Finerfilters RO-NP23-50G Manual

This manual suits for next models

5

Table of contents

Other Finerfilters Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Adey

Adey MagnaClean Atom Installation and servicing

3M

3M ScaleGard HP Installation and operation instructions

Osmio

Osmio Clarity user manual

spotzero

spotzero ZTCII2000 User manual & installation guide

MASSEY FERGUSON

MASSEY FERGUSON CENTORA 7282 Workshop service manual

Schaffner

Schaffner ECOsine active FN3420-030-3 Series Operating and installation instructions

Pentair

Pentair STA-RITE POSI-CLEAR RP Installation and user guide

Sears

Sears 625.345600 owner's manual

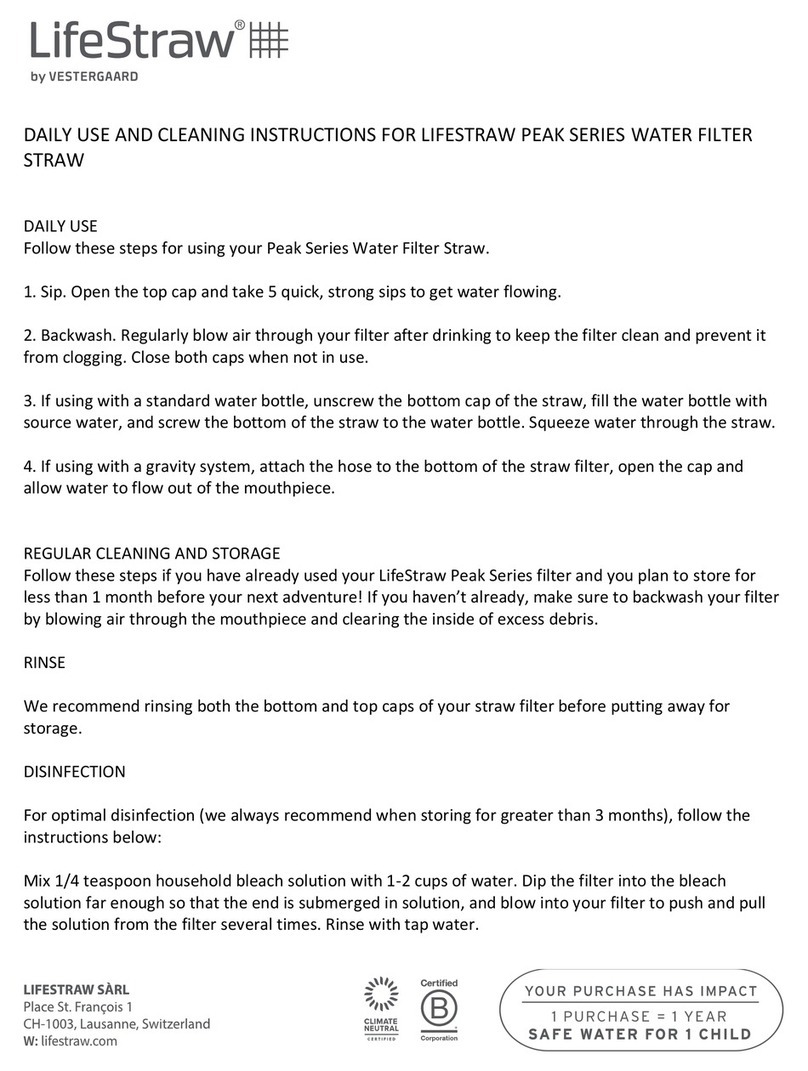

Vestergaard

Vestergaard LifeStraw PEAK Series instructions

PondXpert

PondXpert Triple Action Evolve 4500 How to set up

EasyPro

EasyPro EPU18N Instructions for Operation, Safety, Warranty

GE

GE E4H-16K Operation and maintenance manual