FineTek ECP1 User manual

Contents

1. Reading Labels...............................................................................................................1

2. Product Warranty...........................................................................................................2

2.1 New Product Warranty...............................................................................................2

2.2 Repair Warranty ........................................................................................................2

2.3 Service Network ........................................................................................................3

3. Product Inspection.........................................................................................................4

3.1 Check Content...........................................................................................................4

3.2 Safety Inspection.......................................................................................................4

4. Product Features............................................................................................................5

4.1 Product Features.......................................................................................................5

4.2 Working Principles.....................................................................................................5

4.3 Mechanical Drawing..................................................................................................5

4.4 Product Applications..................................................................................................5

5. Product Specifications ..................................................................................................6

5.1 Product Applications..................................................................................................6

5.2 Panel.........................................................................................................................6

5.3 Appearance and Dimension......................................................................................7

5.4 Hole Dimension.........................................................................................................7

5.5 Ordering Information .................................................................................................8

5.6 Wiring Instructions.....................................................................................................9

6. Installation Instructions...............................................................................................10

6.1 Environmental Safety..............................................................................................10

6.2 Install.......................................................................................................................10

6.3 Installation of Circuits..............................................................................................10

7. Operating Instructions.................................................................................................11

7.1 Button Functions .....................................................................................................11

7.2 Description..............................................................................................................12

7.3 Information on Commands......................................................................................13

7.4 Examples ................................................................................................................14

8. Transportation And Storage........................................................................................15

8.1 Transportation requirements...................................................................................15

9. Maintenance .................................................................................................................15

9.1 Daily Care ...............................................................................................................15

10. Error Message And Troubleshooting .......................................................................15

1

1. Reading Labels

Thanks for purchasing FineTek’s Product. This operation manual describes the

product features, working principles, operation and maintenance methods. It

makes the user fully understand how to use the product correctly, so as to prevent

dangerous situations such as device damage or operator injury.

➢Please read this operation manual completely and carefully before using the product.

➢Please contact the company if this operation manual can’t satisfy your demands.

➢The content of the operation manual is updated based on the version upgrade,

which will be uploaded to the website for the user to access.

➢Please don’t disassemble or repair the product on your own, as this will

make you disqualified from availing of the warranty service. Please send the

product back to the company for repair and calibration, or just contact the

company.

➢Explanation of warning signs:

Danger→ It indicates that wrong operation will cause death or major disasters.

Note→ It indicates that wrong operation will cause injury and device damage to

some extent.

Electric shock→ It warns of possible electric shock.

Fire→ It warns of possible fire.

Prohibited→ It indicates the prohibited wrong behavior.

2

2. Product Warranty

2.1 New Product Warranty

➢Wedon’t charge for the inspection, part/s and repair for the product of the

company that has a defect within 12 months from the delivery date and meets

the warranty terms.

➢If the product defect is not due to human error during its transportation, user

may

➢change to a new unit from the company within 7 days from delivery date.

➢When the product needs to be sent back to the factory for repair, please send

the whole set, and don’t disassemble the parts. Moreover, please be sure it is

completely packed to avoid damage and causing more loss and defect during

the transportation.

➢The warranty is not available for causes that fall under the following

circumstances, for which the company shall charge for the inspection, part/s

and repair according to the actual condition:

◆The product or its parts are beyond the warranty period.

◆Fault or damage is caused by not following the instruction and use

environment described on the operation manual.

◆The product damage is caused by a force majeure factor (natural

disasters, floods, fire, earthquakes, lightning, typhoon, etc.), human

destruction (scratches, dropping, latch broken, tapping, cracks and

punching), human error (using improper voltage, high-humidity, water

leakage, stain, corrosion, loss, improper storage, etc.) and other

abnormal factors.

◆The damage is caused by the customer or the 3rd party through the

installation, addition, expansion, modification and repair of parts not

authorized or certified by the company.

◆The volume label information is wrongor unclear, sothe product serial

numbercan’t be confirmed.

2.2 Repair Warranty

A 6-month warranty service is provided for the repaired part of the product, during

which the same product can be repaired free of charge in case of the same fault.

3

2.3 Service Network

Company

Address

Telephon

Fax

Taipei Headquarters

(Taiwan)

No.16, Tzuchiang St., Tucheng

Industrial Park, New Taipei City

23678

+886 2 2269 6789

+886 2 2268 6682

Taichung

Sales office

(Taiwan)

+886 4 2465 2820

+886 4 2463 9926

Kaohsiung

Sales office

(Taiwan)

+886 7 333 6968

+886 7 536 8758

Fine automation

Co., Ltd.

(China)

No. 451, Duhui Road, Zhuanqiao

Township, Minhang District,

Shanghai City 201109

+86 021 64907260

+86 021 6490 7276

Aplus FineTek

(Sensor Inc.)

355 S. Lemon Ave, Suite D,

Walnut, CA 91789

1 909 598 2488

1 909 598 3188

FineTek Pte Ltd.

(Singapore Branch)

37 Kaki Bukit Place, Level 4

Singapore 416215

+65 6452 6340

+65 6734 1878

FineTek GmbH

(Germany Branch)

Bei den Kämpen 26

21220 Seevetal-Ramelsloh,

Germany

+49 (0) 4185 8083 12

+49 (0) 4185 8083 80

FineTek Co., Ltd.

(Indonesia Branch)

PERGUDANGAN TUNAS BITUNG

JL. Raya Serang KM. 13,8, Blok

C3 No. 12&15, Bitung Cikupa,

Tangerang 15710

+62 (21) 2923 1688

+62 (21) 2923 1988

4

3. Product Inspection

3.1 Check Content

➢Sensor x 1

➢Fixating buckle x 1; countersunk screw x 2; nut x 2

➢Cable x 1

➢Operation manual x 1

3.2 Safety Inspection

➢Please check whether the external package is deformed or damaged. Please

remember to take a picture for evidence for compensation later.

➢After unpacking, please check whether the content is deformed or damaged,

or has any quality problem. Please remember to take a picture for evidence

for compensation later.

➢After unpacking, please check whether the content is consistent with the

ordering info,

and whether the quantity is right.

➢Please contact the company within 7 days if any of the above situations occur

(attach the picture together with your complaint). Otherwise, we won’t

compensate for, change or repair the product defect.

5

4. Product Features

4.1 Product Features

➢Dual-color LED and red-text alarm displays

➢Analog 4–20 mA output that allows continuous detection of pressure values

➢Anti-corrosion structural design that is suitable for minimally corrosive solution

➢Quick release mount to facilitate calibration and replacement

➢Dual NPN/PNP output that makes pressure control quicker and more convenient

➢IO-Link compatibility to make system integration easier

4.2 Working Principles

With the piezoresistive pressure sensor, as soon as changes in environmental

pressure are detected, the thin film deformation on the pressure sensor

changes too, and the piezoresistive material on the thin film experiences

deformation accordingly. The resistance changes as such as well. Such

resistance change, once read and processed through the Wheatstone bridge

and the amplifier circuit, can be used to measure the size of pressure.

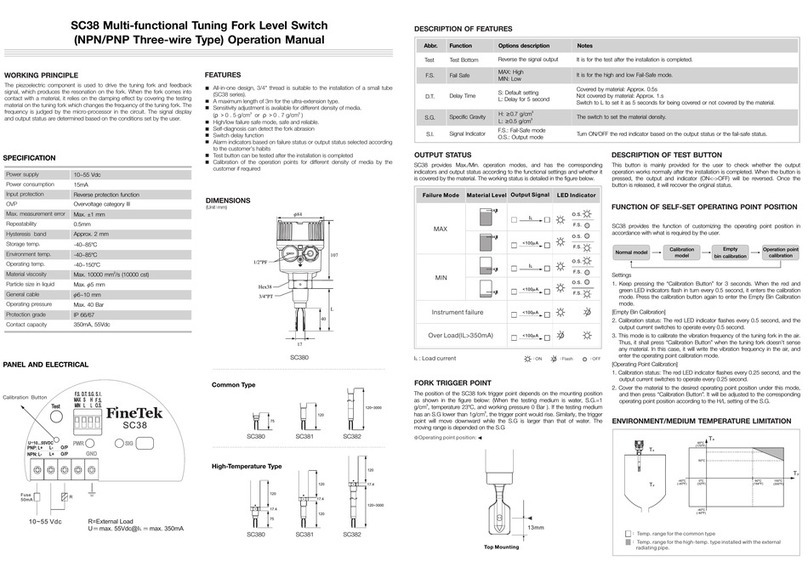

4.3 Mechanical Drawing

4.4 Product Applications

This product is applied to a modularized pressure meter where air, water, and solution with

a pH value are used.

6

5. Product Specifications

5.1 Product Applications

5.2 Panel

There are 4 push buttons on the panel for adjustment of parameters. There are two output

indicators (OUT1/OUT2) and 5 pressure units for selection and shift in display.

Power supply

DC 12~36V

Power consumption

<50mA (@24V unloaded)

Operating temperature

−10 to 60°C

Working medium

Liquid/Slight corrosive liquid/air

Accuracy

±1.5%F.S.

Temperature coefficient

±0.1%F.S./ °C (25°C as the baseline)

NPN/PNP output

current

Maximum pressure tolerance of 30 V/100 mA and breakover

residual voltage of < 1.5 V

NPN/PNP protective

current

180mA

NPN/PNP short-circuit

protection

Yes

Delay time

1.5 ms, 20 ms, 100 ms, 500 ms, 1,000 ms, 2,000 ms, 5,000 ms

Current output

4~20mA

Max. Load resistance

When the power voltage is 12V: 300Ω

When the power voltage is 24V: 500Ω

Linearity: ±1%F.S.

Accuracy : ±2.5%F.S. (ambient temperature of 25 ± 3°C)

Display unit

MPa, kPa, kgf / cm², bar, psi

Display method

Dual-color LED

Display color

Red/Green

Number of digits

displayed

4 (7 segments)

Action indicator

It is lit when the output is ON OUT1 and OUT2: Red

Dimensions

61mm*61mm

7

5.3 Appearance and Dimension

5.4 Hole Dimension

On the installation disc, it is required to make diagonal holes with a diameter of 3.2

mm according to the cross-sectional view B-B above; use the countersunk screws

to hold the disk onto the equipment.

In addition, it is required to make holes with a diameter greater than 51.2 and

smaller than 54 mm according to the forgoing drawing to allow buckling and fixation

once the display pressure meter is inserted into the installation disc.

Cross-sectional view

A-A

Cross-sectional view

B-B

8

5.5 Ordering Information

9

5.6 Wiring Instructions

Quick joint used for the ECP and the cable for

connecting the six conductors of the cable

(1) Brown: 4–20 mA

(2) Green: Control box cover

(3) Blue: OUT1

(4) Black: GND

(5) Red: 24V

(6) Orange: OUT2

Information on OUT1/OUT2 connection:

➢R1 and R2 mean the loads of OUT1 and OUT2.

➢When the system experiences abnormalities, to protect the sensor against

Information on the 4–20 mA connector:

The third pin (brown line) is where the 4–20 mA current is output and is

connected to the input terminal of the positive end of the current meter.

The second pin (black line) is 0V and is connected to the input terminal of the

negative end of the current meter.

5

1

4

Current meter

10

6. Installation Instructions

6.1 Environmental Safety

➢Storage temperature: -40°C ~85°C (-40°F~185°F)

➢Operating temperature: -10°C~60°C (-14°F~140°F)

➢Supply power: 12 VDC ~ 36 VDC

➢Output load current: Max, 50 mA

6.2 Install

Once holes are made on the instrument panel according to Section 5, use the countersunk

screws and nuts (follow the red arrows), and secure the snap disc onto the instrument panel

first. Then, tilt the ECP pressure meter by around 30 degrees. Penetrate it through the snap

disc and let the fixating buckle of the snap disc enter the slot. Turn the ECP pressure meter

clockwise till the pressure meter is in the same orientation as the snap disc and this

completes the installation process.

6.3 Installation of Circuits

Once wiring is completed according to Section 5, finish installing the ECP pressure meter. Link and

insert the quick joint of the cable in the arrow-indicated direction to complete installation of the

circuit.

ECP pressure meter

ECP snap disc

Instrument panel

11

7. Operating Instructions

7.1 Button Functions

Quick key:

➢Press and hold for 3 seconds to initialize pressure

➢Press and hold for 3 seconds to shift (LOCK/UNLK)

➢Press to quickly shift the unit

➢Press to enter the menu in an unlocked state

General operation:

Press Access the next-level menu/enter for confirmation

Press Shift on same-level menu; enter the digit to shift

Press Adjust the value up

Press Return to the previous-level menu (without storing changes to parameters)

12

7.2 Description

7.3

00.00 OUT1

OUT2

Mode

ENT

➔

Type

➔

HiPt

➔

LoPt

➔

Dely

➔

Mode

Type

➔

HiPt

➔

LoPt

➔

Dely

➔

ENT ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

NC/NO

PNP/NPN

2.00 UP 調整數值;

➔切換位數;

ENT確認

➔切換選項

ENT確認

➔切換選項

ENT確認

1.00 UP 調整數值;

➔切換位數;

ENT確認

20 ➔切換選項

ENT確認

NC/NO

PNP/NPN

4.00 UP 調整數值;

➔切換位數;

ENT確認

➔切換選項

ENT確認

➔切換選項

ENT確認

3.00 UP 調整數值;

➔切換位數;

ENT確認

20 ➔切換選項

ENT確認

Shift options

to confirm

to adjust the value;

the digit;

to confirm

to adjust the value;

the digit;

to confirm

options

to confirm

options

to confirm

options

to confirm

to adjust the value;

the digit;

to confirm

to adjust the value;

the digit;

to confirm

options

to confirm

Shift options

to confirm

Shift options

to confirm

(Default: NC)

(Default: NPN)

(Default: NC)

(Default: NPN)

13

7.4 Information on Commands

Level 1 menu:

OUT1 (output settings for the first group)

OUT2 (output settings for the second group)

Level 2 menu: (Level 3 options in red, without entering Mode >NC alternating display)

OUT1 ➔

Mode: OUT1 connection mode options; one can choose normally closed (NC) and normally

open (NO) modes

Type: OUT1 connection type options; one can choose NPN and PNP

HiPT: OUT1 connection activation values; it is activated when the measurement is greater

than this setting

LoPT: OUT1 connection homing values; it homes when the measurement is smaller than

this setting

Dely: Delay time in activation of OUT1.

OUT2 ➔

Mode: OUT2 connection mode options; one can choose normally closed (NC) and normally

open (NO) modes

Type: OUT2 connection type options; one can choose NPN and PNP

HiPT: OUT2 connection homing values; it homes when the measurement is greater than

this setting

LoPT: OUT2 connection activation values; it is activated when the measurement is greater

than this setting

Dely: Delay time in activation of OUT2.

Note: Dely (1.5/20/100/500/1000/2000/5000(ms))

14

7.5 Examples

The default value of OUT1 LoPt is 1kgf/cm2 and that of HiPt is 2 kgf/cm2

Once the measured pressure is greater than HiPt 2 kgf/cm2, the On/Off joint OUT1 starts to

act and the font color turns red.

Once the measured pressure is below LoPt 1 kgf/cm2, the On/Off joint OUT1 starts to

initialize and the font color turns green.

Once the measured pressure is greater than OU2 LoPt 3 kgf/cm2, the On/Off joint OUT2

starts to act.

Once the measured pressure is greater than OU2 HiPt 4 kgf/cm2, the On/Off joint OUT2

starts to home.

The OUT2 joint only acts when the measured pressure is between LoPt and HiPt.

Font color

15

8. Transportation And Storage

8.1 Transportation requirements

To prevent the ECP Pressure Guage from damage during the transportation, please

keep the packaging condition as how it was when it was shipped from the factory

before arriving at the installation site. The storage conditions should meet the

following:

➢Appropriate rainproof and damp-proof treatment must be conducted .

➢Vibration must be reduced and collision with other objects must be prevented

during its transportation.

➢The storage temperature must be in the range of -40~70°C

➢The humidity should be lower than 80%

9. Maintenance

9.1 Daily Care

Periodically check the pressure sensing port to see if it is clogged by foreign matters or

damaged; if it is seriously clogged, clean it. If it is damaged, replace the equipment.

When equipment is removed and before it is re-installed, confirm carefully if pressure is

released from pressurized pipes to avoid leakage of liquids from the pipes.

The disposal of equipment shall be based on local national regulations in an

environmentally friendly way.

In the case of return, please make sure that the product is not contaminated, particularly

by hazardous or poisonous substances. For the transport, suitable packaging is required

to avoid damaging the equipment.

10. Error Message And Troubleshooting

Abnormality

Possible causes

Solution

No display

No power supply

Check the power line and

repair it.

No display

Failure to meet product

specification requirements

in terms of power

Confirm that power supply is

12–30 Vdc and correct it

No response with On/Off

Abnormal wiring

Check wiring, terminal pin,

and correct it

No response with On/Off

Insufficient power supply to

drive output

Check power supply (it has

to be >12Vdc) and correct it

The switch signal is not

stable and works

intermittently.

Make sure the wiring of the

switch signal and power

cable terminals does not

become lose or come off.

Confirm the wire pin again to

ensure the correction

connection of the lines.

Table of contents

Other FineTek Measuring Instrument manuals

FineTek

FineTek EPF Series User manual

FineTek

FineTek EF Technical manual

FineTek

FineTek EPD34 User manual

FineTek

FineTek ECP2 User manual

FineTek

FineTek EPD30 Technical manual

FineTek

FineTek EE310 User manual

FineTek

FineTek EPD36 Technical manual

FineTek

FineTek JTR Series Technical manual

FineTek

FineTek EPR5 User manual

FineTek

FineTek EDX2 User manual