www.Fisher.com

D102803X012

Type 249W Cageless Wafer Style Level Sensor

Contents

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type Number Description 2. . . . . . . . . . . . . . . . . .

Educational Services 3. . . . . . . . . . . . . . . . . . . . . .

Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

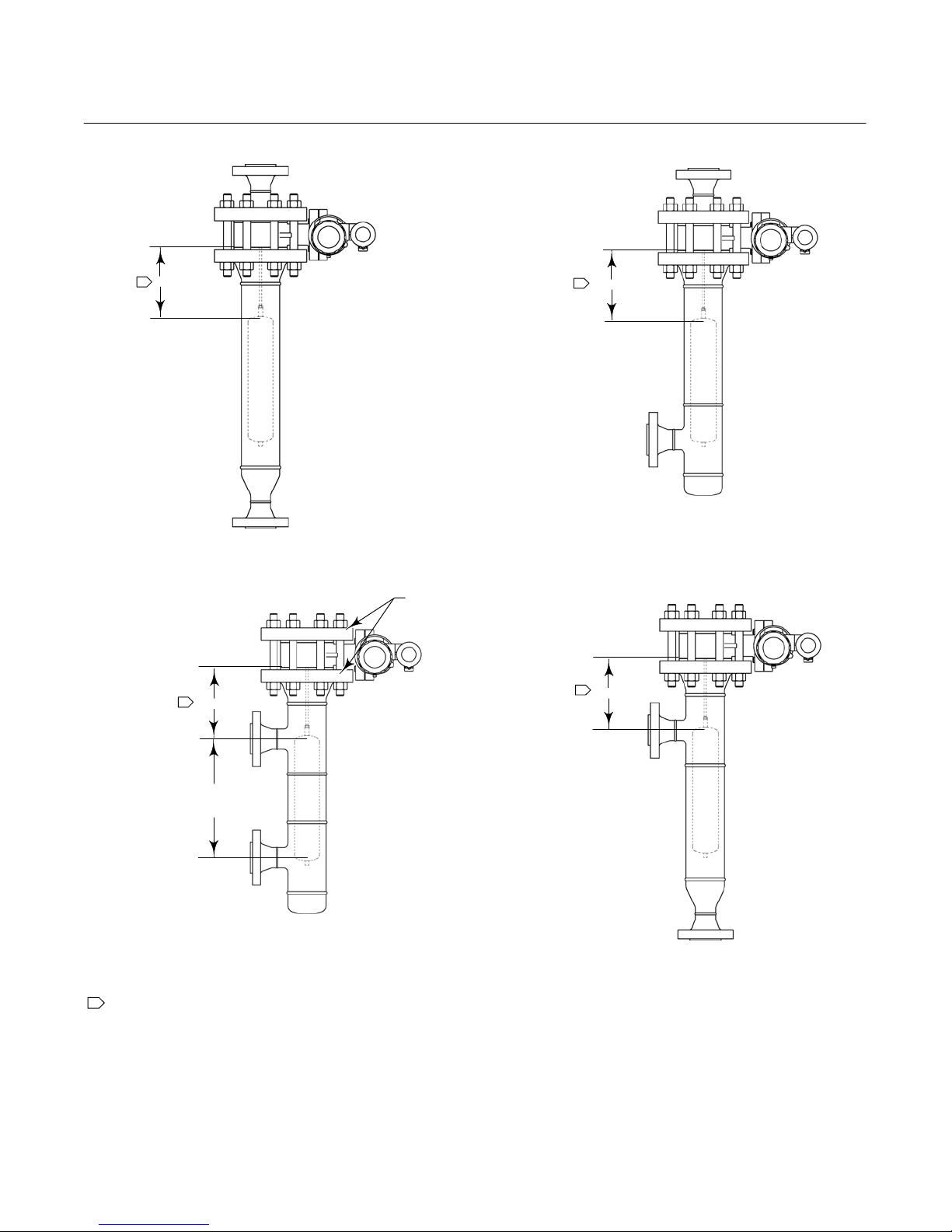

Installation on Top of Vessel 4. . . . . . . . . . . . . . . .

Installation with Displacer Cage

on Side of Vessel 4. . . . . . . . . . . . . . . . . . . . . . .

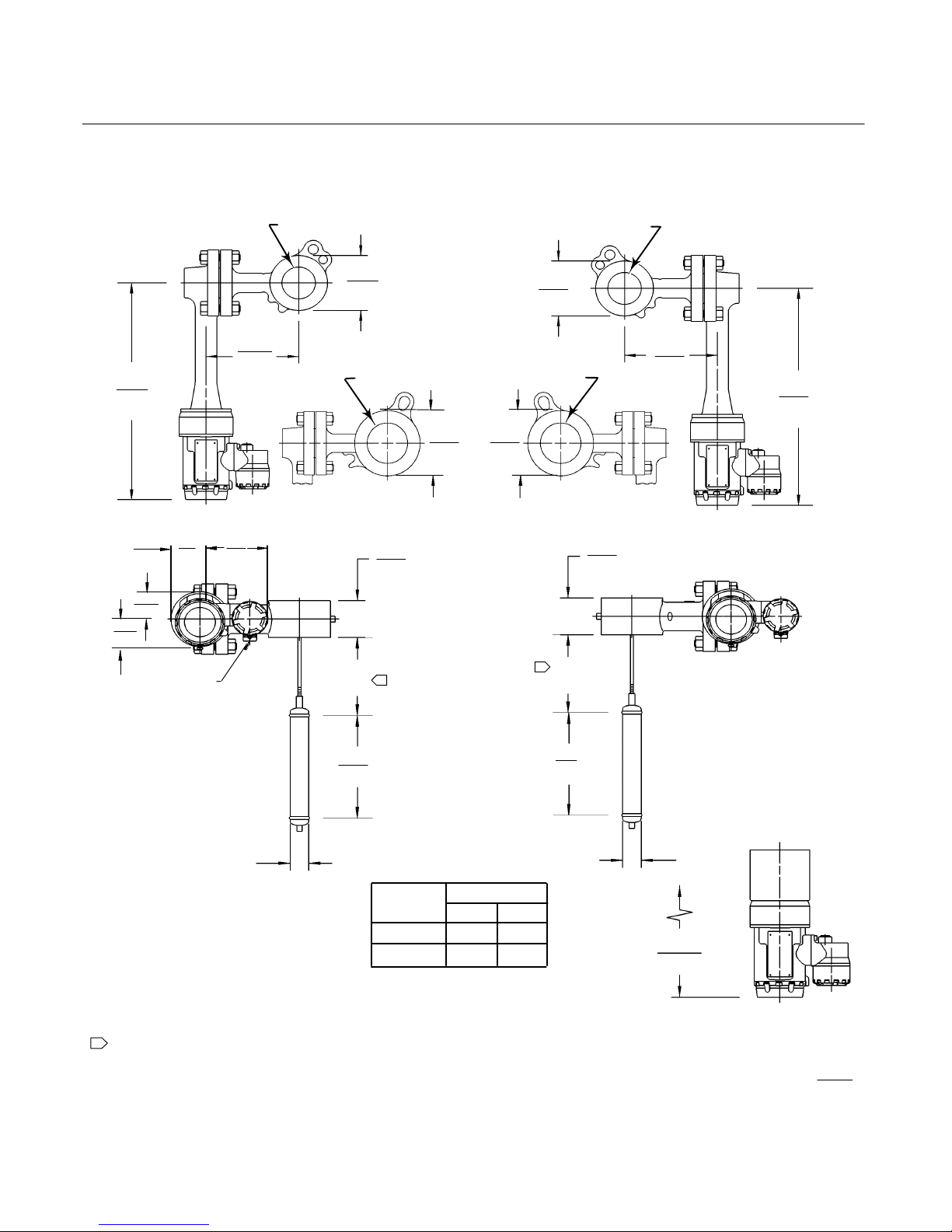

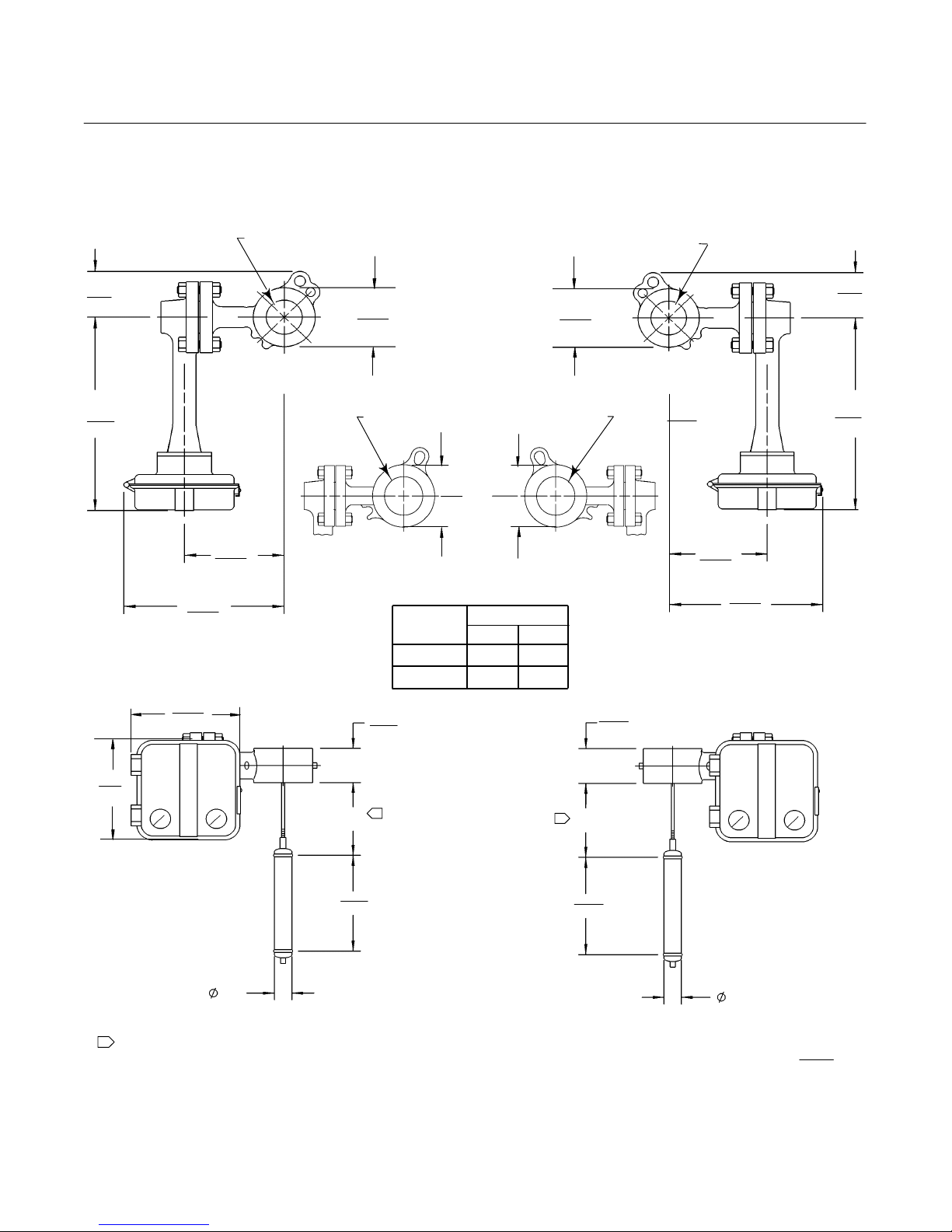

Mounting the Sensor on the Process

Vessel or Displacer Cage 5. . . . . . . . . . . . . . . .

Maintenance 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Displacer and Stem 12. . . . . . . . . .

Replacing the Displacer, Cotter Spring,

Stem End Piece, and Displacer Spud 12. . . . .

Replacing the Displacer Rod/Driver Assembly 13

Replacing the Torque Tube 13. . . . . . . . . . . . . . . .

Replacing the Torque Tube Arm and

Changing the Mounting 14. . . . . . . . . . . . . . . . .

Simulation of Process Conditions for Calibration

of Level-TrolRControllers and Transitters 15. .

Parts Ordering 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining Displacer Stem Length 16. . . . . . . .

Parts List 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Scope of Manual

This instruction manual includes maintenance, and

parts ordering information for the Type 249W

cageless wafer style sensor.

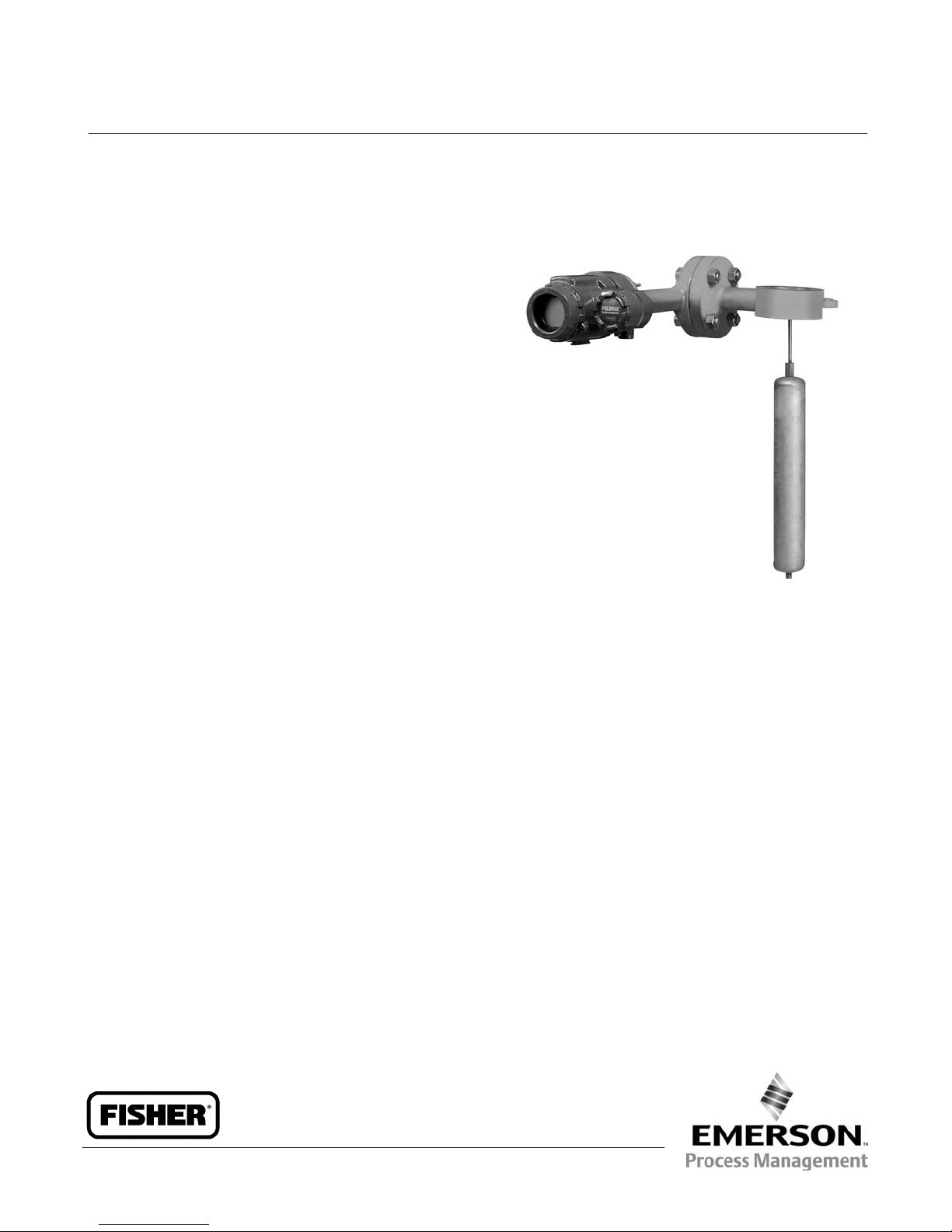

Although the sensor is usually shipped with attached

controller or transmitter, as shown in figure 1, this

manual does not include operation, installation,

calibration, maintenance, and parts ordering

information for the controller/transmitter or for the

complete unit. For this information, refer to the

appropriate controller/ transmitter instruction manual.

W8231 / IL

Figure 1. Type 249W Sensor with DLC3000 Series

Digital Level Controller

No person may install, operate, or maintain a Type

249W sensor and the attached controller or

transmitter without first Dbeing fully trained and

qualified in valve, actuator, and accessory

installation, operation and maintenance, and D

carefully reading and understanding the contents of

this manual. If you have any questions concerning

these instructions, contact your Emerson Process

Managementtsales office before proceeding.

Description

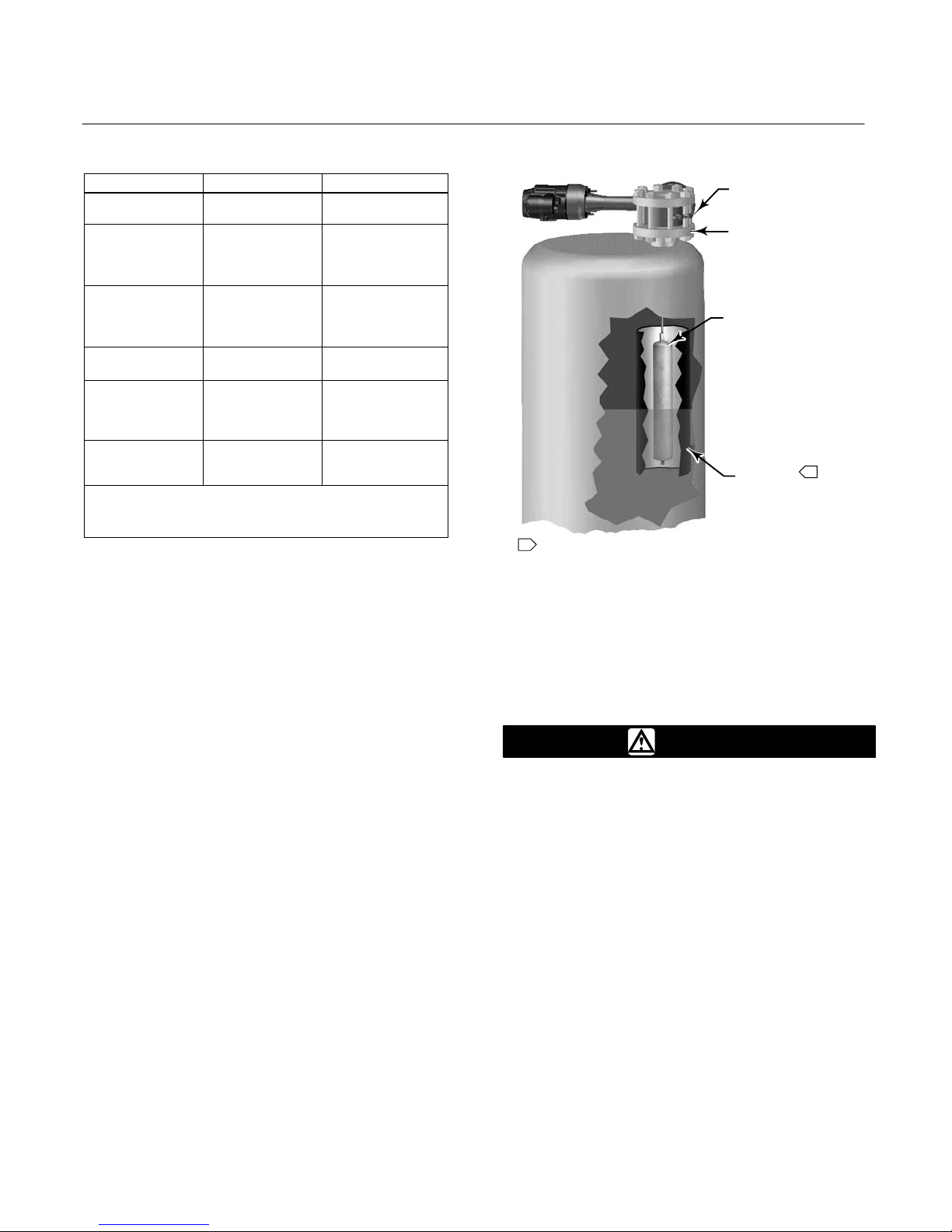

The Type 249W sensor is designed to measure

liquid level, interface level, or density/specific gravity

inside a process vessel.

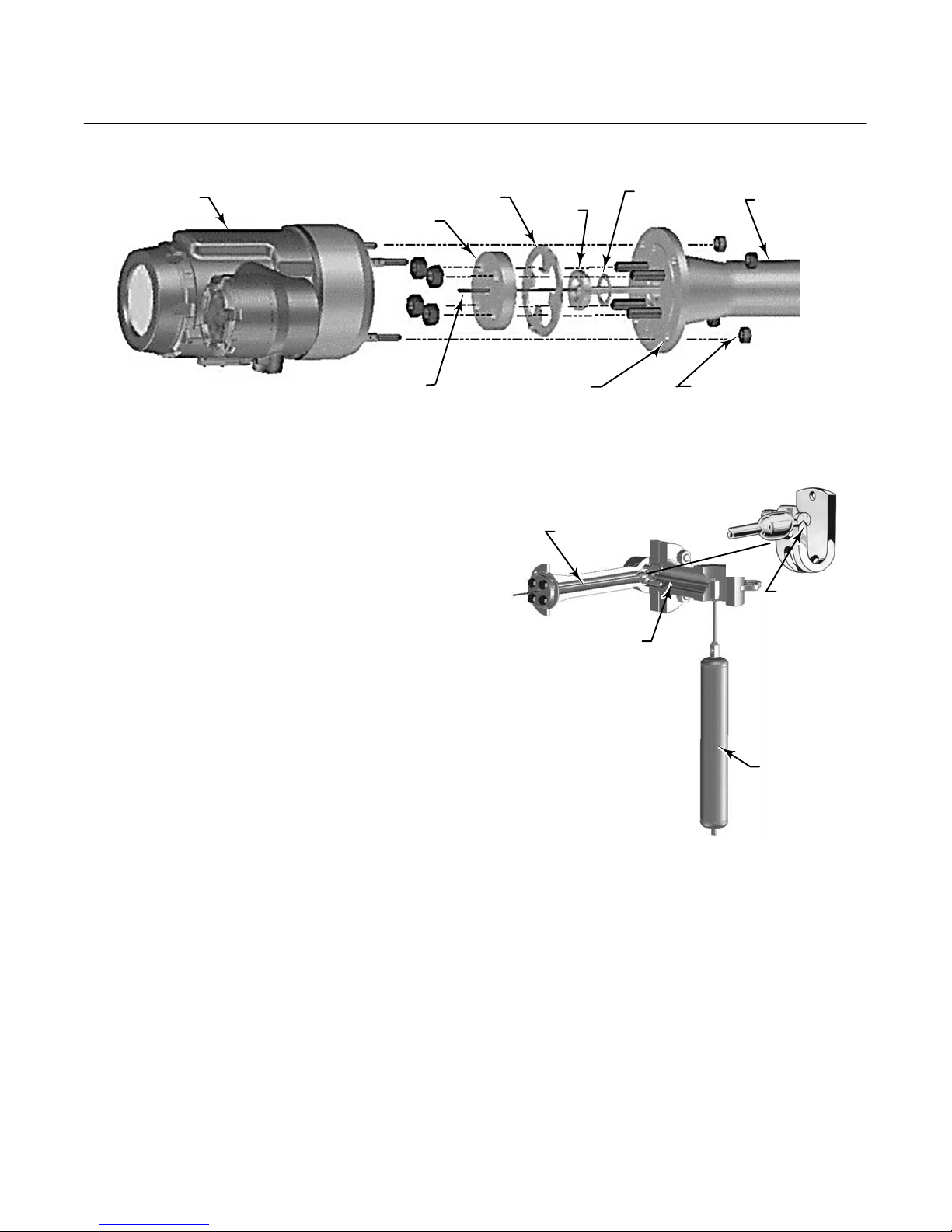

A torque tube assembly (figure 3) and displacer

provide an indication of liquid level, interface level, or

density/specific gravity. The torque tube assembly

consists of a hollow torque tube with a shaft welded

inside it at one end and protruding from it at the

other end.

Instruction Manual

Form 5729

May 2006 249W Level Sensor