FineTek EPD34 User manual

Contents

1. Reading Labels...................................................................................................................1

2. Product Warranty...............................................................................................................2

2.1 New Product Warranty.................................................................................................2

2.2 Repair Warranty............................................................................................................2

2.3 Service Network............................................................................................................3

3. Product Inspection ............................................................................................................4

3.1 Check Content...............................................................................................................4

3.2 Safety Inspection ..........................................................................................................4

4. Summary ..............................................................................................................................4

5. Product Features................................................................................................................5

6. Applicable Scope ...............................................................................................................5

7. Environmental Condition.................................................................................................5

8. Working Principles ............................................................................................................6

9. Technical Performance.....................................................................................................7

9.1 Execution Standards....................................................................................................7

9.2 Basic Parameters and Performance Indicators.......................................................8

9.2.1 Technical Specification Table.................................................................................8

9.2.2 Accuracy class & tolerance.....................................................................................9

9.2.3 Recommended Flow Range for Tube Diameters................................................9

9.2.4 Pressure resistance and inner diameter specification for various tube

diameters............................................................................................................................10

9.2.5 Lining Material.........................................................................................................10

9.2.6 Electrode Material ..................................................................................................11

9.2.7 Housing Protection Rating(IP)..............................................................................11

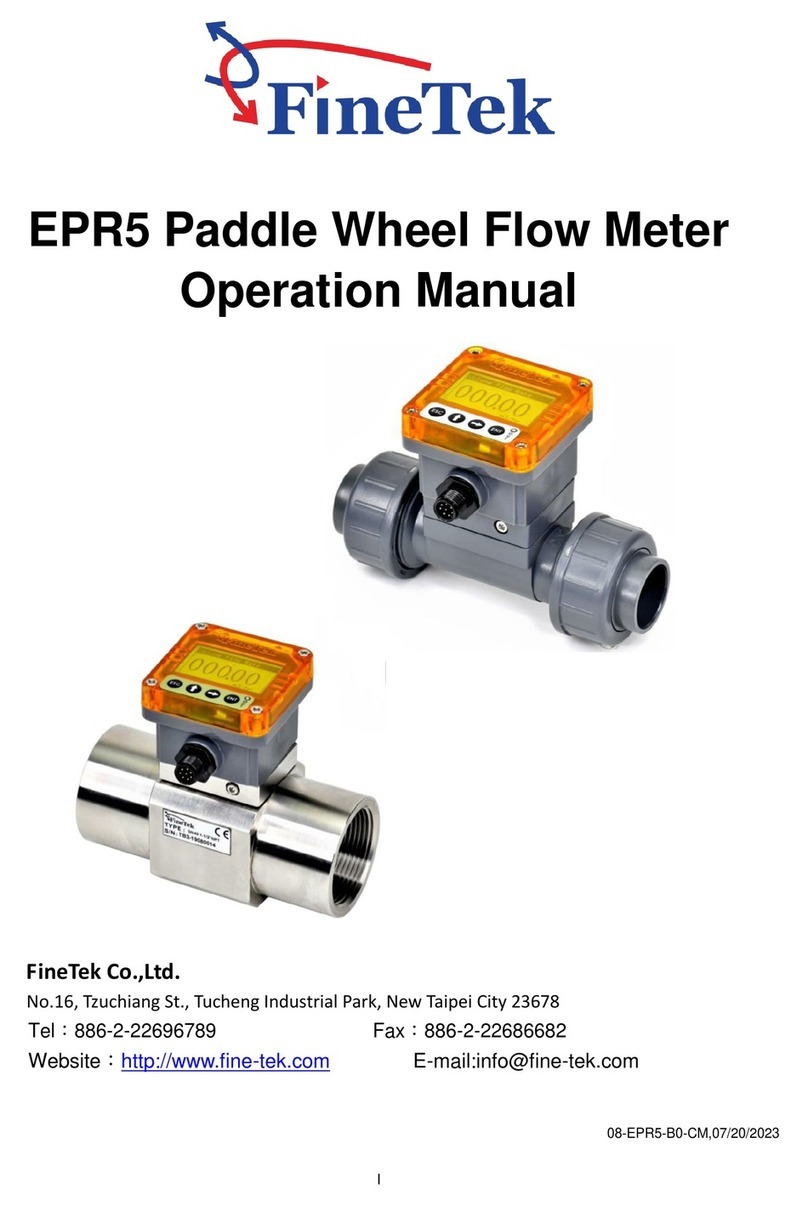

10. Appearance and Dimension.......................................................................................12

10.1 JIS 10K & 20 K..........................................................................................................12

10.2 ANSI 150Lbs & 300Lbs...........................................................................................13

10.3 DIN PN40 & PN16 & PN10.....................................................................................14

11. Installation .......................................................................................................................15

11.1 Conditions required to guarantee the measurement accuracy of the

electromagnetic flow meter:.............................................................................................15

11.2 Safety Measures .....................................................................................................15

11.3 Inspection before Installation.............................................................................15

11.4 Handling....................................................................................................................16

11.5 Correct Installation ................................................................................................16

11.6 Notes for Installation on the Pipe.....................................................................18

11.7 Grounding Requirements.....................................................................................19

12. Wiring and Using ..........................................................................................................20

12.1 Wiring .........................................................................................................................20

12.1.1 Notes for Wiring....................................................................................................20

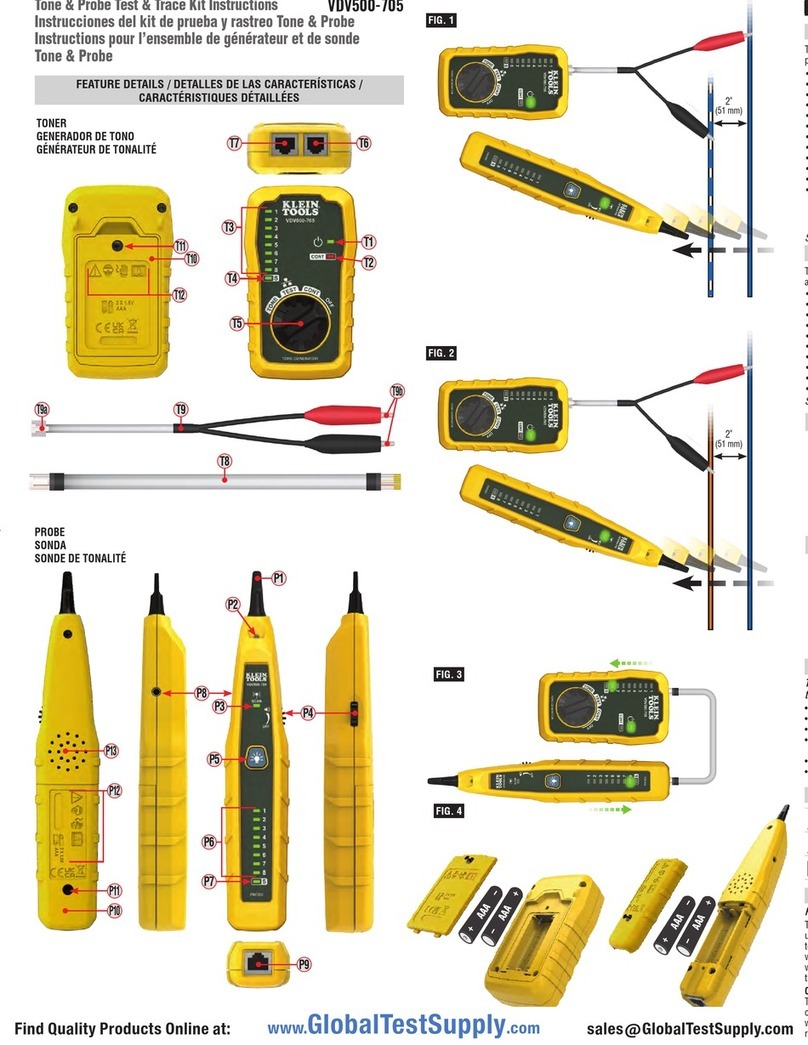

12.1.2 Diagram of Sensor Wiring Terminal...................................................................20

12.1.3 Diagram of Transmitter Wiring Terminal ...........................................................21

12.1.4 Signal Electrical Cable Wiring.............................................................................22

12.2 Input / Output Function Wiring................................................................................23

12.2.1 4-20mA Current output.........................................................................................23

12.2.2 Pulse Output..........................................................................................................23

12.2.3 RS-485 Communication.......................................................................................23

12.2.4 Digital output 1 (DO1)...........................................................................................24

12.2.5 Digital output 1 (DO2)...........................................................................................24

12.2.6 Digital input (DI).....................................................................................................24

12.2.7 Analogy input (AI)..................................................................................................25

13. Inspection before Power-On.......................................................................................25

14. Parameter Functions.....................................................................................................26

14.1 Procedure for Menu Setting....................................................................................26

14.1.1Functions of the Display Interface.......................................................................26

14.1.2 Button Functions in Parameter Setting Status:................................................26

14.2 Various Parameter Setting Ranges.......................................................................27

15. Ordering Information ....................................................................................................30

16. Transportation and Storage........................................................................................31

17. Fault Inspection and Repair........................................................................................32

18. MODBUS Communication Protocol..........................................................................33

1

1. Reading Labels

Thanks for purchasing FineTek’s Product. This operation manual describes the product

features, working principles, operation and maintenance methods. It makes the user fully

understand how to use the product correctly, so as to prevent dangerous situations such as

device damage or operator injury.

Please read this operation manual completely and carefully before using the product.

Please contact the company if this operation manual can’t satisfy your demands.

The content of the operation manual is updated based on the version upgrade, which will

be uploaded to the website for the user to access.

Please don’t disassemble or repair the product on your own, as this will make you

disqualified from availing of the warranty service. Please send the product back to the

company for repair and calibration, or just contact the company.

Explanation of warning signs:

Danger→It indicates that wrong operation will cause death or major disasters.

Note→It indicates that wrong operation will cause injury and device damage to some

extent.

Electric shock→It warns of possible electric shock.

Fire→It warns of possible fire.

Prohibited→It indicates the prohibited wrong behavior.

2

2. Product Warranty

2.1 New Product Warranty

We don’t charge for the inspection, part/s and repair for the product of the company that

has a defect within 12 months from the delivery date and meets the warranty terms.

If the product defect is not due to human error during its transportation, user may change

to a new unit from the company within 7 days from delivery date.

When the product needs to be sent back to the factory for repair, please send the whole

set, and don’t disassemble the parts. Moreover, please be sure it is completely packed

to avoid damage and causing more loss and defect during the transportation.

The warranty is not available for causes that fall under the following circumstances, for

which the company shall charge for the inspection, part/s and repair according to the

actual condition:

The product or its parts are beyond the warranty period.

Fault or damage is caused by not following the instruction and use environment

described on the operation manual.

The product damage is caused by a force majeure factor (natural disasters, floods,

fire, earthquakes, lightning, typhoon, etc.), human destruction (scratches, dropping,

latch broken, tapping, cracks and punching), human error (using improper voltage,

high-humidity, water leakage, stain, corrosion, loss, improper storage, etc.) and

other abnormal factors.

The damage is caused by the customer or the 3rd party through the installation,

addition, expansion, modification and repair of parts not authorized or certified by

the company.

The volume label information is wrong or unclear, so the product serial number can’t

be confirmed.

2.2 Repair Warranty

A 6-month warranty service is provided for the repaired part of the product, during which the

same product can be repaired free of charge in case of the same fault.

3

2.3 Service Network

Company

Address

Telephone

Fax

Taipei Headquarters

(Taiwan)

No.16, Tzuchiang St., Tucheng

Industrial Park, New Taipei City

23678

+886 2-2269-6789

+886 2-2268-6682

Taichung Sales office

(Taiwan)

+886 4-2465-2820

+886 4-2463-9926

Kaohsiung Sales office

(Taiwan)

+886 7-333-6968

+886 7-536-8758

Shanghai Fine Auto Co., Ltd.

(China)

No. 451, Duhui Road, Zhuanqiao

Township, Minhang District,

Shanghai City 201109

+86 021-64907260

+86 021-6490-7276

Beijing Sales office

(China)

Room D921, Fuli Mogan Center,

No. 6,Taiping Street, Xicheng

District, Beijing City(100050)

+86 010-59361535

+86 010-59361512

Guangzhou Sales office

(China)

Room 1605, 1606, Jinxiu Joint

Business Building, No. 1, Tianhe

Road, Yuexiu District, Guangzhou

City (510075)

+86 020-38461387

+86 02038461397

Wuhan Sales office

(China)

Room 2101-2102, Building B,

Century Plaza, No. 14, Zhongnan

Road, Wuchang District, Wuhan

City

+86 27-87332314

+86 27-87332324

+86 027-87332341

Jinan Sales office

(China)

Room 1222, 1223, Tianye

International Plaza, No. 264,

Quancheng Road, Lixia District,

Jinan City (250011)

+86 531-83173652

+86 531-83173670

+86 31-83173670

Nanjing Sales office

(China)

Room 1709, Everest Building, No.

19, Zhongyang Road, Gulou

District, Nanjing City (210008)

+86 025-83176832

+86 025-83176833

+86 025-83176831

Chengdu Sales office

(China)

Room 1509, Building 2,

LANDMARK, No. 51, S 4th

Section, 2nd Ring Road,

Wuhou District, Chengdu

City (610041)

+86 028-84087414

+86 028-85590364

+86 028-84087413

Shenyang Sales office

(China)

Room 2501, Building B, 1st

Mall, No. 1-1, Jianshe

Middle Road, Tiexi District,

Shenyang District(110026)

+86 024-85611026

+86 024-85611053

Zhengzhou Sales office

(China)

Room 1304, Wancheng

Times Sqaure, No.9,

Jianshe Road, Zhongyuan

District, Zhengzhou City

(450007)

+86 0371-55638443

+86 0371-55638440

Finetek Pte Ltd.

(Singapore Branch)

60 Kaki Bukit Place #07-06,

Eunos Techpark 2 Lobby B,

Singapore

415979.415979

+65 6452-6340

+65 6734-1878

FineTeK GmbH

(Germany Branch)

Frankfurter Str. 62, OG D-65428

Ruesselsehim, Germany

+49 (0)6142-17608-0

+49 (0)142-17608-20

4

3. Product Inspection

3.1 Check Content

1 flow meter

1 operation manual

1 product inspection sheet

3.2 Safety Inspection

Please check whether the external package is deformed or damaged. Please

remember to take a picture for evidence for compensation later.

After unpacking, please check whether the content is deformed or damaged, or has

any quality problem. Please remember to take a picture for evidence for compensation

later.

After unpacking, please check whether the content is consistent with the ordering info,

and whether the quantity is right.

Please contact the company within 7 days if any of the above situations occur (attach

the picture together with your complaint). Otherwise, we won’t compensate for, change

or repair the product defect.

4. Summary

The company’s electromagnetic flow meter adopts coil excitation, which is more stable than

the traditional magnetism generation. After strict vibration and anti-noise test, it can work

stably and is highly tolerant of complex environments in the industrial field, which also has

a longer life span in practical application.

The electromagnetic flow meter has kept on evolving since its initial development, which is

widely applied in monitoring various industrial fluid pipes, including power generation, water

treatment, food, medication, shipping, dyeing & finishing, and semi-conductor process

industries. With its simple working principle, the electromagnetic flow meter is widely

applicable in various environments as long as the correct model is selected to match the

fluid properties.

5

5. Product Features

The measurement results is not affected by the change of liquid density, viscosity,

temperature, pressure and conductivity.

There are only two measurement points in the measuring tube without baffle and

movable parts, so it won’t cause pressure loss and jam.

It can test the flow for the conducting fluid and the fluidic containing some solid

granules.

The straight tube section required for the installation just needs the upstream front 5D

and downstream 2D of the flow meter without complicated pipeline design.

The measurement turndown ratio can reach 3:100, which can achieve high accuracy

especially for measuring small flow.

It has a self-diagnosis function, which can automatically detect the excited signal,

whether the measuring tube is empty and whether the electrode is stained or damaged.

The lining can be common NBR(Nitrile), high-temperature or acid-proof & alkali-proof

PTFE(Teflon)

The maximum fluidic temperature permitted can reach 120℃(Teflon)

The flow converter setting is simple, with powerful functionality.

6. Applicable Scope

Conductivity: > 5μS/cm

Fluid properties: Pure liquid and fluidic containing some solid granules.

Application industries: Power generation, water treatment, food, medication, shipping,

dying & finishing, and semi-conductor process

7. Environmental Condition

Ambient environment: -40℃~ 70℃

Relative humidity: 5% ~ 95% of RH, without condensing water

Atmospheric pressure: 86 ~ 106 KPa

Power supply: 100~240Vac 50/60Hz

6

Converter

v

8. Working Principles

The working principle of the electromagnetic unit is based on the Faraday law of

electromagnetic induction. When the conductor moves in the magnetic field, it will

generate induced EMF on both sides of the conductor in the orthogonal direction of the

magnetic field direction and the motion direction. The EMF is directly proportional to the

motion speed of the conductor and the magnetic induction intensity.

As shown in <Figure 1>, the conducting fluidic passes through the insulating tube with the

internal diameter of D(m) at the average flowing speed V(m/s) that is equipped with a pair

of measuring electrodes. Moreover, the tube is in a magnetic field with uniform magnetic

induction intensity of B (T). In this case, the electrodes will induce the EMF (E) at the

orthogonal direction of the magnetic field and the flowing direction. According to the law

of electromagnetic induction, E can be written as Equation (1):

Wherein, k is the proportional coefficient.

The volume flow can be written as

From Equation (1) and (2), we can get:

Thus, EMF can be represented as:

When B is a constant in Equation(3)

Equation(3) can be modified as:

It can be concluded that the flow qv is directly

proportional to the EMF E.

<Figure 1>

7

9. Technical Performance

9.1 Execution Standards

IEC 60068-2-3 EN 61326-1:2013

IEC 61326-1 EN 55011:2009/A/:2010

IEC 60092-504 ISO 4064-1

JIS B2220 JIS B7554-1997

ANSI B16.5 DIN 25 Series

8

9.2 Basic Parameters and Performance Indicators

9.2.1 Technical Specification Table

Item

EPD34

Display

LCM 128* 64 pixel backlit type

Buttons

Tri-button operation

Communication interface

RS-485 (Modbus) (Optional support for ZigBee Pro wireless

transmission)

Accuracy

±0.5% of reading@1m/s(0.2% optional)

Reproducibility

0.02 % F.S. @ 0.1~1.0m/s, 0.2% O.R. @ 1.0~10.0 m/s

Operation temperature of lining

NBR:Temperature resistance<80℃, mainly applied in low-concentrated

acid and alkane liquid. With excellent anti-abrasion property, it can

be used to measure liquid with impurities. It is applicable to coal

slurry, mud and industrial sewage.

Neoprene:Temperature resistance <80℃, resistant to general low-

concentrated acid and alkane. It is applicable to industrial sewage

and tap water.

PTFE: Temperature resistance <120℃. With stable chemical properties,

it is mainly applied in strong corrosive medium such as

concentrated acid and alkane or an environment with requirements

for cleanliness. It is applicable to various liquids and chemical

agents in food processing.

Ambien temperature

-40~70℃

Fluidic conductivity

>5uS/cm

Measuring scope

0.1m/s~10m/s

Current output accuracy

0.1% of Pulse Output Accuracy

Temperature coefficient (100ppm/℃)*Note 1

Current output mode

Proactive

Analog output

4~20mA

Maximum load of current output

<700Ω

Alarming current

3.6mA or 22mA

Frequency output scope

2~8KHz

Pulse width

Automatic (pulse width 50%)

Pulse mode

NPN transistor output 32vdc/200mA

Time constant

0~100s

Control output (DO)

NPN transistor output 32vdc/200mA;2-CH

Control input (DI)

Dry contact ON< 200Ω ;

1,000Ω< OFF ; 1-CH

Simulate output (AI)

4~20mA

Baud rate

1200~57600bps

Protection rating

IP67/NEMA 4X

Enclosure material

Aluminum alloy

Input power

AC100~240Vac

Power consumption

<10 W

Wire inlet specification

M20 x1.5*2 Female

signal power cable

< 100m *Note 2

Excitation mode

Pulse DC

Vibration regulation

IEC 60068-2-3

EMC regulation

IEC/EN 61326-1 Class A table 2

Note 1:Combined with FineTek sensor

9

Note 2:When the signal power cable is longer than 50m, the empty tube detection is unavailable.

9.2.2 Accuracy class & tolerance

9.2.3 Recommended Flow Range for Tube Diameters

Pipe diameter

(mm)

Flow range (m3

/ h)

Flowing speed 0.1~1.0m/s

Flowing speed 1.0~10m/s

40

0.45~4.5

4.5~45.2

50

0.71~7.1

7.1~71

65

1.19~11.9

11.9~119

80

1.81~18.1

18.1~181

100

2.83~28.3

28.3~283

125

4.42~44.2

44.2~442

150

6.36~63.6

63.6~636

200

11.3~113

113~1130

250

17.7~177

177~1770

300

25.4~254

254~2540

10

9.2.4 Pressure resistance and inner diameter specification for various tube diameters

9.2.5 Lining Material

Lining material

Main properties

Application scope

PTFE

1. Stable chemical properties,

resistance to various acid,

alkane, and salt solutions and

various organic solvents. It is not

tolerant to the corrosion of CIF3,

high-temperature OF3 and high-

speed liquid oxygen and ozone.

2. The anti-abrasion property is

average.

1. -20~120℃

2. Strong corrosive medium such

as concentrated acid and

alkane.

NBR

1. Excellent flexibility, highly tearing

force capability, good wear

resistance

2. It is resistant to low

concentrations of acid, alkali, salt

solution;It is not tolerant the

corrosion of oxidizing mediums.

1. < 80℃

2. Neutral-strong wearing mineral

pulp, coal slurry and mud slurry

Neoprene

1. Neutral wearing capability

2. It is resistant to low

concentrations of acid, alkali, acid

corrosion.

1. < 80℃

2. Water, Industrial water ,

Seawater

mm Inch JIS mm Inch mm Inch

25 120K - - - -

32 1-1/4 20K - - - -

40 1-1/2 20K - - 38 1.50

50 210K - - 49 1.93

65 2-1/2 10K - - 64 2.52

80 310K - - 77 3.03

100 410K - - 102 4.02

125 510K - - 128 5.04

150 610K - - 151 5.94

200 810K - - 207 8.15

250 10 10K - - 256 10.08

300 12 10K - - 301 11.85

Inner diameter of measurement tube

Nominal diameter

Specification of

measurement tube

NBR

PTFE

11

9.2.6 Electrode Material

Electrode material

Anti-corrosion property

Stainless steel (316L)

It is applied in water, sewage and organic corrosive medium.

Hastelloy alloy

It is resistant to the corrosion of the medium mixture of oxidizing acid

such as Nitric acid, mixed acid or Sulfuric acid. Moreover, it is resistant

to the corrosion of the oxidizing salt such as or other

substances containing oxidants such as the salt solution of

hypochlorous acid above the ambient temperature and sea water.

Titanium

It is resistant to the corrosion of sea water, various oxides, salt solution

of hypochlorous acid, oxidating acid (including fuming Nitric acid) and

organic acid and alkane. It is not resistant to the corrosion of pure

reducing acid (such as Sulfuric acid and Hydrochloric acid). However,

the anti-corrosion property will be greatly degraded if the acid contains

some oxidants.

Tantalum

It has excellent corrosion resistance. Its characteristic is similar to

glass. In addition to hydrofluoric acid , nitric acid , alkali, it could resist

almost all chemical medium (including boiling hydrochloric acid, nitric

acid and sulfuric acid below 175’C). It could not resist corrosion in

alkali.

9.2.7 Housing Protection Rating(IP)

Transmitter:IP67

Sensor: IP67

12

10. Appearance and Dimension

10.1 JIS 10K & 20 K

Connection specification

JIS 20K

Nominal diameter(mm)

40

50

65

80

100

125

150

200

250

300

Lining material

PTFE

Length

L

200

200

200

200

250

250

300

350

400

500

External diameter

ϕD

140

155

175

200

225

270

305

350

430

480

PCD

ϕC

105

120

140

160

185

225

260

305

380

430

Flange thickness

t

18

18

20

22

24

26

28

30

34

36

Inclined angle of screw

hole

θ°

45

22.5

22.5

22.5

22.5

22.5

15

15

15

11.25

Diameter of screw hole

θh

19

19

23

23

23

25

25

25

27

27

Quantity of screw holes

N

4

8

8

8

8

8

12

12

12

16

Height of sensor casing

H1

125

125

145

145

195

195

270

305

365

406

Total height

H2

276

.4

283.9

303.9

316.4

353.9

376.4

440

476

547

594

Weight (kg)

-

5.5

3

6.17

7.43

10.70

14.87

22.01

29.48

41.82

72.6

8

92.6

0

Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter

shall be increased by 4mm. For DN100~DN200, the lining protective ring is 0.5mm, so the total

length of the flow meter shall be increased by 1mm;

*1:total height(H2) tolerance is 2mm

*2:The weight is only for sensor casing, the meter weight 2.06 KGs is not included.

Connection specification

JIS 10K

Nominal diameter(mm)

40

50

65

80

100

125

150

200

250

300

Lining material

PTFE

Length

L

200

200

200

200

250

250

300

350

400

500

External diameter

ϕD

140

155

175

185

210

250

280

330

400

445

PCD

ϕC

105

120

140

150

175

210

240

290

355

400

Flange thickness

t

14

14

16

16

16

20

22

22

24

24

Inclined angle of screw

hole

θ°

45

45

45

22.5

22.5

22.5

22.5

15

15

11.25

Diameter of screw hole

θh

19

19

19

19

19

19

23

23

25

25

Quantity of screw holes

N

4

4

4

8

8

8

8

12

12

16

Height of sensor casing

H1

125

125

145

145

195

195

270

305

365

406

Total height

H2

276

.4

283

.9

303.9

308.9

346.4

366.4

429

468

534

578

Weight (kg)

-

5.2

5

6.1

3

7.43

8.32

11.35

15.95

21.9

6

31.68

52.48

68.00

13

10.2 ANSI 150Lbs & 300Lbs

Connection specification

ANSI 150Lbs

Nominal diameter(mm)

40

50

65

80

100

125

150

200

250

300

Lining material

PTFE

Length

L

200

200

200

200

250

250

300

350

400

500

External diameter

ϕD

127

152

178

190

229

254

279.4

342.9

406.4

482.6

PCD

ϕC

98.4

120.

6

139.7

152.4

190.5

215.

9

241.3

298.4

361.9

431.8

Flange thickness

t

15.9

17.4

20.6

22.2

22.2

22.2

23.8

27.0

28.6

30.2

Inclined angle of

screw hole

θ°

45

45

45

45

22.5

22.5

22.5

22.5

15.0

15

Diameter of screw

hole

θh

15.9

19

19

19

19

22.2

22.2

22.2

25.4

25.4

Quantity of screw

holes

N

4

4

4

4

8

8

8

8

12

12

Height of sensor

casing

H1

125

125

145

145

195

195

265

305

365

406

Total height

H2

322

335

358

364

408

421

478

525

589

647

Weight (kg)

-

4.93

6.77

9.23

10.70

16.27

19.4

1

25.48

42.62

65.68

98

Connection specification

ANSI 300Lbs

Nominal diameter(mm)

40

50

65

80

100

125

150

200

250

300

Lining material

PTFE

Length

L

200

200

200

200

250

250

300

350

400

500

External diameter

ϕD

156

165

190

210

254

279

317.5

381

444.5

520.7

PCD

ϕC

114.3

127

149.2

168.3

200

235

269.9

330.2

387.35

450.85

Flange thickness

t

19.0

20.6

23.8

27.0

30.2

33.3

34.9

39.7

46.0

49.2

Inclined angle of

screw hole

θ°

45

22.5

22.5

22.5

22.5

22.5

15.0

15.0

11.3

11.3

Diameter of screw

hole

θh

22.2

19

22.2

22.2

22.2

22.2

22.2

25.4

28.6

31.8

Quantity of screw

holes

N

4

8

8

8

8

8

12

12

16

16

Height of sensor

casing

H1

125

125

145

145

195

195

265

305

365

406

Total height

H2

337

341

364

374

421

433

495

542

606

664

Weight (kg)

-

9.08

10.3

2

12.78

16.45

26.6

2

32.9

6

42.28

67.62

98.88

145

Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter

shall be increased by 4mm. For DN100~DN200, the lining protective ring is 0.5mm, so the total

length of the flow meter shall be increased by 1mm;

*1:total height(H2) tolerance is 2mm

*2:The weight is only for sensor casing, the meter weight 2.06 KGs is not included.

14

10.3 DIN PN40 & PN16 & PN10

Connection specification

DIN PN40

DIN PN16

Nominal diameter(mm)

40

50

65

80

65

80

100

125

150

200

Lining material

PTFE

Length

L

200

200

200

200

200

200

250

250

300

350

External diameter

ϕD

150

165

185

200

185

200

220

250

285

340

PCD

ϕC

110

125

145

160

145

160

180

210

240

295

Flange thickness

t

18

20

22

24

18

20

20

22

22

24

Inclined angle of

screw hole

θ°

45

45

22.5

22.5

45

22.5

22.5

22.5

22.5

15

Diameter of screw

hole

θh

18

18

18

18

18

18

18

18

22

22

Quantity of screw

holes

N

4

4

8

8

4

8

8

8

8

12

Height of sensor

casing

H1

125

125

145

145

145

145

195

195

265

305

Total height

H2

334

341

361

369

361

369

404

419

484

524

Weight (kg)

-

5.53

6.17

7.43

10.7

7.03

10.70

14.0

7

19.4

1

26.68

38.42

Connection specification

DIN PN10

Nominal diameter(mm)

200

250

300

Lining material

PTFE

Length

L

200

200

200

External diameter

ϕD

150

165

185

PCD

ϕC

110

125

145

Flange thickness

t

18

20

22

Inclined angle of

screw hole

θ°

45

45

22.5

Diameter of screw

hole

θh

18

18

18

Quantity of screw

holes

N

4

4

8

Height of sensor

casing

H1

125

125

145

Total height

H2

334

341

361

Weight (kg)

-

5.53

6.17

7.43

Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter

shall be increased by 4mm. For DN100~DN200, the lining protective ring is 0.5mm, so the total

length of the flow meter shall be increased by 1mm;

*1:total height(H2) tolerance is 2mm

*2:The weight is only for sensor casing, the meter weight 2.06 KGs is not included.

15

11. Installation

The design, test and power supply for the flow meter are based on the related regulations.

User must strictly follow the instructions to guarantee the safe operation and normal working

of the flow meter.

11.1 Conditions required to guarantee the measurement accuracy of the electromagnetic

flow meter:

The test liquid is conducting.

The measuring pipe must be filled with liquid.

The test liquid must be uniform, so asto prevent the non-uniform conductivity(which

will result in serious interference). If you need to add some chemicals dynamically,

it should be added in the downstream of the flow meter.

The electromagnetic flow meter must be well grounded. Especially in the plastic pipe,

the grounding ring must be installed in order to perform solid grounding.

The straight tube section is required to be at least 5D at the flow meter inlet (internal

diameter of the measuring pipe), and at least 2D at the flow meter outlet.

The flow meter should be kept away from strong EMI, and it should not be installed

near the large motors or transformers.

11.2 Safety Measures

To guarantee human and device safety, the instructions below must be followed:

Before selecting the location and installing the flow meter, the user should carefully

read the related parts in this manual, and consider the safety requirements for the

flow meter, related devices and machine body environment.

The flow meter installation and repair must beperformed by the personnel with some

flow meter knowledge.

The flow meter sensors and pipes must be correctly installed, and the sealing must

be safe and reliable. The liquid pressure should not exceed the maximum working

pressure described on the flow meter specification.

Proper measures must be taken to prevent electrical shock accident.

The handling equipment of the flow meter should meet the safety requirements.

11.3 Inspection before Installation

Check whether the flange, lining, casing and outgoing line sleeve are damaged.

Open the box cover to check whether the wiring printed circuit is loosened or

damaged.

Check whether the model number on the nameplate is consistent with the order

information.

16

11.4 Handling

The flow meter must be handled with the correct handling method. The safety load and

protection action of the handling equipment should meet the related regulations. The

transmitter box (for integrated flow meter) or enclosure (for separated flow meter) must

not be tied up to handle the flow meter.

11.5 Correct Installation

It is very important to select the installation site and install the flow meter correctly. If

any mistake is made during the installation, it will affect the measuring accuracy or the

life span of the flow meter, or even cause damage. When selecting the installation site,

please pay special attention to the following:

a. The axis of the measuring electrode must be approximate to the horizontal direction

(Generally, the angle from the level line is within 10°.)

b. The measuring pipe must be filled with liquid.

c. The flow meter must be equipped with the straight tube section in the length of at

least 5×D at the front side (D is the internal diameter of the flow meter), and the

straight tube section in the length of at least 2×D at the rear side (D is the internal

diameter of the flow meter).

10°

10°

5D

17

d. The flowing direction of the fluidic is the same as the arrow direction on the flow meter.

e. Please prevent the vacuum in the pipe, which will damage the lining of the flow meter.

f. The flow meter must be free from strong electromagnetic field. The magnetic intensity

of the flow meter installation site must be smaller than 400A/m.

(It should not be installed near large motors or transformers)。

g. There should be enough space left surrounding the flow meter for installation and repair.

h. If the measuring pipe vibrates, a support frame should be set up on both sides of the flow meter.

i. When measuring the mixture of different media, the distance between the mixing point and the

flow meter must be 30×D at least (D is the internal diameter of the flow meter)).

j. For convenient cleaning and maintenance of the flow meter, a bypass pipe must be installed.

k. When installing the flow meter of the PTFE lining, the bolt connecting two flanges should

be fastened evenly. Otherwise, it will damage the PTFE lining. Please use the torque

wrench as much as possible.

l. The flow meter should be protected from strong vibration and great temperature change.

In the meantime, damage of the corrosive liquid on the flow meter should be prevented.

m. If the flow meter is installed at a position with direct sunlight, shielding facilities should

be set up.

n. When installing the sensor, the measuring pipe and the process pipe must be on the

same axial line. For the senor with the nominal diameter of DN50 or below, the axial line

deviation should not exceed 2mm. For those of DN65~DN150, the axial line deviation

should not exceed 3mm. For those of ≥DN200, the axial line deviation should not exceed

4mm.

o. The shim installed between the flanges should have excellent anti-corrosion property.

The shim should not intrude in the pipe, which will block the flowing fluidic

p. Fasten the bolts and screws of the flow meter. The screw threads should be undamaged

with good lubrication condition. The bolts with torque wrench must be fastened based

on the flange size and torque.

q. When welding or flame-cutting the pipes near the sensor, isolation measure must be

conducted, so as to prevent the lining from heating. Moreover, the flow meter must be

powered off, or it will damage the flow meter.

Table of contents

Other FineTek Measuring Instrument manuals

FineTek

FineTek EDX2 User manual

FineTek

FineTek JTR Series Technical manual

FineTek

FineTek EPD30 Technical manual

FineTek

FineTek EPR1 Series Technical manual

FineTek

FineTek EPR5 User manual

FineTek

FineTek EPD36 Technical manual

FineTek

FineTek SC38 User manual

FineTek

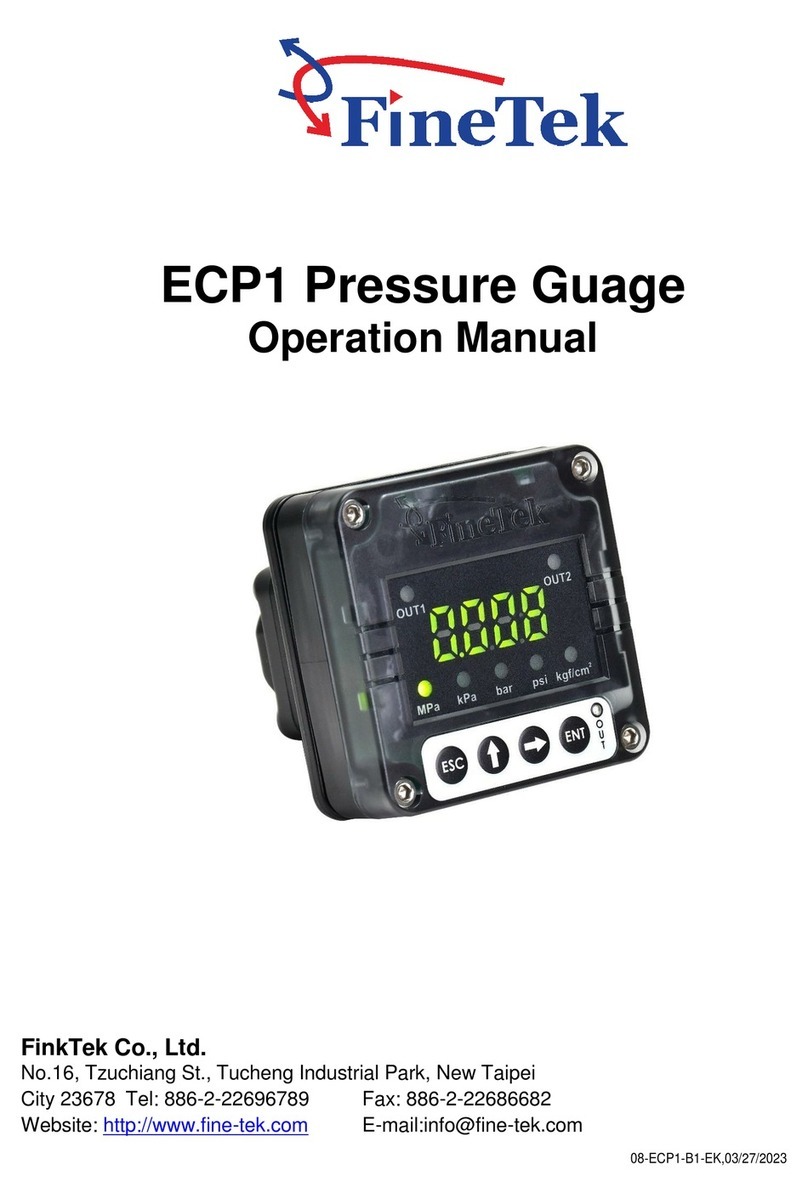

FineTek ECP1 User manual

FineTek

FineTek EPF Series User manual

FineTek

FineTek EF Technical manual

Popular Measuring Instrument manuals by other brands

YOKOGAWA

YOKOGAWA GD402G /M1 user manual

DynAmp

DynAmp LKAT Plus Installation, operation and service manual

Norland

Norland 388S631 Repair Procedure

VOLTCRAFT

VOLTCRAFT Gamma Check Pro operating instructions

SAEHAN

SAEHAN DHD-3 user manual

Endress+Hauser

Endress+Hauser Proline Cubemass C 100 PROFIBUS DP operating instructions