Fisher & Paykel DishDrawer DS602I User manual

Other Fisher & Paykel Dishwasher manuals

Fisher & Paykel

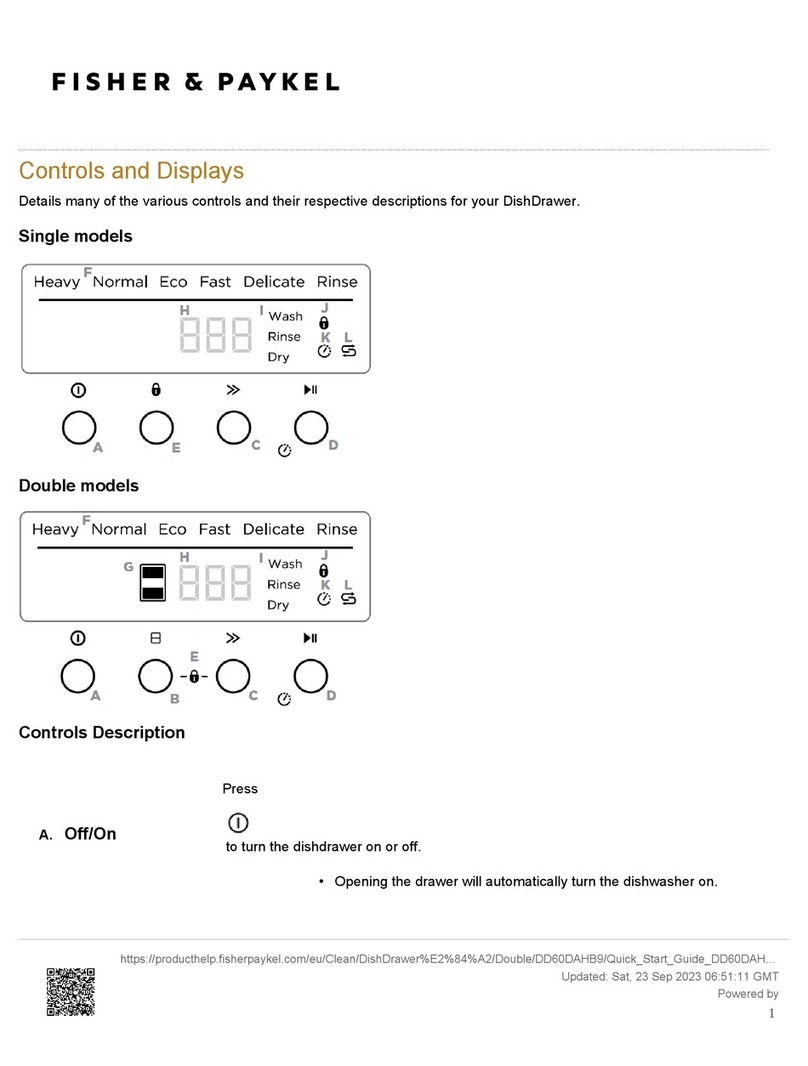

Fisher & Paykel DishDrawer DD60DA User manual

Fisher & Paykel

Fisher & Paykel DD60DAHB9 User manual

Fisher & Paykel

Fisher & Paykel SINGLE DISHDRAWER DD24SHTI User manual

Fisher & Paykel

Fisher & Paykel DishDrawer DD603 PREFINISHED User manual

Fisher & Paykel

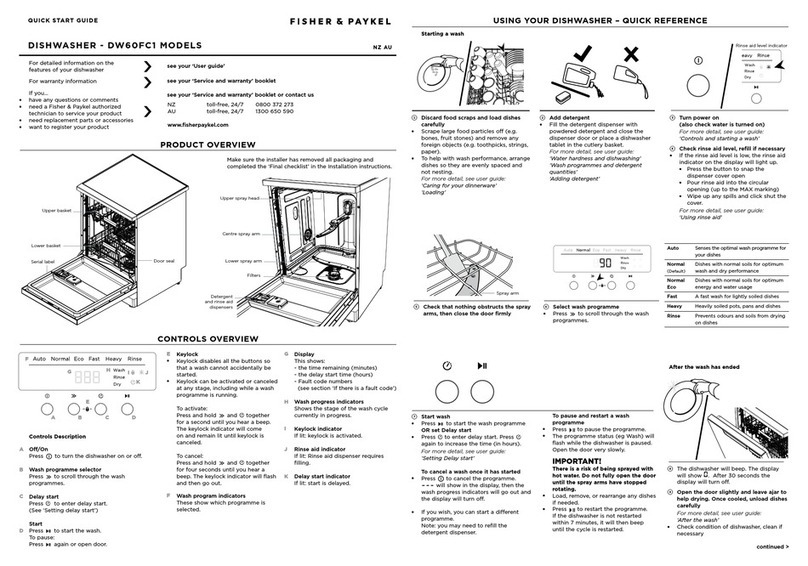

Fisher & Paykel DW60FC1 User manual

Fisher & Paykel

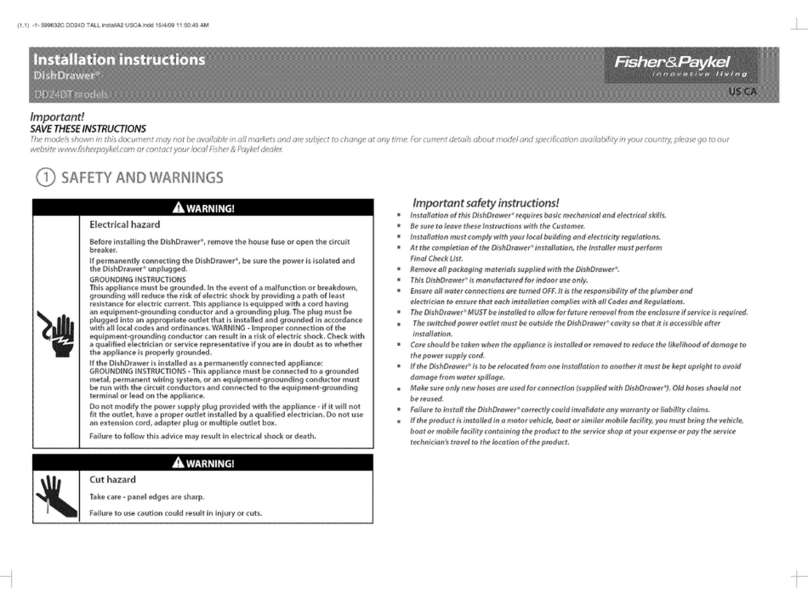

Fisher & Paykel DishDrawer DD24DT Series User manual

Fisher & Paykel

Fisher & Paykel DD60DAW9 User manual

Fisher & Paykel

Fisher & Paykel DishDrawer DD603HDishDrawer DD603I User manual

Fisher & Paykel

Fisher & Paykel DD*C Series User manual

Fisher & Paykel

Fisher & Paykel DD60DAHX9 User manual

Fisher & Paykel

Fisher & Paykel DD36SDFTX1 User manual

Fisher & Paykel

Fisher & Paykel DW60FC User manual

Fisher & Paykel

Fisher & Paykel DishDrawer DD24SHTI7 User manual

Fisher & Paykel

Fisher & Paykel DishDrawer DD603 PREFINISHED User manual

Fisher & Paykel

Fisher & Paykel DishDrawer DD605 Series User manual

Fisher & Paykel

Fisher & Paykel DishDrawer DS602 User manual

Fisher & Paykel

Fisher & Paykel DishDrawer DS605 User manual

Fisher & Paykel

Fisher & Paykel Dishdrawer DD60DI User manual

Fisher & Paykel

Fisher & Paykel DOUBLE DISHDRAWER DD24DV2T User manual

Fisher & Paykel

Fisher & Paykel DishDrawer DD603 PREFINISHED User manual