FPX103C Auto DUAL LOOP AUTO/MANUAL FIRE CONTROL PANEL Iss 1.0

SUMMARY:

Dual detection loops with full fault monitoring.

Automatic extinguisher operation after shutdown.

“Double knock” automatic activation logic.

Automatic Engine/fuel/fan shutoff capability.

“Spindown” delay ensures extinguishant is not vented.

Extinguisher activation button with anti-tamper tag.

Universal 12 or 24Vdc electrical power.

Low power consumption in “PARKED” mode.

Full fault monitoring on all detector and firex circuits.

Supports up to 6 aerosol fire extinguisher/generators.

Very low false activation potential, tamper seal on ManOp

The unit is reverse polarity, transient and EMC protected.

Custom behavior logic available on request.

Shutdown and delayed firex activation improves effectiveness and saves cost of extra extinguishant.

Most existing extinguishing systems release the agent into a high airflow environment which makes it

almost completely ineffective. Given that a 7 Liter 4 stroke engine at 3000RPM (that’s 50revs/sec)

aspirates 175 Liters or 0.175m3of air per second, add to this ventilation fan flow and the necessity for

a shutdown with engine/fan spindown delay before activation is obvious.

The FPX103C has effectively eliminated spurious activation warranty costs which are regularly caused

by the inherent characteristics of microprocessors, semiconductor power switches and inquisitive

fingers. Our tamper evident tag technology and our strict electronic design rules has proven highly

effective. To eliminate the inherent hazards of microprocessor control the FPX103C uses a fully

parallel path programmable logic device, which is coded using a language called VHDL, commissioned

by US DOD and used for high reliability and safety critical applications.

FEATURES:

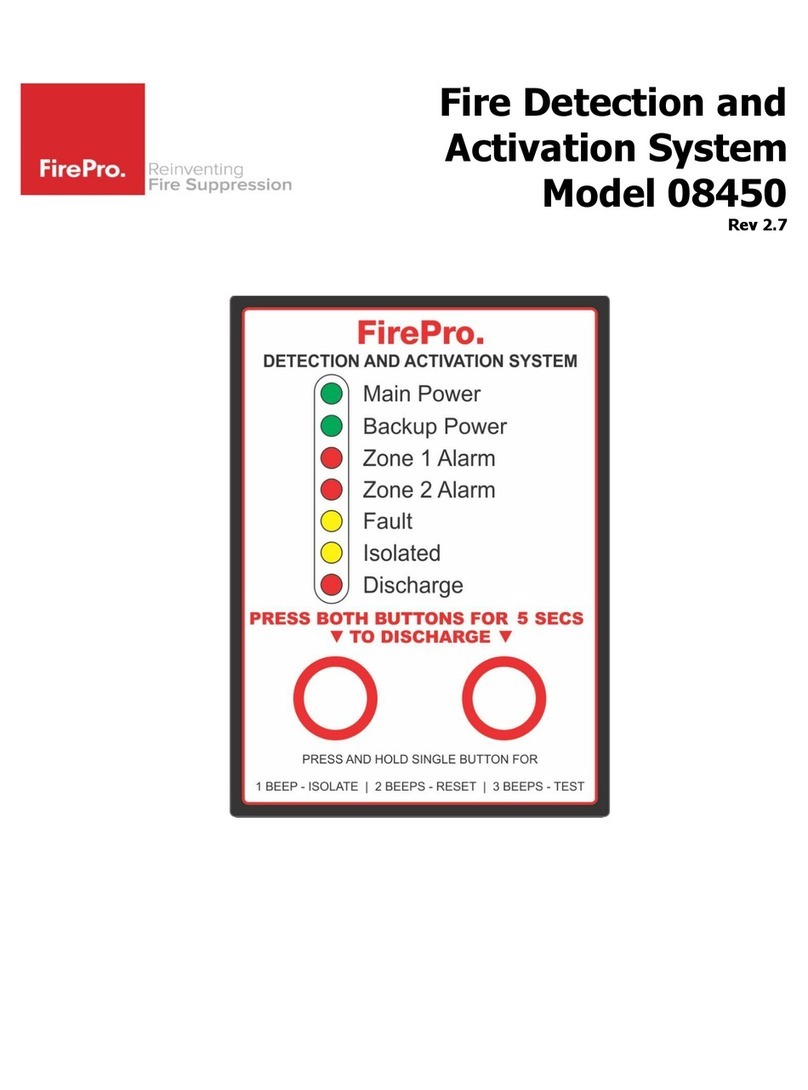

2-wire Smoke, thermal or Linear Heat Sensors up to 50M are continuously monitored for alarms, open

circuit and chassis faults. LED flash codes indicate the location of an alarm or fault condition.

An internal alarm sounder and relay to drive a loud external audible alarm unit up to 2Amps.

Uncommitted relay change-over contacts are available for fuel shutoff, engine/fan shutdown.

The delay option provides a selectable spin-down time so that the extinguishant is not wasted.

“PARKED MODE” is entered when unit senses that ignition is turned off and provides automatic

extinguisher operation should both loops alarm - switching off engine during a double alarm will also

enter timed auto activation mode (aka driver “legging it” protection).

There is an electrical input for an override keyswitch to circumvent shutdown circuits for restarting.

FUNCTIONAL NOTES:

Any loop alarm condition will operate audible and visual alarm indications as follows:

Single loop alarm condition produces internal pulsed alarm (1 per sec) and fan shutdown.

Dual loop alarm condition produces internal pulsed alarm (2 per sec) and automatic

extinguisher and fuel solenoid operation after spindown delay (user set on dip switches),

audible alarm goes continuous.

Alarm LED flash code indicates which loop is in alarm (1=1blink, 2=2blinks, 1&2=3blinks).

The spindown delay allows time for fan and engine to stop before extinguisher is activated. This is to

save extinguishing agent that would otherwise be wasted through venting. The timer tracks the