FISHER HAMILTON SAFEAIRE series User manual

2

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

Fisher Hamilton is pleased to have had the privilege of

furnishing your laboratory equipment. This is a major

investment, and your equipment is built to withstand extremes

of temperature, stress and corrosion provided you give it

reasonable care and use.

This manual gives you full information for the operation and

care of fume hoods and other Fisher Hamilton equipment

items.

Utility and fine appearance can be assured for many years by

following simple procedures. regular schedule of

maintenance will be most effective.

If you have a special problem or would like extra copies of this

manual, write to the Technical Service Department, Fisher

Hamilton, Two Rivers, Wisconsin 54241.

Table of Contents

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Perchloric Acid Hoods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Hood Identi ication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–19

Fume Hood Superstructures . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Floor-Mounted Fume Hoods . . . . . . . . . . . . . . . . . . . . . . . . . 5–9

HOPEC IV Fume Hoods . . . . . . . . . . . . . . . . . . . . . . . . . . 10–11

Air Chamber, Auxiliary Air Fume Hoods . . . . . . . . . . . . . . . . . 11

Ba les . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–13

Sa ety Shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–15

Blower Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–18

Fume Hood Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Exhaust Filter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Minihelic Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

WARNING/OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . 20

MAINTENANCE AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . 21–27

General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fume Hood Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

How to Replace Fluorescent Light Tube . . . . . . . . . . . . . . . 21-22

Servicing Fume Hood Fixtures . . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning Fume Hood Interiors . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacing Sash Glass and Cables . . . . . . . . . . . . . . . . . . 23–25

Servicing Supply Chamber Air Filter . . . . . . . . . . . . . . . . . . . . 26

Exhaust Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Blower RPM Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Manometer, Monitoring Exhaust Filters . . . . . . . . . . . . . . . . . . 27

FIELD TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28–30

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

GENERAL

Fume hoods are exposed to extremes o temperature, reagent

umes and working sur ace abuse. Regular care will prolong

service li e and insure sa e working conditions.

The exhaust system and blower o a ume hood must unction

properly or sa ety. Maintenance personnel should service the

an and motor assembly regularly, lubricate as required, and

make sure that the exhaust system is ree rom obstructions.

Semiannually, accumulated deposits should be removed rom

the impeller blade and housing.

A simple test with lighted match or smoke will show i the air is

being drawn into the hood. More accurate checks o air velocity

can be made with a thermal anemometer. See Inspection and

Field Evaluation procedure.

Always place equipment and apparatus as ar back into the

ume hood as possible since this provides greater assurance o

proper ume collection and removal.

Large, bulky apparatus or equipment should be placed in the

ume hood to permit air low around it, and never placed so as

to inter ere with the operation o the ba le system. Raise large

items an inch or two above work sur ace. Spilled liquids, acids,

or corrosive materials should be immediately wiped up and the

sur ace neutralized with water or the proper neutralizing agent

so as to prevent damage to the work sur ace and the hood

interior or to apparatus and equipment installed in the hood.

Remember that special ume hoods are required or the

handling o Perchloric Acid. See next page.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

3

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

PERCHLORIC ACID HOODS

The properties o perchloric acid require that a specially

designed ume hood be set aside or exclusive use with this

material. The hood is equipped with a cold water spray device

or washdown o the interior sur aces. A trough is placed

across the back o the hood or collection and disposal o

washdown waters. Operating personnel should be well trained

in the proper handling techniques and be amiliar with the

characteristics o this material.

Frequency o washdown, both hood interior and exterior

system, is determined by the usage and concentration o

reagents. This can range rom a weekly procedure to one that

occurs a ter every use. Washdown should always be ollowed

by an inspection to veri y that all areas are clean and that the

wash system is unctioning properly.

Some o the hazards o perchloric acid which justi y the use o

a special hood are:

1. Perchloric acid is a very strong acid, capable o producing

severe burns when in contact with skin, eyes or respiratory

tract.

2. As an aqueous solution, it can cause violent explosions i

improperly handled.

3. It reacts with other substances to orm unstable materials

which are susceptible to exploding either by impact, riction,

or spontaneous combustion.

Persons using perchloric acid should be thoroughly amiliar with

its hazards. Many reported laboratory accidents have involved

less than one gram o reactant. Listed below are some common

sa ety practices that should be ollowed:

• Spilled perchloric acid should be thoroughly washed away

with large amounts o water.

• The use o organic chemicals or materials in the hood should

be avoided.

• Goggles or other e ective eye protection should be used

whenever possible, as well as utilization o the ume hood

sash or additional sa ety.

• Gas lames or oil baths should not be used within the hood.

• Organic chemicals should not be kept in storage areas set

aside or perchloric acid storage.

• A schedule should be made or regular washdown and

inspection o hood interior, ductwork and blower to guard

against a build-up o dangerous perchloric materials.

• Only a luorocarbon grease should be used as a blower

lubricant, since any other type is to be considered potentially

hazardous.

• Washdown procedure should be per ormed a ter completion

o usage with all apparatus removed rom hood.

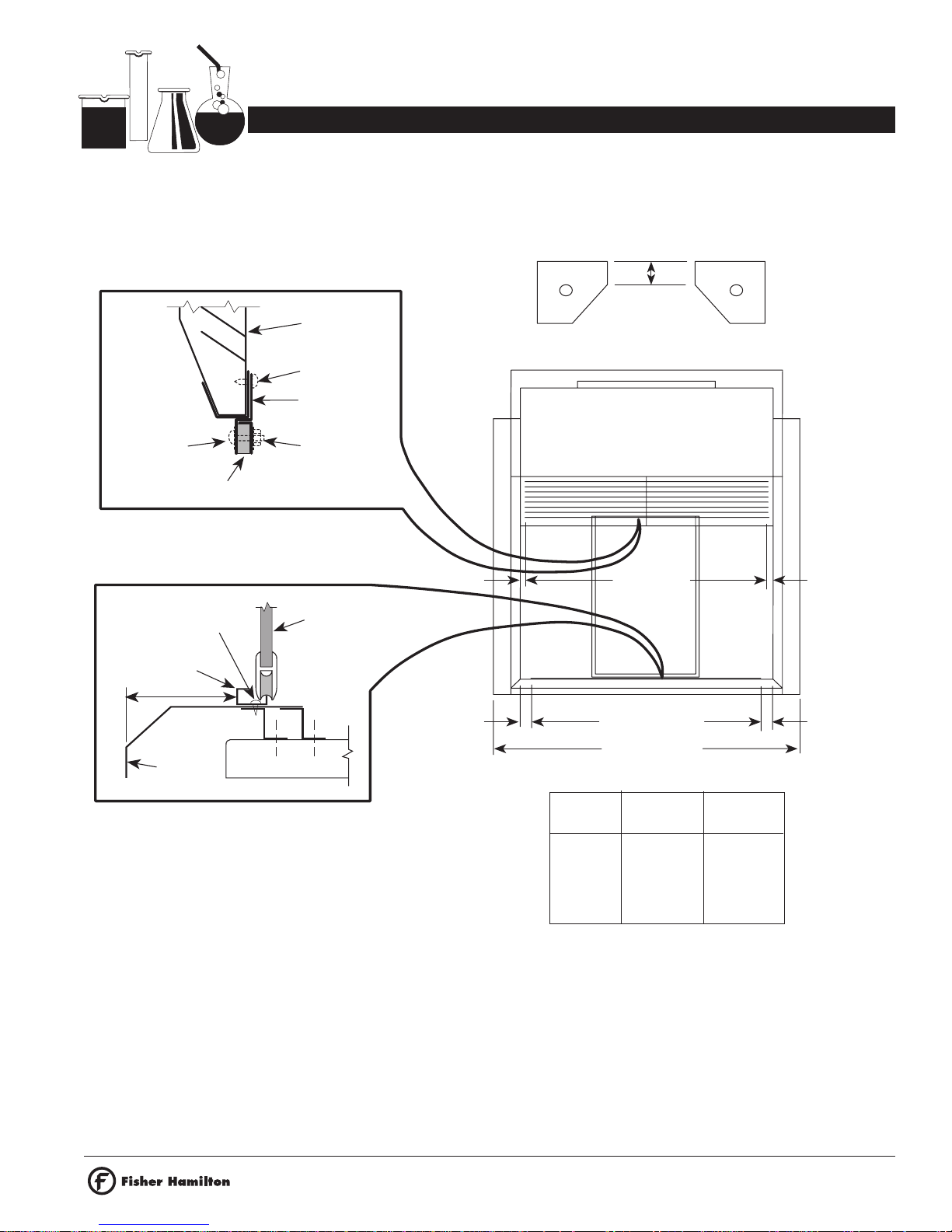

HOOD IDENTIFICATION

Fisher Hamilton Inc Two Ri ers, WI 54241

Item/Room No. . . .

Item: 158C Room: 207

Job/Unit No. . . . . TX 394381 012 H012M Unit: 0005093

Product No. . . . . . FH3943810244 Entity:

Description . . . . . Desc: X54L836PD – DWG. HD01

Project Name . . . Project Name: RICE UNIVERSITY – OLD CHEMISTRY

Shop Order No. . . Shop Order #: 161914 P.O. No.: 22492/26108

Clr:

G1

G1

UNCRATED

Bar Code No. . . . . 018021957

Louver

Panel Side

Panel

2-Part Label

(Located

on backside

o collar and

inside o

louver panel)

Gasketed

Access

Panel

Liner

Sash Ba les

TX 394381 FH3943810244

X54L836PD – DWG. HD01

Placed on backside o collar

Placed on inside

o louver panel

4

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

FUME HOOD SUPERSTRUCTURE INSTALLATION

Side Enclosure Panels

1. Lower the side panel into the side rame o the ume hood

superstructure, engaging the rame’s lower lip. While

pressing down on the two black catches, rotate the side

panel and engage the rame’s upper lip. Gently apply

additional pressure to the panel and release the catches to

secure the panel to the hood.

Shipping

Screws

Weight

Pan

Work Sur ace

Top o

Fume Hood

Shipping

Screw

Louver

Panel

No. 10 X 5/8"

Screws

2. Remove two (2) shipping screws that secure the counter-

balance weight pan to the rear top rail.

3. Remove screws rom sash hold-down clips. Open the sash

and remove blocking, being care ul not to damage sill or

ba les.

NOTE: Ba les can be installed at this time, or a ter the hood is

in place on the work sur ace. See Pages 12–13.

8. Drill two (2) each 1/8" diameter pilot holes at each side

structural rame into the work sur ace and secure same

with our (4) No. 10 X 5/8" screws saved rom the

shipping skid.

9. Reinstall end panels.

10. Caulk hood to work sur ace with silicone sealant.

6. Remove two (2) shipping screws rom the top o the louver

panel. These screws must be remo ed to allow future

access to the fluorescent lights.

7. Check the ollowing items:

• That the counterweight operates ree o obstructions.

• That the cables align properly in the pulleys.

• That there is proper horizontal sash alignment and

counterweight balance.

• That the sash does not bind in the sash guides.

4. Remove shipping screws holding the ume hood rame to

the skid. Save our (4) o these screws, No. 10 X 5/8", to

secure hood to the work sur ace.

5. Place the ume hood on the work sur ace taking care to

protect the work sur ace.

Catches

Side Panel

Lower Lip

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

5

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

1. Attach le t-hand side assembly (2) to back assembly (1).

Take back panel assembly and stand vertically, as shown,

and slide into end assembly. (Angle lange o end assembly

its between back panel and horizontal members o back

assembly). Secure each corner with two #8 X 5/8" PPHSMS

at mating holes on top and bottom corners o joined

assembly. Repeat steps with right-hand end (3). Attach each

ba le support with two each #8 X 3/4" PPHTCS through

back panel into support. Do not over-tighten.

#8 X3/4" PPHTCS

#8 X5/8" PPHSMS

1

2

1

2

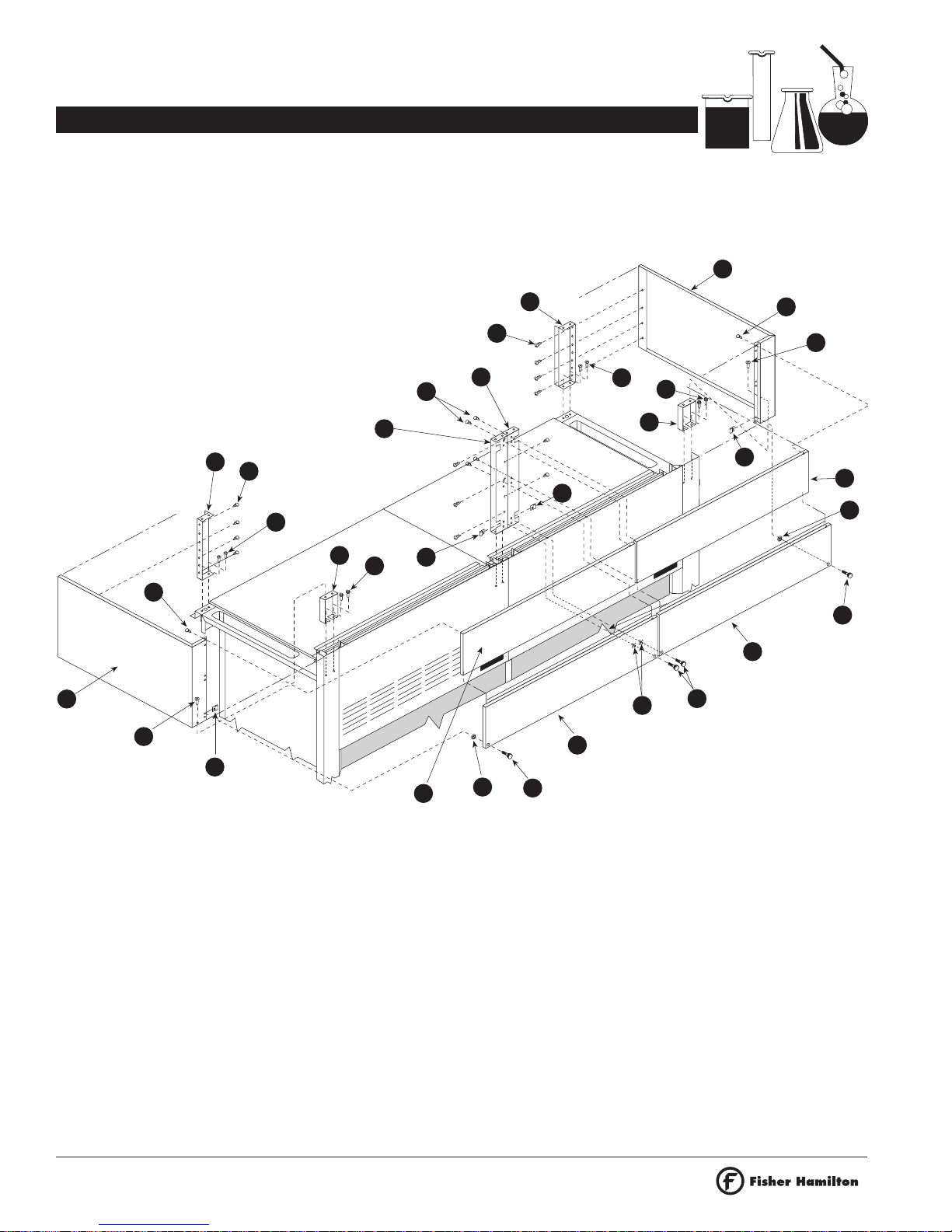

ASSEMBLY INSTRUCTIONS FOR KNOCKED-DOWN

FLOOR-MOUNTED FUME HOODS

General - When receiving ume hood assemblies, inspect or

damage immediately. I damage is noted, request the delivering

carrier to note and describe damage on bill o lading prior to

your signature. Noti y carrier immediately and request

inspection.

Open boxes and crates and examine or hidden damage. I

damage is noted, save containers and request an inspection.

Move all components to installation area.

2. Attach top assembly (4), as shown at le t, to

back and ends with eleven (11) #10 X 5/8"

PPHSMS. Top assembly its underneath right-

hand rear pulley bracket assembly. Secure

exhaust collar to rear rail.

#10 X5/8" PPHSMS

2

TOP

BACK REAR PULLEY

BRACKET ASSEMBLY

6

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

5

3. Attach le t rear pulley assembly (5) using three (3) #8 X 5/8"

PPHSMS. Attach right rear plate assembly (6) using three (3)

#8 X 5/8" PPHSMS. Slide 3" sheave (7), then 2" sheave (8)

over threaded stud. Loosely asten with 1/4-20 KEPS nut.

Install right-hand cable retainer support (27) using two (2)

#8 X 5/8" PPHSMS.

27

8

7

6

ASSEMBLY INSTRUCTIONS FOR KNOCKED-DOWN FLOOR-MOUNTED FUME HOODS

#8 X5/8" PPHSMS

9

4. Remove pieces o tape (9) holding top panel extrusion in

place. Li t header panel (11) and place bottom in right-hand

and le t-hand ba le clips (10). (Short header panel - bypass

hoods, does not have ba le clips). Bottom extrusion on

header panel aces outward. Fasten top o header panel to

angle with #8 X 5/8" PPHSMS.

10

11

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

7

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

5. Install our (4) ba les as indicated.

Install ba les with notches down.

Proceed rom bottom to upper ba le

(12, 13, 14, 15). I remote control is

included with hood, place

intermediate ba le (14) in already

installed remote control ba le arm

(16). Lower and intermediate ba les

are the same size. Insert upper ba le

into collar extrusion per Detail “B”.

Test remote control ba le adjuster or

unction. 16

15

14

13

12

COLLAR

TOP PANEL

UPPER

BAFFLE

DETAIL “B”

INTER-

MEDIATE

BAFFLE

LOWER

BAFFLE

BOTTOM

BAFFLE

UPPER

BAFFLE

ASSEMBLY INSTRUCTIONS FOR KNOCKED-DOWN FLOOR-MOUNTED FUME HOODS

6. Install rear top sash (17) in right-hand and le t-hand rear

sash guides. Sashes are installed rom the top o the hood.

Lower the sashes into the sash guides. The rear top sash

must be located above the stops located approximately hal

way up the sash guides. Locate the ront bottom sash (18) in

the ront right-hand and le t-hand sash guide. Remove the

tape rom the cable assemblies that are taped to each sash.

Uncoil the cable and place on top o hood.

17

REAR TOP

18

FRONT BOTTOM

8

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

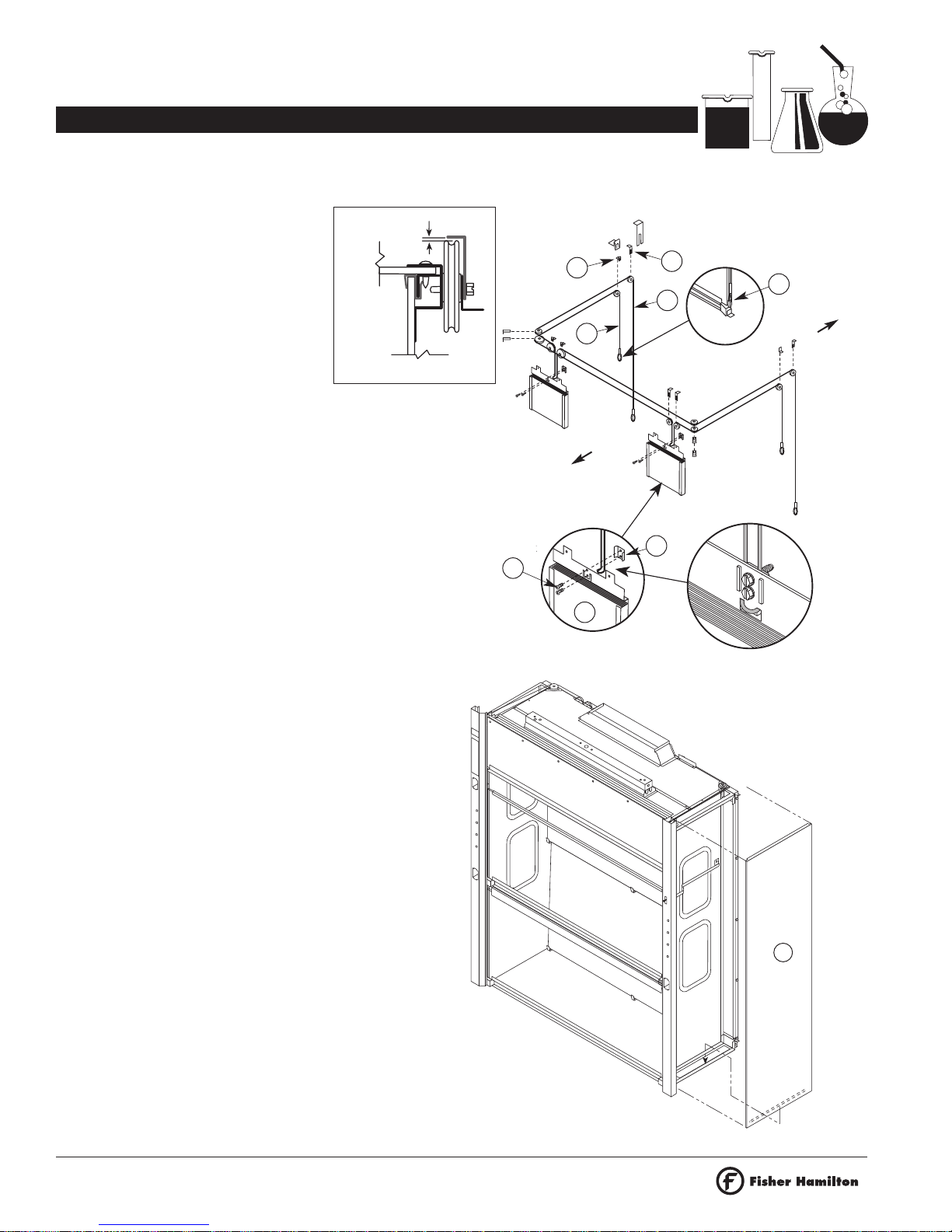

7. Be ore hood is pushed against wall, place top rear sash

cable (19) over pulleys as shown in instructions. Brace

bottom o sash about 6" above sash stops, with 2 x 4 or

similar, to allow or a more manageable cable. Attach weight

(20) to cable, Detail “C”. Fasten cable clamp (23) and two

(2) 1/4-20 X 3/4 HHTCS (24), do not completely tighten

screws. Repeat process with ront bottom sash cable (21).

Test sash level, alignment and travel. Make any necessary

adjustment. I necessary, ine tune weight pan. Fasten clamp

screws tightly. Attach all cable retainers (22, 25). Do not

over-tighten retainers – allow 1/16" or pulley movement. See

Detail “D”. The nylon tape (26) at the cable loops at the ends

o the sash pull is no longer necessary, remove and discard.

25

Retainer Must

Not Touch

Sheave

0.062"

DETAIL “D”

22

21

19

26

BOTTOM

FRONT

REAR

TOP

23

20

24

BACK

OF

HOOD

FRONT

OF

HOOD

ASSEMBLY INSTRUCTIONS FOR KNOCKED-DOWN FLOOR-MOUNTED FUME HOODS

8. Position ume hood in a permanent location. Have quali ied

personnel attach all required electrical devices and plumbing

ixtures. Lower the side panel (27) onto the side rame o the

ume hood, engaging the rame’s lower lip. While pressing

down on the two black catches, rotate the side panel and

engage the rame’s upper lip. Gently apply additional

pressure to the panel and release the catches to secure the

panel to the hood.

27

28

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

9

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

9. Attach lintel panel (28) to ront o hood. Engage top o

panel with studs on top, inside o ront access panel and

asten bottom o panel to angles on ront access panel with

#8 X 5/8" PPHSMS. Drive screws as shown.

10. Make sure hood is square and aligned.

#8 X5/8" PPHSMS

ASSEMBLY INSTRUCTIONS FOR KNOCKED-DOWN FLOOR-MOUNTED FUME HOODS

10

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

HOPEC IV FUME HOOD INSTALLATION

1. Install and level two ume hood base cabinets with rear

illers and kneespace panel as required.

2. Depending on height requirements, install either the top iller

rame assembly alone or in combination with the optional-

height iller rame.

HOPEC IV Hood

Base

Cabinet

Trough

Assembly

Run silicone

sealant bead

on back lange o

trough. Place work

sur ace into rame

and onto trough

lange.

I the TOP FILLER FRAME ONLY IS

REQUIRED, insert rough assembly into top

iller rame and locate ront lower edge o

trough lush with cabinet or optional height

iller. Secure to the base cabinet using

eight (8) No. 10 X 5/8" PPHSMS through

the side returns o the Top Filler Frame into

the ront and rear returns o the base

cabinet.

I the OPTIONAL HEIGHT FILLER FRAME

IS REQUIRED, it is installed by aligning

it’s bottom 3/4" return on the base

cabinet and securing with (4) No. 10 X

5/8" PPHSMS screws. Insert through

assembly into Top Filler Frame and locate

ront lower edge o trough lush with

cabinet or optional height iller. Attach the

Top Filler Frame to the Optional Filler

Frame using eight (8) No. 10 X 5/8"

PPHSMS through the side returns o the

Top Filler Frame into the ront and rear

returns o the base cabinet.

36"

Work Sur ace

Height

Top Filler Frame

Optional Filler

Filler

End view showing HOPEC IV hood,

Top Filler Frame and Base Cabinet.

Optional

Height Filler

Top Filler

Frame

Work

Sur ace

Base

Cabinet

HOPEC IV Hood

Base

Cabinet

36"

Work Sur ace

Height

Top Filler Frame

Filler

End view showing HOPEC IV hood,

Top Filler Frame, Optional Height

Filler and Base Cabinet.

Trough

Assembly

Run silicone

sealant bead

on back lange o

trough. Place work

sur ace into rame

and onto trough

lange.

Lower ront

edge o trough

should be lush

with ront o

cabinet

Top Filler

Frame

Work

Sur ace

Base

Cabinet

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

11

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

HOPEC IV FUME HOOD INSTALLATION (cont..)

Base

Cabinet

INSTALLING AIR CHAMBER – AUXILIARY AIR

FUME HOODS

Upper

Screws

Filler

Screws

3. Set the ume hood trough onto the top iller rame. The rear

edge o the trough will set over the ront horizontal rail and

the return edge on the trough will secure it in place.

NOTE: I a drain tube is required, it should be installed at

this time. The tube is located at the le t end o the trough

and is ed through the top o the le t hand base cabinet into

a one gallon container.

4. Install poly vent, i required, through pre-drilled holes in the

backs o base cabinets. The tail piece o the vent is supplied

with a double compression assembly to lock it in place.

5. Seal the top edge o the trough assembly with a RTV silicon

or other applicable sealer and then place the ume hood

work sur ace into the Top Filler Frame. I base cabinet poly

vents are used, align them to the pre-cut holes in the work

sur ace.

6. Install cupsinks i required. The ume hood base cabinets are

supplied with pre-punched holes in the back panels above

the stone liner or cupsink drains. Cupsink assemblies are

supplied with the sink, an extension pipe, an elbow, and a

pipe section that protrudes through the hole in the base

cabinet back. The cupsink assembly is designed to it two

conditions.

A. When the ume hood assembly is supplied with the

Optional Height Filler Frame, the cupsink assembly is

ished through the sink cutout hole in the work sur ace

and the drain line hole at the rear o the base cabinet.

B. When the ume hood is supplied with only the Top Filler

Frame, the extension pipe below the cupsink is removed

to maintain alignment with the base cabinet rear drain

hole. The pipe extension should be saved in the event

that the Optional Height Filler Frame be required at a later

date.

7. Move the HOPEC IV ume hood to the area o installation.

Per orm Steps 1–10 on Page 4.

Top Filler

Frame

Work Sur ace

Front

Horizontal Rail

Trough

Drain Tube

Must Be Flush

Keyhole Slots

Lower Screws

4. Install the le t- and right-hand illers along with two (2)

screws each side, accessible rom inside the air chamber.

Front

Access

Post Screws

5. Install louver panel by hooking top edge onto studs in

chamber. Secure with three (3) screws.

6. Install sash enclosure by hooking top rame lange onto

o set angle on back o air chamber.

Stud

1. With hood on work sur ace, lower air make-up tubing to

expose our (4) mounting holes in galvanized rame. Install

screws into upper mounting holes, tightening hal way.

2. Li t the air chamber up and onto the upper mounting screws.

Two people are required or this procedure, one at each end

o the chamber. While chamber is supported by the upper

screws, install the lower mounting screws. Tighten all

mounting screws securely.

3. Li t make-up air tubing back up and into PVC elbows at ends

o air chamber. Secure with screws provided with elbows.

12

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

BAFFLE INSTALLATION AND ADJUSTMENT

Fisher Hamilton provides two choices o ba le design

concepts:

1. Multi-position ixed.

2. Remote exterior control

Baffle Installation

Install ba les according to in ormation on the next page.

See label located on interior right-hand wall or repositioning

instructions or Multi-Position Fixed Ba le. See label located

on right ront post or Remote Exterior Ba le adjustment

instructions.

Baffle Adjustment

Fisher Hamilton ume hoods have three ba le settings:

A. Normal or Average.

B. Lighter-than-Air or high thermal loading.

C. Heavier-Than-Air

Position Ais or normal exhaust requirements. Locate ba le in

center o movement arc. All slots are unctional. This ba le

position is suitable or most ume generating activities.

Ba le position Bis or lighter-than-air gases, or high heat

loads. The top slot is open to maximum. The upper portion o

perimeter slot is operational. The intermediate horizontal slot is

operational and bottom slot is restricted. Fume hood air low is

concentrated in the upper portion o enclosure or e icient

capture and exhaust o lighter-than-air umes and hot gases.

The ba le at position Cprovides maximum air low across the

work sur ace or the collection and removal o umes generated

at the work sur ace and heavier-than-air gases. In this position,

perimeter slot and intermediate slot remain open and

operational, top slot is closed.

A – Normal Exhaust

Requirements B – High Heat Loads or

Lighter-Than-Air Gases

C – Hea ier-Than-Air Gases

and Surface Fumes

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

13

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

BAFFLE INSTALLATION AND ADJUSTMENT (cont..)

Installing Multi-Position Fixed Baffle

1. Place top ba le into position by engaging top edge into

ront exhaust collar extrusion. Li t ba le up and into upper

support brackets to lock into position.

2. Place center ba le into desired exhaust position by engaging

top edge into appropriate slots on bottom o uppermost

ba le support brackets, see positioning label on right-hand

side panel. Li t and lock ba le into position.

3. Place lower ba le into proper position. Li t and lock ba le

into lower support brackets.

Installing Remote Exterior Control Baffle

1. Place top ba le into position by engaging top edge into

ront exhaust collar extrusion. Li t ba le up and into upper

support brackets to lock into position.

2. Align orked end o remote arm with any o three (3) slots in

right-hand upper ba le support bracket. Li t center ba le up

and into slots in upper ba le supports, being sure to capture

right-hand edge o ba le between ingers o remote control

arm. Li t and lock ba le into position.

3. Place lower ba le into proper position. Li t and lock ba le

into lower support brackets.

Exhaust Collar Extrusion

Top

Baffle

Center

Baffle

Lower

Baffle

Upper Support Bracket

Ba le Positioning Label

Lower Support Bracket

Top Baffle

Center Baffle

(Remote)

Center Baffle

(Fixed)

and Lower Baffle

14

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

INSTALLING SAFETY SHIELDS IN RESTRICTED BYPASS, CONSTANT VOLUME BYPASS, AND RADIOISOTOPE

FUME HOODS

1. Locate lower track assembly according to dimensions

shown.

2. Use lower track assembly as template or locating holes.

Drill .128" diameter holes in sill as illustrated, through

existing holes in track assembly.

3. Fasten track with No. 8 X 3/8" PPHSMS.

4. Locate upper retainer on rear lange o louvered panel.

Locate retainer .91" (29/32") rom inside edge o ront

vertical panel. Drill .128" diameter holes using retainer as

template. Fasten with No. 8 X 3/8" PPHSMS.

5. Position and asten bumpers using No. 8-32 X 3/4" PPHMS,

washers and hex nuts.

6. Install sa ety shield by inserting top into upper retainer

channel, then lowering bottom (with rollers) into lower track

assembly.

Louvered Panel

8 X 3/8" PPHSMS

8 X 3/4" PPHSMS

Retainer

Bumper

Sa ety Shield

8 X 3/8" PPHSMS

Lower Track

Sill Work Sur ace

Lower Track

Upper

Retainer

.91"

1.87"

.91"

Hood Width

1.87"

Le t Bumper Right Bumper

.31"

Hood Lower Upper

Width Track Retainer

48.0" 34.62" 36.56"

60.0" 46.62" 48.56"

72.0" 58.62" 60.56"

96.0" 82.62" 84.56"

1.375"

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

15

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

INSTALLING SAFETY SHIELDS IN AUXILIARY AIR FUME HOODS

1. Locate lower track assembly according to dimensions

shown.

2. Use lower track assembly as template or locating holes.

Drill .128" diameter holes in sill as illustrated, through

existing holes in track assembly.

3. Fasten track with No. 8 X 3/8" PPHSMS.

4. Locate upper retainer on rear lange o louvered panel.

Locate retainer .91" (29/32") rom inside edge o ront

vertical panel. Drill .128" diameter holes using retainer as

template. Fasten with No. 8 X 3/8" PPHSMS.

5. Position and asten bumpers using No. 8-32 X 3/4" PPHMS,

washers and hex nuts.

6. Install sa ety shield by inserting top into upper retainer

channel, then lowering bottom (with rollers) into lower track

assembly.

Louvered Panel

8 X 3/8" PPHSMS

8-32 X 3/4"

PPHMS and

Washer

Retainer

Bumper

Sa ety Shield

8 X 3/8" PPHSMS

Lower Track

Sill Work Sur ace

Lower Track

Upper

Retainer

.91" .91"

1.87"

Hood Width

1.87"

Le t Bumper Right Bumper

.31"

Hood Lower Upper

Width Track Retainer

48.0" 34.62" 36.56"

60.0" 46.62" 48.56"

72.0" 58.62" 60.56"

96.0" 82.62" 84.56"

3.56"

Nut & Washer

16

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

INSTALLING CEILING ENCLOSURE TO FUME HOODS OTHER THAN AUXILIARY AIR AND POSTLESS SASH

Hardware included:

1 - Front panel

1 - Front panel-removable

2 - Side panels

2 - Front support brackets

2 - Rear support brackets

1 - Bag assembly

Tools required:

#2 Phillips screwdriver.

1. Fasten support brackets (1) in ront top o rame assembly in

holes provided. Use 1/4-20 X 3/4" hex head thread cutting

screws (HHTCS) (2) urnished in bag assembly to asten

brackets.

2. Fasten rear support (3) to rear top o rame assembly. Use

No. 8 X 5/8" Phillips pan head sheet metal screws (PPHSMS)

(4) urnished in bag assembly.

3. Install right-hand (5) and le t-hand (6) side panels to

supports using No. 8 X 5/8" PPHSMS (4).

4. Install ront panel (7) to side panels with No. 8 X 5/8"

PPHSMS.

5. Subassemble thumb screws (8) and push retainers (9) to

removable panel (10).

6. Insert hole asteners (11) in larger hole in lange o side

panels.

7. Insert top lange o removable panel under and behind ront

panel. Fasten thumb screws and tighten.

7

5

10

2

1

2

1

3

4

4

34

4

4

6

4

4

4

9

8

98

11

11

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

17

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

INSTALLING CEILING ENCLOSURE TO AUXILIARY AIR FUME HOODS

Hardware included:

1 - Front panel-removable

2 - Side panels

2 - Front support brackets

2 - Rear support brackets

1 - Bag assembly

Tools required:

#2 Phillips screwdriver.

1. Fasten support brackets (1) in ront top o rame assembly in

holes provided. Use 1/4-20 X 3/4" hex head thread

cutting screws (HHTCS) (2) urnished in bag assembly to

asten brackets.

2. Fasten rear support (3) to rear top o rame assembly. Use

No. 8 X 5/8" Phillips pan head sheet metal screws

(PPHSMS) (4) urnished in bag assembly.

3. Install right-hand (5) and le t-hand (6) side panels to

supports using No. 8 X 5/8" PPHSMS (4).

4. Install clips (12) into top square holes o removable panel

(10).

5. Subassemble thumb screws (8) and push retainers (9) to

removable panel (10).

6. Insert hole asteners (11) in larger hole in lange o side

panel.

7. Insert clip o top lange o removable panel into square holes

o side panels. Fasten thumb screws and tighten.

5

10

2

1

2

1

3

4

4

34

4

4

6

4

9

8

98

11

11 12

12

18

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

INSTALLING CEILING ENCLOSURE TO POSTLESS SASH TYPE FUME HOODS

Hardware included:

2 - Front panels

2 - Front panels-removable

2 - Side panels

2 - Front support brackets

2 - Rear support brackets

2 - Middle support brackets

1 - Bag assembly

Tools required:

#2 Phillips screwdriver.

1. Fasten support brackets (1) in ront top o rame assembly in

holes provided. Use 1/4-20 X 3/4" hex head thread

cutting screws (HHTCS) (2) urnished in bag assembly to

asten brackets.

2. Fasten rear support (3) to rear top o rame assembly. Use

No. 8 X 5/8" Phillips pan head sheet metal screws

(PPHSMS) (4) urnished in bag assembly.

3. Install right-hand (5) and le t-hand (6) side panels to

supports using No. 8 X 5/8" PPHSMS (4).

4. Install two middle supports (12) to louver panels with our

No. 8 X 5/8" PPHSMS (4).

5. Install ront panels (7) to side panels and middle supports

using No. 8 X 5/8" PPHSMS (4).

6. Subassemble thumb screws (8) and push retainers (9) to

removable panels (10).

7. Insert hole asteners (11) in larger hole in lange o side

panels.

8. Insert top lange o removable panels under and behind ront

panels. Fasten thumb screws and tighten.

5

10

2

1

2

1

3

4

4

34

4

4

6

4

9

8

98

11

11

12

4

12

4

7

7

4

10

98

11

11

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

INSTALLATION

19

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

FUME HOOD MONITOR

Models 54L0335 and 54L0405

Proper ume hood operation is key to laboratory sa ety, com ort

and energy management. OSHA requires that laboratories take

measures to ensure proper and adequate operation o ume

hoods. Recommendations include the use o a continuous air

monitoring device. The ANSI Z9.5 and NFPA 45 standards

rein orce these requirements.

Fisher Hamilton monitors have the ability to monitor true ume

hood ace velocity using thermal sensors located in the

instrument. The thermal sensors are exposed to clean

laboratory air only. They can be sur ace-mounted in minutes

eliminating the need or expensive panel cutouts.

Each model is equipped with indicator lights that illuminate

based on a pre-determined set-point. An audible 85dB

piezoelectric alarm sounds and a red indicator light illuminates

to warn o potentially dangerous low air low conditions.

•54L0405

– Low low set point

– Audible and visual alarm

– I/O options

•54L0335

– Analog meter

– Audible and visual alarm

– I/O control

Fisher Hamilton ume hood monitors are shipped with operation

manuals

EXHAUST FILTER INSTALLATION

Product Numbers 54L296, 54L297, 54L298 and

54L299

The pre- ilter cover aces

forward on Restricted

Bypass and Constant

Volume Bypass hoods.

INSTALLATION OF MINIHELIC GAUGE

Replacement ilter sets consist o one rough and one HEPA

ilter.

Product Number 54L302 – Filter set or 54L296 or 54L298.

Product Number 54L300 – Filter set or 54L297 or 54L299.

Pre-Filter

Cover

Front o

Fume Hood

The pre- ilter cover aces to

the left on Auxiliary Air

hoods.

Pre-Filter

Cover

Front o

Fume Hood

Securely attach the ilter inlet collar to hood exhaust transition

using same method as ollowed in the duct system. Filter outlet

may be attached to duct using lexible connector or same as

inlet connection.

Sensor block and sensor tube,

two req’d each

Connect to low side o

Minihelic Gauge

Thick-wall vinyl laboratory

tubing, cut to length

Minihelic Gauge range 0"-3"

W.C., reads ilter pressure drop

Front Post

Connect to

high side o

Minihelic Gauge

20

Dimensions are nominal and illustrations and speci ications are based

on the latest product in ormation available at the time o publication.

The right is reserved to make changes at any time without notice.

SAFEAIRE®LABORATORY FUME HOODS

OPERATION, MAINTENANCE AND INSTALLATION INSTRUCTIONS

WARNING/OPERATING INSTRUCTIONS

WARNING/OPERATING INSTRUCTIONS

Re er to Operation

Instructions on le t-hand

ront post. Data rom the

“As Manu actured” test

should be logged in this

area along with any

urther Field Test results.

(See Page 28 and 29)

WARNING

This product is intended or use with certain chemicals that

can cause serious injury or illness through inhalation or

physical contact. While this product is intended to minimize

exposure to certain hazardous chemicals when selected,

installed and operated properly, its per ormance and the sa ety

o the user is a ected by a number o actors. These include the

HVAC

system, the speci ic chemicals and processes being used,

proper operation and the condition o the room.

Be ore using this ume hood, consult the owner’s industrial

hygienist or sa ety representative to make sure: 1) the speci ic

ume hood alarms, controls and the HVAC system have been

properly selected and are operating correctly, 2) the hood has

been tested a ter installation and routinely therea ter to ensure

the ume hood is providing the proper containment or the

speci ic chemicals and processes being used, 3) there has

been appropriate training on the correct use o the ume hood

and handling o the speci ic chemicals and the ume hood

operating instructions have been reviewed, 4) any personal

protective devices that are required are properly selected and

provided, and 5) the ume hood is being operated at the

appropriate ace velocity. The ume hood should never be

operated with the sash in the ull open position.

OPERATING INSTRUCTIONS

Failure to follow these instructions could result in physical

injury or illness.

Caution: Do not use hood for perchloric acid procedures.

1. Do not use this ume hood unless you have received proper

training rom the owner’s industrial hygienist or sa ety

representative.

2. This ume hood is not intended to be used with all chemicals

or all chemical processes. Consult the owner’s industrial

hygienist or sa ety representative to determine whether the

hood is appropriate or the chemicals and processes to be

used.

3. Veri y that the ume hood exhaust system and controls are

operating properly and providing the necessary air low. I in

doubt, the owner’s industrial hygienist or sa ety

representative should be consulted. It is recommended that

the hood be equipped with an air low monitoring device.

Be ore using the ume hood, veri y that the monitor is

operating properly by testing the monitor.

4. The hood should not be operated with the sash in the ull

open (set-up) position. When the hood is in use, the opening

o the sash glass should be kept at a minimum. On a

vertical rising sash, the sash glass should be no higher than

18". Horizontal sliding panels on combination sashes must

be closed when sash is raised vertically. The sash should

remain closed when the hood is not in use.

5. Place chemicals and other work materials at least six (6)

inches inside the sash.

6. Do not restrict air low inside the hood. Do not put large

items in ront o the ba les. Large apparatus should be

elevated on blocks. Remove all materials not needed or the

immediate work. The hood must not be used or storage

purposes.

7. Never place your head inside the hood.

8. External air movement can a ect the per ormance o the

hood. Do not operate near open doors, open windows or

ans. Avoid rapid body movements. Do not open the hood i

there are cross-dra ts

or turbulence in ront o the hood. Do not open the sash

rapidly.

9. I this hood is equipped with adjustable ba les, do not

adjust the ba les without consulting the owner’s industrial

hygienist or sa ety representative.

10. Wear gloves and other protective clothing i contact with

contaminants is a hazard.

11. Clean spills immediately.

12. I umes or odors are present, stop operating the hood,

close the sash and contact the owner’s industrial hygienist

or sa ety representative immediately.

13. It is recommended that this ume hood be tested and

certi ied annually by the owner according to applicable

industry and government standards.

Table of contents

Popular Laboratory Equipment manuals by other brands

Helmer Scientific

Helmer Scientific i.Series Service and maintenance manual

Civco

Civco GUS G32-S Operator's manual

Gema

Gema OptiFlow IG07 Operating instructions and spare parts list

Kinematics

Kinematics 4400/PVC operating instructions

Scilogex

Scilogex SCI550-H user manual

Hydac

Hydac OFX Operating and maintenance instructions

Thermo Scientific

Thermo Scientific Heraeus Multifuge X1 Instructions for use

Markes International

Markes International HiSorb Agitator U-HSAG-20 Instructions for use

HF Scientific

HF Scientific M100+ 28060 Owner's and user's manual

Gossen MetraWatt

Gossen MetraWatt SECULIFE UP operating manual

Bullard

Bullard TacSight SE35 user manual

HTL

HTL SWIFTPET manual