I

Table Of Contents

1.Operation manual use ............................................................................................ 1

2. Product warranty.................................................................................................... 2

2.1 New product warranty ....................................................................................2

2.2 Repair warranty..............................................................................................2

2.3 Service Network.............................................................................................3

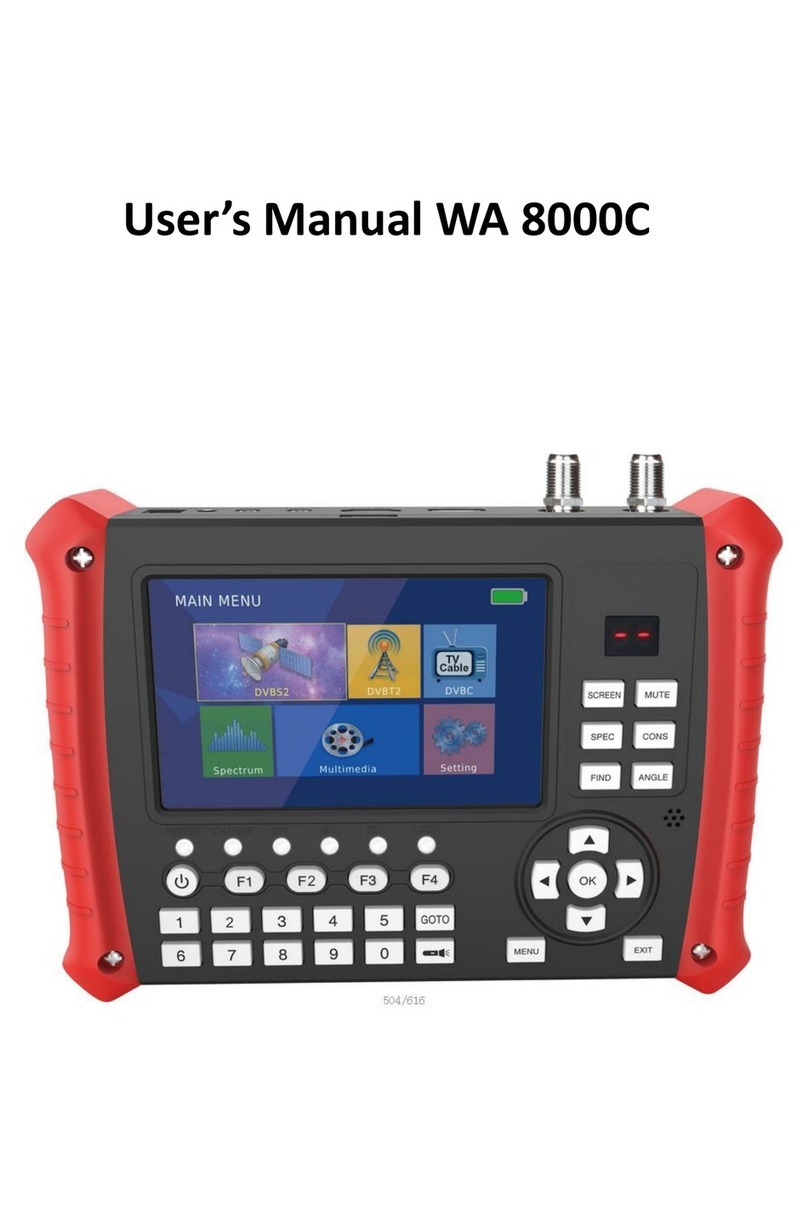

3. Product description................................................................................................ 4

3.1 Data label.......................................................................................................4

3.3 Product introduction .......................................................................................4

3.4 Product applications.......................................................................................4

3.5 Product features.............................................................................................5

4.Dimensions.............................................................................................................. 9

4.2 Without Display (Engineering Plastics)..........................................................11

4.3 T-fitting (Engineering Plastics)...................................................................... 12

4.4 Technical Parameter.................................................................................... 13

4.5 Assembly Instructions .................................................................................. 15

4.6 Troubleshooting............................................................................................ 16

5. Wiring instructions............................................................................................... 19

5.1 Safety........................................................................................................... 19

5.2 With Display M12 Connector........................................................................ 19

5.4 Without Display Connector........................................................................... 20

5.5 Without Display Wiring................................................................................. 20

6.Display Module Adjustment and Setting............................................................. 21

6.1 Button Operations ........................................................................................ 21

6.2 Start Screen.................................................................................................. 21

6.3.1 Flow Rate Unit.......................................................................................... 22

6.3.2 Flow Total Unit.......................................................................................... 22

6.3.3 K Factor.................................................................................................... 22

6.3.4 Pipe Diameter........................................................................................... 23

6.3.5 Filter Set ................................................................................................... 23

6.3.6 Reset Total................................................................................................ 23

6.4 Output Signal Settings.................................................................................. 24

6.4.1 Pulse Out Mode........................................................................................ 24

6.4.1.1 Pulse Out Unit....................................................................................... 24

6.4.1.2 Total Alarm ............................................................................................ 24

6.4.1.3 Flow Rate Alarm.................................................................................... 25

6.4.1.4 Alarm Status.......................................................................................... 25

6.4.2 Analog Output Setting............................................................................... 26