3

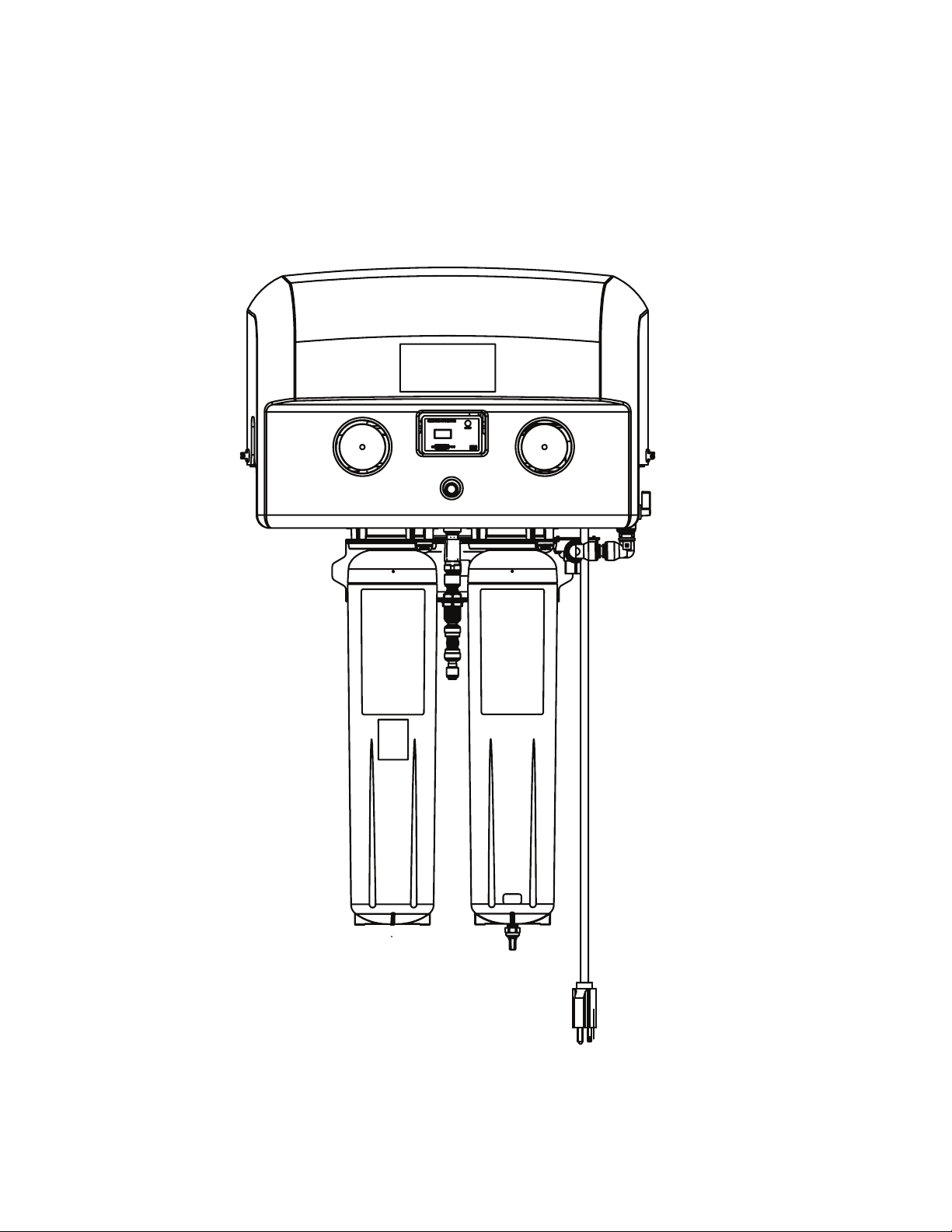

Read, understand, and follow all safety information contained in these instructions prior to installation

and use of the 3M™Water Filtration Products ScaleGard™HP reverse osmosis system. Retain these

instructions for future reference.

Intended use:

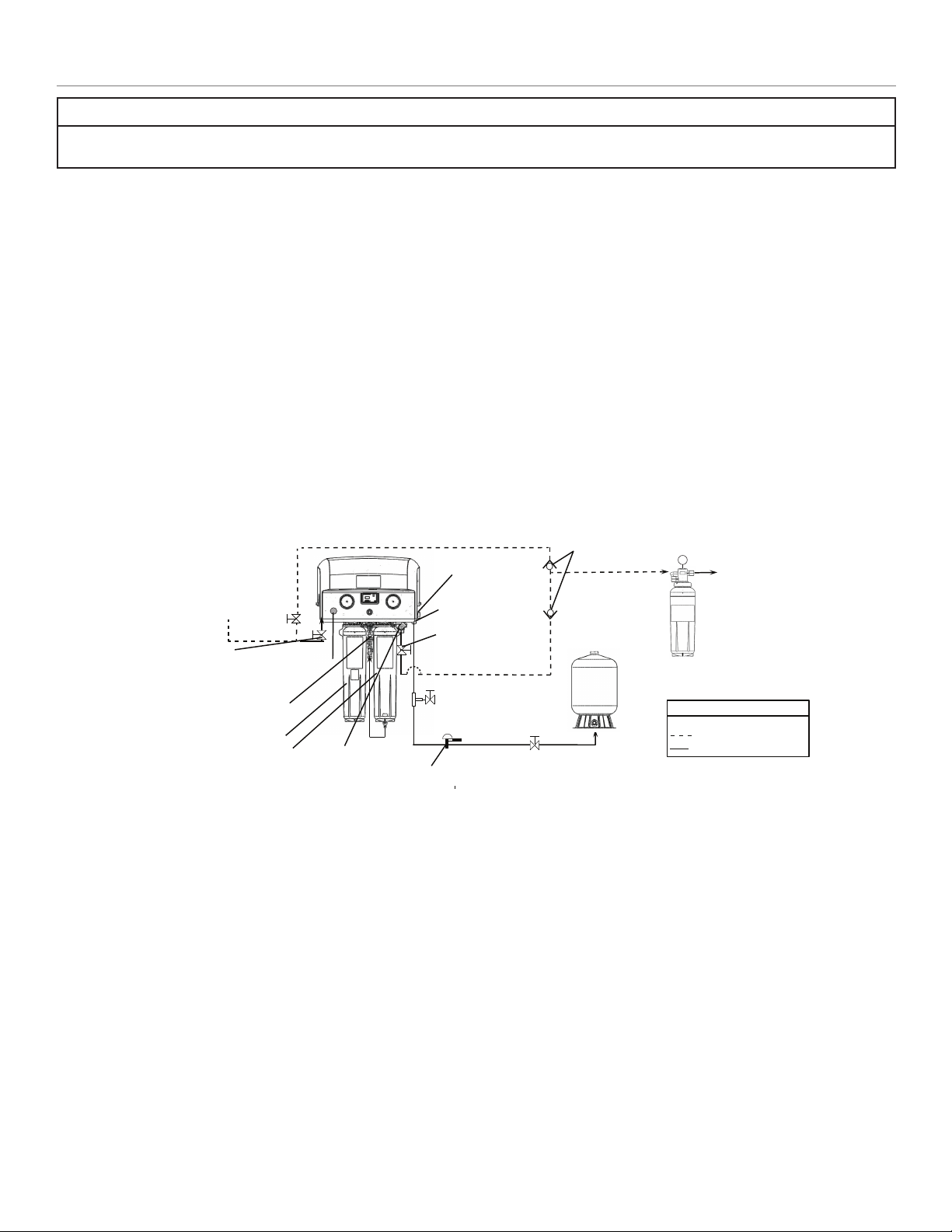

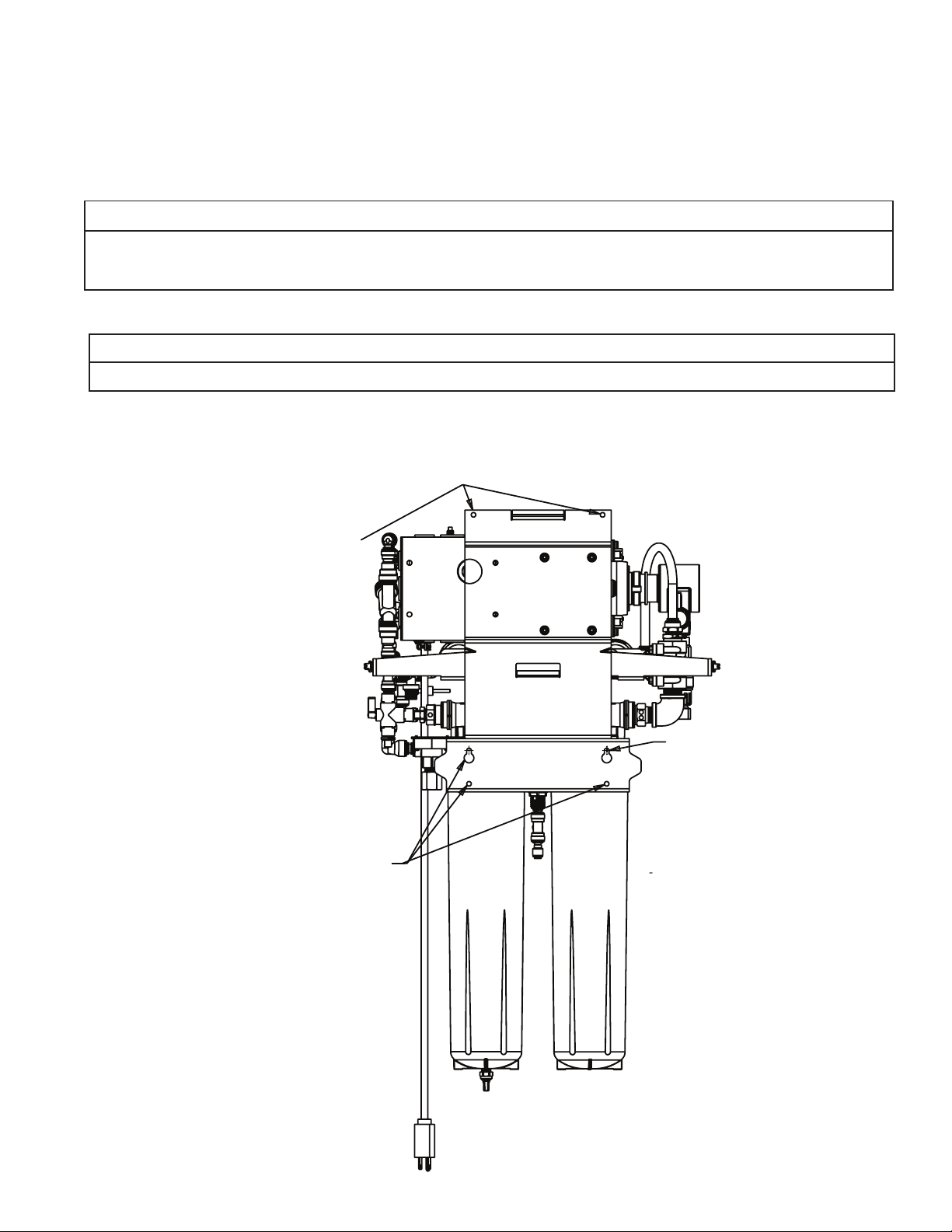

The ScaleGardTM HP reverse osmosis system is intended for use in filtering potable water and has not been evaluated for other

uses. The product is installed at the point of use and must be installed as specified in the installation instruction by a qualified

professional.

SAFETY INFORMATION

EXPLANATION OF SIGNAL WORD CONSEQUENCES

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARNING

Indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury and/or property damage.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury and/or property damage.

NOTICE

Indicates a potentially hazardous situation, which, if not avoided, may

result in property damage.

CAUTION

To reduce the risks associated with environmental contamination which, if not avoided, could result in minor or moderate injury:

• At the end of useable life, dispose of this system in accordance with applicable local regulations or laws.

To reduce the risks associated with impact which, if not avoided, could result in minor or moderate injury:

• Depressurize system as shown in manual prior to cartridge removal.

To reduce the risks associated with heavy objects which, if not avoided, could result in minor or moderate injury:

• Follow safe lifting procedures.

WARNING

Read entire manual. Failure to follow all guides and rules could cause personal injury or property damage.

• Check with your local public works department for plumbing codes. You must follow their guidelines as you install the water ltration system.

• Your water ltration system will withstand up to 125 pounds per square inch (psi) water pressure. If your water supply pressure is higher than 80 psi, install a

pressure reducing valve before installing the water ltration system.

• An approved post lter and tank must be used with the RO system.

To reduce the risk associated with choking:

• DO NOT allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with the ingestion of contaminants:

• DO NOT use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system. Systems certied for

cyst reduction may be used on disinfected water that may contain lterable cysts.

To reduce the risk associated with hazardous voltage due to an installer drilling through existing electric wiring or water pipes in the area of

installation:

• DO NOT install near electric wiring or piping which may be in path of a drilling tool when selecting the position to mount the lter bracket.

To reduce the risk associated with back strain:

• Follow safe lifting procedures.

To reduce the risk of physical injury:

• All hydro-pneumatic pressurized tanks MUST have an appropriate pressure relief valve installed. Pressure relief valve must be maintained and inspected

every 6 months. Contact a plumbing professional if you are uncertain how to select/install/maintain a pressure relief valve.

To reduce the risk associated irritation from Sodium Metabisulte during installation:

• Sodium Metabisulte (CAS 007681-57-4) is used in a 1% preservative solution within the reverse osmosis membrane.

• DO NOT put this system into service before the RO tank is ushed as specied in the installation instructions. Wear eye and face protection during installation.

• To request an MSDS relating to this product call 203-238-8965 or visit the web at http://solutions.3m.com). For emergencies, call 800-364-3577 or 651-

737-6501 (24 hours).

To reduce the risk associated with ingestion of water contaminaed with sanitizer:

• After installation, sanitizer MUST be ushed from the system before rst use as directed within the installation instructions.

SAFETY INFORMATION CONTINUED ON NEXT PAGE

IF CONNECTION IS MADE TO A POTABLE WATER SYSTEM, THE SYSTEM SHALL BE PROTECTED AGAINST BACKFLOW.