First Choice Lincat Silverlink 600 SLR6 User manual

SPARE PARTS DIAGRAM FOR

First Choice Group

Blakeney Way, Kingswood Lakeside

Cannock, Staffs, WS11 8LD

TEL: 01543 577778 FAX: 01543504141

Email: [email protected]

Web: www.firstchoice-cs.co.uk

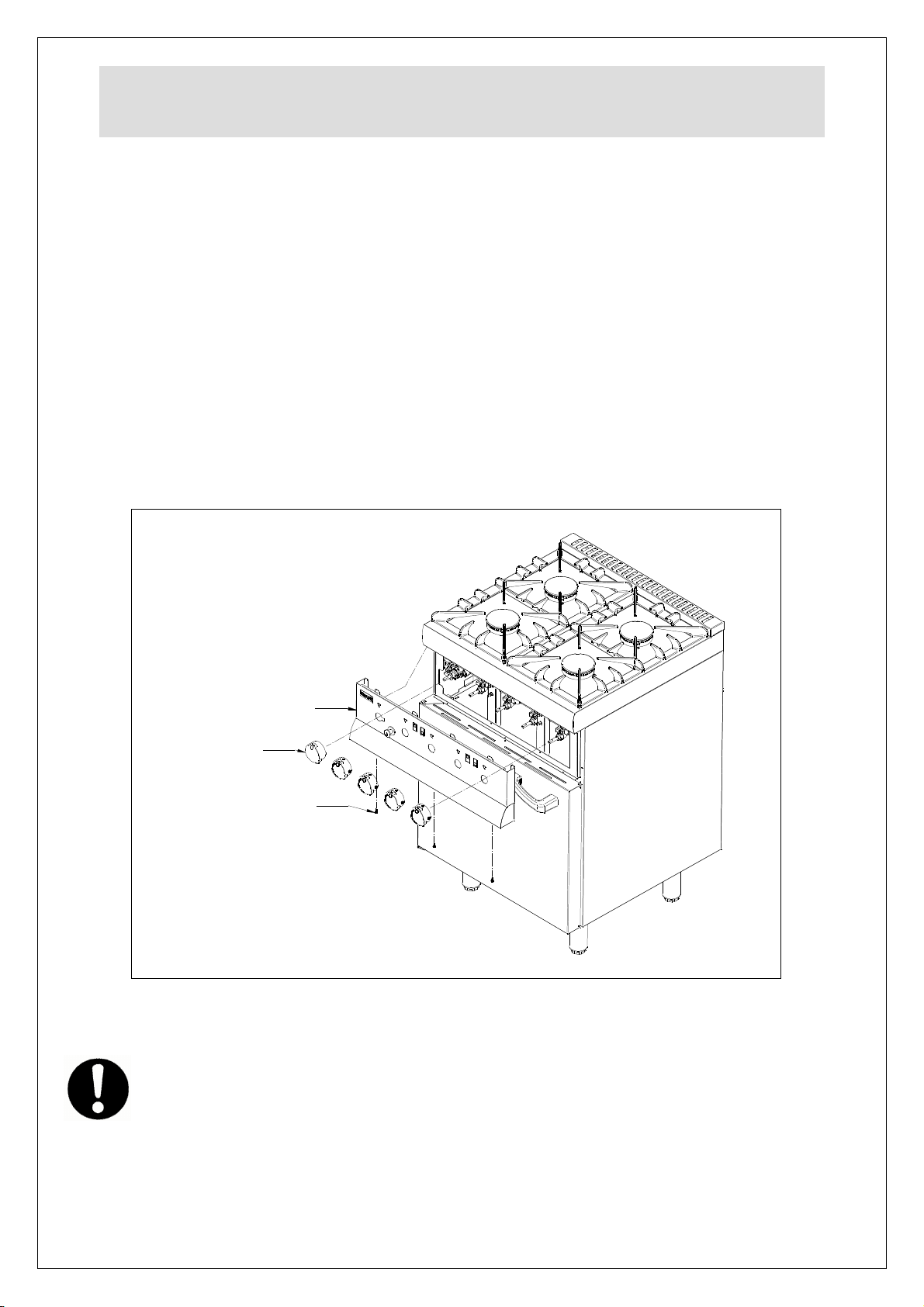

Gas Oven Range

Silverlink 600 Range

IS 514 ECN 3706 Page 1 of 20

Installation, Operating, Servicing and

Conversion Instructions

Silverlink 600 Gas Ranges

SLR6, SLR6C, SLR9 and SLR9C

Please make a note of your product details for

future use:

Date Purchased:_________________________

Model Number:__________________________

Serial Number:__________________________

Dealer:_________________________________

_______________________________________

IS 514 ECN 3706 Page 2 of 20

CONTENTS

Important Information 2

Warnings and Precautions 3

Technical Data 4

Checklist of Enclosures 5

Installation and Commissioning 6

Operating Instructions 7

Cleaning 9

Servicing, Maintenance and Component Replacement 10

Conversion 15

Fault Finding 17

Spare Parts List 18

Accessories 19

Service Information and Guarantee 20

IMPORTANT INFORMATION

Read these instructions carefully before using this product, paying particular

attention to all sections that carry warning symbols, caution symbols and notices.

Ensure that these are understood at all times

.

WARNING!

This symbol is used whenever there is a risk of personal injury.

CAUTION!

This symbol is used whenever there is a risk of damaging your Lincat product.

NOTE:

This symbol is used to provide additional information, hints and tips.

KEEP THIS MANUAL FOR FUTURE REFERENCE

IS 514 ECN 3706 Page 3 of 20

WARNINGS AND PRECAUTIONS

This appliance must be installed, commissioned, serviced and converted by a

qualified person in accordance with national and local regulations in force in the

country of installation.

Strip plastic coating and clean the appliance before use.

During operation parts may become hot - avoid accidental contact.

Parts protected by the manufacturer shall not be adjusted by the user.

Do not obstruct or block the flue.

Installation must include sufficient ventilation to prevent the occurrence of

unacceptable concentrations of substances harmful to health in the room in which

they are installed.

After operation, some parts of the appliance will remain hot for a period of time.

Please take care to avoid accidental burns.

IS 514 ECN 3706 Page 4 of 20

TECHNICAL DATA

Model

SLR6 SLR9

Dimensions

Overall height (mm) 925 to hob 960 to pan support

Width (mm) 600 900

Depth (mm) 600

Weight (kg) 69kg (Net) 85kg (Net)

Hob cooking surface w x d (mm) 590 x 500 890 x 500

Usable oven capacity w x d x h (mm) 425 x 345 x 400 660 x 345 x 400

Oven shelf size (mm) 420 x 345 700 x 345

Heat Input

Total heat input Natural(Gross) 23.8 kW 35.5kW

Total heat input Propane(Gross) 23.8 kW 35.5kW

Total heat input Butane(Gross) 20.6kW 30.7kW

Oven rating Natural(Gross) 5.8 kW 8.5 kW

Oven rating Propane(Gross) 5.8 kW 8.5 kW

Oven rating Butane(Gross) 5.8 kW 8.5 kW

Hob rating, per burner Natural(Gross) 4.5 kW

Hob rating, per burner Propane(Gross) 4.5 kW

Hob rating, per burner Butane(Gross) 3.7kW

Hob Low Rate (all gasses) ≈0.85kW

Connection and Operating Pressures

Gas inlet connection R

P

½ (½" BSP)

Supply Pressure - Natural 20mbar

Supply Pressure - Propane 37 mbar

Supply Pressure - Butane 28-30mbar

Gas C

onsumption

Total gas rate – Natural 2.27 m

3

h

-

1

3.38 m

3

h

-

1

Total gas rate – Propane 1.70 kg h

-

1

2.54 kg h

-

1

Total gas rate – Butane 1.50 kg h

-

1

2.23 kg h

-

1

Hob burner gas rate - Natural 0.43m

3

h

-

1

Hob burner gas rate - Propane 0.32kg h

-

1

Hob burner gas rate - Butane 0.27kg h

-

1

Oven burner gas rate - Natural 0.55m

3

h

-

1

0.81m

3

h

-

1

Oven burner gas rate - Propane 0.41kg h

-

1

0.61kg h

-

1

Oven burner gas rate - Butane 0.42kg h

-

1

0.62kg h

-

1

Hob Low Rate Natural ≈0.08m

3

h

-

1

Hob Low Rate Propane ≈0.06kg h

-

1

Hob Low Rate Butane ≈0.06kg h

-

1

Oven temperature range ≈130 – 250 °C

IS 514 ECN 3706 Page 5 of 20

CHECK LIST OF ENCLOSURES

Model

SLR6

SLR9

Tick

Warranty Card 1 1

Pan Supports 2 3

User Instructions 1 1

IS 514 ECN 3706 Page 6 of 20

INSTALLATION AND COMMISSIONING

Site this appliance beneath an extraction canopy for the removal of combustion

products.

Installation must include sufficient ventilation to prevent the occurrence of

unacceptable concentrations of substances harmful to health in the room of

installation. There must be a minimum free area of 4.5cm

2

per kW of total heat

input.

Allow for a sufficient flow of fresh air for complete gas combustion.

Do not connect directly to any flue, ducting or mechanical extraction system.

The gas supply hose or tubing shall comply with national requirements in force and

shall be periodically examined and replaced as necessary.

An equipotential bonding terminal is provided to allow cross bonding with other

equipment.

Install this appliance on a level surface ensuring all vents are unobstructed. Any

partitions, walls or furniture must be of non-combustible material and not be closer

than 50mm

Ensure there is a space of at least 1000mm between the working surface and any

ceiling.

GAS SUPPLY AND CONNECTION

Connection is at the rear of the unit via a R

p

½ (½" BSP)

When making the connection to the appliance an isolating cock should be fitted into the

supply line close to the unit, for emergency shutdown or servicing purposes.

SUPPLY PRESSURES

The appliances are intended to be connected directly to the gas supply without further

adjustment for those countries where the supply pressure does not exceed the pressures

as detailed above. For those countries where the supply pressures exceed the pressures

as tabled then the supply pressure must be regulated to the pressures as detailed above.

For the purposes of proving connection integrity access to the pressure test nipple is as

follows:

•To gain access to the gas pressure test nipple open the oven door/s.

•Remove the control knobs.

•Remove the anti-tamper screws securing the fascia

•Remove the oven ignitor lead.

•The test nipple is found on the manifold rail.

FIRST TIME LIGHTING

The procedure for first time lighting may only be carried out by registered personnel.

To light any individual burner it may be necessary to purge all pipe work of air.

To do this, depress and hold in the full on position as many controls knobs as possible

until there is evidence of free gas flow. Upon detection of gas flow return all but one control

knobs to the 'OFF' position and light the gas at the burner corresponding to the control

knob in the depressed position. When the gas at the burner is burning correctly shut it

down and repeat the lighting process for the remaining burners.

IS 514 ECN 3706 Page 7 of 20

OPERATING INSTRUCTIONS

Only qualified or trained personnel should use this appliance.

LIGHTING SEQUENCE

Please ensure that the gas isolation valve for the appliance is turned to the open position

before attempting to light this unit.

Hob Burners

From the OFF position: press and turn the control knob anti-clockwise to any position

between the two stylized flames to allow gas through to the burner.

Maintaining the control knob depressed, manually light the gas at the burner using a

taper or piezo ignitor wand.

On establishing a flame at the burner, keep the knob depressed for approximately 15

seconds then release. The burner should remain lit.

If the appliance has stood unused for any length of time it may be necessary to purge

the burner feed pipes of air. To purge the burner feed pipes of air depress and rotate a

control knob to the full on position. Maintain the knob in the depressed position for 20-

30seconds and then light the gas at the burner. Repeat as necessary until the gas

ignites.

Oven Burner

Open the oven door/s

From the OFF position press and turn the oven thermostat knob anti-clockwise to the

stylized star position to allow gas to flow through to the oven burner.

Maintaining the control knob depressed, push the oven ignitor button until an audible

click is heard. A spark will be generated at the oven burner. The gas at the oven burner

should light. It may be necessary to repeat the ignition process a number of times until

the gas lights.

On establishing the flame at the oven burner, maintain the thermostat knob in a

depressed state for approximately 15 seconds and then release the control knob. The

gas should remain lit.

Rotate the thermostat knob to the desired temperature setting.

USING THE APPLIANCE

Ensure the pan supports are centrally placed on the hob to.

It is recommended that a burner is lit first before placing large pans over the burner.

It is not recommended that multiple lit burners are covered at any one time by large

gastronome pans or detachable griddle plates.

PAN PLACEMENT

Pans should be placed centrally on the pan support in relation to the burner for maximum

efficiency.

PAN SIZES

The recommended pan base diameters are no smaller than 150mm and no larger than

400mm.

Pans should never be placed in such a position that they become a hazard from tipping

IS 514 ECN 3706 Page 8 of 20

NOTE

Oven Temperatures

The temperatures on the thermostat knob are a guide and generally reflect the

temperature at the centre of the oven. The temperatures in the oven will vary from top

to bottom. It may be necessary to periodically rotate product being cooked to ensure

even cooking.

OPERATION OF THE APPLIANCE

•The appliance should not be left unattended when in use for any lengthy period of

time.

•Pans should only be filled to a level no more than to prevent a boil over situation.

•Periodically inspect liquid volumes to prevent a boil dry situation.

•Frying of product should never be left unattended.

•Use hand and arm protective when handling hot pans to avoid injuries from burns.

.

OVEN DOORS

•Care must be taken when opening the oven doors when the appliance is in

operation due to the rapid escape of hot air.

•Use hand and arm protective when handling hot roasting pans and baking trays to

avoid injuries from burns.

IS 514 ECN 3706 Page 9 of 20

CLEANING

Do not use a water jet or steam cleaner, and do not immerse this appliance.

Clean all panels with warm water and mild detergent, do not use abrasive materials.

Dry with a soft cloth.

It is important that users of the appliance systematically check and clean down as

necessary areas of the hob and oven cavity that have accumulated oils, fats and other

combustible debris from previous cooking. Particular attention must be paid to the burner

head ports. Ensure they are always clear. Ensure the appliance and all its parts are in a

cold state before commencing any cleaning routine.

Areas to Check

•Burner Caps – Check burner caps are clean and centrally seated on the burner head

•Burner Heads – The burner heads can only be fitted in one orientation onto the burner

body. As a guide the recess with the two ports aligns with the thermocouple.

•Pan Supports – The pan supports are manufactured from cast iron and are heavy. For

ease of cleaning they can be removed from the appliance and placed in a suitable dish

washer.

•Oven Shelves – The shelves can easily be removed for routine cleaning. Stubborn burned

on deposits can be cleaned using suitable approved cleaning agents and scourers

•Oven Base Tray – Can be easily removed for cleaning

•Oven Cavity – To clean the oven cavity remove the shelves and base tray and remove

any solids and accumulated fats, oils and spillages.

IS 514 ECN 3706 Page 10 of 20

SERVICING, MAINTENANCE AND

COMPONENT REPLACEMENT

The replacement of serviceable parts can only be carried out by registered authorised

personnel and must and must be in possession of up to date licensing.

FASCIA PANEL REMOVAL

Care should be taken when removing the fascia panel as the oven ignitor lead will be

attached to the ignitor.

•Open the oven door/s

•Remove the screws SS situated underside of the fascia panel FF.

•Remove the control knobs CC by pulling free from the valve spindles. Be aware

spring clips are fitted to each control knob

•Tilt the fascia panel from the bottom up and then pull clear of the hob top.

•Disconnect the ignitor lead from the ignitor button and temporarily tie to the manifold

rail.

•Access to the valves, thermostat, pipe work and thermocouples are from the front

aperture

OPERATIONAL CHECK

Commissioning must include an operational check of all controls.

•Check that each burner can be lit at both full rate and low rates

•Check that each burner will remain lit when turned to low rate

SS

FF

CC

Fig1

IS 514 ECN 3706 Page 11 of 20

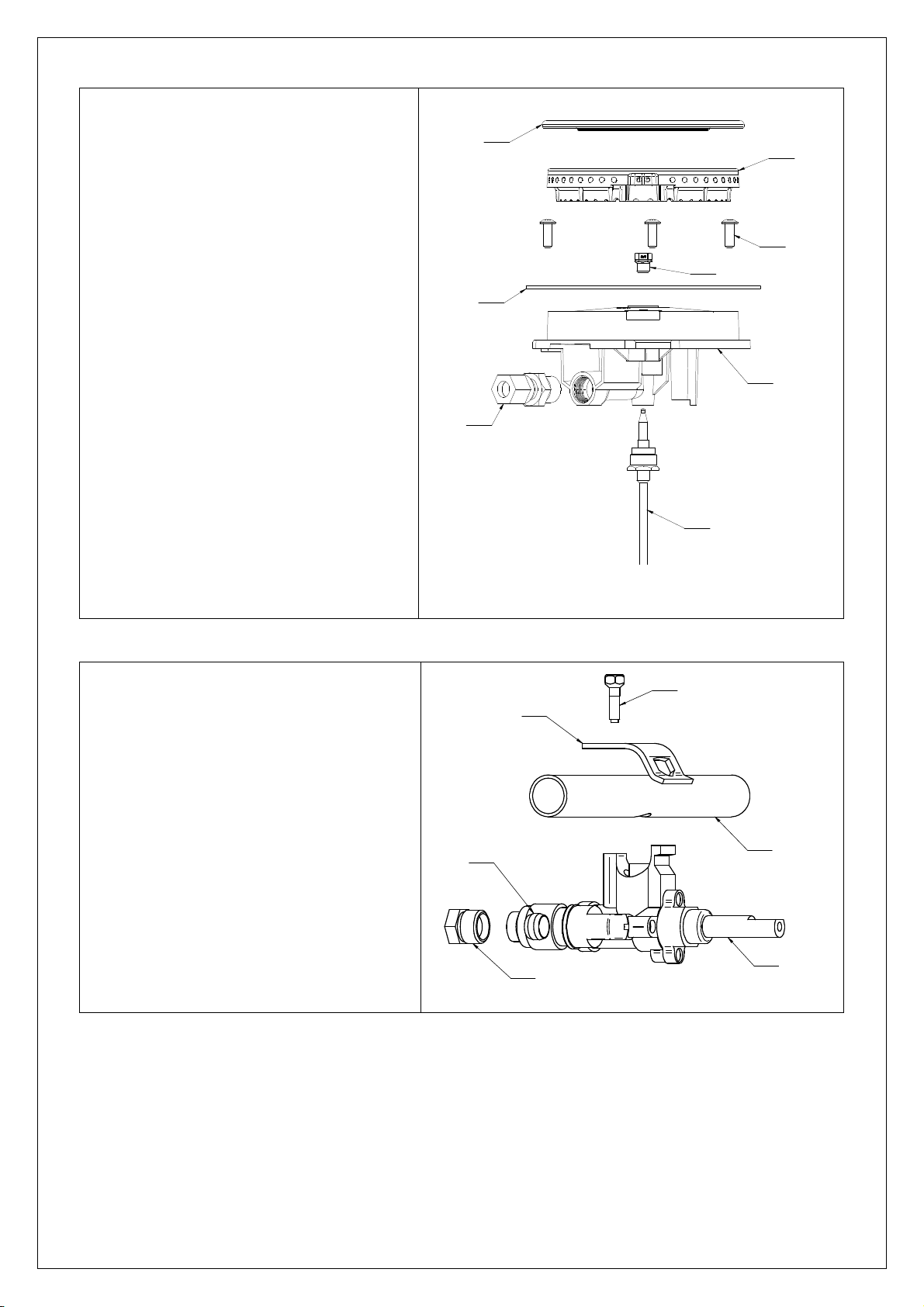

Hob Burner Components

Isolate the gas supply to the appliance

To replace the burner and its parts:

Remove the burner cap 'BU09'

Remove the burner head 'BU08'

Remove the 3 screws 'FAS601

Remove the control knobs from the valves

Remove the fascia panel

Loosen the burner feed pipe connection

nut on 'CO15'

Loosen the thermocouple nut 'TC01'

connection at the corresponding valve

Remove the burner body 'BU07' and the

gasket 'FAS351'

Remove the injector 'JExx' (dependent on

gas type) from the burner body

Remove the thermocouple 'TC01' from the

burner body

Remove the remaining section of the

'CO15' from the burner body. Note: When

replacing CO15 a suitable gas tight

thread sealant must be used

Replace and reassemble any or all parts

as applicable

Reconnect the gas supply

Perform leak test to prove integrity of

joints

Valve Components

Isolate the gas supply from the appliance

To remove the valve and its parts:

Remove the control knobs

Remove the fascia panel

Loosen the thermocouple 'TC01' nut at the

valve body 'VA10'

Loosen the burner feed pipe nut 'BU159' at

the valve

Remove the valve clamp screw 'BU209'

Lift the valve clamp 'BU208' from the valve

and the manifold 'MAxx' (dependent on

appliance)

Free the valve from the manifold

Replace and reassemble parts as

necessary

Reconnect the gas supply

Perform leak test to prove integrity of joints

MAxx

VA10

BU158

BU159

BU208

BU209

Fig 2

Fig 3

TC01

CO15

JEXX

FAS601

BU08

BU09

FAS351

BU07

IS 514 ECN 3706 Page 12 of 20

Oven Burner Components

Ignitor Electrode

To remove the ignitor (IG16) electrode remove the lead from the electrode

Remove the retaining screw FAS360 and nut FAS016

Replace the ignitor, secure and refit the lead

Thermocouple

Loosen the lock nut at the tip side of the thermocouple (TC33) and withdraw from the burner

bracket

Remover the control knobs and fascia panel

Loosen the thermocouple nut at the thermostat

Bind the new thermocouple thermostat end to the tip of the old thermocouple and gently feed old

and new through into position

Remove the binding and the old thermocouple

Make good the thermocouple connection at the thermostat

Lock the thermocouple head to the burner bracket to the dimensions details. See thermocouple

setting

Oven Burner

Isolate the gas supply from the appliance

Remove the thermocouple and ignitor electrode

Remove the burner injector ( see Gas Conversion)

Remove the burner retaining screws

Replace the new burner and refit parts

Reconnect the gas supply

Check joints for leak free integrity

F A S 6 0 9

B U x x

F A S 6 3 0 IG 1 6

T C 3 3

J E x x

W A 1 3

C O 1 3 3

F A S 0 1 6

Fig 4

IS 514 ECN 3706 Page 13 of 20

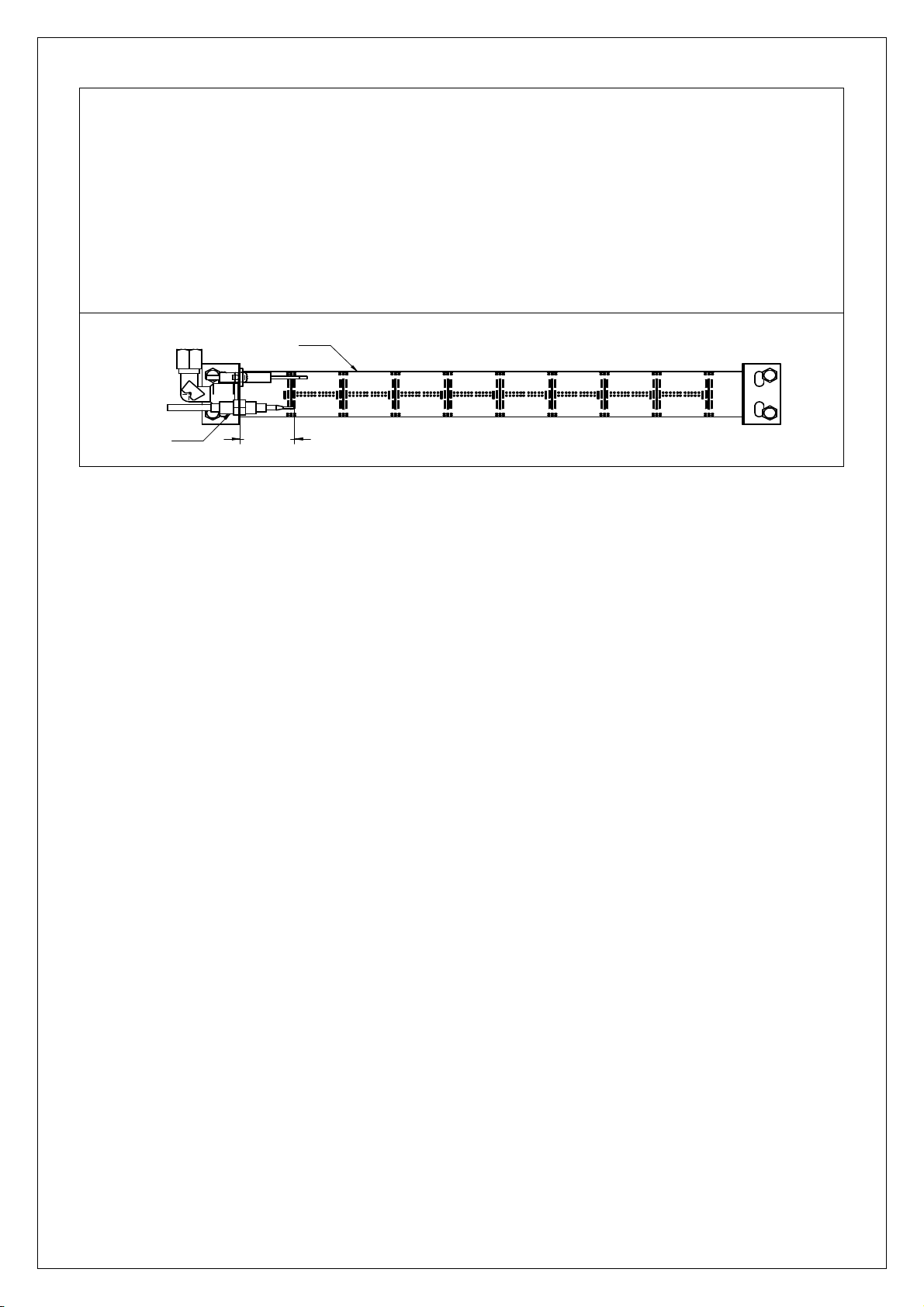

Thermocouple Setting

To correctly position the thermocouple the lock nuts will require setting on the barrel of the

thermocouple body

Feed the replaced thermocouple as detailed above

Position the thermocouple as detailed below and to the dimension given

Lock the thermocouple into place

Light the oven burner and set the thermostat to approximately 190

o

C

Allow the oven to reach temperature with the doors shut and turn the thermostat to the lowest

setting (1301

o

C)

Check that the flame remains established at the burner

If the flame at the burner at the lowest setting drops out minor adjustments may be necessary to

maintain the flame

38 ±1

TC 33

BUxx

Fig 5

IS 514 ECN 3706 Page 14 of 20

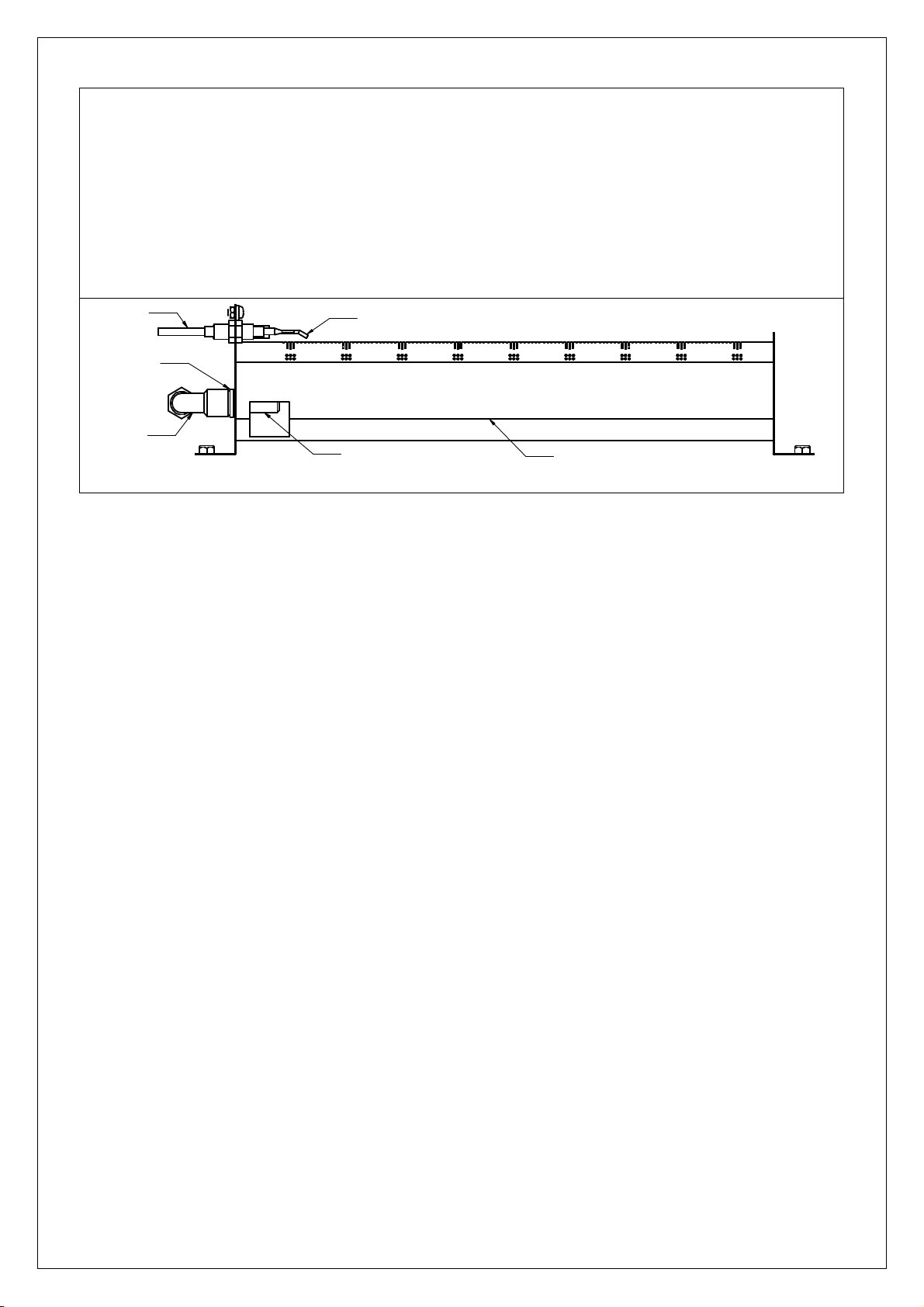

Thermostat Replacement

Isolate the gas supply to the appliance

To replace the thermostat remove the control knobs and fascia panel

Supporting the thermostat body and loosen the thermostat feed nut TH17C

Loosen the clamp screw FAS150 and lock nut FAS033 sufficiently to free the thermostat

brackets TH17k and TH17L

Free the thermostat TH17A from the manifold Maxx

Free the thermocouple TC33 from the thermostat body

Free the thermostat bulb from the oven cavity bracket (remove oven shelves to ease

access)

Feed the thermostat bulb and capillary through the top of the oven cavity liner

Withdraw the thermostat

Connect the thermocouple to the new thermostat

Fit the new thermostat to the manifold and secure ensuring the seal is fitted to the saddle

of the thermostat

Carefully unwind the capillary and feed the thermostat bulb through the top of the liner and

reset the bulb in its bracket. Ensure all capillary slack is fed back above the top liner

Make good the gas feed connection nut to the thermostat.

Reconnect the gas supply

Check joints for leak free integrity

Refit the fascia panel and control knobs

Check the low flame function of the oven burner as detailed in thermocouple setting

TH17A

MAxx

TC33

TH17C

TUxx

FAS150

FAS033

TH17K TH17L

Fig 6

IS 514 ECN 3706 Page 15 of 20

Hob Burner Injector Changes

Model Gas Inlet

Pressure ∅

∅∅

∅Mark Part Number

All

G20

20mbar

1.64

164

JE155

G30

28

-

30mbar

0.98

98

JE157

G31

37mbar

1.10

110

JE156

Oven Burner Injector Changes

Model Gas Inlet

Pressure ∅

∅∅

∅Mark Part Number

SLR6

G20

20mbar

1.90

190

JE107

G30

28

-

30mbar

1.25

125

JE109

G31

37mbar

1.25

125

JE109

SLR9

G20

20mbar

2.40

240

JE50

G30

28

-

30mbar

1.50

150

JE51

G31

37mbar

1.50

150

JE51

Burner Injector

The burner injector is fitted to the base of

the burner body

Remove the burner cap 'BU09'

Remove the burner head 'BU08

Access to the burner injector 'JExx' is

through the venturi to the base of the burner

body 'BU07'. To remove un-screw by

turning anticlockwise

The correct size of the injector appertaining

to gas type is marked on one of the

hexagonal faces of the injector.

Replace with the correct injector applicable

to gas type and reassemble burner parts

BU09

BU08

JExx

BU07

Hob Burner Bypass Injector Adjustment

Remove the control knobs

Adjustment for conversion from Natural gas

to Propane or Butane:

Rotate the bypass injector clockwise full

home, do not over tighten.

Replace the control knobs

Adjustment for conversion from Propane or

Butane to Natural gas :

Ensure the bypass injector is fully home, do

not over tighten

Rotate the bypass injector between 1/3 to

1/2 of a turn anticlockwise

Replace the control knobs

CONVERSION

Fig 7

Fig 8

IS 514 ECN 3706 Page 16 of 20

Oven Burner

To replace the oven burner injector

Loosen the nut on the feed elbow CO133

Free the elbow and injector from the burner BUxx

Free the injector JExx from the elbow

Replace the injector applicable to the gas type with the washer WA13 and tighten against

the elbow

Refit the injector assembly to the burner

Reconnect the elbow nut

Check joints for leak free integrity

CO133

WA13

JExx

TC33 IG16

BUxx

Replace gas specific labels for which the appliance has been converted

Replace data plate corresponding to gas type

Fig 9

IS 514 ECN 3706 Page 17 of 20

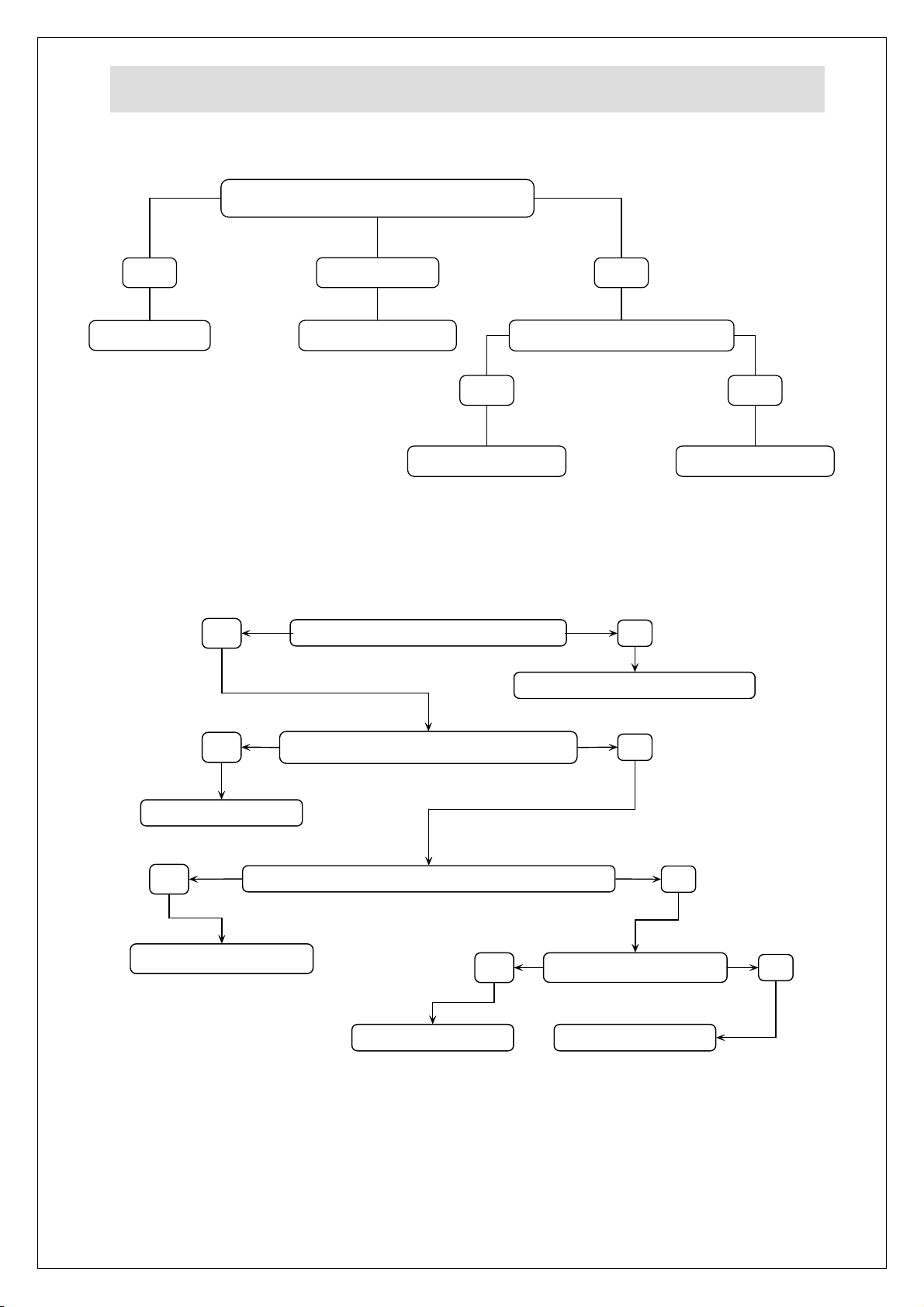

•Piezo oven ignitor not sparking

•Burner/s will not light or stay lit

FAULT FINDING

Check for a Short in High Tension Lead

Yes No

Replace Lead

Lead Detached

Reconnect Lead Check Electrode for Fracture

Yes No

Replace Electrode Replace Piezo Ignitor

Is There Gas at the Burner?

Yes No

Are Thermocouple Connections Loose?

Is the Thermocouple Voltage Less than 5mV?

Is the Valve Damaged?

Check Injector for Blockages

Tighten Connections

Replace Valve

Yes

Yes

Yes

No

No

No

Replace Thermocouple

Recheck System

IS 514 ECN 3706 Page 18 of 20

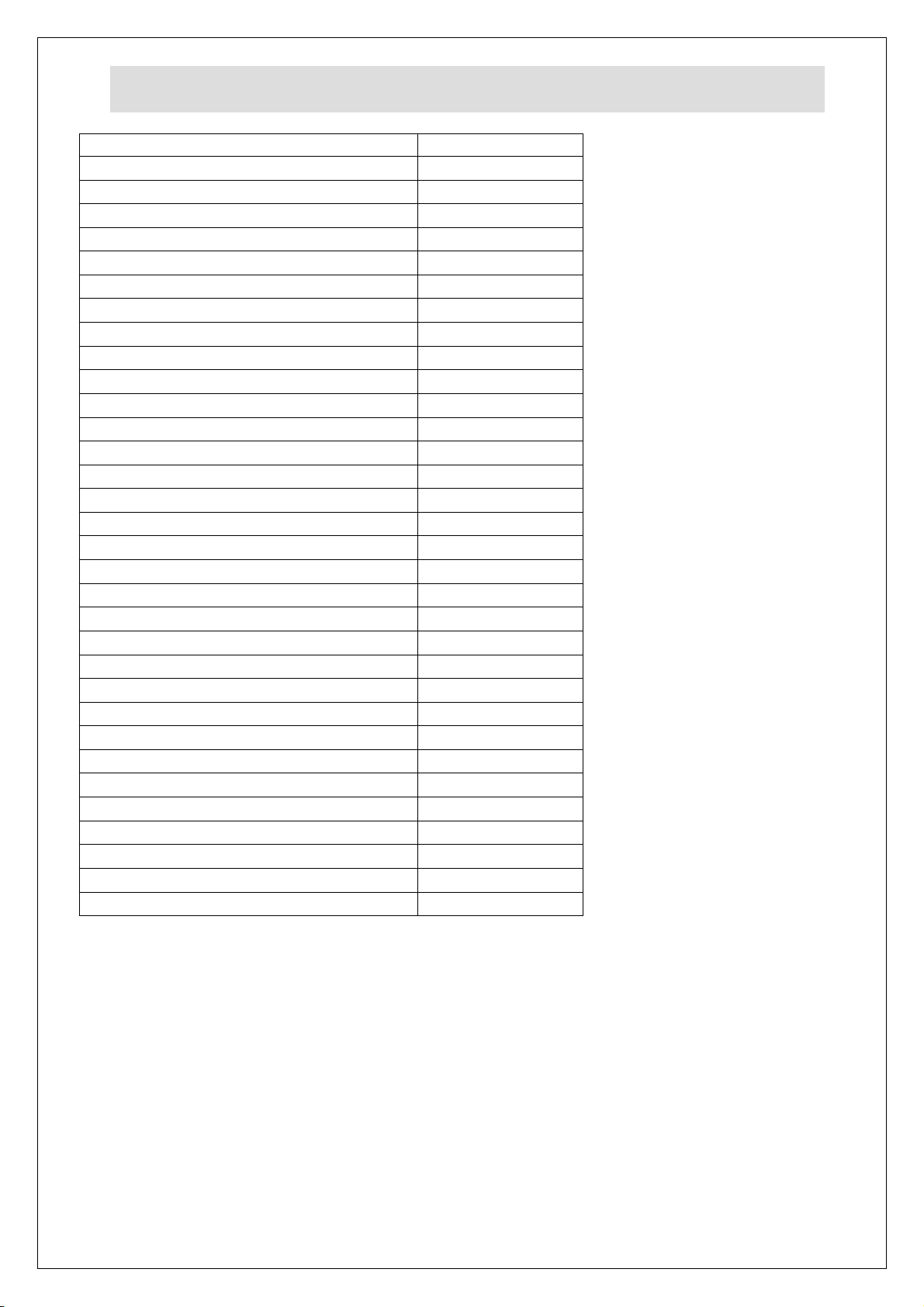

Description

Part number

Hob burner body BU07

Hob Burner head BU08

Hob burner cap BU09

Door bush BU55

Oven burner – SLR9 BU78

Oven burner – SLR6 BU86

Fixed castor CA86

Adjustable leg FE29

Piezo ignitor IG12

Ignitor electrode IG16

Ignitor lead IG18

Manual of Instruction IS08

Oven injector (Natural) SLR6 JE107

Oven injector (Propane) SLR6 JE109

Oven injector (Butane) SLR6 JE109

Hob injector (Natural) JE155

Hob injector (Propane) JE156

Hob injector (Butane) JE157

Oven injector (Natural) SLR9 JE50

Oven injector (Propane) SLR9 JE51

Oven injector (Butane) SLR9 JE51

Thermostat control knob KN191

Hob control knob KN196

Pan support PA25

Oven shelf SLR6 SH87

Oven shelf SLR9 SH88

Side rack ovens SR11

Hob thermocouple TC01

Oven thermocouple TC33

Thermostat (complete) TH17

Hob Valve (complete) VA10

Copper Washer WA13

SPARE PARTS LIST

IS 514 ECN 3706 Page 19 of 20

Part Number

Description

Used on

ACCESSORIES

This manual suits for next models

3

Table of contents

Other First Choice Oven manuals

Popular Oven manuals by other brands

Whirlpool

Whirlpool sb100pes3 Installation instruction

Lebensstil Kollektion

Lebensstil Kollektion LKSO-2801WD instruction manual

Ovention

Ovention Double MiLO2-16 Installation and operating manual

Whirlpool

Whirlpool SBIOOPED Use and care guide

Cuisinart

Cuisinart TOB-60C Series INSTRUCTION AND RECIPE BOOKLET

Thermador

Thermador Pro Harmony PA30GLBH Installation