275

(10,8

)

480

(18,9)

2

3

1

1 FRONT COVER

2 REAR CASING

3 FIXING PLATE

9

Available models and versions

The product is available in three models:

• Stand Alone

• Inverter Net

• Future Net

Three versions are available for each model, depending on the mode of connection to the vehicle: T2C, T2S, T3A.

Version code Description Related models

T2C T2 Cable Stand Alone, Inverter Net and Future Net with cable

T2S Type T2 socket

Stand Alone, Inverter Net and Future Net with socket

T3A Type T3A socket

In the vicinity of the sockets of the products supplied in the T2S and T3A versions, there is a label identifying the type of

socket installed on the product.

Stand Alone, Inverter Net and Future

Net version T2S AC EN 62192-2 TYPE 2 Plug and socket ≤480V

RMS C

Stand Alone, Inverter Net and Future

Net version T3A AC EN 62192-2 TYPE 3-A Plug and socket ≤480V

RMS D

Inverter Net Additional features

The Inverter Net model is distinguished by its ability to communicate with the FIMER REACT 2 solar inverter manage-

ment system through the RS485 port of the device (the connection of which is illustrated in the Communication Cables

Connection section).

From a functional and operational point of view, all the procedures valid for the Stand Alone version are also valid for

the Inverter Net model.

In addition, through the FIMER REACT 2 solar inverter management system, both device operation and parameter

monitoring activities and remote control or management activities are available. For an explanation of these functions,

refer to the instruction manual of the FIMER REACT 2 solar inverters and the relevant documentation of the manage-

ment system employed.

The Inverter Net model can be managed from smartphones via Bluetooth connection and an app.

Future Net Additional features

The Future Net model includes connectivity features that enable remote monitoring and management of the device.

This model is equipped with a SIM card slot for connection to the 3G/4G mobile network.

Charging operations can be enabled via the User RFiD card (configured via the dedicated management portal for

charging and not via the RFiD Master as for the Stand Alone / Inverter Net versions), via the mobile app (which commu-

nicates with the device both via Bluetooth and WiFi connection) or via a dedicated management portal (WiFi-3G / 4G

connection).

Instructions on how to use the management portal are available in the dedicated user manual.

Four different power ratings are available for the T2C (T2 Cable) and T2S (T2 Socket) versions: 3.7 kW (single-

phase), 7.4 kW (single-phase), 11 kW (three-phase) and 22kW (three-phase).

For the T3A version (T3A Socket) , only the 3.7 kW (single-phase) power rating is available.

10

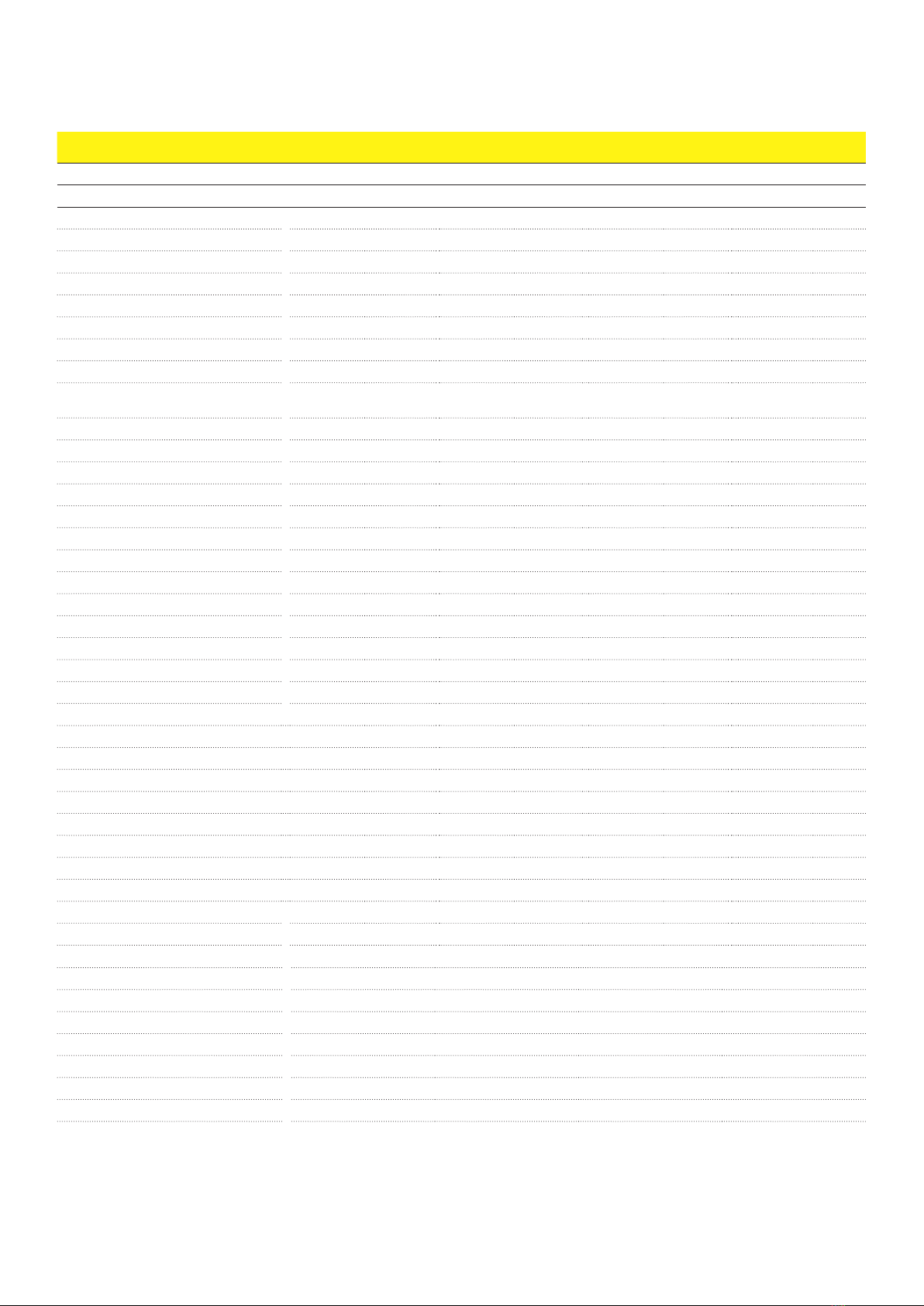

Technical Data

Model FIMER FLEXA AC Wallbox - Stand Alone

Maximum power 3.7 kW 7.4 kW 11 kW 22 kW

Standard IEC61851-1

Charging mode Mode 3

Available outputs 5m cable (Type 2) or Socket (Type 2 or Type 3A)

Power system 1P + N + PE 1P + N + PE 3P + N + PE 3P + N + PE

Rated voltage 230V AC ± 10% 230V AC ± 10% 230/400V AC ± 10% 230/400V AC ± 10%

Frequency 50-60 Hz

Rated current 16 A 32 A 16 A 32 A

Rated impulse withstand voltage (Uimp) 4 kV

Rated conditional short-circuit current of an

assembly (Icc) 10 kA

Rated Diversity Factor (RDF) 1

Degree of pollution 2

EMC classification Class B emissions

Protective measures against electric shock Class I

Connection to the power supply network Permanently connected to the grid

Type of grounding system TT or TN (both with PE)

Indoor / outdoor installation Outdoor

Fixed or removable installation Fixed

Overvoltage category III

IP protection class IP 55

IK protection Class IK08

Casing material 100% recycled plastic

Dimensions 275mm x 480mm x 140mm

Weight 7 kg (Socket), 8.5 kg (Cable)

Operating temperature -25….+50°C

Storage temperature -25…+70°C

Humidity 0 ... 95% (without condensation)

Altitude Up to 2000 m

Product intended for use Ordinary person

Location in area with Unrestricted access

Thermal-magnetic circuit breaker Not included

Residual-current device Not included (only RCM 6mA DC included)

Energy meter Compatible with external MID meters or TA meters

Certification CE, AUX, UL (Planned)

Bluetooth

••••

RFiD

••••

OCPP

----

3G / 4G connection

----

Ethernet connection

----

Wifi

----

Status LED

••••

Remote SW update

----

11

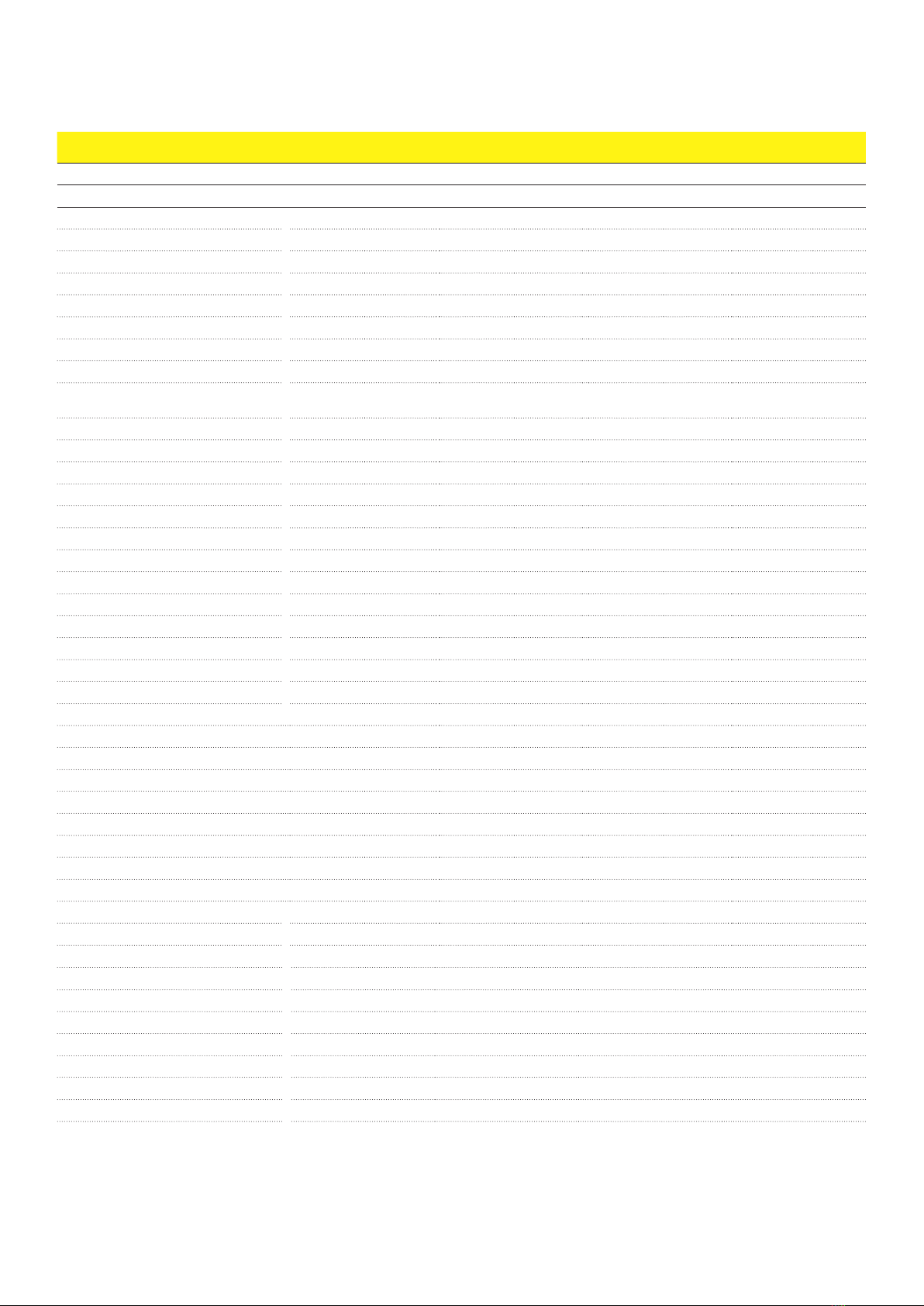

Technical data

Model: FIMER FLEXA AC Wallbox- Inverter Net

Maximum power 3.7 kW 7.4 kW 11 kW 22 kW

Standard IEC61851-1

Charging mode Mode 3

Available outputs 5m cable (Type 2) or Socket (Type 2 or Type 3A)

Power supply system 1P + N + PE 1P + N + PE 3P + N + PE 3P + N + PE

Rated voltage 230V AC ± 10% 230V AC ± 10% 230/400V AC ± 10% 230/400V AC ± 10%

Frequency 50-60 Hz

Rated current 16 A 32 A 16 A 32 A

Rated impulse withstand voltage (Uimp) ≥4kV

Rated conditional short-circuit current of an

assembly (Icc) 10 kA

Rated Diversity Factor (RDF) 1

Level of pollution 2

EMC classification Class B emissions

Protection measures against electric shock Class I

Connection to the power supply network Permanently connected to the electricity grid

Type of grounding system TT or TN (both with PE)

Indoor / outdoor installation Outdoor

Fixed or removable installation Fixed

Overvoltage category III

IP protection class IP 55

IK protection class IK08

Casing material 100% recycled plastic

Dimensions 275mm x 480mm x 140mm

Weight 7 kg (Socket), 8.5 kg (Cable)

Operating temperature -25….+50°C

Storage temperature -25…+70°C

Humidity 0 ... 95% (without condensation)

Altitude Up to 2000 m

Product intended for use Ordinary person

Position in area with Unrestricted access

Thermal-magnetic circuit breaker Not included

Residual current device Not included (only RCM 6mA DC included)

Energy meter Compatible with external MID meters or TA meters

Certification CE, AUX, UL (Planned)

Bluetooth

••••

RFiD

••••

OCPP

----

3G/4G Connection

----

Ethernet connection

----

Wifi

----

Status LED

••••

Remote SW update

••••

12

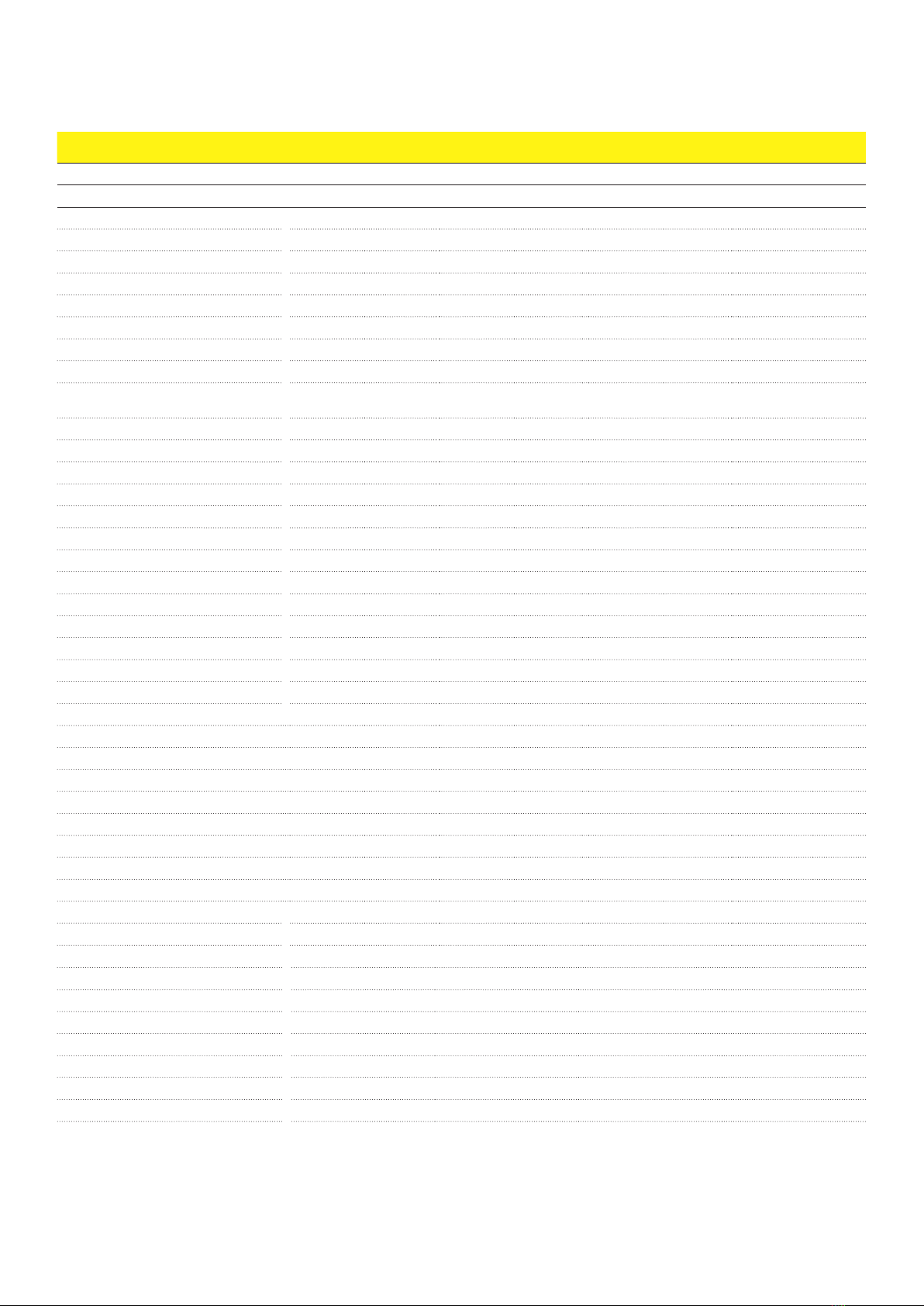

Technical data

Model: FIMER FLEXA AC Wallbox - Future Net

Maximum power 3.7 kW 7.4 kW 11 kW 22 kW

Standard IEC61851-1

Charging mode Mode 3

Available outputs 5m cable (Type 2) or Socket (Type 2 or Type 3A)

Power supply system 1P + N + PE 1P + N + PE 3P + N + PE 3P + N + PE

Rated voltage 230V AC ± 10% 230V AC ± 10% 230/400V AC ± 10% 230/400V AC ± 10%

Frequency 50-60 Hz

Rated current 16 A 32 A 16 A 32 A

Rated impulse withstand voltage (Uimp) ≥4kV

Rated conditional short-circuit current of an

assembly (Icc) 10 kA

Rated Diversity Factor (RDF) 1

Level of pollution 2

EMC classification Class B emissions

Protection measures against electrical shocks Class I

Connection to the power supply network Permanently connected to the electricity grid

Type of grounding system TT or TN (both with PE)

Indoor / outdoor installation Outdoor

Fixed or removable installation Fixed

Overvoltage category III

IP protection class IP 55

IK protection class IK08

Casing material 100% recycled plastic

Dimensions 275mm x 480mm x 140mm

Weight 7 kg (Socket), 8.5 kg (Cable)

Operating temperature -25….+50°C

Storage temperature -25…+70°C

Humidity 0 ... 95% (without condensation)

Altitude Up to 2000 m

Product intended for use Ordinary person

Location in area with Unrestricted access

Thermal-magnetic circuit breaker Not included

Residual-current device Not included (only RCM 6mA DC included)

Energy meter Compatible with external MID meters or TA meters

Certification CE, AUX, UL (Planned)

Bluetooth

••••

RFiD

••••

OCPP

OCPP 1.6 Json OCPP 1.6 Json OCPP 1.6 Json OCPP 1.6 Json

G0 3G / 4G

••••

Ethernet connection

••••

WiFi

••••

Status LED

••••

Remote SW update

••••

13

Safety and equipment

Safety warnings

Please read this document carefully before installing and starting up the product.

The installation and start-up phases of the device should only be carried out by qualified personnel who are able to

identify hazards and act safely.

Even the maintenance, repair or subsequent repositioning phases must be carried out only by qualified personnel: there

are no components that can be repaired by the user or maintained independently.

Children or persons not deemed capable of assessing the risks involved in the installation must not handle the product.

Both domestic and non-domestic animals must be kept away from the equipment.

Failure to observe all or part of the instructions in this document may lead to serious or fatal injury.

The qualified installer must always ensure that the installation is carried out in accordance with the local regulations in

effect at the time of installation.

Proper use

The device requires an earth connection via a dedicated equipotential cable, to be connected to the earth terminal

inside the device.

In any case, it is necessary to verify, prior to installation, that the power supply system is fully compliant with the state of

the art and carried out by qualified personnel in accordance with local and international regulations.

The device is only safe to use if it is used as intended.

Different uses and unauthorised modifications to the appliance or to any of its components are not permissible and are

therefore considered to be non-compliant.

The device is designed to be connected and to communicate information and data via a network interface. It is the sole

responsibility of the user to provide and ensure at all times a secure connection between the product and the user's

data network or any other network (as the case may be). The user must establish and maintain all appropriate meas-

ures (such as, but not limited to, the installation of firewalls, the application of authentication measures, data encryption,

the installation of anti-virus programs, etc.) to protect the product, the network, its system and interface against any type

of security breach, unauthorised access, interference, intrusion, loss or theft of data or information. FIMER and its affili-

ates shall not be liable for any damage or losses related to any such security breaches, any unauthorised access, inter-

ference, intrusion, loss or theft of data or information. The data, examples and diagrams in this manual are only included

to describe the product and should not be regarded as a declaration of guaranteed properties. All persons responsible

for installing the equipment specified in this manual must ensure that each intended installation is suitable and accept-

able, including compliance with any applicable safety or other operational requirements. In particular, any risk in applica-

tions where a system failure or product failure would create a risk of damage to property or persons (including but not

limited to personal injury or death) shall be the sole responsibility of the person or entity installing the equipment, and

those responsible for it are advised to ensure that all measures are taken to eliminate or mitigate such risks.

This document has been carefully checked by FIMER but deviations cannot be completely ruled out. If errors are

detected, the reader is kindly asked to notify FIMER. Except for explicit contractual commitments, in no case can

FIMER be held responsible for any loss or damage resulting from the use of this manual or from the installation of the

equipment.

The product should not be displayed freely on the internet. In order to ensure maximum security of information and

operation, it is necessary for the device to remain protected from any attempt to connect to it from the internet. There-

fore any communication should only originate from the device and not the other way around.

If you require further information, support or wish to make a report regarding cyber security, please write to the e-mail

address itteb.cybersecurity@fimer.com.

2

14

Product handling

The total weight of the product without packaging is approximately 7 kg for the Socket version and 8.5 kg for the Cable

version: be sure to use suitable equipment for handling it.

Transport and store in a dry place away from heat sources (following the technical guidelines) in the original packaging

only.

Never grasp the product by the charging cables or connectors.

15

Installation

WARNING: Failure to observe the instructions given in this manual may cause serious damage to both the product

and the installer (in the most serious cases, injuries may be fatal). Please read this manual carefully before installing,

starting up and using the product. FIMER recommends using experienced professionals who comply with current regu-

lations in order install the product correctly.

The following table shows the main local restrictions prescribed in the IEC 61851-1 standard that the installer must

consider before selecting and installing the device. However, it remains the responsibility of the installer to verify that

these regulations are still in effect and above all to check whether additional local regulations apply and could restrict

the use of these devices in the country of choice:

Country National restrictions

IT For the CABLE and T3A SOCKET versions, an additional device capable of interrupting the power supply must be used

(see External Residual-Current Device Management)

NL For the CABLE and T3A SOCKET versions, an additional device capable of interrupting the power supply must be used

(see External Residual-Current Device Management)

FR The CABLE and T3A SOCKET versions cannot be used in residential and public applications

UK The CABLE and T3A SOCKET versions cannot be used in residential and public applications

DK The CABLE and T3A SOCKET versions cannot be used in residential and public applications

ES The CABLE and T3A SOCKET versions cannot be used in residential applications and for all applications up to 16A

SE The CABLE and T3A SOCKET versions cannot be used

JP Device not suitable for this country

US Device not suitable for this country

CA Device not suitable for this country

Preparing for Installation

Before proceeding with the installation, make sure that:

• Input power is completely switched off and remains so until installation is complete

• The work area is adequately cordoned off (access by person who are not involved in the work must be prevented)

• Installation should not be carried out with wet hands and no water jet should be directed towards the product

• Installation should not be carried out in rain, fog or high humidity

• The product packaging is completely intact and without any obvious damage (if the product is damaged, contact your

seller or request support at www.fimer.com)

• The product and all components (including cables) are completely intact and without any obvious defects or faults

To ensure correct operation of the product in line with the local regulations in effect, calculate the distance between the

power supply panel and the installation site to determine the voltage drop, cable thickness and existing load, which are

useful for identifying the maximum operating current.

The entire electrical system to which the product is connected must first be correctly sized by a qualified profes-

sional. The device’s electrical data, which should be referred to in order to correctly size the power supply system, are

displayed on the device’s nameplate.

3

16

The installation of the product must comply with all applicable local and international standards in force for the construc-

tion and installation of electrical/electronic equipment, including, but not limited to, the IEC 60364-1 and IEC 60364-5-52

standards.

The power supply system must meet the following requirements:

• A TN or TT system, in both cases with a PE cable

• Power supply:

- Models with three-phase connection: 400 V AC ± 10% - 50Hz / 60Hz

- Models with single-phase connection: 230 V AC ± 10% - 50Hz / 60Hz

Tools required

1. Cutter

2. Flathead screwdriver or screw gun

3. Marker/pencil

4. Drill and 8mm diameter bit suitable for the material of the fixing surface to be drilled

5. Hex keys

6. Wire stripping pliers

FIMER accepts no liability for damage to property or persons deriving from the use of these tools. Installation must

be performed by qualified personnel and in compliance with the regulations in place for the installation of electrical

equipment.

Package Contents

• N.1 FIMER FLEXA AC Wallbox

• N.1 fixing plate

• N.4 8x40 wall plugs

• N.14 40x14 screws

• N.4 white caps

• N.1 "4 hole" gasket

• User counterpart connectors

• Installation manual, warranty certificate and declaration of conformity

Space and positioning

Before choosing where to install the product, consult your electric vehicle manual and follow any pertinent instructions.

Make sure that there are no heat sources, flammable substances or electromagnetic sources in the installation area,

either during installation of the product or throughout the product’s lifetime.

In addition, the installation site must be sufficiently ventilated to ensure proper heat dissipation.

For versions of the product with mobile cellular or Wi-Fi connection, ensure that the selected area has cellular reception

or Wi-Fi coverage.

Before installation, ensure that the environmental conditions (such as temperature, altitude and humidity) comply with

the product specifications.

To ensure the functionality of the device and to guarantee its proper usage by the user, the space around the device

must be clear to allow for air circulation, cable manoeuvrability, charging procedures and both routine and non-routine

safety maintenance operations.

In addition, the space needed to park the electric vehicle to be charged must be taken into account.

For locations where the device will be exposed to direct sunlight or weather for most of the day, it is advisable to install

a cover to protect the charging station.

In addition:

• Make sure that there are barriers or poles to protect the charging device from collisions;

• Design the parking layout for easy access to the charging cable;

• Provide a safe and comfortable environment for users and to prevent vandalism or theft;

• Install the charging device in a place where it can be clearly seen or monitored;

• Install sufficient lighting around the device.

17

Unpacking

Before installing the device, it is necessary to check, when unpacking, that the various parts of the device do not display

any physical damage due to impacts, tears or abrasions.

If any damage is detected, the installation procedure must be aborted immediately and technical support must be

contacted.

The various components are protected by packaging and adhesive tape: before installation, each component must be

cleaned of any traces of dust, packaging or adhesive tape.

The images below are for illustrative purposes and may not show all internal components of the product or may contain

negligible differences from the actual configuration.

1. Open the main packaging

2. Using suitable handling equipment, remove the device from the casing and place it on the work surface

3. Remove the 10 screws that hold the front cover to the rear casing and separate the two parts of the product

18

Wall mounting plate installation

The images below are for illustrative purposes and may not show all internal components of the product or may contain

negligible differences from the actual configuration.

The product can be installed either on the wall or on a dedicated FIMER FLEXA STAND.

This document shows the installation procedure for wall mounting, while the installation procedure for the FIMER

FLEXA STAND is supplied with the FIMER FLEXA STAND.

1. Establish the installation location, taking into account the minimum distances from the ceiling, walls and

floor provided in the drawing. The installation height of the Wallbox must be such that the lowest point of the vehicle

connector when placed in its resting position is at a height of between 1.2 - 1.5 m (47 - 59 inches) above ground level,

corresponding to the lower edge of the plate.

2. Place the fixing plate on the wall and use it as a template to make marks at the fixing holes (a) using a marker or

pencil.

N.B. Pay attention to the orientation of the plate. To ensure a more precise final position, it is best to use a spirit

level to check the correct alignment of the plate to the wall when marking.

3. Remove the plate from the wall and, using a drill, make 4 holes (a) Ø 8 mm at the previously drawn marks. The

minimum depth of the hole must be 60 mm (2.4 inch). Then remove any drilling residue from the holes.

4. Separate the 4 screws from the respective 4 wall plugs Ø 8 x 40 mm (supplied)

The wall plugs supplied are universal, suitable for solid or cavity brick walls. For installation on walls made of different

materials (e.g. plasterboard) specific plugs are required, which must be installed after the maximum permissible load

has been verified.

5. Insert the 4 plugs into the holes just

made. Place the fixing plate on the wall,

matching the 4 holes in the plate to the 4

holes just drilled in the wall.

6. Secure the plate by screwing the 4

screws previously removed from the wall

plugs into the corresponding plugs set into

the wall.

Measurements are in mm (inches).

Ø 8 x 40

(a)

(a)

≥ 500

(≥ 19,6)

1200 ÷ 1500

(47 ÷ 59)

≥

250

(≥

9,8)

60

2,4

(≥

9,8)

≥

250

19

Wallbox installation

During installation, the electrical connection of the power supply must be disabled, and the entire working area must be

cordoned off, with only qualified and authorised personnel able to access it.

The power supply to the equipment must remain switched off. Failure to follow these instructions can lead to

serious damage to persons and property, including death.

The images below are for illustrative purposes and may not show all internal components of the product or may contain

negligible differences from the actual configuration

1. Position the Wallbox close to the wall-mounted plate, so that the four side tabs of the fixing plate correspond to the

four side slots of the rear casing.

3. Use 4 screws Ø 14 x 40 mm to secure the rear casing of the device to the fixing plate with a tightening torque of 1.7

Nm.

≥ 500

(≥ 19,6)

≥

250

(≥

9,8)

1200 ÷ 1500

(47 ÷ 59)

20

Connection of power and earth cables

During installation it is necessary to prevent the electrical connection of the power supply and to cordon off the entire

work area, with only qualified and authorised personnel able to access it.

The equipment must be powered by cables that are properly dimensioned and capable of withstanding the current

flow for which the product has been designed. Make sure that the cables are of suitable size before wiring and that the

maximum permissible bending radii are not exceeded. The device’s electrical data, which should be referred to in order

to correctly size the power supply system, are displayed on the device’s nameplate.

The power supply to the appliance must remain switched off throughout this step.

Failure to comply with these instructions can lead to serious damage to people and property, including death.

The images below are for illustrative purposes and may not show all the product’s internal components.

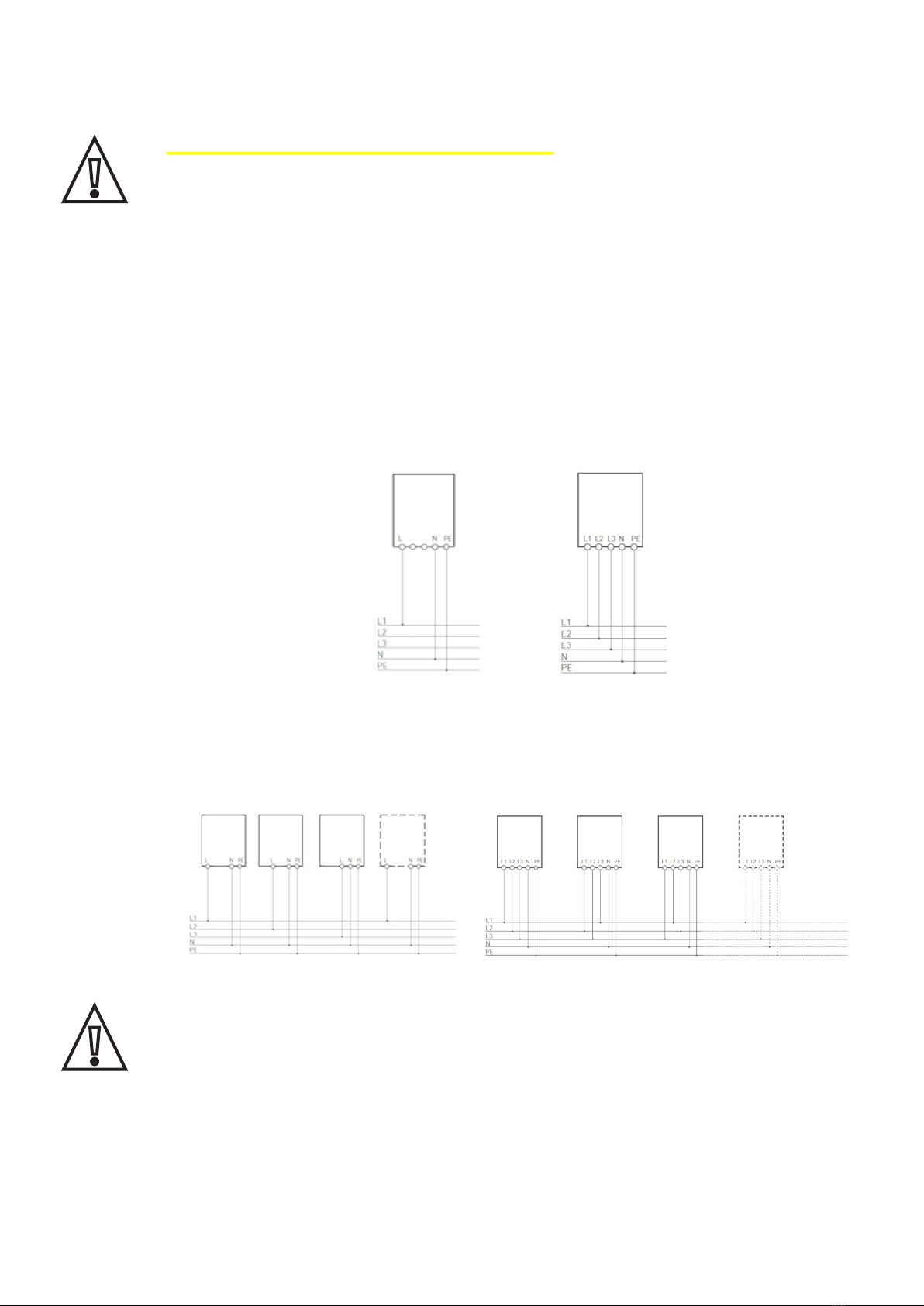

The following diagram shows how to electrically connect the device in single-phase and three-phase systems. In the

case of a single-phase device connected to a single-phase power supply, the available LN pair replaces the quad

L1-L2-L3-N visible in the diagram.

Single-phase Three-phase

In case of multiple installations, it is suggested to provide for phase rotation:

Single phase Three-phase

If the installer plans to carry out an installation with phase rotation, the manufacturer must be notified of this method

only in the case when there is a master-slave type configuration between the devices. This allows the manufacturer to

configure the devices appropriately for this installation. Otherwise, there is no need to inform the manufacturer.

This manual suits for next models

5

Table of contents

Popular Automobile Accessories manuals by other brands

Sytech

Sytech SY-1537BT user manual

Quadratec

Quadratec QuadraTop Adventure Top S With Flip Back... quick start guide

Radium

Radium EMS instruction manual

Alpha

Alpha A1-14-24-P User manual & installation guide

Thule

Thule Low Rider 821 instruction manual

OMEX

OMEX Shift Light Sequential Installation and user instructions