[9.1.1] Smoke Response

To determine if smoke is capable of entering the sensing chamber, visually identify any obstructions. Plug the exhaust

and sampling tube holes to prevent ducted air from carrying smoke away from the detector head, then blow smoke such

as cigarette, cotton wick, or punk directly at the head to cause an alarm. REMEMBER TO REMOVE THESE PLUGS

AFTER THIS TEST, OR THE DETECTOR WILL NOT FUNCTION PROPERLY.

[9.1.2] Filter Replacement

The filters do not substantially affect smoke performance even when up to 90% of the filter is clogged. Quarterly visual

inspection usually suffices to determine whether the filters should be replaced because only a high percentage of con-

tamination affects performance. If further testing is required, compare differential pressure readings with and without the

filters installed using a manometer. If the difference exceeds 10%, replace the filters. In no case should the pressure

differential fall below 0.03 inches of water.

[9.2] Standby, Alarm, And Sensitivity Tests

[9.2.1] Standby And Trouble

Standby — If programmed by the system control panel, look for the presence of the flashing LEDs through the transpar-

ent housing cover. The LED will flash with each communication.

Trouble — If programmed by the system control panel and the detector LEDs do not flash, then the detector lacks

power (check wiring, panel programming, or power supply), the detector board is missing (replace), or the

unit is defective (return for repair).

Test — The trouble condition can be caused intentionally to verify correct operation of the system. Remove the

detector board to cause a trouble condition locally and at the system control panel.

F300-10-00 6 I56-0020-004R

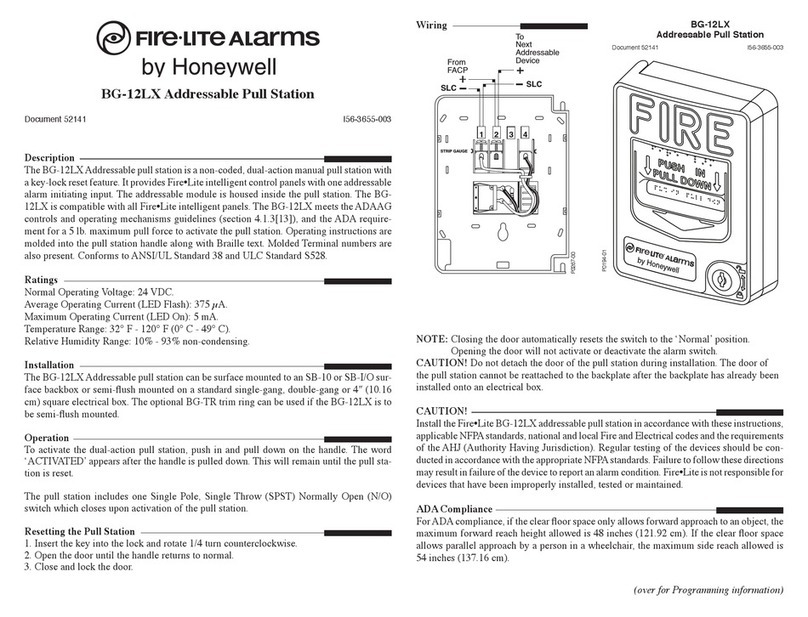

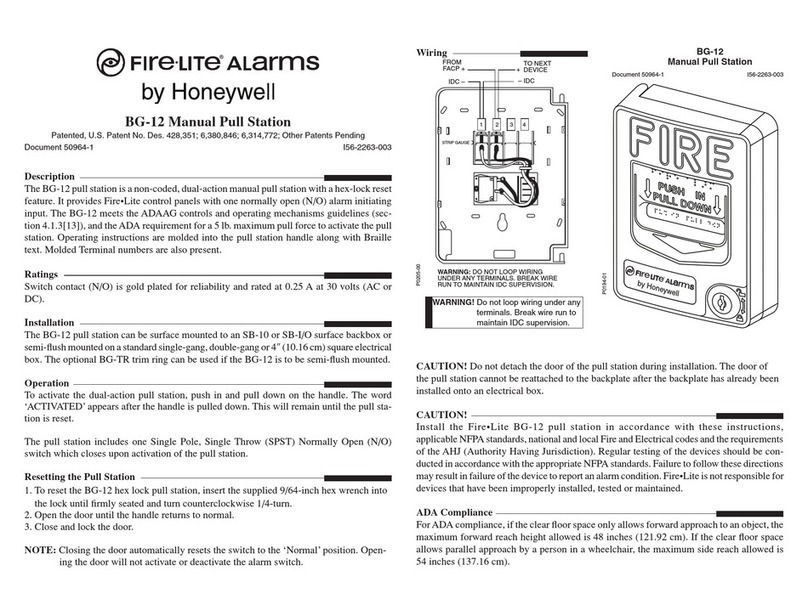

Figure 8. Wiring Diagram for D350P Duct Smoke Detector using a UL listed control panel

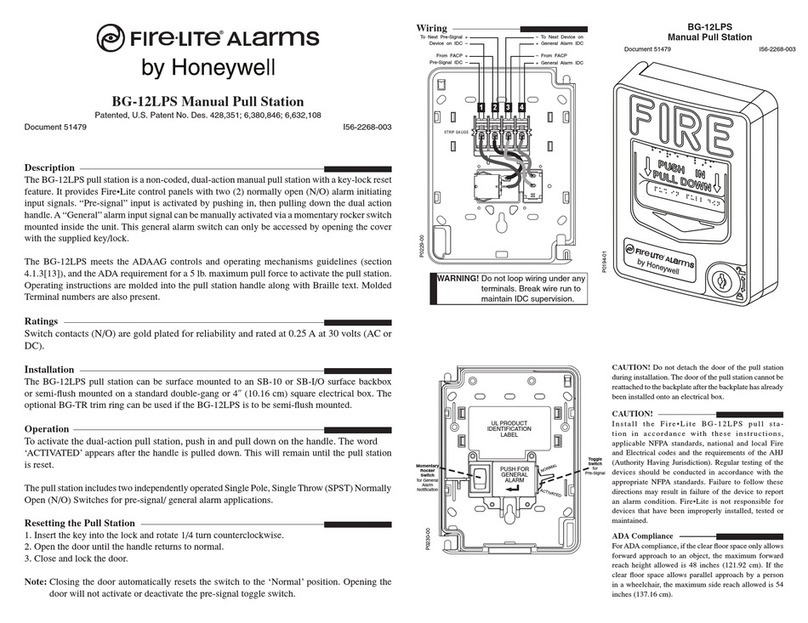

Figure 10. System Wiring Diagram for D350P Duct

Smoke Detector with RTS451/RTS451KEY

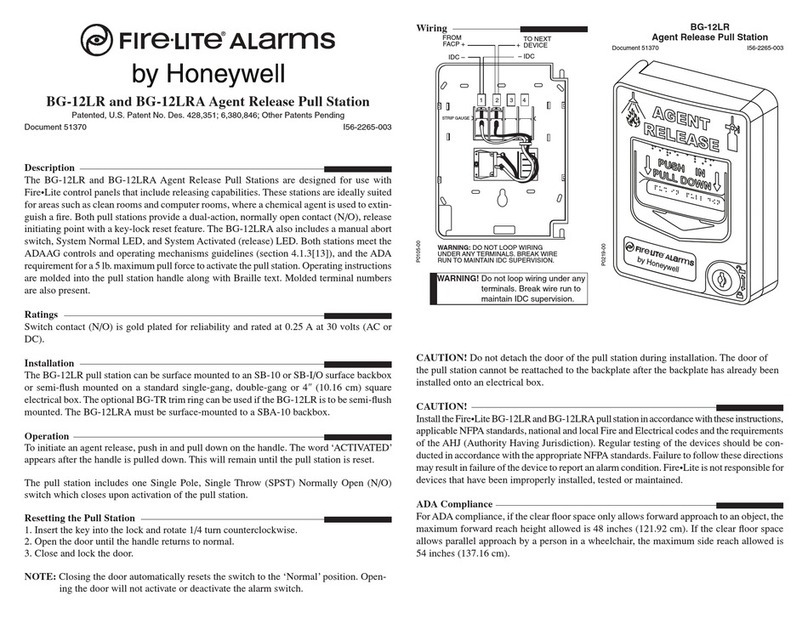

Figure 9. Wiring Diagram for D350P Duct Detector

with optional RA400Z

Accessory Current Loads at 24VDC

COIL NOTE

Please note that the magnetic coil supplied with the RTS451 and

RTS451KEY is not required when these accessories are used with

the D350P detectors. The functionality of the magnetic coil has been

designed into the circuitry of the duct smoke detector.

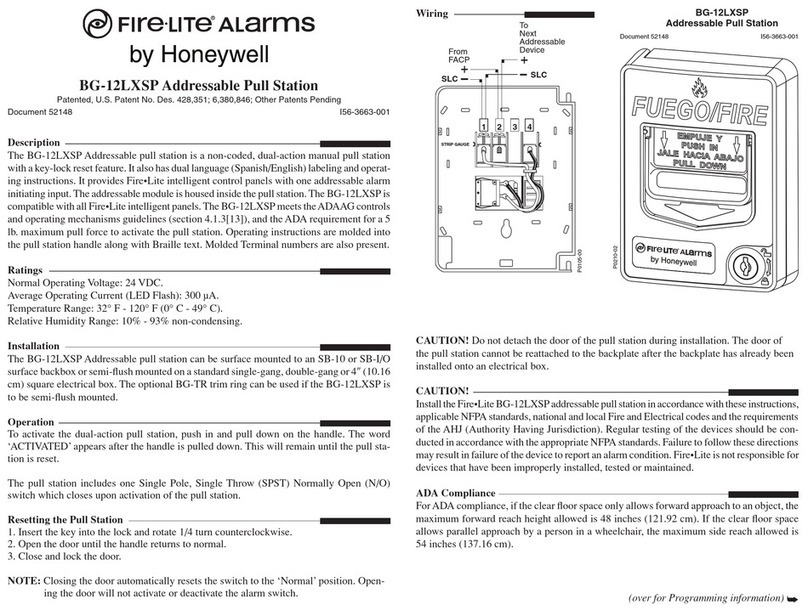

[3] Secure The Detector Housing To The Duct

Slide the foam gaskets over the tube bushings as shown

in Figure 3. Use the two 11/4” long sheet metal screws to

screw the detector housing to the duct.

CAUTION: Do not overtighten the screws.

[4] Sampling Tube Installation for Ducts Greater Than

11⁄2 Feet Wide

The sampling tube is identified by a series of air inlet holes

on the tube. A plastic tube is included for ducts up to 11⁄2

feet wide. All other lengths must be purchased separately.

Order the correct length, as specified in Table 1, for width

of the duct where it will be installed. It is recommended

that the sampling tube length extend at least 2⁄3 across the

duct width for optimal performance. The exhaust tube is

molded onto the base of the duct housing, and the A2440-

00 Exhaust Tube Extension is available as an accessory

in those cases where the molded exhaust port does not

extend at least 2 inches into the duct.

The sampling tube is always installed with the air inlet

holes facing into the air flow. To assist proper installation,

the tube’s mounting flange is marked with an arrow. Make

sure the sampling tube is mounted so that the arrow points

into the air flow (see Figure 4). Figure 5 shows the various

combinations of tube mounting configurations with respect

to air flow. Mounting the detector housing in a vertical ori-

entation is acceptable, provided that a metal sampling tube

is used and the air flows directly into the sampling tube

holes as indicated in Figure 4.

[4.1] Installation For Ducts Greater Than 11⁄2 Feet But

Less Than 8 Feet Wide

1. If the tube is longer than the width of the air duct, drill a 3⁄4″

hole in the duct opposite the hole already cut for the sam-

pling tube. Make sure the hole is 1″ to 2″ below the inlet

hole on the opposite side of the duct to allow moisture

drainage away from the detector. If the tube is shorter

than the width of the air duct, install the end cap into the

sampling tube as shown in Figure 4. Sampling tubes over

3 ft. long must be supported at the end opposite the duct

smoke detector.

2. Slide the tube into the housing bushing that meets

the air flow first. Position the tube so that the arrow

points into the air flow, as shown in Figure 4.

3. Secure the tube flange to the housing bushing with two

#6 self-tapping screws.

4. For tubes longer than the width of the air duct, the tube

should extend out of the opposite side of the duct. If

there are more than 2 holes in the section of the tube

extending out of the duct, select a different length using

Table 1. Otherwise, trim the end of the tube protruding

through the duct so that 1

″

to 2

″

of the tube extend out-

side the duct. Plug this end with the end cap and tape

closed any holes in the protruding section of the tube.

Be sure to seal the duct where the tube protrudes.

F300-10-00 3 I56-0020-004R

Figure 3. Installation of foam gaskets over sampling

tube bushings:

Figure 5. Tube mounting configurations with varying

air flow direction:

Table 1. Sampling tubes recommended for different

duct widths:

Outside Duct Width Sampling Tube Recommended*

1 to 2 ft. (0.3 to 0.6 m) ST-1.5

2 to 4 ft. (0.6 to 1.2 m) ST-3

4 to 8 ft. (1.2 to 2.4 m) ST-5

8 to 12 ft. (2.4 to 3.7 m) ST-10

*Must extend a minimum of 2⁄3 the duct width.

Figure 4. Air duct detector sampling tube:

NOTE: Only metal sampling tubes can be installed in

orientations C and D.

A78-2703-00

SCREW HOLES FOR

ATTACHING HOUSING

TO DUCT WORK.

SAMPLING

TUBE

END CAP

AIR HOLES

ARROW

MUST FACE

INTO AIR FLOW

AIR FLOW DIRECTION

FLANGE

AIR FLOW

DIRECTION

DETECTOR

HOUSING

DOTS INDICATE POSITION OF

SAMPLING TUBE HOLES

AIR FLOW

DIRECTION

DETECTOR

HOUSING

SAMPLING

TUBE

EXHAUST

TUBE

AIR FLOW

DIRECTION

EXHAUST

TUBE

SAMPLING

TUBE

SAMPLING

TUBE

EXHAUST

TUBE

DETECTOR

HOUSING

AIR FLOW

DIRECTION

DETECTOR

HOUSING

A. B.

C. D.

HORIZONTAL MOUNTING OF HOUSING

VERTICAL MOUNTING OF HOUSING

NOTE: The sampling tube end cap is critical to the proper

operation of the duct smoke detectors. The end cap is

needed to create the proper air flow to the sensor of the

duct smoke detector.

TEST

RA400Z

RTS451

KEY

COMMON

COM(+)

COM(–)

TEST

RA400Z

RTS451

KEY

COMMON

COM(+)

COM(–)

+

–

COM (+)

COM (–)

COM (+)

COM (–)

COMMUNICATION

LINE

UL LISTED CONTROL

PANEL

1ST DETECTOR

IN LOOP

2ND DETECTOR

IN LOOP

DEVICE STANDBY ALARM

RA400Z 0mA 10 mA Max.

RTS451/RTS451KEY 0mA 7.5 mA Max.

TEST

RA400Z

RTS451

KEY

COMMON

COM(+)

COM(-)

RA400Z

COMMON

+–

DH200P RA400Z

TEST

RA400Z

RTS451

KEY

COMMON

COM(+)

COM(-)

RA400Z

COMMON

TEST

RTS451

KEY

COM(+)

COM(-)

456

12 3

FIELD INSTALLED

JUMPER

COMMON TEST

LED RESET

FOR RTS451, TERMINAL 3 IS NOT USED.

(RTS451 DOES NOT HAVE A TERMINAL 6.)

FOR RTS451KEY, TERMINALS 3 AND 6

ARE NOT USED.

DH200P RTS451/RTS451KEY