First Degree Fitness E820A User manual

USER GUIDE

E820A

2

3

Introduction

WARNING

Do not remove hands while crank is in motion. The crank will continue to rotate and could

cause injury.

Congratulations on your purchase of E820A.

FIRST DEGREE FITNESS is proud to present the Rower as a FULL COMMERCIAL USE

product featuring patented Adjustable Fluid Resistance.

As with any piece of fitness equipment, consult a physician before beginning your E820A

exercise program.

Follow all instructions carefully for correct assembly, Tank filling, water treatment,

service and safety.

Access to our world-wide distributor and service network is available at

www.firstdegreefitness.com

Check contents of Box 1 and Box 2 to ensure all parts are present and correct prior to

assembly.

Training with the E820A

4

Contents

Safety ................................................................................... 5

Assembly ............................................................................... 7

E820A Box 1 & Box 2 Contents................................................ 8

Assembly Instructions ............................................................. 9

Operation Instructions 13

Bluetooth Auto-Adjust Monitor............................................... 16

Calibration Procedure ........................................................... 17

Maintenance & Troubleshooting 18

Tank Belt Adjustment 20

International Warranty........................................................... 21

5

Safety

Safety Information

•Before using this product, it is essential to read this ENTIRE operation manual and

ALL instructions. The Rower is intended for use solely in the manner described in this

manual.

•UNDERSTANDING EACH AND EVERY WARNING TO THE FULLEST IS IMPORTANT

•As with any piece of fitness equipment, consult a physician before beginning your

Rower exercise program.

•Please be aware that any fitness regiment, before being undertaken, is best preceded

by a physical checkup from a certified physician.

•Injuries to health may result from incorrect or excessive training.

• WARNING Heart rate monitoring systems may be inaccurate. Over exercise may

result in serious injury or death. If you feel faint, stop exercising immediately.

•Do not allow children unattended access to the machine.

•Please keep hands away from moving parts, as indicated by the warning label on the

Main Frame of your machine.

•If any of the adjustment devices are left projecting, they could interfere with the

user’s movement.

•Do not store in freezing conditions with water in the Tank as it can expand and crack

the components.

Installation

•Place on a stable, flat surface in a horizontal position during use for maximum

stability.

•Check regularly and follow all instructions for maintenance as specified in this manual.

•Replace immediately any defective parts and do not operate unit until all repairs are

complete.

6

Safety

Proper Usage

• Do not use any equipment in any way other than designed or intended by the

manufacturer. It is imperative that FIRST DEGREE FITNESS equipment is used

properly to avoid injury.

• Injuries may result if exercising improperly or excessively. It is recommended that all

individuals consult a physician prior to commencing an exercise program. If at any time

during exercise you feel faint, dizzy or experience pain, STOP EXERCISING and consult

your physician.

• Keep body parts (hands, feet, hair, etc.), clothing and jewelry away from moving parts

to avoid injury.

• Follow instructions provided in this manual for correct foot position and basic rowing

techniques.

• For more detailed rowing techniques, please refer to our International website

www.firstdegreefitness.com

Inspection

• DO NOT use or permit use of any equipment that is damaged and/or has worn or broken

parts. For all FIRST DEGREE FITNESS equipment use only replacement parts supplied by

FIRST DEGREE FITNESS.

• EQUIPMENT MAINTENANCE - Preventative maintenance is the key to smooth operating

equipment as well as to keep your liability to a minimum. Equipment needs to be

inspected at regular intervals.

• Ensure that any person(s) making adjustments or performing maintenance or repair of

any kind is qualified to do so.

• DO NOT ATTEMPT TO USE OR REPAIR ANY ACCESSORY APPROVED FOR USE WITH THE

FIRST DEGREE FITNESS EQUIPMENT WHICH APPEARS TO BE DAMAGED OR WORN.

• Check regularly and follow all instructions for maintenance as specified in this manual.

• Replace immediately any defective parts and do not operate unit until all repairs are

complete.

Operating Warnings

• Keep children away from the equipment. Parents or others supervising children must

provide close supervision of children if the equipment is used in the presence of children.

• Do not allow users to wear loose fitting clothing or jewelry while using equipment. It is

also recommended to have users secure long hair back and up to avoid contact with

moving parts.

• All bystanders must stay clear of all users, moving parts and attached accessories and

components while machine is in operation.

• WARNING Do not insert fingers into Tank!

7

Assembly

Live area and Training area

Product Specifications

Product Class: SC

Braking System: Speed Independent

Product Net Weight: 84.6kg (186.12lb)

Product Gross Weight: 107kg (235.4lb)

Maximum Safe Operating Surface Area: 276cm (108.66”) Length x 222cm (87.40”) Width

Dimensions: 1560mm (61.42”) Length x 1020mm (40.16”) Width x 1400mm (55.12”) Height

Maximum User Weight: 150kg (330lb)

Footprint:2160mm x 1620mm or upright 1400mm x 1020mm

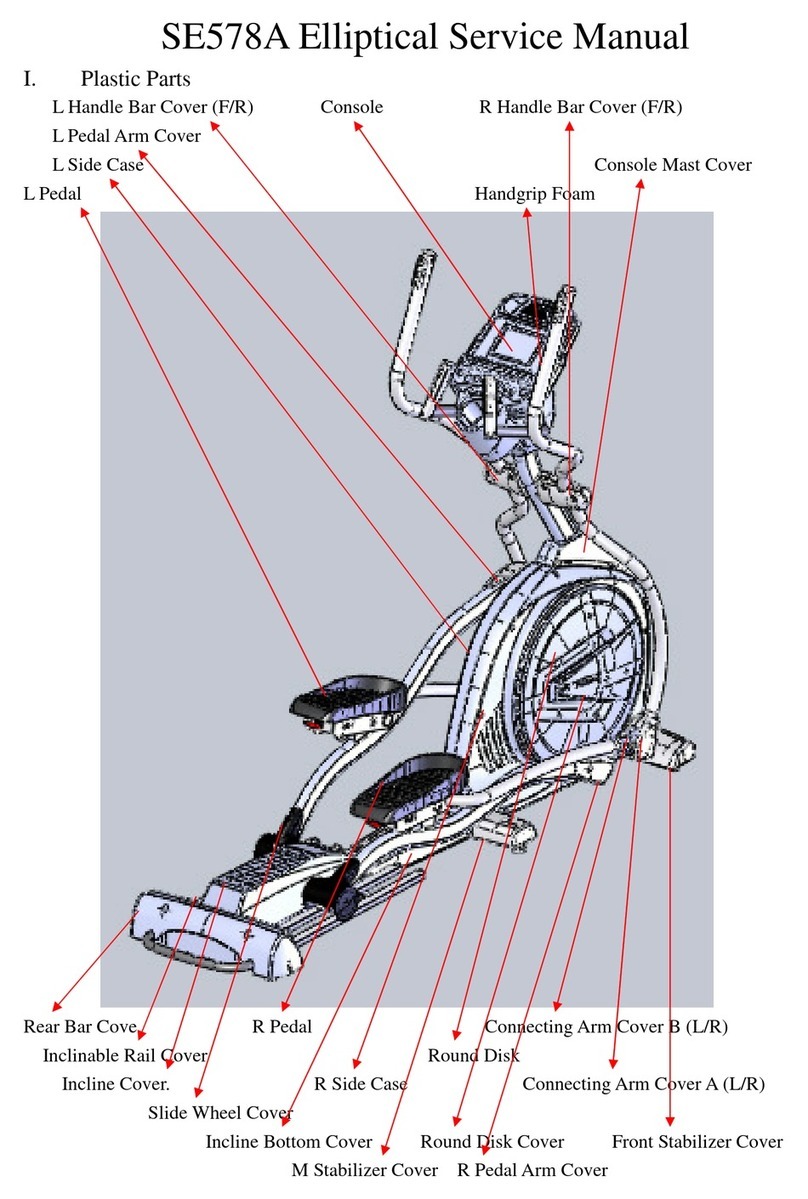

Product Highlights

Seat Frame

Main frame

Telescoping tube / gas assisted shock

Complete Platform

Control Arm

10 x fluid Force

-massive range

Of resistance at

The turn of a lever

Auto-level, Bluetooth

monitor - real time

power in watts per

repetition

8

E820A Box 1 & 2 Contents

Item Qty.Description Item Qty. Description

1 1 Main Frame with Telescoping Tube

and Internal Gas Assist Shock 7 9 Foot Levelers

2 1 Baseplate 8 1 Multi-tool

3 1 Seat Frame 9 1 Touch up paint

4 1 Seat Back 10 2 D Cell Duracell Battery

5 1 Lower Seat 11 1 Funnel and Hose

6 1 Right pedal 12 1 Owners Manual

Hardware KIT

13 1 Handle Bar & Dome Nut 19 8 M6 Washer

14 8 M6x20mm Bolt 20 3 M10 Washer

15 4 M8x15mm Bolt 21 4 M8 Springs Washer

16 8 M8x45mm Bolt 22 1 4mm Allen Key

17 3 M10x20mm Bolt 23 1 6mm Allen Key

18 2 M10 Nyloc Nut 24 4 Water Treatment Tablets

9

Assembly Instructions

8

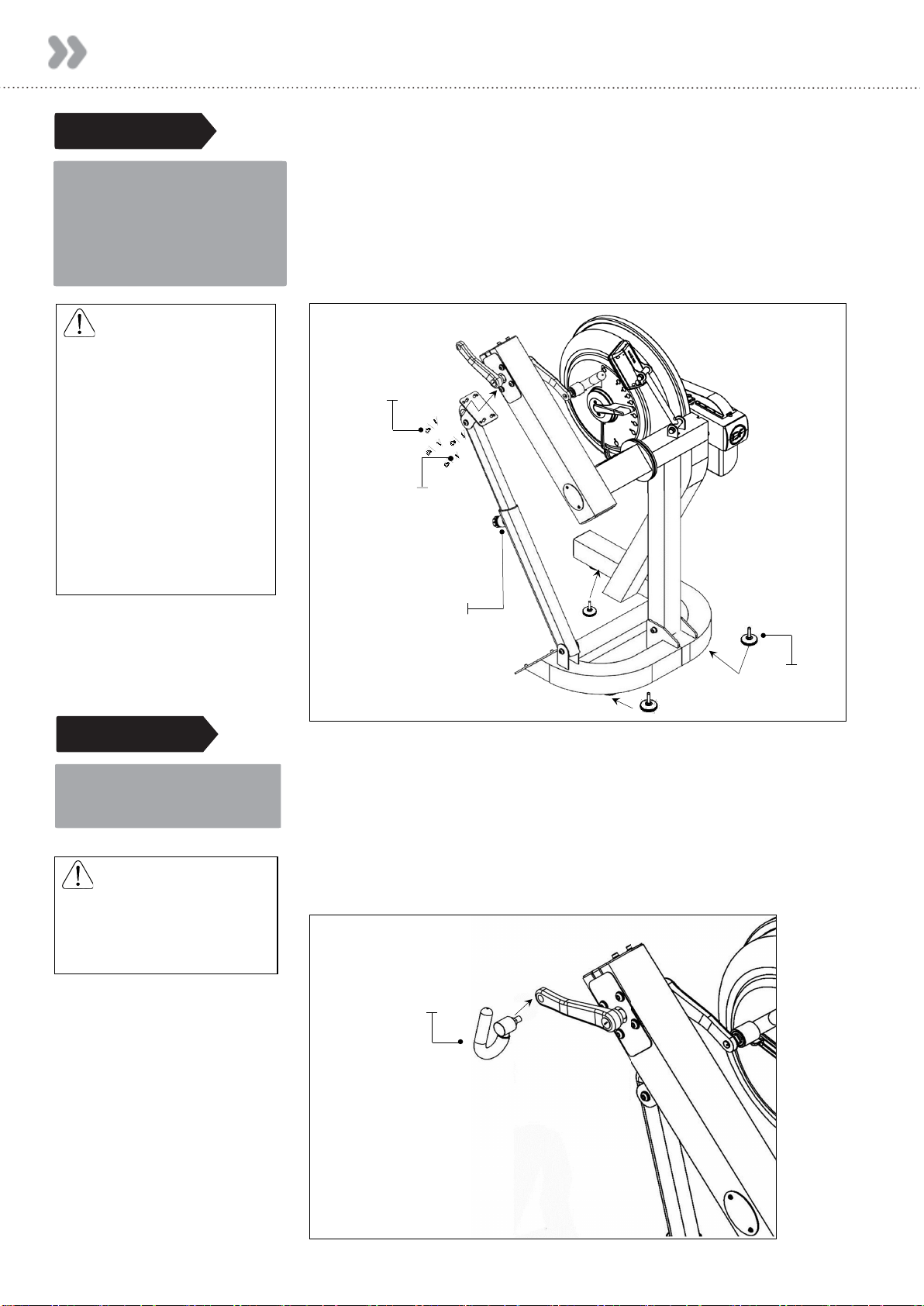

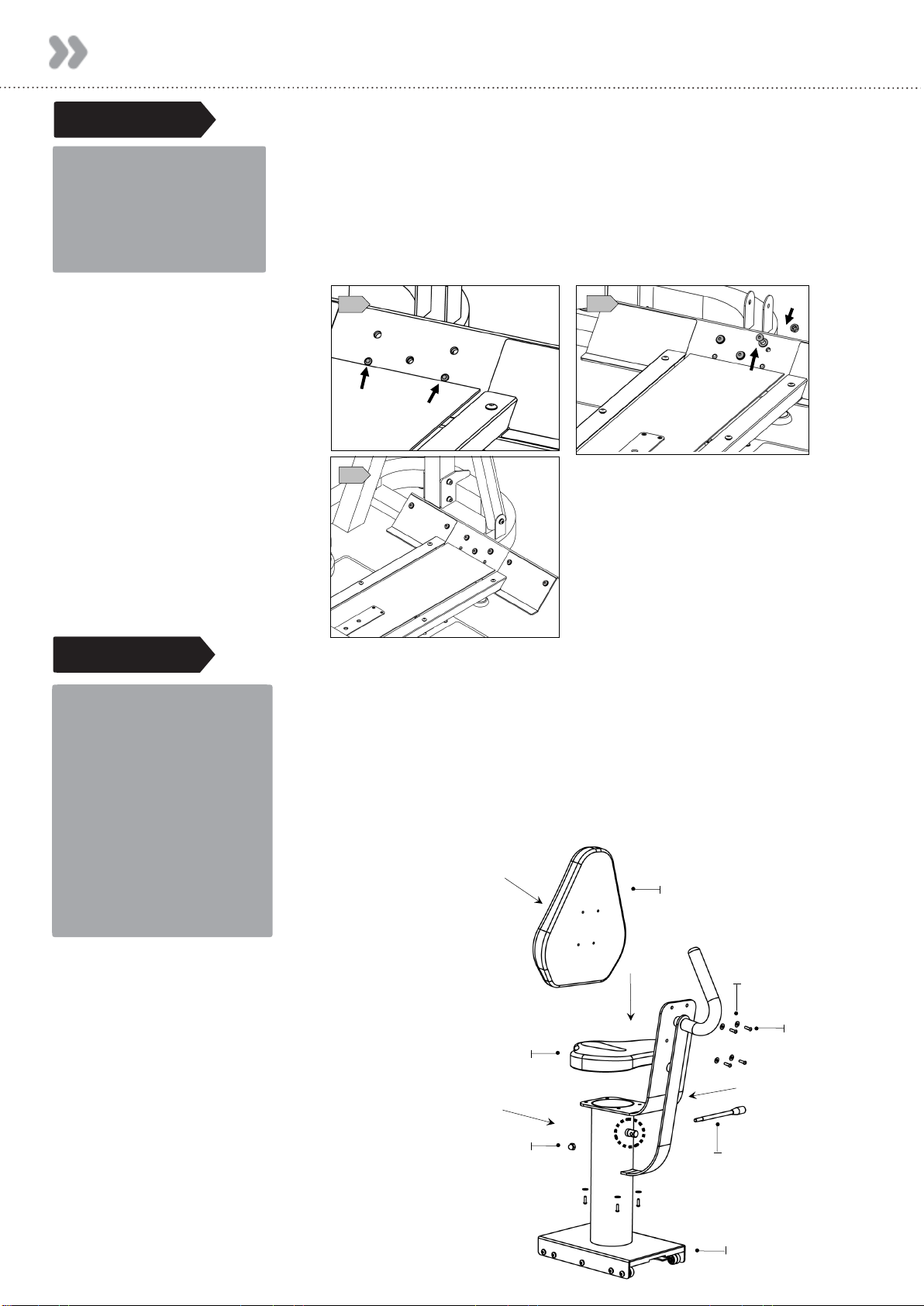

STEP 1 Main Frame Assembly Instructions

a) Attach Telescoping Tube to the underside of the

control arm using 4xM8x15mm Bolts[15] and 4x M8

Spring Washers[21].

b) Thread the 3xFoot levelers[7] into underside of base.

Adjust as required.

2

1

12

REQUIRED

4 x M8 x 15mm Blots [15]

4 x M8 Spring Washers [21]

3 x Foot Levelers[7]

1

REQUIRED

Right Pedal [6]

STEP 2

a) Secure Right Pedal [6] onto Crank arm. The pedal threads

have a blue coating which will feel very tight when threaded

onto the crank arm. This is a type of thread locker, and

once in contact with the crank arm threads will activate in

approximately 15minutes.

CAUTION

The control arm is heavy

and may swing freely during

this stage of assembly.

The Adjuster Knob is

pre-tightened from the

factory in the optimal

position for assembly in

relation to the control arm.

Do not loosen the Adjuster

knob until the Telescoping

Tube has been safely

secured to the underside

M8 Spring Washers

Adjuster Knob

Foot Leveler

M8x15mm Bolts

2

CAUTION

Extreme over-tightening

could damage the aluminum

threads on the crank arm.

Note: Allow 15 minutes for the thread

locker to activate before first time use.

Check pedal tightness periodically

thereafter with a 15mm wrench.

Right Pedal

Crank Arm Assembly Instructions

10

Assembly Instructions

b) Mount the Left Channel over the top of the footplate

dome Bolts and then slide forward. Once Channel is

properly positioned, attach to T-Track using

4x M8x45 mm Bolts[16]. Repeat this procedure to

install Right Footplate and Channel.

STEP 3 Installing the Baseplate

a) Tilt the T-Channel slightly to allow the footplate (with

pre-installed Bolts) to slide underneath as shown.

8

2

1

12

REQUIRED

T-Track

Channel Right

Channel Left

2 x Footplate

8 x M8x45mm Blots [16]

Foot Leveler [7]

Footplate T-Track

2

1

Left

Channel

Slide Channel

forward

1

Channel Slot

2

3

8x45mmBolts

4

c) Stand Baseplate upright to install 6x Foot Leveler[7]

as shown. Once foot levelers are installed, the

completed Baseplate can be installed onto the Main

Frame of the E820.

Footplate

Channel Left

Footplate

Channel Right

T-Track

1

Completed Baseplate

1

2

11

Assembly Instructions

STEP 4 Installing Baseplate to the Main Frame

2

1

REQUIRED

3 x M10x20mm [17]

2 x M10 Nylock Nut [18]

3 x M10 Washer [20]

a) Mount the baseplate onto the Main Frame using

mounting pins as a locator

Then, secure with 3x M10x20mm Bolt[17], 2x M10

Nylock Nut[18] and 3x M10 Washer[20].

Note : Center M10 Bolt does not require Nut.

1

2

3

STEP 5 Seat Assembly and Installing Seat to the Main Frame

1

REQUIRED

Seat Frame [3]

Seat Back [4]

Lower Seat [5]

4 x M6x20mm Bolts [14]

4 x M6 Washer [19]

Handle Bar [13]

Dome Nut [13]

a) Thread the Handle Bar [13] through the Shaft

b) Tighten the Handle Bar [13] with the Dome Nut[13]

c) Install Seat Back[4] with 4x M6x20 Bolts[14] and M6

Washer[19].

d) Install Lower Seat[5] with 4x M6x20 Bolts[14] and M6

Washer[19].

b)

a)

c)

d)

Seat Frame

Handle Bar

M6 x 20 Bolt

M6 Washer

M10 Dome Nut

Lower Seat

Seat Back

12

Assembly Instructions

STEP 6 Installing Seat to the Main Frame

a) Seat Stop: Must be lowered to allow seat onto

Baseplate track. Must ALWAYS be in the LOCKED

position when seat is occupied on Baseplate. Must be

lowered to allow seat removal. To LOCK, raise and

locate. To UNLOCK, lift and drop rearward.

CAUTION

The Seat Stop Must be in

the locked position whenever

the seat is in use..

WARNING

Do not under any

circumstances attempt to

remove / install seat while

occupied.

b) Seat Installation: Tilt the seat slightly upward to allow

the front rollers to engage the channel. Then, lift the

rear level and, while engaging the Seat Lock Release

Lever, slide the seat onto the Baseplate as shown.

Usage: The seat has four positions. To move forward

or rearward, depress the Seat Lock Release Lever

and move freely to whichever position you require.

c) To remove the seat: Lift and lower the Rear Safety lock,

depress the Seat Lock Release Lever and slide the seat

rearward.

13

Operation Instructions

Chain Tensioning Bolts: Allows for tightening the Chain or adjustment from side to

side. Make sure when tightening only to adjust the same amount for both Bolts,

otherwise the sprocket will be misaligned.

Note: Tightening the right Bolt only will pull the right side of the crank assembly

toward you, tightening the left will pull the left side toward you. Use this feature to

realign the rear with the front sprocket if needed or when changing to a new chain.

E820 Control Arm

Crank arm Bolts: Loosen

all 8 Bolts slightly before

adjusting/tightening the

Chain. Inspection plate: Open to

check chain tension.

Warning: Do not check

chain tension by hand!

Adjuster Knob: Loosen to al-

low the Control Arm to travel

through 90 degrees of travel.

Note the Telescoping Tube is

gas assisted.

Tighten securely when desired

workout position is reached.

14

CAUTION

Use a drop cloth under

the Tank when filling to

avoid damaging to floor or

carpet.

Do not fill past the

calibration mark as

indicated on the Tank

level sticker or water

spillage may occur.

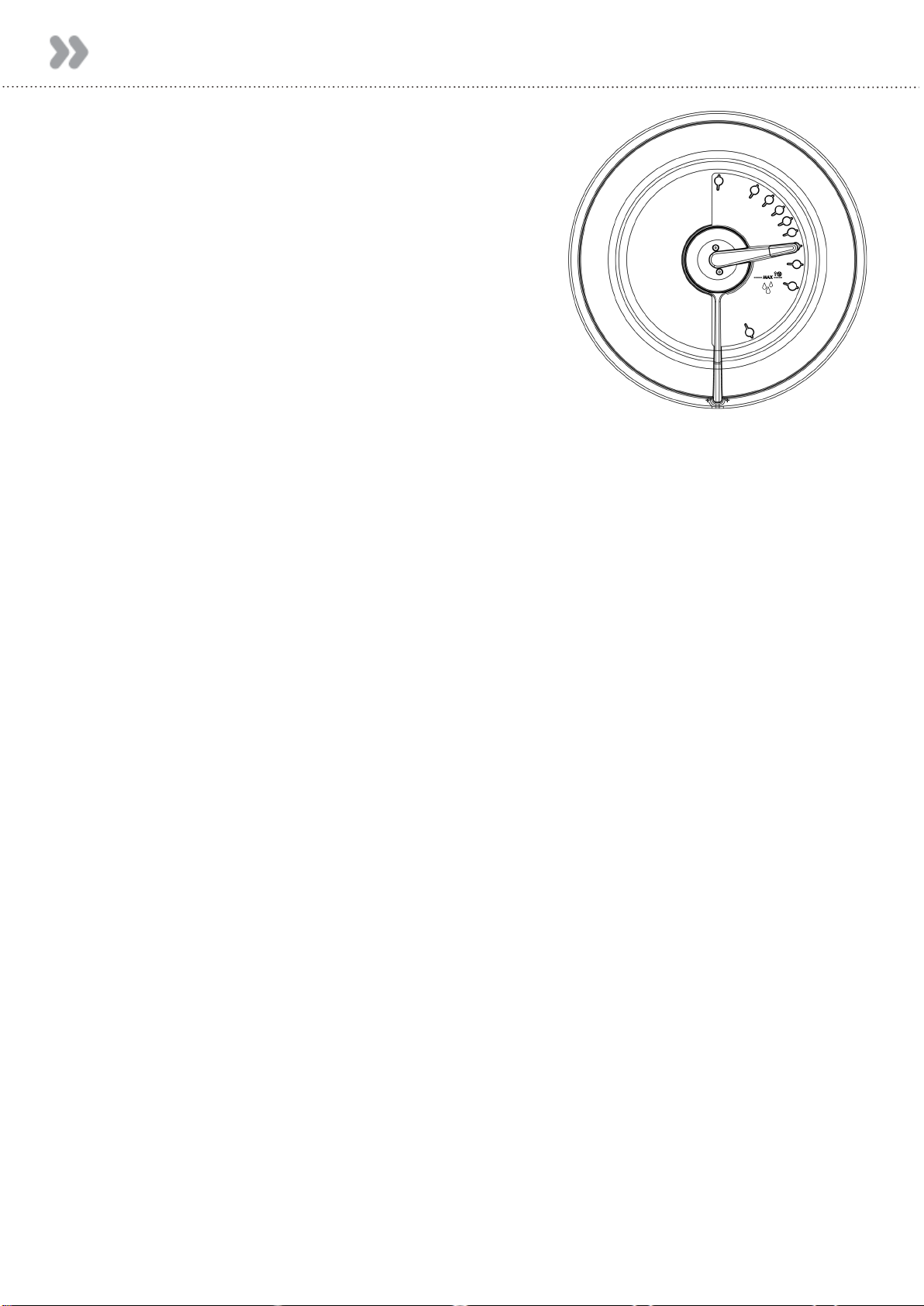

Tank Filling and Water Treatment

Operation Instructions

REQUIRED

Funnel and Hose[11]

a) Filling requires a large bucket (not supplied) and the

supplied water Funnel and Hose[11]. Filling will take

approximately 8 liters of water.

b) Open the yellow fill plug on the back of Tank and insert

hose (rotating the impeller slightly may be necessary

to allow the hose to pass). In areas where tap water

quality is known to be poor, FD F recommends the use

of distilled water.

c) Move the Tank adjuster handle to level 10 and begin

filling. Do not fill the Tank higher than the level

indicator on the front of the clear shell.

d) Once filling is complete follow the water treatment

schedule below.

INITIAL WATER TREATMENT

Add One Water Treatment Tablet per full Tank. Do NOT, UNDER ANY CIRCUMSTANCE,

USE A WATER TREATMENT TABLET OTHER THAN THOSE SUPPLIED WITH YOUR UNIT.

Your unit purchase includes 4xWater Treatment Tablets, which is sufficient for several

years of use.

To purchase additional Water Treatment Tablets, please consult your nearest regional

dealer/distributor or check our website at www.firstdegreefitness.com

WARNING

Impeller blades are sharp!

Do not Place fingers in

Tank to adjust impeller

position.

It is recommended to use

the end of the hose should

the impeller require

adjustment

CAUTION

In areas where tap water

quality is known to be

poor, FDF recommends

the use of distilled water.

NOTE: For simple, fast and efficient filling and/or drainage of the Fluid Tank, we have a

battery operated pump (rechargeable via USB) available as an option. We recommend

this to any commercial facility, with multiple units, that has a need to drain and refill

Tanks from time to time. To purchase, contact your nearest First Degree Fitness

distributor or go to our website on www.firstdegreefitness.com for details.

Note: The Lower Black Tank Plug is Permanently Sealed.

Orange Tank Plug

Water Funnel

and Hose

supplied with

unit

15

Operation Instructions

CHANGING RESISTANCE LEVEL

Changing resistance on your Unit is simple. The level

of resistance is determined by the level indicator lo-

cated on the front of the Tank. Level one indicates

lightest resistance, level ten represents heaviest

resistance. The Tank’s variable fluid resistance

technology ensures an instant catch and constant

resistance throughout the movement.

Your Unit computer will automatically adjust to the

resistance level selected on the Tank. Allow three to

four seconds after adjusting resistance handle for

the correct resistance level to be achieved.

LONG-TERM WATER TREATMENT

WARNING: DO NOT USE ANY OTHER WATER TREATMENT TABLET OTHER THAN THOSE SUPPLIED WITH

YOUR UNIT.

The amount of time between water treatments can vary greatly depending on your

unit’s location and exposure to sunlight. Typically you can expect to treat your Tank

water every 12-24 months. If water becomes discolored or shows signs of algae /

bacterial growth simply add one Water Treatment Tablet.

16

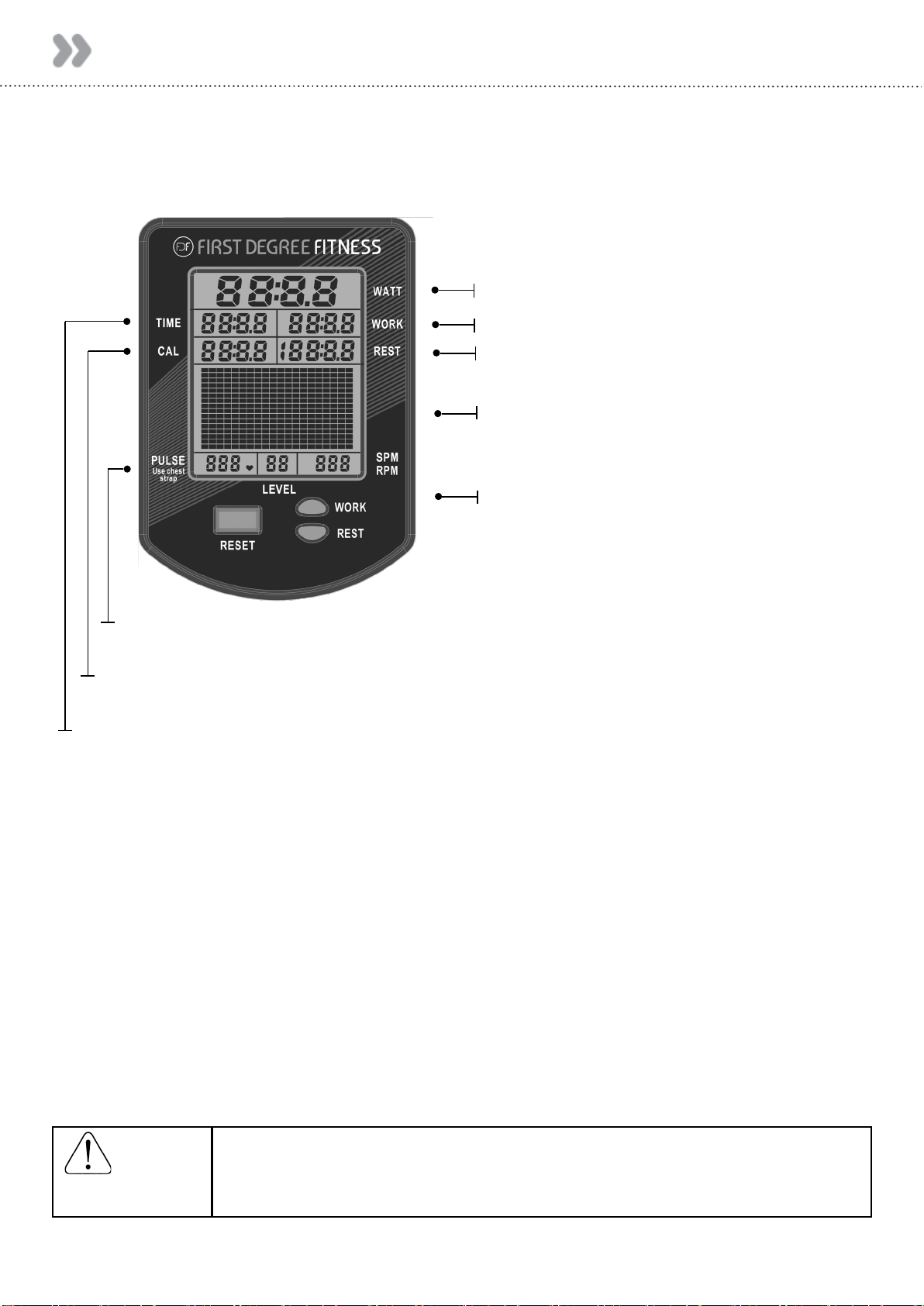

Bluetooth Auto-Adjust Monitor

Auto Start: Commence exercise to activate.

Reset all values: Press and hold RESET button for 3 seconds.

Auto Power Down: Over 5 minutes. All values revert to zero after restart.

WARNING:

Heart rate monitoring systems may be inaccurate, Over exercising

may result in serious injury or death. If you feel faint stop exercising

immediately and seek professional medical advice.

NOTE: Heart Rate Transmitter Chest Strap is sold separately.

WATT: Measures peak power in watts, calculating the strength and acceleration provided to accurately

measure a user’s power.

TRAINING DATA: Data gathered from each workout is displayed in a power curve and cumulative power

graph, enabling real-time comparisons for effective progressive training.

AUTO ADJUST LEVEL: Built in potentiometer automatically adjusts the computer’s resistance level

according to the position of the Fluid Force Lever on the Tank .

BLUETOOTH CONNECTIVITY: Each Unit is fitted with the most advanced console technology, enabling

Bluetooth connectivity with any compatible smart device. Designed to integrate with rowing and

fitness apps, the console will assist with effective training progression, capturing and comparing data

for the competitive individual. (Including FDF Power Zone APP available via FDF Website)

PULSE: Compatible with Polar Heart Rate Receiver and Transmitter Chest Strap.

WATT: Power measured in watts

WORK: Duration of exercise segment

POWER GRAPH: Press RESET to change display

from Power Curve to Cumulative Power Graph

LEVEL: Auto-level adjust to Fluid Force lever

CAL: Calories burned per hour at the current Watts. Shows total calories burned when exercise is

stopped.

REST: Duration of rest period

TIME: Auto start elapsed time.

17

Calibration Procedure

Press and hold 「RESET」and「REST」for 5 seconds.

Display will show “ - - - - “

Turn handle to Level 1.

Press Reset.

Display will now show Level 2.

Level 1 Calibration is complete.

Turn handle to Level 2.

Press Reset.

Display will now show Level 3.

Level 2 Calibration is complete.

Repeat for 3,4,5,6,7,8,9,10. Level 10

Press Reset.

Repeat the steps back to level 1.

Calibration is complete.

18

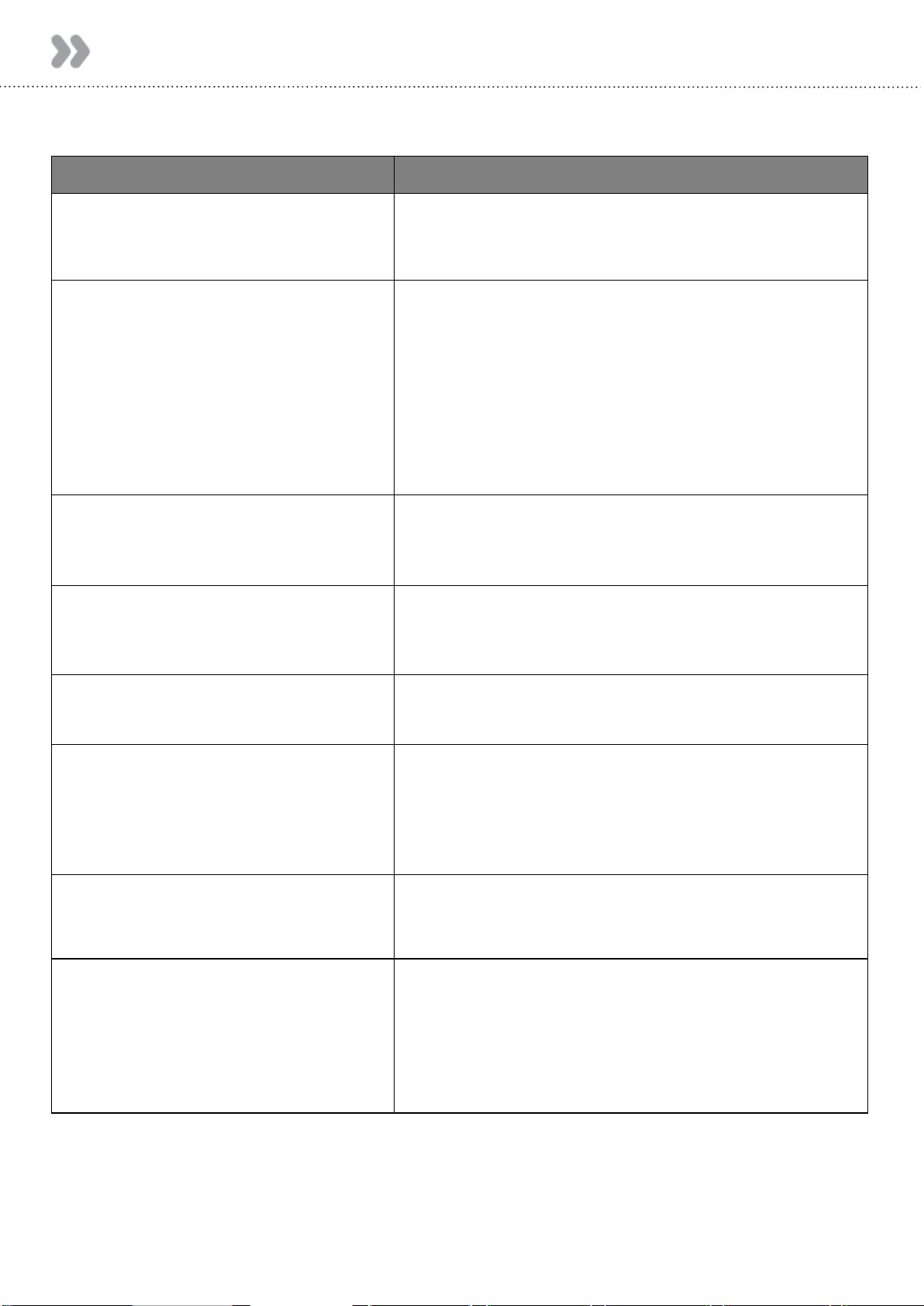

Maintenance & Troubleshooting

For further information, manuals and warranty requests visit

www.firstdegreefitness.com/support

Problem Solution

Water changer color or becomes cloudy. Change Unit location to reduce direct exposure to sunlight.

Add water treatment or change Tank water as directed in

the water treatment section of this manual. Consider

using distilled water to refill Tank.

I want to drain the fluid Tank on my

E820A.

It is recommended to take your unit outdoors, open the

Orange fill plug, and lay unit on its back to facilitate draining

process.

For simple, fast and efficient filling and/or drainage of the

Fluid Tank, we have a battery operated pump (rechargeable

via USB) available as an option. We recommend this to any

commercial facility, with multiple units, that has a need to

drain and refill Tanks from time to time. To purchase,

contact your nearest First Degree Fitness distributor or go

to our website on www.firstdegreefitness.com for details.

The computer display is erratic and

illuminates, but does not register with

movement.

It is possible that there is a loose connection. Check that the

computer lead is connected properly to the unit. If connected

properly check Sensor gap. Contact your local dealer if this fails

to address the problem.

The computer does not illuminate after

battery installation.

Replace/reinstall batteries in correct position and try again.

If the LCD screen fails to illuminate, try rotating the batter-

ies slightly in the computer.

If this fails, contact your local service center.

The Bluetooth Auto-Adjust Monitor LEVEL

is not synchronized with the Tank LEVEL.

Bluetooth Auto-Adjust Monitor LEVEL needs to be

recalibrated. Please refer to "Calibration Procedure"

page 17 of this manual.

Knocking noise from inside the control arm

while training, especially when changing

directions

Chain requires tightening or adjustment.

Open inspection plate located on front of control arm and

check tension using a screwdriver or other tool. Use the

chain tensioning Bolts located at the rear of the control

arm to tighten or adjust as needed. The chain should have

approx. 3mm of slack when properly adjusted. See P.13 for

details.

Pedal is loose (either left or right) and

cannot be retightened.

Aluminum crank arm threads are stripped.

Contact service center for replacement. Then check weekly

as recommended.

Pedals slip during hard training.

PK Tank belt requires tightening.

Remove large inspection plate next to the Tank, insert a

long tool to push the rear end cap out from the inside,

exposing the Tank belt tensioning Bolt. Loosen Tank Bolts

slightly. Remove upper rubber belt cover to expose the PK

belt. Tighten the Tank tensioning Bolt until the belt is too

tight to be twisted from side to side more than 45 degrees

by hand.

19

Maintenance & Troubleshooting

To ensure maximum lifespan and optimal performance follow these steps:

1. Keep your E820A in a dry, clean climate controlled environment at room

temperature.

2. Only treat water with FDF genuine Water Treatment Tablets. Refer to ‘water

treatment’ section on page 14.

3. Periodically clean your machine with disinfectant, applied using a lint free cloth.

4. Wipe dust off the machine.

5. For information on how to service your machine visit

firstdegreefitness.com/support

Item Time Frame Instructions

Seat and Frame. Weekly. Wipe down weekly with lint free cloth or more often with

heavy club use.

PK Belt Tension. Monthly. Check monthly for signs of slippage. Adjust/tighten as

required.

Tank and Water

Treatment. 12 months to 2 years. Follow instructions as specified in the “Water Treat-

ment” section of this manual.

Chain Drive.

Check every 100 hours for

correct

tension.

Open the inspection plate and check tension using a

screwdriver or other tool. Tighten as required using

chain tensioning Bolts located at the end of the control

arm.

Handle Assembly.

Check weekly using Multi-

Tool (supplied) to ensure

Handle Assembly is

securely tightened into

Crank Arm.

The handle should be checked on a regular basis.

Continued use of a loose Handgrip can cause

damage to the Crank Arm threads, necessitating

replacement.

20

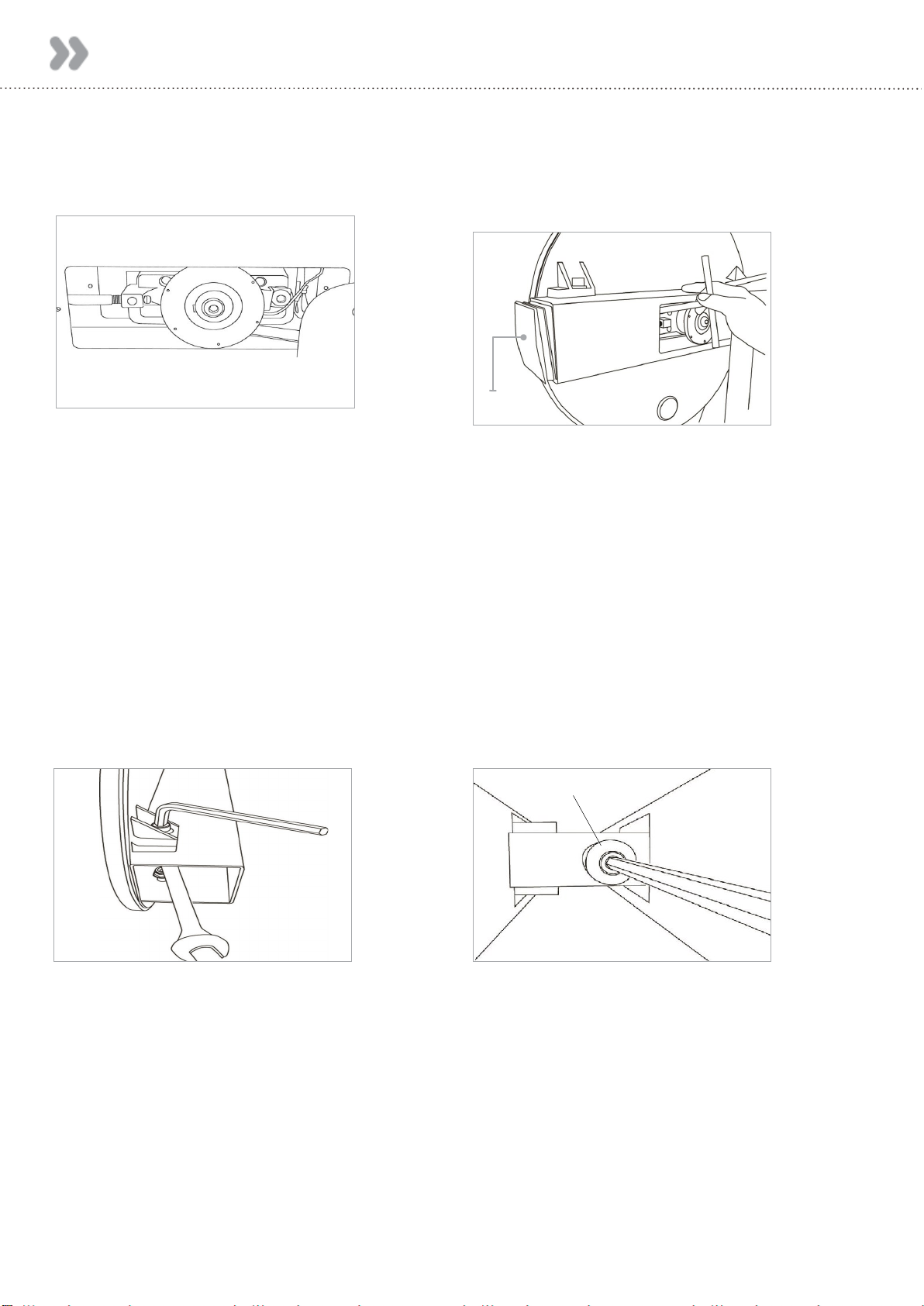

Tank Belt Adjustment

1. Remove large metal inspection plate. 2. Using a long tool, push out the rear

end cap as pictured below left. This

will give you access to the Tank

tensioning Bolt (shown lower right).

3. Loosen both the rear and front Tank

Bolts slightly as shown. Remove

front Rubber Belt Cover.

4. Using a 6mm Allen Key, tighten the

Belt using the Tank Tensioning Bolt

until the belt no longer slips during

hard rowing.

End Cap

Note: Do not over tighten Tank Bolts.

Tip: Twist the Belt by hand to gauge

tightness. Correct tension should be

obtained when no longer able to twist

more than 45 degrees

Tank Tensioning Bolt

Table of contents

Other First Degree Fitness Elliptical Trainer manuals

Popular Elliptical Trainer manuals by other brands

Gazelle

Gazelle GAZELLE POWER PLUS owner's manual

York Fitness

York Fitness Active 120 owner's manual

Xterra

Xterra EU150 owner's manual

Horizon Fitness

Horizon Fitness Endurance 4 owner's manual

NordicTrack

NordicTrack Cxt 1100 Elliptical Manuale d'istruzioni

NordicTrack

NordicTrack Audiostrider Cx650 Elliptical Gebruiksaanwijzing