FINO FINOCAM A5 Operation manual

FINOCAM A5

06260DE

Original FINO

Germany

Tischfräsmaschine

Table Milling Unit

Gebrauchsinformation•User Information•Mode d’emploi

Información sobre el uso•Informazioni d’uso

Gebruiksaanwijzing•Instrukcja stosowania

FINO

•der feine Unterschied•the fine difference•la fine différence•la fina diferencia•la fine differenza

Version 1/2016. Read the User Manual prior to commencing work!

1. About this document 3

• Used symbols • Structure of safety notes

2. Safety instructions & regulations 3

• General safety instructions • Regulations

3. Machine description 6

• Connection panel• Front cover• Working chamber • Accessories container

• Air extraction concept • Manufacturing software and computer • Sound emission

• Technical data

4. Installing the machine 11

• Checking the scope of delivery • Choosing the installation site

• Machine installation (scheme) • Installing the pneumatics

• Installing the air extraction system • Establishing the electric connection

• Removing the transport lock • Connecting the manufacturing computer

• Testing the machine

5. Running the machine 18

• Starting up the machine • Job execution overview • Inserting/changing tools

• Inserting and removing workpieces • Executing jobs • Interrupting the job execution

• Operation interruption or abortion of job execution • Emergency release of the front cover

6. Machine maintenance and cleaning 25

• Definition of wear parts • Maintenance table • Inspection

• Cleaning the working chamber and measuring key • Cleaning the collet chuck

• Checking the hoses, cables and connections • Cleaning the housing

• Checking the service unit • Exchanging the main fuse • Calibrating the axes

• Replacing the tool changer inserts

7. Disposal 32

8. Troubleshooting 32

9. Index 36

CONTENTS

2

1. About this document

1.1 Used symbols

Instructions

➤General instruction

MSpecific manual action

SSpecific action in the manufacturing software

➡Result

Additional symbols

➲Cross reference

•List

Information to make work more efficient.

Important instructions without any danger

for people or objects.

Additional information

Structure of safety notes

Type and source of hazard

Further explanations and consequences when igno-

ring hazards.

➤Instructions to avoid hazards.

The following signal words may occur in this docu-

ment:

DANGER indicates a hazardous situation which will

result in death or serious injury.

WARNING indicates a hazardous situation which can

result in death or serious injury.

CAUTION indicates a hazardous situation which, if

not avoided, can result in minor or moderate injury.

NOTICE indicates a situation which can lead to phy-

sical damage of the product or in the surrounding

area(s).

SIGNAL WORD

!

DANGER

!

WARNING

!

CAUTION

!

NOTICE

2. Safety instructions & regulations

2.1 General safety instructions

Incorrect operation of the machine

➤Read this document carefully before installing

and operating the machine.

➤If it is unclear how to operate the machine in

any way, do not use the machine and contact

customer service.

➤Make sure that every user has access to this

document.

➤Instruct every user on safe and proper machine

handling.

Danger to life due to an electric shock

If you come into contact with electrically

charged parts, you can suffer from an elec-

tric shock. Water increases the risk signifi-

cantly.

➤Do not remove the housing of the machine.

➤Only have qualified electricians work on any

electric equipment.

➤Run power cables so that they cannot be dama-

ged by sharp edges.

➤In the following cases, disconnect the

machine from the electrical source imme-

diately and prevent it from being restarted:

• When machine connections, compressed air

hoses or electric cables are damaged

•Before you check or run electric cables

➤Never perform any troubleshooting while the

machine is operating.

➤Only have authorized service technicians repair

the machine.

➤Replace damaged cables with original manu-

facturer’s spare parts.

➤Install an operational Residual Current Device/

Ground Fault Circuit Interrupter on the electric

circuit of the machine.

➤Do not touch the machine and especially the

cables with wet or damp hands.

➤Remove any liquids near the machine imme-

diately.

DANGER

!

3

ENU

Respiratory diseases when processing

harmful materials

If you inhale harmful materials during their proces-

sing, your respiratory tracts may be damaged.

➤Only process materials when an air extraction

system is running.

➤Avoid materials which can damage your health

during dry machining.

➤Use a suction device with an extra-fine particle

filter.

Crushing hazard and risk of cutting injuries

through moving machine parts

Through the moving axes and the rotating spindle

you can suffer bruises and cuts.

➤Only operate the machine when the front cover

is closed and the safety interlock is activated.

➤Store the key for the emergency release in a

place where only authorised persons have

access.

➤Do not circumvent or deactivate safety devices

of the machine.

➤Check the machine regularly for damage,

especially the safety devices.

➤Have damaged safety devices repaired by an

authorised service centre unless stated other-

wise in this document.

➤Use only original manufacturer’s equipment and

original spare parts in the machine.

➤Keep children and animals away from the

machine.

➤Do not remove the housing of the machine.

Administrator mode: risk of cutting injuries

and bruises as well as hazards through

ejected debris

If you operate the machine in “Administrator mode”

with the front cover open, the risk of injury is increa-

sed significantly!

➤Operate the machine in “User“ mode only unless

you have been authorised by FINO GmbH to use

other profiles.

➤Even if you are an authorised user, use the

“Administrator mode” with the front cover open

only when necessary.

WARNING

!

➤While in “Administrator mode”: Do not

reach into the working chamber while

the axes are moving or during machining.

➤While in “Administrator mode”:

Everyone within reach of the machine

must wear protective eye wear.

Hearing damage due to loud noise

➤In case of extraneous machining noise check the

working conditions: Ensure that the workpiece is

fixed properly, and verify the condition of the

tool and the material you are using.

➤If loud noise cannot be avoided, wear

ear protection during processing.

Risk of injuries through loose pneumatic com-

ponents under air pressure when connections

are open

Loose pneumatic components can move extremely

fast and unpredictably and may cause injury.

➤Before you run the pneumatic hoses, close the

compressed air supply valve.

➤Before you check the pneumatic hoses and

pneumatic connections, set the air pressure to a

minimum value.

➤In case of defective machine connections

and pneumatic hoses, disconnect the

machine from the external compressed air

supply and the electrical source to prevent

it from being restarted.

➤Contact customer service if connections are

damaged or defective.

4

Trip, fall and slipping hazards

➤Keep the working environment and

installation site clean.

➤Run cables in such a way that persons

cannot trip over them.

Risk of cutting injuries and burns

If you touch tools or sharp edges on workpieces or

the machine, you may suffer from cuts. If you touch

the hot spindle body or hot tools, you may suffer

from burns.

➤Wear gloves when you perform manual work at

the machine or with workpieces/tools.

Reduced ability to act with insufficient lighting

In case of an insufficient lighting your judgement

and/or your precision may be reduced.

➤Make sure that the lighting in your working

environment is sufficient.

Risk of injury in case of malfunctions caused

by insufficient maintenance

If you do not maintain the machine as often as is

required, malfunctions may occur which can lead to

injuries.

➤Take note of the intervals and conditions mentio-

ned in the maintenance table in this document

and carry out the respective maintenance steps

accordingly.

Health risks through constant malpositioning

if your working environment is not sufficiently

ergonomic

Over the long run, an improper or one-sided positio-

ning can be a risk to your health.

➤Set up an ergonomic work environment.

➤Ensure the seat height and monitor position is

ideal and the lighting is sufficient.

CAUTION

!

2.2 Regulations

If you violate the following regulations, you may lose

your entitlement for benefits. In addition, we cannot

be held liable for any damage resulting from such

violations.

2.2.1 Intended use

The FINOCAM A5 has been designed for easy to

medium machining work in the dental sector.

➤Only process materials that you can select in

FINOCAM. Only use the machine commercially.

➤Before creating jobs, verify if the objects being

prepared may be utilized at the place of use

according to local and/or national regulations or

other authorized organisations or entities (e. g.

professional associations, health authorities). In

particular, verify if the material is approved for

the machined object type and if the object type

is designed in accordance with applicable regu-

lations. Neither the manufacturing software nor

the CNC machine will inform you about possible

regulatory infringements, but will executes jobs

in accordance with the preferences and materi-

als set by the user.

➤Verify that each object type and each material in

your jobs are authorized to manufacturing mate-

rials. If mandated by local or national regula-

tions, obtain relevant authorization from the

responsible organisation or entities (e. g. pro-

fessional associations, health authorities).

➤Only manufacture objects which correspond to

the object types that you can select in the import

view in FINOCAM. While you can import/manu-

facture any other objects as well, neither the

manufacturing software nor the CNC machine

are designed for these other objects and should

not be used in this way.

➤Do not manufacture implants or parts of objects

that are designed to have contact with implants.

These parts include parts of two-part abutments

which contain the connection geometry for the

implant. Do not manipulate the connection geo-

metry of prefabricated abutments (“prefab abut-

ments”) and you must always check finished

objects for accurate connection geometries (i.e.

that connection geometries of finished jobs have

not been damaged).

5

ENU

2.2.2 Controlling the machine through

software

You control the CNC machine through specially

designed applications which are supplied with the

machine.

➤Only use program versions that are officially

released for the machine.

➤Always use the newest program versions that

are available for the machine.

➤Before installing or operating the machine, be

sure to read the documentation for the applica-

tions.

2.2.3 Maintenance and cleaning

➤Clean and maintain the CNC machine as

required. Only then can the machine reach a

long service life.

➤Only carry out maintenance work which is de-

scribed in this document. Otherwise you risk

your health and may damage the machine.

2.2.4 Synchronous spindle SFK 300P

➤Do not use unbalanced tools at high rotational

speeds. Such an imbalance puts a great strain

on the spindle’s ball bearings, which can cause

the bearings to be dam- aged.

➤When working in the working chamber, do not

apply manual pressure against the spindle.

2.2.5 Unattended operation

➤Unattended operation of the CNC machine

should only occur if the following conditions are

met:

• The national and local laws allow it.

• The working chamber of the machine is comple-

tely clean.

• Unauthorized users cannot access the machine.

• The room in which the machine is located has an

automatic fire detection system.

2.2.6 Transport ation and storage

Damaging of the machine if you transport the

machine without the transport lock

If you transport the machine without installing the

transport lock first, the machine may get damaged.

➤Before every transport, install the transport lock

as it was installed at delivery

• Ambient temperature: between 10 °C and 35 °C

• Relative air moisture: max. 80 %, non-conden-

sing

• For (un)packing and positioning two people are

required

• Weight of the machine: approx. 91 kg

➤Always transport multiple machines

individually and do not stack them.

➤Only trained transport personnel may transport

the machine to the installation site.

➤Always transport the machine in an upright posi-

tion.

➤Transport and position the machine only with a

closed accessories container.

➤In case of overseas transport, take proper

measures against corrosion.

➤To carry the machine, use the left and right grips

located on the bottom of the machine.

3. Machine description

Fig. 1: Front view of the FINOCAM A5

NOTICE

6

1Connection panel (➲Fig. 2)

2Front cover

3View window to the working chamber

4Recessed grip for opening

5Accessories container

6Opening for the air extraction system

With your FINOCAM A5 you can process workpieces

of different materials to create high quality objects

for the dental sector.

You can find a list of the materials which you can

process with the FINOCAM A5 in the FINOCAM

manufacturing software.

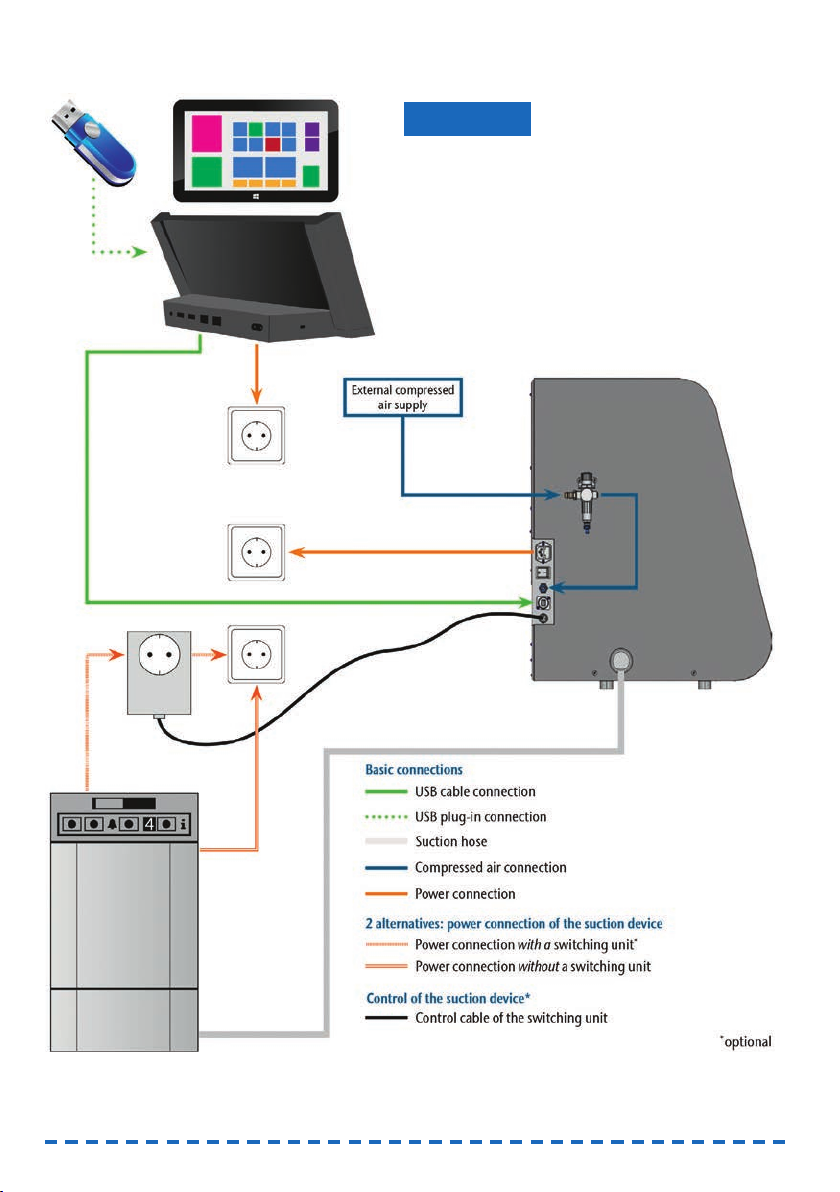

3.1 Connection panel

Fig. 2: The connection panel

1Power connection 100 – 240 V AC, 50/60 Hz,

including glass fuse T6,3A L250V

2Main power switch

3Pneumatic connection

4USB connection

5Switching output for suction device

3.2 Front cover

The front cover locks the working chamber and

protects the user from injuries during operation.

Crushing hazard when opening or closing the

front cover

When you open or close the front cover, the moving

front cover may crush your fingers.

➤When you open and close the front cover, use

one hand and keep the other hand away from the

machine.

➤When you close the front cover, ensure your

hands do not get caught between the front cover

and the machine housing.

CAUTION

!

Damaging of the machine when opening the

front cover by force

When the CNC machine is not supplied with power or

when the axes are moving, the front cover remains

locked. If you open the locked front cover by force,

the machine may get damaged.

➤Never open the front cover by force.

➤Connect the machine to the electrical source

and switch it on first before opening the front

cover.

➤To open the front cover, grasp the recessed grip

and pull the front cover upwards.

Fig. 3: The FINOCAM A5 with the front cover open

➤To close the front cover, put your hand flat on

the upper edge of the front cover and push the

front cover downwards.

3.3 Working chamber

The machine processes all workpieces in the working

chamber.

Fig. 4: The working chamber of the FINOCAM A5

NOTICE

7

ENU

1Rotational axis B

2Workpiece holder and rotational axis A

3Fixing disc

4Collet chuck for picking up tools

5Spindle

6Tool changer for up to 16 tools

Colours of the working chamber lighting

If the working chamber lighting is insufficient,

provide additional lighting.

Your FINOCAM A5 illuminates the working chamber

in different colours. The colour will change depen-

ding on the state of the machine. You will find the

colours and respective machine statuses in the follo-

wing table:

3.4 Accessories container

In the accessories container below the working

chamber, you can store workpieces, tools, and the

spindle service set ready to hand.

➤To access the accessories container, simply pull

it out of machine.

Fig. 5: Opening the accessories container

Colour Status

Green Machine is ready, front cover closed

White Machine is ready, front cover closed

Blue Machine is executing a job

Red A machine malfunction has occurred

8

Fig. 6: The open accessories container

(blanks and tools not provided)

➤To close the accessories container, push it into

the machine until it is completely closed.

3.5 Air extraction concept

The air extraction concept consists of:

• Air that is emitted from the spindle and the

bellow

• The external air extraction system (suction

device, suction hose, optional switching unit)

• The vacuum sensor

During job execution, the machine constantly blows

air into the working chamber (➲ Fig. 7, upper arrows).

An external suction device that you connect to the

CNC machine with a suction hose extracts the

machining debris from the working chamber (➲ Fig.

7, lower arrow).

This concept decreases the soiling and wear of

sensitive machine parts.

The air extraction system does not replace the

regular cleaning of the machine. Without regular

cleaning, the machine life decreases signifi-

cantly.

Through the air extraction, a vacuum develops in the

working chamber which is constantly monitored by a

vacuum sensor (display in FINOCNC: ➲ chapter

4.9). If the vacuum is too weak, machining is not

possible. If the vacuum becomes too weak during a

running job, FINOCNC interrupts machining until the

vacuum is sufficient again (➲ chapter 5.7).

The current strength of the vacuum displays in

FINOCNC (➲chapter 4.9 or in documentation for the

manufacturing software).

Sound measurement

Measuring conditions:

• Processed material: CoCr

• Tool status: new

• Distance to sound source: 1 m

• Measurement according to ISO 3746,

engineering method 3

3.8 Technical data

Base system

• Dimensions (W/D/H):

approx. 450 x 530 x 630 mm

• Weight: approx. 91 kg

• Air pressure (min./max.): 6 bar/8 bar

• Recommended air pressure: 7 bar

• Air consumption: ca. 40 l/min at 6 bar,

approx. 50 l/min at 8 bar

• 5-axis mechanism;

positioning range (x/y/z): 165.5 x 108 x 93 mm

• Complete housing of the working chamber;

front cover with a safety contact and safety

interlock

• Vacuum sensor for monitoring the extraction

capacity

• Minimum extraction capacity: 2500 l/min

• Accessories container in drawer shape

• Working chamber lighting with different colours

to indicate the machine state

Rotary axes

• Rotation range: 360 ° (A) | ±35 ° (B)

• Exchangeable workpiece holder

Spindle

• Synchronous spindle rotating up to 60,000 RPM

• Nominal power under continuous load (S1):

300 Watts

• Maximal Power (Pmax): 500 Watts

• 4-fold bearing

• Hybrid ceramic ball bearing

• Pneumatic collet chuck ø 3 mm

• Cone cleaning and sealing air

Operating condition Maximum A-weighted

sound pressure level

Processing 71 dB(A)

All other operating

conditions (tool change,

movement of the axes

etc.)

<70 dB(A)

9

ENU

Fig. 7: Air extraction concept in the working chamber

3.6 Manufacturing software and

computer

To operate the machine, you must use a computer

running Windows®(“manufacturing computer“)

which should connect to the machine via the provi-

ded USB cable.

You can process manufacturing jobs with the manu-

facturing computer in 2 steps:

1. With FINOCAM you can create jobs with the

objects that you want to machine. FINOCAM

already contains all important parameters for the

different materials.

2. You can execute the jobs with the CNC software

FINOCNC. This application offers additional

maintenance and control functions for the

machine.

You must use a different computer together with

a scanner and suitable software to create 3D

models of the objects (not provided, sold by

specialist dealers).

3.7 Sound emission

The actual sound emission of the machine varies

heavily depending on the manufacturing material

and the machining conditions.

➤If the machine is too loud, check the operating

conditions. Ensure that the workpiece is fixed

properly, check the condition of the tool and the

material in use.

➤If loud noise cannot be avoided, wear ear pro-

tection during machining.

10

Tool changer

• Automatic tool changer for 16 tools

• Maximum tool length: 40 mm

• Automatic tool length measurement and tool breakage monitoring via measuring key

• Compressed air monitoring for the automatic tool change

For additional information on tools see ➲ chapter 5.4.

11

4. Installing the machine

4.1 Checking the scope of delivery

M Unpack the machine and ensure you have recei-

ved the following items:

ENU

11 CNC machine FINOCAM A5

21 spindle service set in the accessories container

31 power supply cord

41 USB cable

51 service unit for compressed air

61 torque wrench 1.5 Nm in the accessories container

71 drill bit (2.8 mm) for tool positions

81 calibration set: 1 micrometre, 3 blanks,

1 calibration tool

91 measuring pin

10 1 key for the emergency release of the front cover

11 1 Advanced Tool Board (ATB) in the accessories

container

12 1 pneumatic hose

13 2 tool changer inserts (as spare parts)

14 1 USB dongle

Without illustrations:

• This document

• Documentation for FINOCAM & FINOCNC

• 1 socket wrench in the accessories container

for replacing the measuring key (to be used

by the service technician)

• 4 screws for the workpiece fixation as spare

parts

➤Please keep the machine packaging for future

transport.

4.2 Choosing the installation site

➤The installation site must meet the following

criteria:

• Firm and even surface, must carry the weight

of the machine

• Room temperature ideally between 18° Celsius

and 25° Celsius, maximum room temperature

32° Celsius

• Machine location must be dust-free

• Relative air moisture maximum 80 %,

non-condensing

• Alternating current source with 100-240 V

and 50/60 Hz

• Compressed air supply that meets the require-

ments of the machine (➲ chapter 4.4)

• Sufficient space at the sides of the machine

(➲ page 10)

4.3 Machine installation (scheme)

12

Damage to the machine due to incorrect

installation

➤Carry out the installation in the given order.

➤Ensure to remove the transport lock before instal-

ling the manufacturing computer (➲chapter 4.7).

NOTICE

13

ENU

4.4 Installing the pneumatics

Risk of injuries through leaking compressed

air and lashing pneumatic hoses

Open or loose pneumatic connections can cause

severe injuries.

➤Make sure that during installation and service

of the pneumatic hoses and of the service unit

compressed air is not running through the hoses

and connections.

➤After installing the pneumatic hoses but before

running compressed air through the hoses and

connectors, check if the hoses are securely

inserted into the correct connectors and are not

damaged.

➤Do not run compressed air through damaged

hoses and connectors.

The spindle may suffer bearing damage and

electrical damage if the compressed air is

contaminated

The incoming compressed air must be dry and oil-

free according to ISO 8573-1 because the service

unit only serves as an indicator for contaminated

air.

Air purity according to ISO 8573-1

Solid particles, Class 3,

Filtration degree better than 5 µm for solid particles

Water content, Class 4,

Maximum pressure dew point +3 °C

Residual oil content, Class 3,

Maximum oil content: 1 mg/m3

➤Ensure that the compressed air meets the above

requirements.

➤Connect the machine to the compressed air

supply only via the provided service unit.

The spindle requires compressed air for the

following tasks:

• For the opening and closing of the collet chuck

during tool change.

• For the sealing air which prevents foreign bodies

from entering the spindle.

Air consumption of the machine:

• approx. 40 l/min at 6 bar

• approx. 50 l/min at 8 bar

WARNING

!

NOTICE

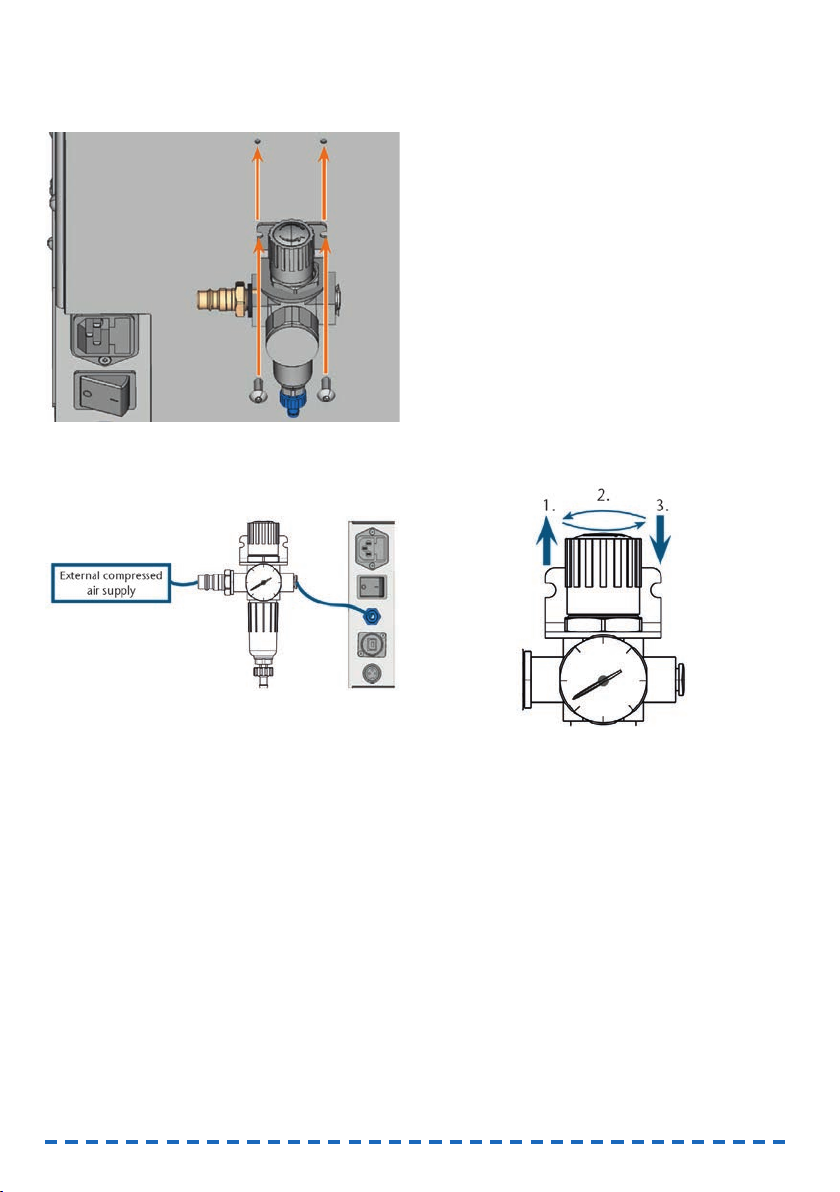

4.4.1 Overview service unit

Via the service unit you connect the CNC machine to

your compressed air supply and regulate the inco-

ming pressure for the machine.

Fig. 8: The service unit:

Regulation and checking the air pressure

1Rotary knob for pressure regulation

2Pneumatic connection to the machine (ø 6 mm)

3Manometer for monitoring the outgoing pressure

4Water separator

5Discharging screw

6Pneumatic connection for external

compressed air supply

4.4.2 Mounting the service unit

on the CNC machine

Failure of the water separator caused by a

wrong alignment of the service unit

The service unit must always be mounted in an

upright position because otherwise the water

separator will not work.

➤Mount the service unit in an upright position

(➲ Fig. 8). On the left side of the CNC machine

are two drilled holes which you can use to mount

the service unit on the machine.

NOTICE

14

M1. Remove the two blind screws in the drilled holes.

M2. Mount the service units with the provided lens

head screws in an upright position.

Fig. 9: Mounting the service unit on the machine

4.4.3 Installing the pneumatic hoses

to the service unit

Fig. 10: Installation of the service unit (scheme)

M1. Close the external compressed air supply valve.

M2. Use the provided pneumatic hose to connect the

right pneumatic connection of the service unit

[Fig. 8, 2] with the pneumatic connection of the

machine.

M3. Connect the external compressed air supply with

the left pneumatic connection of the service unit

[Fig. 8, 6].

M4. Check the installation carefully for errors and

damage. Do not run compressed air through

damaged or loose hoses and connections!

M5. Open the external compressed air supply.

M6. Check the air pressure on the manometer

[Fig. 8, 3]. If it does not lie between 6 bar and

8 bar, adjust it with the service unit (➲chapter

4.4.4)

4.4.4 Adjusting the air pressure with

the service unit

Setting the air pressure is only necessary if the air

pressure shown by the manometer does not lie

between 6 bar and 8 bar.

M1. Check if the service unit is correctly connected

to the machine and the compressed air supply

(➲chapter 4.4.2 onwards).

M2. Pull the rotary knob on top of the service unit

slightly upwards.

M3. Turn the rotary knob in the desired direction until

the pressure lies between 6 bar and 8 bar

(recommended: 7 bar):

• Turning it towards “+“ you increase the

pressure

• Turning it towards “–“ you decrease it

M4. Push the rotary knob down again.

➡The knob is locked and cannot be changed

inadvertently.

Fig. 11: Setting the air pressure

4.5 Installing the air extraction system

How the air extraction system works:

➲chapter 3.5

Available components of the air extraction system:

• Suction device including suction hose

•Switching unit for switching the suction device

on and off via the CNC machine

• Hose connection for suction hose: if the suction

hose does not fit into the machine

Which components are required and how you can

combine them is listed in the following table.

You obtain the switching unit via customer service if

necessary.

4.5.1 Requirements for the suction

device

➤Use a suction device with the following

properties

only:

• Designed for the commercial use in the

dental sector

• Equipped with a filter of the filter class M

• Suitable for the operating site of the CNC

machine

• Equipped with safety devices which protect

you from static discharges (e. g. through an

anti-static suction hose)

• Minimum extraction capacity: 2500 l/min

4.5.2 Absauggerät anschließen

➤Before the installation of the suction device read

the documentation for the device and have the

documentation always ready at hand.

M1. Check if the connection of the suction hose has

an outer diameter of 45 mm. If the diameter is

different, use the optional hose connection

(➲chapter 4.5.3.)

M2. Insert the suction hose of the suction device into

the opening for the air extraction of the CNC

machine. Make sure that the suction hose is

firmly connected.

Fig. 12: Inserting the suction hose into the machine

Component Source Required? Prerequisite

Suction device Customer service,

specialist dealers

Yes –

Switching device Customer

service

Nein –

Hose connection Customer

service

If the suction

hose does

not fit

Ask customer

service

M3. If you want the machine to automatically switch

the suction device on and off, install the

switching unit (➲chapter 4.5.4. If you require a

switching unit, contact customer service.

M4. Continue with the installation of the suction devi-

ce as described in the documentation for the

device.

4.5.3 Connecting the suction hose with

the optional hose connection

If you can connect the suction hose of your

suction device directly to the CNC machine, you

do not need the hose connection.

M1. Obtain the hose connection via customer ser-

vice.

M2. Turn the thread of the hose connection counter-

clockwise until the connection is completely

open. If the thread gets detached from the hose

connection, place it onto the connection again

and turn it clockwise once so that it is screwed

to the connection again.

M3. Insert the suction hose of the suction device

completely into the hose connection on the side

of the thread.

Abb. 13: Inserting the suction hose

into the hose connection

M4. Turn the thread of the hose connector clockwise

up to the stop.

➡The suction hose is firmly attached to the hose

connection.

M5. Insert the hose connection into the opening for

the air extraction system of the machine. Ensure

it is firmly connected.

15

ENU

Fig. 14: Inserting the hose connection into

the opening for the air extraction system

➡The installation of the suction hose with the

optional hose connection is complete.

4.5.4 Installing the switching unit

M1. Connect the power cable of the suction device to

the switching unit.

M2. Connect the control cable of the switching unit

to the switching output at the connection panel

of the CNC machine.

M3. Plug the switching unit into a power socket.

Fig. 15: Connecting the switching unit to

the suction device and the machine

4.6 Establishing the electric connection

Damaging of the machine through heavy

voltage fluctuations

Heavy voltage fluctuations can disrupt the control

unit and can cause system failure.

➤Plug the machine’s power cord in a dedicated

circuit current or ensure that no devices are

connected that can cause heavy voltage fluctua-

tion when switched on.

NOTICE

Damaging of the machine if the transport lock

and the manufacturing computer are installed

When you connect the machine to the electrical

source and the manufacturing computer is con-

nected, the machine starts referencing. During this

process, the transport lock which is installed at deli-

very can damage the mechanics of the machine.

➤Do not connect the machine to the electrical

source if the manufacturing computer and the

transport lock are installed.

➤If the transport lock is installed, disconnect the

USB connector between the machine and the

manufacturing computer before connecting the

machine to the electrical source.

M1. Plug the provided power cord into the power

connection at the connection panel of the CNC

machine.

M2. Put the plug of the cord into a socket that is pro-

tected by a Residual Current Device/Ground

Fault Circuit Interrupter.

4.7 Removing the transport lock

Before operating the machine for the first time, you

must remove the transport lock. The transport lock

prevents the spindle from getting damaged during

transport.

M1. Disconnect the USB connector between the ma-

chine and the manufacturing computer.

M2. Connect the machine to the electrical source.

M3. Switch on the machine via the main power

switch.

Fig. 16: Turning on the main power switch

M4. Open the front cover.

NOTICE

16

Fig. 17: Removing the transport lock

1Upper part of the transport lock

2Bottom part of the transport lock

M5. Carefully pull the bottom part of the transport

lock (2) towards you and out of the working

chamber.

M6. Carefully lift the upper part of the transport lock

(1) out of the workpiece holder. Pull it towards

you and out of the working chamber.

M7. Clean the working chamber from parts of the

transport lock that may have broken off.

M8. Store the transport lock safely to use it for future

transports.

4.8 Connecting the manufacturing

computer

The transport lock must not be installed when

you connect the manufacturing computer to the

machine (➲ chapter 4.7).

M1. Switch on the machine.

M2. Close the front cover.

M3. Start the manufacturing computer.

M4. Use the provided USB cable to connect a USB

port of your computer or docking station with

the connection panel of your CNC machine.

M5. Insert the dongle into a USB port of the manu-

facturing computer or docking station.

S6. Install the newest version of FINOCAM and

FINOCNC that is released for the machine. For

more information on this, read the documenta-

tion for the applications.

S7. Start FINOCNC and click on the de-

picted icon in the icon bar.

S8. Click on the depicted icon in the lower

icon bar.

➡The application settings view displays.

S9. Click on the depicted icon beside the

text Port number.

➡FINOCNC will try to establish a connection to the

CNC machine. If this is successful, the applica-

tion will display the port number beside the icon

and the machine references.

The machine will not reference if the front cover

is open.

M10.If the front cover was open at step S9, close it. If

the machine does not reference as a result, quit

FINOCNC and restart the application.

M11.If FINOCNC did not determine the port number,

read how to determine the port number manually

in the documentation for the application.

4.9 Testing the machine

After the first installation or after a re-installation, for

example after a transport, you should test the basic

functions of the machine.

M1. Switch on the machine.

M2. Close the front cover.

➡The machine starts up. The working chamber is

illuminated in white.

M3. Open the compressed air supply valve.

S4. Start the manufacturing computer and start

FINOCNC.

➡The machine will reference and the working

chamber will illuminate in green. The machine is

now in

default position

.

S5. In the upper icon bar, click on the

depicted icon.

M6. Switch on the suction device and select the

necessary extraction level.

S7. If the machine controls the suction

device via a switching unit, click on the

depicted icon.

➡The suction device is operating and a vacuum

develops in the working chamber.

M8. With the value bars and icons depicted below,

verify that the compressed air and the vacuum in

the working chamber are sufficient.

17

ENU

18

➡The icons display in blue when the compressed

air and the vacuum are sufficient.

Fig. 18: Top: Value bar and icon for compressed air

Bottom: Value bar and icon for the vacuum

S9. Move the spindle to the cleaning posi-

tion by clicking on the depicted icon.

➡The spindle should move through the working

chamber at constant speed.

S10. Move the spindle from the cleaning

position back to the default position by

clicking on the depicted icon.

➡The spindle moves to the default position at

constant speed.

S11. If the machine controls the suction devi-

ce, click on the depicted icon.

M12.If you control the suction device manually,

switch it off. The suction device stops operating.

M13.Open and close the front cover.

➡The front cover can be opened and closed

easily.

M14.If a result did not occur as described, check the

following depending on the error:

• The USB connection & USB driver installation

(➲ chapter 4.8 & documentation for the manu-

facturing software)

• The compressed air supply (➲ chapter 4.4)

• The set extraction capacity of the suction device

• The installation of the air extraction system

(➲chapter 4.5)

M15.If you cannot solve a problem that occurred,

contact customer service.

5. Running the machine

5.1 Starting up the machine

M1. Close the front cover.

M2. Switch on the machine and the manufacturing

computer.

➡The machine and manufacturing computer start

up. When the machine has started up, the wor-

king chamber is illuminated in white.

M3. If machine controls the suction device, switch on

the device and select the necessary extraction

level.

➡The suction device is not running.

If you control your suction device manually, you

switch on the device immediately before job

execution.

S4. Start FINOCNC.

➡The machine references. Afterwards the working

chamber is illuminated in green. The machine is

now ready for use.

The machine will not reference if the front cover

is open.

M5. If the working chamber is illuminated in red,

switch the machine off and on again. If the wor-

king chamber is still illuminated in red, contact

customer service.

M6. If the front cover was open at step S4, close it.

S7. If the machine does not reference as a result,

quit FINOCNC and restart the application.

5.2 Job execution overview

Damaging of the machine when using

damaged tools or workpieces

If tools or workpieces are damaged, parts can break

off and damage the machine during job execution.

➤Check the workpieces and tools thoroughly for

damage before every job execution.

Carrying out a typical job with the FINOCAM A5 is as

follows:

1. Create a job in FINOCAM

2. Insert the tools into the machine

3. Insert the workpieces into the machine

4. Execute the job in FINOCNC

The steps in the manufacturing software are descri-

bed in the corresponding documentation. The follo-

wing text describes how to perform manual work with

the CNC machine.

NOTICE

19

ENU

5.3 Inserting/changing tools

Damaging of the spindle or the tool positions

if you use improper tools

Improper tools can damage the collet chuck of the

spindle and/or the tool positions.

➤Only use tools with a sufficiently large chamfer

at the tool shank.

➤Install a retaining ring as a stop ring according to

DIN 471-A3.

➤Only insert tools with a maximum diameter of

3 mm at the thickest part into the collet chuck.

➤Only insert tools with a maximum cutting edge

diameter of 2.6 mm into the tool changer.

We recommend original tools as they are desig-

ned especially for the designated jobs.

You can insert up to 16 tools into the tool changer.

The machine can change tools automatically during

machining so that it executes jobs without your inter-

ference.

Fig. 19: Tool changer positions in the working chamber of

the machine (marked orange)

You can equip the tool changer in two ways:

• Via the spindle – you insert a tool into the collet

chuck and the spindle will deposit the tool in the

tool changer. This function is described in the

documentation for the manufacturing software.

• By inserting the tools into the tool changer

manually. This is described below.

You insert the tools manually as follows:

S1. Start FINOCNC.

S2. Call up the job execution view and select the job

that you want to execute from the job list.

➡FINOCNC displays the tools that are assigned to

the job in the lower part of the application win-

dow.

M3. Open the front cover.

NOTICE

M4. Insert the tools into the tool positions of the tool

changer:

• Insert the tools straight into the tool positions

and push them in until the ring touches the

rubber (➲ Fig. 20).

• The positions of the tools in the tool changer

must match the tool positions in FINOCNC

(➲ Fig. 21).

If the positions of the tools in the tool changer

do not match the tool positions in FINOCNC, the

machine will use the wrong tool(s) during job

execution and the job result will become unusa-

ble.

Fig. 20: Inserting tools straight into the tool position

Fig. 21: Top: tool positions 1 – 16 in the tool changer

Bottom: tool positions 1 – 16 in FINOCNC

5.4 Inserting and removing workpieces

On delivery, your FINOCAM A5 processes blanks

with a diameter of 98.5 mm.

5.4.1 Inserting blanks

You put blanks into the workpiece holder and immo-

bilize them with a fixing disc.

Fig. 22: The fixing disc (blue) is attached to the workpiece

holder (grey) with 4 screws (orange)

M1. Open the front cover.

M2. Unscrew the 4 screws which attach the fixing

disc to the workpiece holder.

M3. Remove the fixing disc and the blank in the

workpiece holder (if any).

M4. Place the blank into the workpiece holder.

Fig. 23: Placing the blank into the workpiece holder

M5. Place the fixing disc onto the workpiece holder

on top of the blank.

20

Table of contents

Other FINO Power Tools manuals