Pneumatic Connections

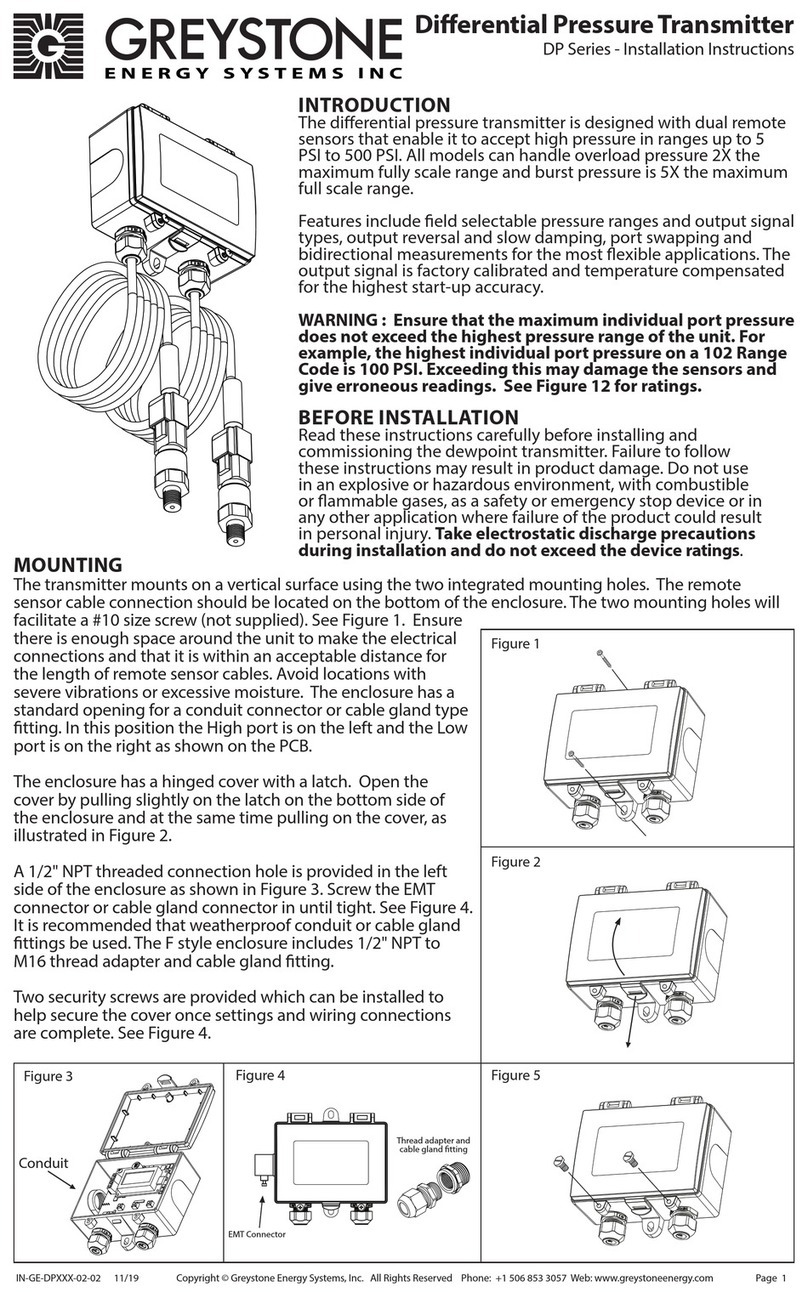

The two pressure ports on the end of the enclosure are labeled High and Low. The output signal reads a positive value when the port

pressure is higher on the High port than the Low port so ensure these ports are connected correctly. Use 0.170” I.D. flexible tubing

for the pressure connections. Arrange the tubing to minimize stress on the connections and ensure there are no kinks in the tubing.

For most accurate measurements, do not leave the Low port open to the atmosphere, run a return line from the Low port to the vicinity

of the point being measured.

Ensure the tubing to be used is clean and do not allow material to fall into the pressure ports as contamination could damage the

sensor. When removing tubing use care to avoid breaking the ports. In some cases, it is better to cut the tubing off rather than pulling

it off but be careful not to cut the fitting or an air leak may occur.

Power-Up Instruction

Before turning on the power, verify all wiring to ensure that it complies with one of the included wiring diagrams and verify that the

output signal type is correctly selected with the switches. Also, review the specifications to ensure the power supply is correct and

that the pressure is within the correct range.

At this time, also inspect the internal pressure tubing that connects the sensor to the external ports to ensure that the tubing did not

get kinked during shipping or installation.

Proper operation can be verified by measuring the output signal. For voltage output configuration, measure the voltage between the

OUT and COM terminals. The voltmeter should read between 0-5 VDC or 0-10 VDC depending on the output range selected. For

current output configuration, insert a mA meter in series with the OUT terminal. The mA meter should read between 4 and 20 mA.

Operation

If the unit is set to a unipolar range such as 0-2 “WC, then the pressure applied to the High port must be higher than the pressure

applied to the Low port. In this case, if the Low port is left open to ambient pressure and the High port is used to measure a positive

pressure, then the output pressure can be calculated as follows:

Pressure = [(Output current - 4 mA) / 16 mA] x Range

Pressure = (Output voltage / 5 V) x Range

Pressure = (Output voltage / 10 V) x Range

In the case of 0-2 “WC, 4 mA or 0 V = 0 “WC and 20 mA or 5 V or 10 V = 2 “WC. Since the transmitter is linear, 1 “WC would be 12

mA or 2.5 V or 5 V. If the positive pressure connection is reversed, then the transmitter will always output 4 mA or 0 V.

If the unit is set to a bipolar range such as ±2 “WC, then the pressure applied to the High port should be higher than the pressure

applied to the Low port for a positive output response. In this case, differential pressure can be measured using both ports. If the High

port has a positive pressure with respect to the Low port, then the output indicates a positive pressure. Negative pressure is indicated

if the High pressure is less than the Low pressure. For bipolar ranges, the output pressure can be calculated as follows:

Pressure = [(Output current - 4 mA) / 16 mA] x 2 x Range - Offset

Pressure = (Output voltage / 5 V) x 2 x Range - Offset

Pressure = (Output voltage / 10 V) x 2 x Range - Offset

Calibration

All pressure ranges are factory calibrated and no calibration is necessary. The user may adjust the zero point if desired when changing

ranges for example. Make sure the unit is warmed up for at least 10 minutes (1 hour is best) before making a zero adjustment. With

both ports open to the ambient pressure, press and hold the ZERO button for at least 3 seconds. Release the button after at least 3

seconds and the device will calculate and store the new zero point.

Generally, it is not recommended that the span calibration be performed in the field unless a high-quality calibrator with low differential

pressure ranges is available and the temperature of the sensor can be maintained. Contact the factory for information on this type of

calibration.