Fire Pro 08100 User manual

Control Panel

Model 08100

Rev 4.0

Page | 1

Contents

1Introduction ................................................................................................. 2

2Components List........................................................................................... 3

3Design Considerations................................................................................... 4

4Installation of FirePro Generators .................................................................. 5

5Connection of Multiple FirePro Generators...................................................... 6

6Installation................................................................................................... 7

7Sservicing & Maintenance ............................................................................. 9

8Specifications ............................................................................................... 9

9Safety Data Sheet (SDS) FirePro...................................................................10

Control Panel

Model 08100

Rev 4.0

Page | 2

1Introduction

General Information

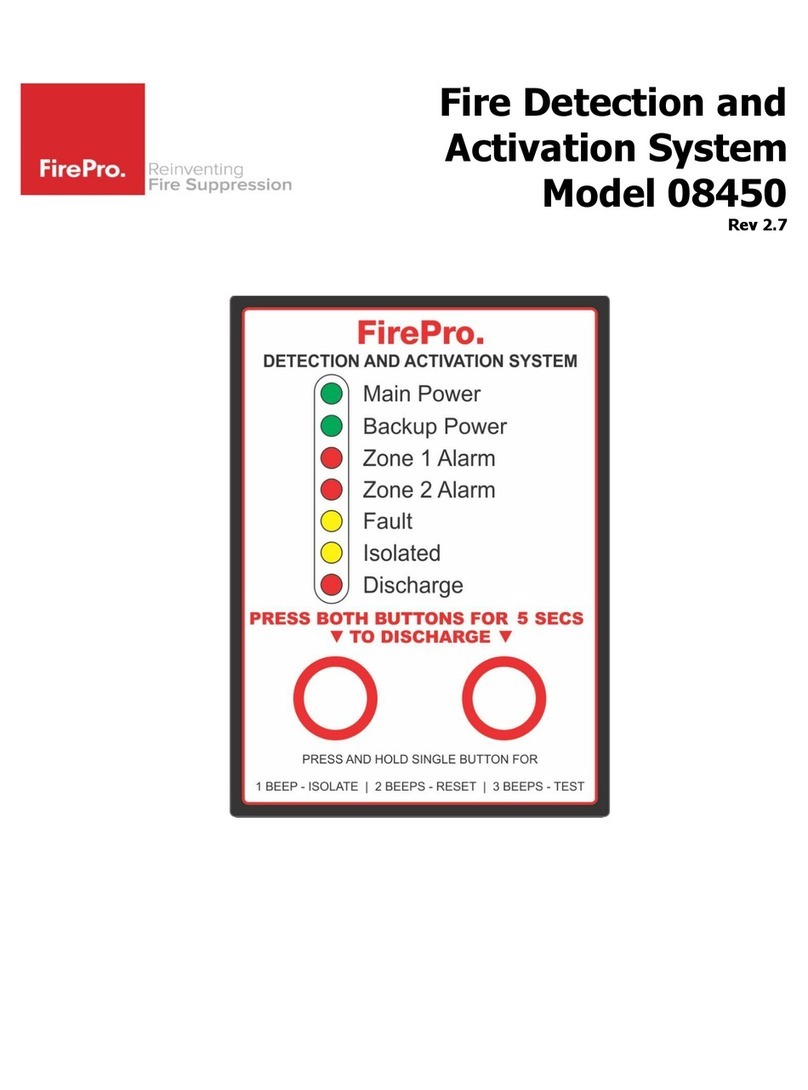

The FirePro FP-08450 Fire Control Panel is a combined detection and extinguishant system.

The FIP (fire indicator panel) incorporates:

-1x Non Monitored Detection circuit using Linear Heat Detection Cable;

-1x Non Monitored Extinguishing Discharge circuit;

-1x Non Monitored Siren/Strobe circuit;

-FirePro Monitor Indicators -

oPower ON light iluminated –system okay and ready for activation.

oFIRE Red light –Fire Alarm.

How Does it Work

All FirePro Fire Extinguishing Aerosol Generators use the latest generation FPC solid compound.

Upon activation, the solid compound is transformed into a rapidly expanding, highly efficient gas,

based on Potassium salts. It does not deplete oxygen levels. Its built-in fail-safe activation system

ensures operation of the generators when required, even if everything else fails. The FirePro

Aerosol Generators have a certified life of 15 years, with minimal maintenance required.

Ozone Depletion Potential (O.D.P.) = 0

Atmospheric Life Time (A.L.T.) = 0

Global Warming Potential (G.W.P.) = 0

Non-corrosive & Non-toxic

In Case of Fire

If a fire occurs, equipment operators should do the following:

1. Detection will initiate an alarm condition on the FirePro System

2. Evacuate all personnel from the risk area.

3. Close all hatches and openings, and shutdown engines and any extraction fans or vents.

4. Manual actuation is from Panel via switch. The Actuate Switch has a Protective cover to

prevent accidental activation. To activate the system flip open the Protective switch cover

and push the spring loaded toggle switch.

5. When pressed then the manual release switch will immediately ACTIVATE the Fire System.

It will also activate the alarm(s) and the Fire LED will flash.

6. Keep the FirePro suppression gas within the risk until the fire is extinguished and not able

to re-ignite.

7. Do not start engine or fans until the fire is extinguished. Operating the exhaust fans will

enable the gas to escape the risk area and could allow the fire to re-ignite.

8. Do not enter the risk until it has been rendered safe.

9. Recommended clean up after discharge is with soapy water or cleaning agent based on

citric acid.

10. Following a discharge, replace all installed FirePro Generators.

This is a MANUALLY ACTIVATED SYSTEM

Control Panel

Model 08100

Rev 4.0

Page | 3

2Components List

FP-08100

Control Panel

FP-08850

Additional FirePro Activation.

Allows for programmable delay

on activation.

Agent Release Circuit

Siren / Strobe Circuit

FP-08918

Wiring loom and Splitter Cable for installaion

of multiple FirePro generators.

FP-08940

Siren/Strobe

Discharge Circuit

FirePro Aerosol Generator

100g –500g Unit.

Constructed from Stainless Steel.

Comes with installed Deutsch Plug for easy

install

FP-6200

Heavy Duty Bracket 316 SS.

Suits FP-100, 200, 500 FirePro Aerosol

Generators.

FirePro Aerosol Generator

1200g –5700g Unit.

Constructed from Stainless Steel.

Comes with installed Deutsch Plug for easy

install.

FP-6100

Heavy Duty Bracket 316 SS.

Suits FP-1200, 2000, 3000 5700 FirePro

Aerosol Generators.

Detection Circuit (Circuit 1 Alarm & Circuit 2 Alarm)

FP-09510

Linear Heat Detection Cable 182° C

Supplied in Cut Lengths with Deutsch

Plugs for easy install. Lengths: 1,2,4,6 &

8m

FP-08800

FirePro Simulator –for Testing &

Commissioning.

Installation Components

Service Components

FP-09500

2 Hour Fire Rated Shielded Cable.

FP-08960

Signage for the System. A sheet of

different size labels.

Control Panel

Model 08100

Rev 4.0

Page | 4

3Design Considerations

3.1 Main Power Supply Input

The FP-08800 Fire Control Panel provide a single power supply input that is compatible with 12

/ 24vDC. If adequate power is not supplied, the power LED will not be illuminated.

3.2 Siren/Strobe Output

When a fire is detected by the LHD cable (if Installed), the internal siren in the FIP will sound

and the RED fire indicator light will flash, and the external siren (if installed) will sound. The

internal and external sirens will also sound whenever the fire system activation occurs.

3.3 Discharge Output

The maximum number of FirePro generators able to be discharged by the FP-08800 Fire Control

Panel is limited by the voltage of the main power supply. That is:

Voltage 12vDC Max = 2 Units

Voltage 24vDC Max = 4 Units

If a risk area requires a greater number of FirePro generators, the Discharge Delay module

must be used. The module will discharge generators in multiples up to the maximum as above.

If the number of FirePro generators connected to each output is greater than the

maximum, the fire system will not operate.

When multiple FirePro generators are connected to a single output, they must be connected

using the FP-08919 Splitter Lead.

3.4 Detection Circuit

The detection circuit can support Linear Heat Detection Cable.When a fire is detected by the

LHD cable (if Installed), the siren in the FIP will sound and the RED fire indicator light will flash.

To activate the Fire System lift the cover for the switch and push the toggle switch. The siren

will stop once the activation switch has been pushed and the fire indicator light will stay

illumated.

3.5 Mounting

The panel is to be mounted vertically by means of two bolts or screw through

the mounting holes in the flange on the outside of the FIP, as shown below.

No penetrations are to be made through the casing of the panel, except for

cable entry. It may be necessary to complete all wiring and any programming

of the detection mode prior to mounting the FIP.

Control Panel

Model 08100

Rev 4.0

Page | 5

3.6 Cabling Requirements

Cable Requirements - All cabling in the FirePro Installation

MUST be done using 0.75mm shielded Fire Rated Cable. Care

taken to ensure that all cables are isolated, and that RF

shielding on cable is stripped back to ensure that there is not

accidental grounding. Cables are colour coded for easy

identification.

Extension Leads - Deutsch Plugs must be used to ensure

water-proof connections are made throughout the installation.

In Addition to Color Coding the back of the panel is

Marked as shown.

4Installation of FirePro Generators

FirePro Condensed Aerosol Fire Extinguishing System Arrangement.

•FirePro units and system components installed to allow inspection and maintenance.

•Locate FirePro units where they are not exposed to mechanical damage, exposed to

chemicals, or weather conditions, that may render them inoperative. Protective provisions

shall be adopted, if necessary.

•FirePro units shall be securely installed. Use heavy duty brackets where necessary.

Brackets should be capable of handling the risk environment, including vibration.

FirePro units must be installed at NOT less than the minimum safe distances as

specified in the design calculations.

Means for prompt rescue of any trapped personnel shall be provided, including:

•Adequate aisle ways/routes of exit.

•Alarms –audible and visual, that operate immediately on detection of the fire.

•Signs in accordance with relevant standards for the installation.

System components shall be positioned to the minimum clearances from energized electrical

parts as per: AS 4487 and AS 3000.

Handling and Storage - when handling the Condensed Aerosol Generators do not:

•Disassemble the unit

•Carry out any welding work in the vicinity of the fire

extinguishing system components.

•Exert force or impact which creates physical or

mechanical damage to the casing.

STORAGE and OPERATIONAL CONDITIONS

•Temperature: –54 and +54°C

•Humidity: maximum 98% RH

•Service life: 15 years (date of manufacture appears on each generator)

Colour

Circuit

Red

Power

Yellow

Activation

Green

Detection

Orange

Sounder

Control Panel

Model 08100

Rev 4.0

Page | 6

FP Unit 1

FP Unit 2

FP Unit 1

FP Unit 4

Activation

Cable

Splitter

Lead

Extension Lead

FP Unit

2

Activation

Cable

Extension Lead

Splitter Lead

FP Unit 3

Positioning

CORRECT

FP Units directing the aerosol stream away from opening

INCORRECT

FP units are directing the stream towards the opening.

5Connection of Multiple FirePro Generators

Where multiple FirePro Generators are installed, connect using the

FP-08919 Splitter Lead.

Splitter Leads can be installed at any point on the activation. For

ease of install, servicing and efficient field wiring, Splitter Leads

should be installed in areas easy to access and minimise extension leads.

The supply voltage of any system will determine the no of FirePro units which can be used

12vDC Max = 2 FP Units

24vDC Max = 4 FP Units

Where additional units are required in the system use Discharge Delay Module(s).

Connection of 2 FirePro Units

Connection of 4 FirePro Units

Control Panel

Model 08100

Rev 4.0

Page | 7

6Installation

Wiring Diagram Overview

Power Supply

Power –12 to 30vDC

5A fuse or circuit breaker to be installed on incoming power supply.

Siren / Strobe Unit

BANSHEE multi-tone sounder/strobe - suitable for internal or external locations.

SpecificationsData

Voltage:

9 –30vDC

Current:

12v - Max 60mA

24v - Max 39mA

Sound Output:

101dB(A)

Beacon:

0.7j

Flash Rate:

60/min (1Hz)

Temperature:

-20 C to +55 C

IP Rating:

FP-08940 –IP 45

FP-08941 –IP 66

Control Panel

Model 08100

Rev 4.0

Page | 8

Detection –Linear Heat Detection(only)

The panel may be installed with fire detection or with no detection. If Detection required

simply connect the LHD cable to the detection circuit. Linear Heat Detection (LHD) is a line-

type form of fixed temperature heat detection used in common commercial and industrial

environments. This linear cable can detect a fire anywhere along its entire length. LHD Cable

detection systems are easy to design, install, operate and maintain. Max 500m of LHD Cable

can be used. LHD Cable works using a twisted pair, tri-metallic conductors sheathed in

advanced thermal polymers. In a fire the LHD insulation will breakdown and make contact,

signalling the control panel of an alarm. As the LHD is not monitored by the panel –NO End of

Line resistor is required.

The linear cable must be installed appropriately for the risk area.

Control Panel

Model 08100

Rev 4.0

Page | 9

7Servicing & Maintenance

The FirePro Suppression system should be serviced at least every 6 months in accordance with

AS 1851, more often in aggressive environments. Periodic visual inspections of the installed

system must also be conducted by the operators to ensure all installed parts are free from

debris, rust, or electrical faults. Six Monthly servicing must only be undertaken by

accredited service technicians.

NO PERSONNEL SHOULD BE IN THE RISK AREA DURING TESTING

UNTIL THE FIP IS FULLY ISOLATED

Servicing and Maintenance Procedure

1. Disconnect the FirePro activation circuit (Yellow) at the panel, and

connect the FirePro simulator.

2. Visually inspect all installed FirePro Generators, cable, connections,

detection devices and siren/strobes. Look for any signs of damage or

wear and replace as necessary.

3. Test the function of all connected detection devices. Testing method will

depend on the specific device, check product manual if unsure.

4. Test the function of the siren/strobe by putting the detection circuits into

alarm and ensure that the siren/strobe can be heard and is illuminated.

5. Activate the system –after ensuring the FirePro Simulator is connected. Note: the

FirePro Simulator stay illuminated until the reset button on the simulator is pressed.

6. Reconnect the FirePro activation circuit.

System Logbook

A logbook recording all the relevant events concerning the installation. The logbook contains

the items required that provide for the recording of all events during the life of the installation.

Content of logbook:

Devices used

Date of each inspection

Comments re outcome of each inspection

In the appendices of the Logbook:

Schematic diagrams

Photos of the Original FirePro Installation

Inspection reports

8Specifications

Size of Dash Panel

125mm (w) x 95mm (h)

Size of Dash Cutout

105mm (w) x 68mm (h) Min clearance behind Panel 80mm

Max Number of FirePro Units

12v - 2 FP Units

24v –4 FP Units

Power Supply

12-24vDC

Fuse for Power Supply

5A

Max of Linear Heat Detection

50m

Control Panel

Model 08100

Rev 4.0

Page | 10

9Safety Data Sheet (SDS) FirePro

This is an EXTRACT ONLY from the full SDS. The SDS is prepared by Chemwatch - to view the

full SDS go to

www.chemwatch.com.au

.

PRODUCT NAME CELANOVA FIREPRO

PRODUCT USE Fire extinguishing

agent.

HAZARDOUS SUBSTANCE. DANGEROUS GOODS.

According to NOHSC Criteria, and ADG Code.

POISONS SCHEDULE - None

RISK

SAFETY

•Contact with combustible material may cause fire.

•Harmful if swallowed

•Irritating to eyes and skin.

•May cause SENSITISATION by skin contact.

•Harmful to aquatic organisms may cause long-

adverse effects in the aquatic environment.

•Cumulative effects may result following exposure

•May produce discomfort of the respiratory. system*

•Possible respiratory sensitiser*.

•May possibly affect fertility* (limited evidence).

•Keep away from combustible material

•Avoid exposure - obtain special instructions before use.

•To clean the floor and all objects contaminated by this material

use water and detergent.

•Keep away from food drink and animal feeding stuffs.

•In case of contact with eyes rinse with plenty term of water and

contact Doctor or Poisons Information Centre.

•If swallowed IMMEDIATELY contact Doctor or. Poisons

Information Centre (show this container or label).

•This material and its container must be disposed of as hazardous

waste.

FIRST AID MEASURES

SWALLOWED

•If swallowed do NOT induce vomiting.

•If vomiting occurs, lean patient forward or place on left side (head-down position, if possible) to maintain

open airway and prevent aspiration. Observe the patient carefully.

•Never give liquid to a person showing signs of being sleepy or with reduced awareness.

•Give water to rinse out mouth, then provide liquid slowly and as much as casualty can comfortably drink.

•Seek medical advice.

EYE

•If this product comes in contact with the eyes:

•Wash out immediately with fresh running water.

•Ensure complete irrigation of the eye.

•Seek medical attention without delay; if pain persists or recurs seek medical attention.

•Removal of contact lenses after an eye injury should only be undertaken by skilled personnel.

SKIN

•If skin contact occurs:

•Immediately remove all contaminated clothing, including footwear.

•Flush skin and hair with running water (and soap if available).

•Seek medical attention in event of irritation.

INHALED

•If dust is inhaled, remove from contaminated area.

•Encourage patient to blow nose to ensure clear passage of breathing.

•If irritation or discomfort persists, seek medical attention.

Table of contents

Other Fire Pro Control Panel manuals

Fire Pro

Fire Pro FP-08450 User manual

Fire Pro

Fire Pro Sigma XT Reference guide

Fire Pro

Fire Pro 08451 User manual

Fire Pro

Fire Pro FPC-2 User manual

Fire Pro

Fire Pro FPC-2 User manual

Fire Pro

Fire Pro FP-22408 User manual

Fire Pro

Fire Pro 08451 User manual

Fire Pro

Fire Pro FPC-2 User manual

Fire Pro

Fire Pro FPX103C User manual