Fire Pro 08451 User manual

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 1

Contents

1Introduction 2

2Components List 3

3Design Considerations 4

4Installation of FirePro Generators 6

5Connection of Multiple FirePro Generators 7

6Installation 8

7Wiring Diagram 11

8Programming 12

9Control Panel Indicators & Operation 12

10 Commissioning and Test Procedure 14

11 Servicing and Maintenance 16

12 Troubleshooting 17

13 RFI Environments 18

14 Safety Data Sheet (SDS) - FirePro 18

15 Vehicle and Mobile Plant Installation Notes (AS5062) 19

16 Specifications 20

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 2

1Introduction

1.1 General Information

The FirePro FP-08451 Fire Control Panel is a combined detection and extinguishant system is

compliant for vehicle and mobile plant installations (AS5062).

The FIP (fire indicator panel) incorporates:

-2x Detection circuits;

-1x Extinguishing Discharge circuit;

-1x Siren/Strobe circuit;

-1x Agent Release Notification circuit;

-Programmable Activation (automatic and/or manual);

-Fault Monitoring system;

-Isolation Function.

How Does it Work

All FirePro Fire Extinguishing Aerosol Generators use the latest generation FPC solid compound.

Upon activation, the solid compound is transformed into a rapidly expanding, highly efficient gas,

based on Potassium salts. It does not deplete oxygen levels. Its built-in fail-safe activation system

ensures operation of the generators when required, even if everything else fails. The FirePro

Aerosol Generators have a certified life of 15 years, with minimal maintenance required.

Ozone Depletion Potential (O.D.P.) = 0

Atmospheric Life Time (A.L.T.) = 0

Global Warming Potential (G.W.P.) = 0

Non-corrosive & Non-toxic

1.2 In Case of Fire

If a fire occurs, equipment operators should do the following:

1. Detection will initiate an alarm condition on the FirePro System

2. The siren/strobe will operate and if shutdown relays have been installed, equipment

shutdown will be initiated.

3. Evacuate all personnel from the risk area and alert the Fire Brigade.

4. Close all hatches and openings, and shutdown engines and any extraction fans or vents.

5. Manual Activation: Press and hold both mode switches continuously for 5 seconds to

activate the system.

6. Automatic Activation: The control panel will automatically begin the activation sequence

when fire has been detected on Circuit 1 Alarm.

7. Keep the FirePro suppression gas within the risk until the fire is extinguished and not able to

re-ignite.

8. Do not start engine or fans until the fire is extinguished. Operating the exhaust fans will

enable the gas to escape the risk area and could allow the fire to re-ignite.

9. Do not enter the risk until it has been rendered safe.

10.Recommended clean up after discharge is with soapy water or cleaning agent based on citric

acid.

11.Following a discharge, replace all installed FirePro Generators and Thermal Fuse Couplings.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 3

2Components List

FP-CP-08451

Fire Control Panel

Detection and extinguishant

control system

2x DP-3000

4x DP-2000

2x FP-08950

1x

1x

1x

Deutsch Plug 3 Pin M/F, c/w heatshrink

Deutsch Plug 3 Pin M/F, c/w heatshrink

End-of-line Plug 27kΩ ½W (Detection)

End-of-line Diode 1N4004 (Siren/Strobe)

End-of-Line Resistor 3k3Ω ½W (Discharge)

Operator’s Manual

Agent Release Circuit

Siren / Strobe Circuit

FP-08825

Thermal Fuse Coupling

See 3.2 Agent Released

FP-08940

Siren/Strobe

Discharge Circuit

FirePro Aerosol

Generator

100g –500g Unit.

Constructed from Stainless Steel.

Comes with installed Deutsch Plug for

easy install

FP-6200

Heavy Duty Bracket 316 SS.

Suits FP-100, 200, 500 FirePro Aerosol

Generators.

FirePro Aerosol Generator

1200g –5700g Unit.

Constructed from Stainless Steel.

Comes with installed Deutsch Plug for

easy install.

FP-6100

Heavy Duty Bracket 316 SS.

Suits FP-1200, 2000, 3000 5700 FirePro

Aerosol Generators.

Detection Circuit (Circuit 1 Alarm & Circuit 2 Alarm)

FP-08920

Marine Grade Thermal Detector 60°C

Fixed. Other temperatures available on

request.

FP-14053

Manual Actuator

Internal OR External

FP-9510

Linear Heat Detection Cable 182° C

Supplied in Cut Lengths with Deutsch Plugs for easy install. Lengths: 1,2,4,6 & 8m

Installation Components

Service Components

FP-09500

2 Hour Fire Rated Shielded Cable.

FP-08960

Signage for the System. A sheet of

different size labels.

FP-08919

Wiring loom and Splitter Cable for

installaion of multiple FirePro generators.

FP-08800

FirePro Simulator –for Testing &

Commissioning.

Additional Modules

FP-08850

Discharge Delay Module

Allows additional FirePro generators to be

discharged

FP-08860

Shutdown Relay Module

Provides facility for equipment shutdown

FP-08870/8871/8872

Power Control Module

Provides back up power for control panel.

FP-08879

Voltage Sensitive Relay

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 4

3Design Considerations

3.1 Power Supply Input

The FP-08451 Fire Control Panel provide a single power supply input that is compatible with 12

/ 24vDC. The main power supply should be connected directly to a battery or power source,

not through a distribution board. The main power must not be interrupted if the

vehicle/equipment is powered down. The FirePro Battery Lead (P/N FP-14016) may be used to

connect power to the control panel. If a secondary power supply is required for an installation,

a Power Control Module will be required.

3.2 Agent Released Input

The Agent Released input provides an indicator to the operator to notify if the suppression

system has been activated. For the indicator to operate, the FP-08825 Thermal Fuse Coupling

must be used. Thermal Fuse Couplings are single use only. If the suppression system has

operated, the thermal fuse coupling must be replaced. If the Agent Release output is not used,

the circuit must be bridged out and sealed using the supplied deutsch plugs.

3.3 Siren/Strobe Output

The recommended siren/strobe is the Banshee Sounder-Strobe. In a typical install, the

maximum number of supported sirens/strobes that can be installed is 5. When installed,

Siren/Strobes are to be clearly visible and audible at all points around the risk area.

The siren/strobe output is a monitored circuit. The supplied end-of-line diode (1N4004) must

be installed on the last siren/strobe in the circuit, otherwise the fire control panel will display a

fault. If a siren/strobe is not used, the supplied end-of-line diode (1N4004) must be connected

to the siren output using the supplied Deutsch plugs.

3.4 Discharge Output

The maximum number of FirePro generators able to be discharged by the FP-08451 Fire Control

Panel is limited by the voltage of the main power supply. That is:

Voltage 12vDC Max = 2 Units

Voltage 24vDC Max = 4 Units

If a risk area requires a greater number of FirePro generators, the FP-08850 Discharge Delay

module must be used. The module will discharge generators in multiples up to the maximum

as above.

If the number of FirePro generators connected to each output is greater than the

maximum, the fire system will not operate.

When multiple FirePro generators are connected to a single output, they must be connected

using the FP-08919 Splitter Lead. If a suppression system is not used, the supplied end-of-line

resistor (3k3Ω) must be connected to the Discharge output using the supplied deutsch plugs.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 5

3.5 Circuit 1 Alarm Output

The Circuit 1 Alarm Output is a zoned detection circuit capable of operating up to 30

conventional detectors, 100 metres of linear heat detection cable or 30 manual actuators.

The Circuit 1 Alarm Output can be programmed for detection and alarm, or for automatic

discharge if an alarm is detected on this circuit.

The supplied end-of-line resistor (22k or 27kΩ) must be installed on the last detector or manual

actuator in the circuit, or the fire control panel will display a fault. If detection is not used, the

supplied end-of-line plugs (marked green) must be connected.

3.6 Circuit 2 Alarm Output

The Circuit 2 Alarm Output is a zoned detection circuit capable of operating up to 30

conventional detectors, 100 metres of linear heat detection cable or 30 manual actuators.

The Circuit 2 Alarm Output is a detection and alarm circuit only. When in alarm condition the

siren/strobe will operate, however the suppression system will not discharge until manually

operated. The supplied end-of-line resistor (22kΩ) must be installed on the last detector or

manual actuator in the circuit, or the fire control panel will display a fault. If detection is not

used, the supplied end-of-line plugs (marked green) must be connected.

3.7 Mounting

For correct installation, the Fire Control Panel must be mounted by four bolts or screws through

the mounting holes in the flange on both sides of the Module. No penetrations are to be

made through the casing of the panel.

The Fire Control Panel enclosure is rated IP65, so should be installed in a convenient location,

away from where it may be affected by large amounts of water.

It is necessary to complete all wiring and any programming of the detection mode prior to

mounting the panel.

Dimensions and relevant clearances for installing the FP-08451 Control Panel are below. A

Dash Mount Bracket (P/N FP-08451B) is also available and may be used if the minimum

clearances cannot be met.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 6

3.8 Cabling Requirements

Cable Requirements - All cabling in the FirePro

Installation MUST be done using 0.75mm shielded

Fire Rated Cable. Care taken to ensure that all

cables are isolated, and that RF shielding on cable is

stripped back to ensure that there is not accidental

grounding. Cables are colour coded for easy

identification.

Extension Leads - Deutsch Plugs must be used to

ensure water-proof connections are made

throughout the installation.

4Installation of FirePro Generators

FirePro Condensed Aerosol Fire Extinguishing System Arrangement.

•FirePro units and system components installed to allow inspection and maintenance.

•Locate FirePro units where they are not exposed to mechanical damage, exposed to

chemicals, or weather conditions, that may render them inoperative. Protective provisions

shall be adopted, if necessary.

•FirePro units shall be securely installed. Use heavy duty brackets where necessary. Brackets

should be capable of handling the risk environment, including vibration.

FirePro units must be installed at NOT less than the minimum safe distances as

specified in the design calculations.

Means for prompt rescue of any trapped personnel shall be provided, including:

•Adequate aisle ways/routes of exit.

•Alarms –audible and visual, that operate immediately on detection of the fire.

•Signs in accordance with relevant standards for the installation.

System components shall be positioned to the minimum clearances from energized electrical

parts as per: AS 4487 and AS 3000.

Handling and Storage - when handling the Condensed Aerosol Generators do not:

•Disassemble the unit

•Carry out any welding work in the vicinity of the fire

extinguishing system components.

•Exert force or impact which creates physical

or mechanical damage to the casing.

STORAGE and OPERATIONAL CONDITIONS

•Temperature: –54 and +54°C

•Humidity: maximum 98% RH

Colour

Circuit

Red

Power Supply

Yellow 1

Activation

Yellow 2

Activation Delayed

Green 1

Detection 1

Green 2

Detection 2

Blue

Discharge Advice

Orange

Siren/Strobe

White

Relay Output

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 7

•Service life: 15 years (date of manufacture appears on each generator)

Positioning

CORRECT

FP Units directing the aerosol stream away from opening

INCORRECT

FP units are directing the stream towards the opening.

5Connection of Multiple FirePro Generators

Where multiple FirePro Generators are installed, connect using the

FP-08919 Splitter Lead.

Splitter Leads can be installed at any point on the activation. For

ease of install, servicing and efficient field wiring, Splitter Leads

should be installed in areas easy to access and minimise extension

leads.

The supply voltage of any system will determine the no of FirePro units which can be used

12vDC Max = 2 FP Units

24vDC Max = 4 FP Units

Where additional units are required in the system use Discharge Delay Module(s).

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 8

6Installation

It is recommended that one circuit is installed and connected at a time to isolate the cause of

any faults that may occur during installation. The supplied End-of-line plugs and Test Module

may be used to keep the control panel out of a fault condition.

1. Power: When panel has been mounted in a suitable location, connect main supply power

using a FP-14016 Battery Lead to the power input (marked red).

2. Agent Released Circuit: The Thermal Fuse Coupling (P/N FP-08825) should be screwed

into the thermal port on one of the installed FirePro generators and connected to the control

panel.

3. Siren/Strobe Circuit: Mount the siren/strobe (P/N FP-08940) in a location where it is

visible and audible in all points with the risk area and connect to the “Siren” output on the

module (marked orange). If more than one siren/strobe is being installed, they are to be

connected using the secondary positive/negative terminals in the sounder.

The supplied end-of-line diode should be installed in the secondary positive/negative

terminals of the last siren/strobe in the circuit. The diode is polarised, so the positive lead

of the diode (marked with a grey band) should be terminated in the positive terminal of the

siren/strobe, otherwise a fault will occur on the fire control panel.

4. Circuit 1 Alarm Circuit: This circuit can be programmed for ALARM ONLY (operate

siren/strobe) or AUTOMATIC DISCHARGE (discharges suppression system and operates

siren/strobe). If detection is not used, the supplied end-of-line plugs (marked green) must

be connected to the Circuit 1 Alarm output.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 9

Manual Actuator (P/N FP-14053) can be connected together in quantities up to 30. If a

manual actuator is being used for remote activation, it must be installed on Circuit 1 Alarm.

The supplied end-of-line plugs (marked green) must be connected to the last manual

actuator in the circuit.

Linear Heat Detection: Linear Heat Detection can be installed in cut lengths with Deutsch

plugs fitted. P-Clips must be installed at intervals of 50cm maximum to support the cable.

The supplied End-of-line resistor is mounted in the Deutsch plug.

Conventional Detector (Thermal / Smoke): Conventional Detector (P/N FP-08920

Thermal / FP-94140 Smoke) can be connected together in quantities up to 30. A End-of-line

resistor must be installed in the last detector in the circuit.

Detection Not Used: If detection is not used, the supplied end-of-line plugs (marked

green) must be connected to the Circuit 1 Alarm output.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 10

5. Circuit 2 Alarm Circuit: This circuit is ALARM ONLY and will only operate the

siren/strobe. Connections for detection and manual actuators are the same as Circuit 1

Alarm. This is a monitored circuit so end-of-line plugs (marked green) must be connected.

6. Discharge Circuit: This circuit should remain disconnected until all other circuits are

connected. The control panel must not be in an alarm/fault condition when the FirePro

generators are connected, as this may cause an accidental discharge. A FirePro Test Module

(P/N FP-08800) should be connected to take the control panel out of fault condition and for

any commissioning.

Connecting FirePro Generators: If a single FirePro Generator is being installed, it can be

connected directly to the Discharge output on the control panel.

Discharge Not Used: If the discharge circuit is not used, the supplied end-of-line resistor

(3k3Ω) must be connected to the Discharge output using the supplied deutsch plugs.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 11

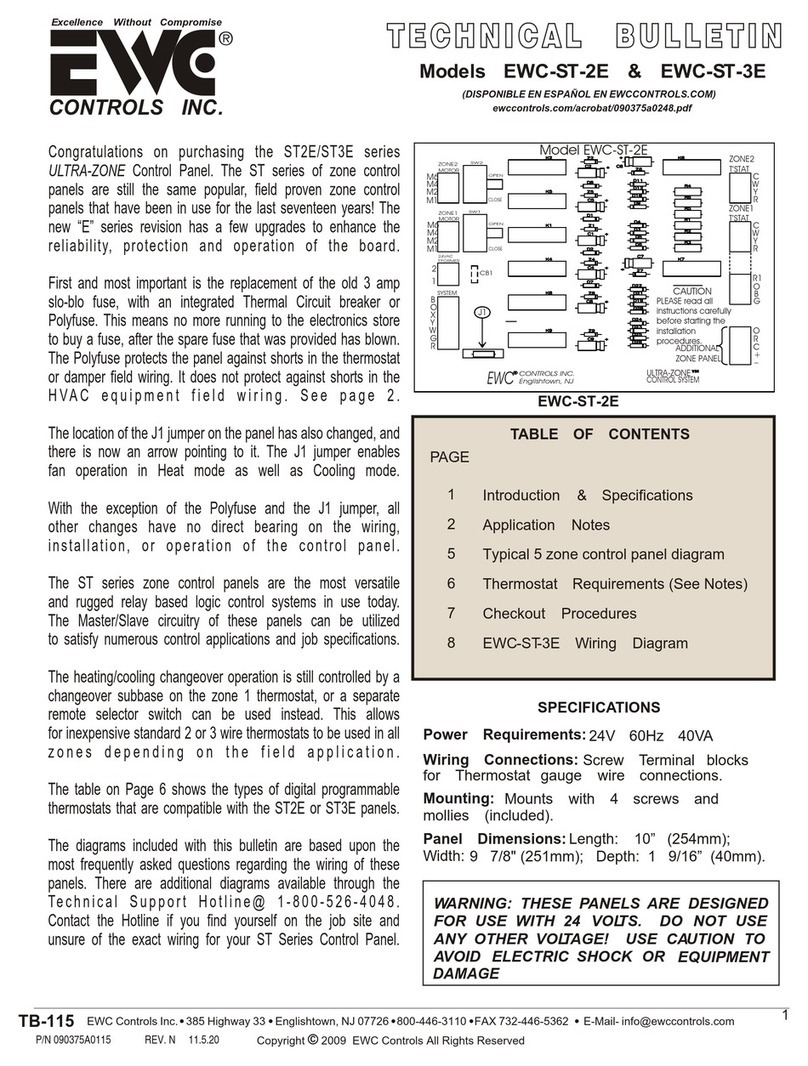

7Wiring Diagram

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 12

8Programming

The FP-08451 Control Panel provides several programming options,

allowing it to be adapted to site conditions. The 2-way DIP switches

inside the panel next to the terminal block allow one of 4 modes to

be selected. To access the DIP switches, open the panel enclosure.

Note: All programmed settings should be recorded in the logbook.

Note: If a Discharge Delay Module (P/N FP-08850) is installed, panel must be programmed for

extended discharge.

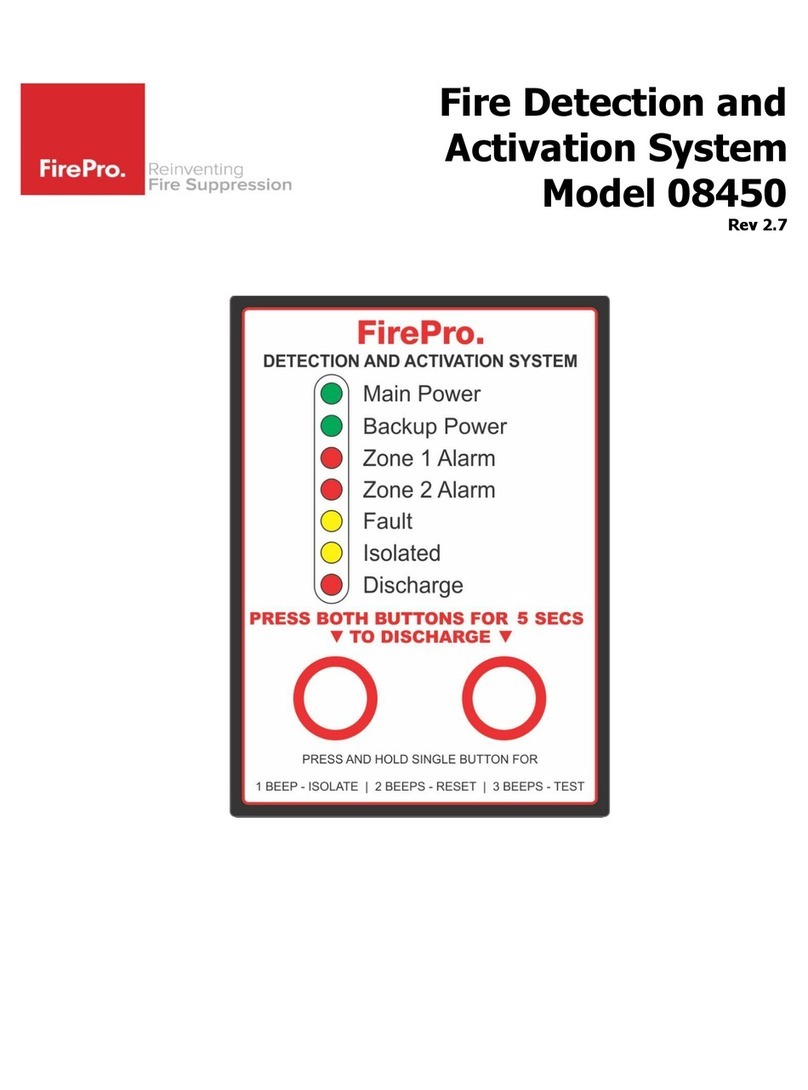

9Control Panel Indicators & Operation

9.1 LED Indicators

The FP-08451 Control Panel uses LED indicators to notify the

operator of the condition of the control panel and each of the

monitored circuits. If an LED is illuminated, it indicates the

following:

Circuit

LED

Condition

Power

Power supply is available

Circuit 1 Alarm

System is in alarm condition

Circuit 2 Alarm

System is in alarm condition

Fault

System is in fault condition and needs servcing

Isolated

System has been isolated using buttons on

panel

Discharging

System has initiated activation sequence

Agent Released

Agent has been released and needs servcing

9.2 Isolate Function

To isolate the control panel, press and hold Mode Switch 1 until a 1 beep is heard and the

“Isolated” LED is illuminated. To restore the control panel to normal operation, press Mode

Switch 1 and ensure the “Isolated” LED turns off.

Isolating disables automatic activation. Manual Activation will remain operational.

When isolated, the control panel continues to monitor for alarm and fault, and show the alarm

and fault indications, but will not operate the siren and the automatic discharge. When

Switch 1

Mode

Switch 2

Mode

OFF

Standard Discharge

Power Applied for 2

seconds

DEFAULT

OFF

Manual Discharge

Detectors operate

siren/strobe only

ON

Extended Discharge

Power applied for 240

seconds

ON

Automatic Discharge

Detection on Circuit 1

Alarm will discharge

system

DEFAULT

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 13

isolated, any change in the detector status, will cause the panel sounder to operate for 1

second as an alert of the status change, but the panel will remain isolated. The isolate function

will also silence the siren/strobe and the internal sounder but will not cancel the alarm or fault

indication.

9.3 Reset Function

To reset the control panel, press and hold Mode Switch 1 until 2 beeps are heard. Following a

reset, the control panel will automatically isolate. To restore the control panel to normal

operation, press Mode Switch 1 and ensure the “Isolated” LED turns off. Note: The control

panel cannot be reset if the activation sequence has been initiated. When the “Discharging”

LED is no longer illuminated, the reset function will become available again.

9.4 Test Function

The control panel includes a test function, enabling the operator to ensure that the control

panel is functioning correctly. To operate the test function, press and hold Mode Switch 1 until

3 beeps are heard. The test function will illuminate all LEDS on the control panel and operate

the internal sounder and any external siren/strobes for 2 seconds, and then return the control

panel to normal operation. The test function does not activate the suppression system. Note:

If any LEDS or siren/strobes do not operate, contact your supplier.

9.5 Discharging the Fire System

To manually discharge the fire system, press and hold both Mode Switch 1 and Mode Switch 2

continuously for 5 seconds. This will immediately operate any installed siren/strobes and any

shutdown relays, to warn any occupants. Manually discharging the fire system should only

performed during commissioning/servicing when the system has been appropriately isolated, or

in case of fire.

9.6 Alarm Silence

To silence the internal sounder and any installed siren/strobes that have operated due to an

alarm condition, press and hold Mode Switch 1 until a 1 beep is heard and the “Isolated” LED is

illuminated. This will also override any installed shutdown relays and allow for operation of the

equipment. Note: Equipment should not be operated until it has been rendered safe by the

appropriate authority. The control panel will remain in an alarm/fault condition until serviced

and reset.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 14

10 Commissioning and Test Procedure

Commissioning should be performed when the fire control panel is not in an

alarm/fault condition. Note: No personnel should be in the risk area until

the fire system is fully isolated.

To ensure that the FirePro system will operate as designed, it should be

inspected and serviced every 6 months, and yearly, in accordance with

AS1851 and AS5062.

Six Monthly Test Procedure:

•Isolate the control panel and disconnect the any installed FirePro

aerosol generators. This will generate a fault on the fire control panel.

•Connect FP-08800 Test Module(s) to the “Discharge” output to the

panel (marked yellow). Turn off the Isolate function. The Test Module

should remain installed throughout the test procedure.

•Control Panel and components:

-Clean and remove dirt, grease or foreign material. Replace any parts that appear

damaged or have been painted.

-Check all indicators are in normal position.

•FirePro Aerosol Generators:

-Inspect FirePro generators to ensure they are in good condition.

-Check mounting brackets are in good condition and secure.

-Check Dust Covers are in good condition –replace as necessary.

-Check FirePro Units are at predetermined aiming points.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 15

•Electrical System Inspection:

-Check Manual Actuators are secure, clean, undamaged.

-Check that anti-tamper seals/pull pins are in place and secure.

-Check all wiring, connection and supports are in intact, undamaged and in correct

position.

•Labels:

-Check manual release, system warning and instruction labels are in place and legible.

•Test the fault monitoring system by disconnecting and reconnecting all connected

detection devices and the siren strobe circuit one at a time. Ensure the “Fault” LED indicator

illuminates and the internal sounder is heard each time a circuit is disconnected.

•Discharge Testing from Control Panel:

-Perform a manual discharge test by pressing and holding both mode switches on the

panel continuously for 5 seconds.

-Following activation, ensure the Test Module Red LED has operated.

-Isolate the panel to silence alarm. Panel should now display a fault.

-Reset Test Module. Panel should no longer be in fault condition.

-Turn off the Isolate function.

•Discharge Testing from External Devices: Each detection and manual actuator device

connected to must be tested individually.

-Perform an automatic discharge test by activating the detectors or manual actuators.

-Following the activation sequence ensure the Test Module Red LED has operated.

-Isolate the panel to silence the alarm. The control panel should now display a fault.

-Reset the Test Module.

-Reset the control panel by pressing and holding a single mode switch until 2 beeps are

heard. The control panel should no longer be in alarm/fault condition.

•System control and indicating equipment.

-During discharge test, ensure operation of all installed siren/strobe(s).

-During discharge test, ensure operation of all installed shutdown relays. This must

shutdown any equipment specified in the risk assessment.

-Test backup battery capacity. Replace every backup battery every 2 years.

•Disconnect the FP-08800 Test Module and reconnect all FirePro aerosol generators.

•Turn off the Isolation function. System is now operational.

Additional requirements for Commissioning of a System after Install or Discharge

•Design Survey - check against the baseline data, for alterations, changes in use or

operating environment, or other factors that could affect the performance of the fire

protection system. (Annual)

•Risk Assessment –required to be prepared and reviewed every 5 years or after any

incident. Review document to ensure system compliance. Check if document is current.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 16

11 Servicing and Maintenance

Inspection and servicing of the installed fire system should occur in accordance with the

relevant Australian Standards (i.e. AS1851 or AS5062). Any alterations to the risk area should

be recorded and where necessary the risk assessment, design calculation and installed

components must be revised to reflect the new operating conditions.

A logbook must be kept, recording all the relevant information from the installation and

servicing. The logbook must contain the following:

Content of logbook:

Appendices of Logbook:

-General details

-Devices used

-Date and outcome each inspection

-Risk Assessment

-Schematic diagrams

-Photos of the original Installation

-Programming of the control panel

-Inspection reports

11.1 Daily Service Schedule

A daily inspection should be performed by the operator prior to operation of the equipment. If

anything does not appear normal, the equipment should not be operated and the fire service

provider alerted. The Daily Inspection should include:

-Visual inspection of the control panel and installed components. These should be accessible

and free from debris, rust, or electrical faults.

-Visual inspection of the control panel to ensure normal functioning. When functioning

normally the only indicator illuminated should be the “Power” indicator (green).

-Visual inspection of anti-tamper seals and travel pins, to ensure they are in place.

11.2 Semi-annual / Annual Service Schedule

Semi-annual and Annual servicing and maintenance are to be undertaken only by

accredited service technicians. Any misuse of the FIP may result in an accidental discharge

of the suppression system and is not covered by warranty.

Servicing should include a visual inspection of all the installed components to ensure they are in

good condition, and that the relevant stream lengths and thermal clearances are observed as

per the original design calculation and risk assessment.

Operation of the fire system should be tested as outlined in 8. Commissioning.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 17

12 Troubleshooting

The FP-08451 Control Panel provides a comprehensive fault monitoring system that will detect

any open-circuit in the Circuit 1 Alarm Output, Circuit 2 Alarm Output, Siren/Strobe Output,

Discharge Output and Agent Released Input and any malfunctions of the control panel’s internal

components.

When in a fault condition, the control panel will operate the “Fault” LED indicator and operate

the internal sounder. The control panel uses a coded sequence to indicate the type circuit to

the operator. Note: To diagnose if a fault is internal or external, attempt to isolate the panel.

If the control panel can be isolated, the fault is external. (see 9.2 Isolating the Control Panel).

12.1 Fault Indicators

A fault will be indicated if any monitored circuit connected to the panel is not complete. This

could be caused by the devices connected or the wiring to each device. This will display as:

Internal Sounder

Fault LED

Fault

1 beep

On

Circuit 1 Alarm

2 beeps

On

Circuit 2 Alarm

3 beeps

On

Discharge Circuit

4 beeps

On

Siren/Strobe Circuit –Version 4 Panel Only

This will require inspection and testing of connections and installed components. End-of-line

plugs should be plugged directly into the panel, to return it normal condition, and then used to

systematically check along the effected circuit(s). If the fault persists, contact your supplier.

12.2 Panel is Unresponsive

If the panel has become unresponsive, check the incoming power supply. Panel will operate

down to approx. 9vDC. If incoming voltage is above this contact supplier.

12.3 Internal Faults

An internal fault cannot be isolated and will display as:

Internal Sounder

Fault LED

Fault

Continuous, steady beep

On

Internal 5vDC Supply OR Watch Dog Circuit

Continuous, pulsing beep

On

Internal Microprocessor

Internal faults can be rectified by powering down the panel and powering up again. This will

reset the system to normal conditions. If the fault persists, contact your supplier.

12.4 Agent Released Fault

Refer to 3.2 Agent Released Input. If the Agent Released LED is illuminated, this indicates a

fault on the Agent Release input. Typical causes are that the thermal fuse coupling has

operated or has been disconnected. To test if the thermal fuse coupling has operated, check

with a multi-meter for a closed circuit. Thermal Fuse couplings are single use only. If the

thermal fuse coupling has operated, it must be replaced (P/N FP-08825). If the thermal fuse

coupling is functioning normally and the fault persists, contact your supplier.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 18

13 RFI Environments

The control panel’s circuit arrangement provides protection designed for the effects of

electromagnetic emissions and prevent accidental discharges of the system. Shielded, fire rated

cable (FP-09500) is MUST to be used throughout every installation to protect the fire system

from electromagnetic emissions. Cables should be installed with appropriate clearances from

any cables or equipment that may produce high levels of RF interference.

14 Safety Data Sheet (SDS) - FirePro

This is an EXTRACT ONLY from the full SDS. To view the full SDS go to www.chemwatch.com.au.

PRODUCT NAME CELANOVA FIREPRO

PRODUCT USE Fire extinguishing agent.

HAZARDOUS SUBSTANCE. DANGEROUS GOODS.

According to NOHSC Criteria, and ADG Code.

POISONS SCHEDULE - None

RISK

SAFETY

•Contact with combustible material may cause fire.

•Harmful if swallowed

•Irritating to eyes and skin.

•May cause SENSITISATION by skin contact.

•Harmful to aquatic organisms may cause long- adverse

effects in the aquatic environment.

•Cumulative effects may result following exposure

•May produce discomfort of the respiratory. system*

•Possible respiratory sensitiser*.

•May possibly affect fertility* (limited evidence).

•Keep away from combustible material

•Avoid exposure - obtain special instructions before use.

•To clean the floor and all objects contaminated by this material use

water and detergent.

•Keep away from food drink and animal feeding stuffs.

•In case of contact with eyes rinse with plenty term of water and

contact Doctor or Poisons Information Centre.

•If swallowed IMMEDIATELY contact Doctor or. Poisons Information

Centre (show this container or label).

•This material and its container must be disposed of as hazardous

waste.

FIRST AID MEASURES

SWALLOWED

•If swallowed do NOT induce vomiting.

•If vomiting occurs, lean patient forward or place on left side (head-down position, if possible) to maintain open

airway and prevent aspiration. Observe the patient carefully.

•Never give liquid to a person showing signs of being sleepy or with reduced awareness.

•Give water to rinse out mouth, then provide liquid slowly and as much as casualty can comfortably drink.

•Seek medical advice.

EYE

•If this product comes in contact with the eyes:

•Wash out immediately with fresh running water.

•Ensure complete irrigation of the eye.

•Seek medical attention without delay; if pain persists or recurs seek medical attention.

•Removal of contact lenses after an eye injury should only be undertaken by skilled personnel.

SKIN

•If skin contact occurs:

•Immediately remove all contaminated clothing, including footwear.

•Flush skin and hair with running water (and soap if available).

•Seek medical attention in event of irritation.

INHALED

•If dust is inhaled, remove from contaminated area.

•Encourage patient to blow nose to ensure clear passage of breathing.

•If irritation or discomfort persists, seek medical attention.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 19

15 Vehicle and Mobile Plant Installation Notes (AS5062)

For AS5062 vehicle installations, a risk assessment must be completed all equipment, and the

design agreed upon by the installer and operators. The risk assessment should include

identification of all fuel and ignition sources, and these must be considered in the system

design.

AS 5062 requires:

Automatic Discharge: The system shall be programmed for automatic discharge on alarm

unless it is determined by the risk assessment why automatic discharge would be inappropriate.

Equipment Shutdown: As determined by the risk assessment, any equipment that may

impede operation of the fire system must be shutdown prior to system discharge. This requires

the installation of the FP-08860 Shutdown Relay Module.

Secondary Power Supply: In addition to the power supply requirements as per 3.1 Power

Supply Input, AS5062 also requires a secondary power supply capable of operating the fire

system for a minimum of 24 hours. This requires the installation of the Power Control Module,

or the identification of a secondary power source in the equipment that will not be affected by

any failure of the primary power supply.

System Discharge Advice: AS5062 requires independent notification of the suppression

system discharged. This requires the installation of the FP-08825 Thermal Fuse Coupling.

Manual Actuation: Should manual actuators must be installed on Circuit 1 Alarm to allow for

remote manual activation of the suppression system. This requires the installation of FP-14053

Manual Actuators and Circuit 1 Alarm to be programmed for automatic discharge.

Fire Detection and Activation System

Model 08451

Rev 3.1

Page | 20

16 Specifications

General

Dimensions

148L x 84W x 35D mm

Material

Diecast Aluminium, UV Tolerant

Ingress Protection

IP65

Operating Temperature

-40 to 85 degrees Celsius

Fault Monitoring –External

-Circuit 1/2 Alarm –Open/Closed

-Siren/Strobe –Open/Closed

-Discharge –Open/Closed

Fault Monitoring –Internal

-Poly-switch fuse operated

-Loss of internal 5V supply

-Internal microprocessor malfunction

Power Supply Input

Mains Operating Voltage

12-30VDC

Mains Operating Current

20mA on 12V

23mA on 24V

Backup Power

See FP-08870 / 08871 / 08872 manual

Detection Output

Circuit 1 Alarm &

Circuit 2 Alarm

No. of Detection Zones

2

Operating Voltage

12-30VDC (same as main supply voltage)

Detection End-of-line

27kΩ / 22kΩ ½W Resistor

Maximum Detectors per Zone

-30 Conventional Detectors

-100m Linear Heat Detection

-30 Manual Actuators

Alarm Threshold

3.6V Fault sensing threshold: 0.53V

Compatible Detectors

Hochiki SLV-AS Smoke Detector

Hochiki DCD-AE3M Thermal Detector

14053 Manual Actuator

09510 180˚C Linear Heat Detection

Discharge Output

Discharge Output Current

1.5A at 12vDC

1.5A at 24vDC

Discharge End-of-line

3K3Ω ½W Resistor

Max FirePro Units

2 at 12vDC

4 at 24vDC

Standard Discharge Delay

5 seconds from automatic/manual activation

Max Discharge Delay Modules

2 DDM’s at 12vDC

4 DDM’s at 24vDC

Max FirePro units using DDM’s

6 at 12vDC

20 at 24vDC

Siren/Strobe Output

Siren/Strobe Output Current

Max 0.5A

Siren/Strobe Output

Protection

0.5A poly-switch resettable fuse

Siren/Strobe End-of-line

1N4004 Diode

Max Siren/Strobes

5

Compatible Siren/Strobes

Banshee Sounder Strobe

Max Siren Shutdown Modules

2 at 12vDC

4 at 24vDC

Agent Released Input

Input Type

Thermal Switch, NC, Latching, Non-resettable

Operation

Thermal Event >80˚C

BANSHEE multi-tone sounder/strobe - suitable for internal or external locations.

SpecificationsData

Voltage:

9 –30vDC

Current:

12v - Max 60mA

24v - Max 39mA

Sound Output:

101dB(A)

Beacon:

0.7j

Flash Rate:

60/min (1Hz)

Temperature:

-20 C to +55 C

IP Rating:

FP-08940 –IP 45

FP-08941 –IP 66

Other manuals for 08451

1

This manual suits for next models

1

Table of contents

Other Fire Pro Control Panel manuals

Fire Pro

Fire Pro Sigma XT Reference guide

Fire Pro

Fire Pro FPC-2 User manual

Fire Pro

Fire Pro FP-08450 User manual

Fire Pro

Fire Pro 08100 User manual

Fire Pro

Fire Pro 08451 User manual

Fire Pro

Fire Pro FPC-2 User manual

Fire Pro

Fire Pro FPX103C User manual

Fire Pro

Fire Pro FPC-2 User manual

Fire Pro

Fire Pro FP-22408 User manual

Popular Control Panel manuals by other brands

Mitsubishi Electric

Mitsubishi Electric GT1020 Series Startup guide

LEGRAND

LEGRAND 67206 user guide

Mircom

Mircom FA-1025T Installation and operation manual

auto maskin

auto maskin Marine Pro 200E Series Configuration manual

Votronic

Votronic VPC Jupiter 100 Installation and operating manual

Slate

Slate Raven MTX2 manual