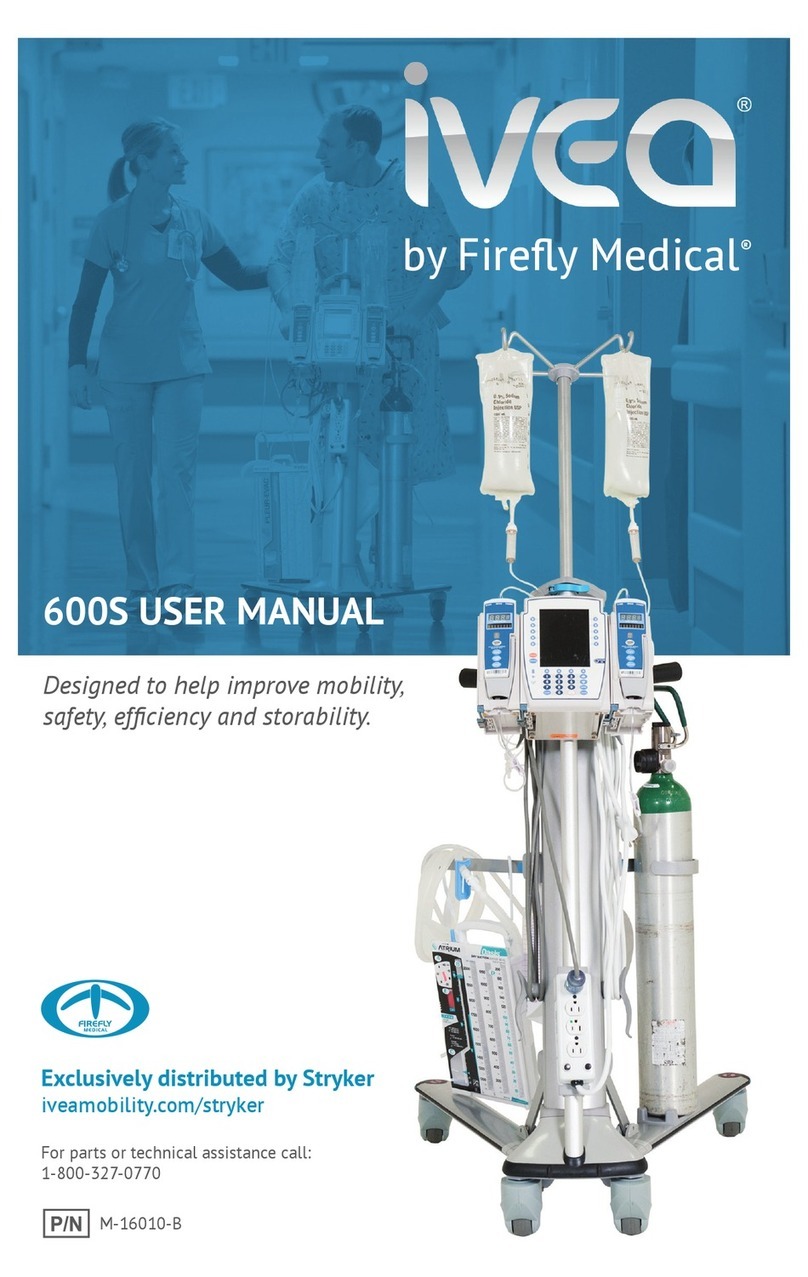

Firefly Medical ivea 600S User manual

®

by Firey Medical®

600S

RECOMMENDED

INSPECTION AND

MAINTENANCE

Designed to help improve

iveamobility.com

®

16282-A

®

2IVEA® 600S • Recommended Inspection and Maintenance

Table of Contents

Recommended Safety Precautions .......................................................................3

Recommended Quarterly Inspection and Maintenance .....................................................4

Recommended Annual Inspection and Maintenance .....................................................5-6

Recommended Accessory Bracket Assembly (16276S) Arm Retightening Procedure .............................7

Recommended Caster Retention Adjustment Procedure ....................................................8

Recommended Handle Bracket Clamp Tension Adjustment Procedure ........................................9

Recommended IV Pole Clamp Tension Adjustment Procedure ..............................................10

Disposal ............................................................................................11

This guide is designed to assist you in maintaining your IVEA. See also IVEA 600S User Manual for additional

instructions on maintenance, disinfection, and troubleshooting.

3IVEA® 600S • Recommended Inspection and Maintenance

Recommended Safety Precautions

Inspection and adjustment of IVEA should always be performed by qualied personnel in compliance with their

institution’s policies and procedures for maintenance of durable medical goods.

WARNINGS and CAUTIONS

• It is recommended that personnel who inspect and adjust IVEAs rst familiarize themselves with the Warnings

and Cautions related to IVEA caregiver/patient use located in the IVEA 600S User Manual

4IVEA® 600S • Recommended Inspection and Maintenance

2X Grips: in good condition;

secure on handle tubes

4X Casters: roll & swivel freely; with

blue pedal engaged, both wheel

& swivel lock securely; with yellow

pedal engaged, swivel locks in

straight forward orientation as shown

2X Handle Release Buttons:

pop out fully when handles

are deployed

Pole Adjustment Lever:

see page 10

Foot Pedal: operates freely by hand

(IVEA deployed, no load); spring

returns pedal to raised (locked)

position. Main Column of IVEA should

move downward when forced if

and only if Foot Pedal is depressed.

IVEA should sit squarely

on floor with no rocking.

Apply 60 lbs.[27 Kg] to

handles to confirm

structural integrity.

Perform these inspections every

3 months

or more frequently.

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

4X E-Clip:

fully engaged

in pin groove

Handle Bracket Detail

2X Pins: secure;

not protruding

Handle Blade

2X Handle Latches:

must fully engage

Handle Blade

when deployed

Handle Height Lever: see page 9

Orange Lock Pin Indicator:

flush when IVEA deployed

and locked, protrudes

when folded/unlocked

Recommended Quarterly Inspection and Maintenance

5IVEA® 600S • Recommended Inspection and Maintenance

IV Hooks: not distorted

from original shape

Top Cap: secure; no play

O2 Hoop & Chest Drain Arm: lock

securely in both deployed &

folded positions; no excess free

play: see page 7

Catheter Bag Hook:

secure; not damaged

O2 Tank Cup: secure; not damaged

4X Casters: do not fall

out when folded IVEA

is carried or trolleyed:

see page 8

2X Trolley Wheels: roll freely

2X Outlet Strip Clamps:

no cracks; screws tight

4X Cord Hooks: present

& secure

Accessory Bracket: firmly

attached to Main Column

Tipping hazard label legible

IV Pole: telescopes freely; stops

at full extension; maintains

rotational alignment

2X Spring Buttons:

protrude & lock IV Hooks

securely to IV Pole

In addition to quarterly inspections, perform these inspections every year or more frequently.

2X "No Step" Label: legible

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Serial number label legible

Y

Chest Drain Arm Pin: present

Continued on next page.

Safe working load label legible

(located on left edge of column)

Recommended Annual Inspection and Maintenance

6IVEA® 600S • Recommended Inspection and Maintenance

18X Screws on underside of

both legs: if loose, retighten to

fully seated

Y

Y

Y

Y

Y

6X Screws on underside of cover:

if loose, retighten to fully seated

using a T20 Torx driver

Move up-down

In fully latched

condition, move

handles up-down.

Free-play at tip

should not exceed

0.25" (6mm)

Free-play at tips of

elevated legs should

not exceed

0.25"

(6mm)

In addition to quarterly inspections, perform these inspections every year or more frequently.

Recommended Annual Inspection and Maintenance (cont.)

7IVEA® 600S • Recommended Inspection and Maintenance

G

Mast

C

Access Hole

D

16276S Accessory

Bracket Assembly

H

Arm Screw access hole

A

16136S T20

Plastite Screws

B

Catheter Bag Hook

F

Cover

E

Hex Socket Screw

(inside Bracket)

Accessory Bracket Assembly (16276S) Arm Retightening

Tools/supplies: T20 screwdriver; Long solid-shaft 5mm hex key or slender hex screwdriver; 3mm hex key or hex

screwdriver.

1. Locate and remove 3 T20 Plastite Screws (A) and Catheter Bag Hook (B).

2. Locate Access Hole (C) of Accessory Bracket (D). Insert 5mm hex key or hex screwdriver through hole to engage

drive socket of Hex Socket Screw (E) inside Bracket. Unscrew Hex Socket Screw 3 full turns, no more, and slide

Cover (F) up Mast (G) just enough to provide access to Arm Screw Access Hole (H). You may have to wiggle the

bracket a bit to ease sliding.

3. Insert 3mm hex key or screwdriver through Arm Screw Access Hole (H) and engage the drive socket of the

screw within. Tighten screw to the point where the arm does not wiggle side to side but can still pivot easily.

Reassembly

1. Slide Cover back into place, again wiggling the Bracket to ease sliding.

2. Replace Catheter Bag Hook (B) and 3 T20 Plastite Screws (A). Tighten Plastite screws just until lightly nger-

snug. NOTE: Once snug, screw torque is not critical to safety or function, but overtorquing could cause strip-

out.

3. Once again Insert 5mm hex key or hex screwdriver through hole to engage drive socket of Hex Socket Screw

(E) inside Bracket.

4. Drive Screw (E) until it is nger-snug and no joint free-play remains. NOTE: Once snug, screw torque is not

critical to safety or function, but overtorquing could cause strip-out.

8IVEA® 600S • Recommended Inspection and Maintenance

Caster Retention Adjustment

This procedure can be used to restore retention to a caster that is prone to falling out during transport. Procedure

is identical for leg end casters and nose casters except for an additional orientation step required by leg end

casters, explained below.

Tools/supplies: thin at blade screwdriver; pliers; puncture-resistant glove.

Procedure

1. Pull caster (A) fully out of its socket.

2. Protect your off-hand with a puncture-resistant glove.

3. Holding the caster rmly in your off-hand and grasping the brass grip ring (B) with your ngers to prevent it

from spinning, insert the blade of screwdriver (C) into the gap in the grip ring and twist the screwdriver to

enlarge the gap slightly.

4. Check the resulting t of the caster in its socket. Adjust gap as needed to optimize t and retention by further

expansion (with the screwdriver) or compression (with pliers) of the grip ring.

5. Partially reinsert caster stem into socket.

6. If a leg end caster (with yellow pedal), orient the Notch (D) located in the edge of the caster’s hexagonal plate

(E) as shown, facing directly up the length of the leg. This aligns it with a mating tab (F).

7. Push the caster the rest of the way into place, embedding the hexagonal plate in its mating recess.

8. Check the locking and braking functions of the caster to assure that they are all operational. See IVEA 600S

User Manual.

A

Caster (leg

end type shown)

C

Screwdriver

D

Notch

B

Grip Ring

E

Hex Plate

C

Hex Recess

F

Tab

9IVEA® 600S • Recommended Inspection and Maintenance

Handle Bracket Clamp Tension Adjustment

If handle bracket is drifting down in use:

Tools/supplies: 5mm hex key or driver. weights totalling 75lb to 100lb.

1. Loosen the blue Lock Lever (A) and raise the Handle Bracket to its highest position. Lock the lever.

2. Insert a 5mm hex key or driver into the drive socket of Hex Socket Screw (B). Turn the screw clockwise 1/4 turn.

3. Hang bags of weights totalling 75-100lb on the handles, distributing the load more or less evenly, to test

holding power. If bracket holds, you’re done.

4. If bracket slips downward, perform steps 1-3 repeatedly until slipping is eliminated.

A

Lock Lever

B

Hex Socket

Screw

10 IVEA® 600S • Recommended Inspection and Maintenance

IV Pole Clamp Tension Adjustment

Tools/supplies: 3mm hex key or driver; IV bags or similar hangable weights totalling 11lb.

1. Clean/disinfect IV pole to remove oils, lotion residues, etc.

2. Place a typical set of IV bags or equivalent weight totalling 14lb on the IV hooks of the IVEA, unlock and

extend the IV Pole to half of full extension, supporting the IV Pole by hand. Place lever into locked position,

while continuing to manually support the IV Pole.

3. With IV Pole Lock Lever (A) in closed position as shown, increase or reduce Hex Socket Screw (B) tightness until

IV hooks are just able to maintain height without slipping. Avoid overtightening.

4. Release IV Pole Lock Lever and conrm ability to telescope IV Pole.

NOTE: IV pole is intended to be fully retracted during ambulation. If a correctly loaded IV pole slips downward

only during ambulation, this is an indication of misuse, not of misadjustment.

A

IV Pole

Lock Lever

B

Hex Socket

Screw

11 IVEA® 600S • Recommended Inspection and Maintenance

Disposal

NOTE: This product or any part removed from it, upon retirement from service, should be disposed of in compliance

with your institution’s disposal policies. The aluminum components of the IVEA (mast, handles, equipment pole, IV

pole, legs, brackets) are recyclable if all attached components are removed.

12 IVEA® 600S • Recommended Inspection and Maintenance

16282-A

600S RECOMMENDED INSPECTION AND MAINTENANCE

Designed and Manufactured by:

Firey Medical, Inc.

P.O. Box 2022

Fort Collins, CO 80522

by Firey Medical®

®

Other manuals for ivea 600S

1

Table of contents

Other Firefly Medical Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual